Inspecting Industrial/Commercial Facilities For Pollutants Of

advertisement

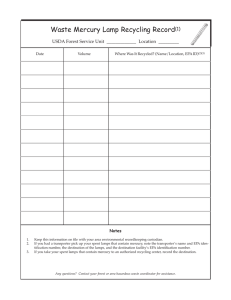

Inspecting Industrial/Commercial Facilities For Pollutants Of Concern During Stormwater Inspections Kristy McCumby Hyland City of Sunnyvale 1 Presentation Overview Regulatory Requirements Pollutants of Concern Copper Mercury PCBs Inspection Forms 2 Regulatory Requirements Stormwater Municipal Regional Permit Provision C.11 Mercury Controls Provision C.12 Polychlorinated Biphenyls (PCBs) Controls Provision C.13 Copper Controls BASMAA Regional Training Materials Guidance Manual for SW Inspectors on SCVURPPP website 3 Pollutant of Concern (POC) COPPER 4 Copper POC since the late 1980s. SF Bay listed as impaired by copper in 1989 Government agencies and businesses made significant investment in copper source identification and copper reduction measures As of July 2003, all San Francisco Bay segments listed for copper have been removed from the State’s 303(d) list of impaired water bodies and placed on the monitoring list Site Specific Objectives (SSOs) adopted Jan 2009 5 Sources of Copper in Stormwater Vehicle brake pads Copper air emissions Architectural copper Industrial copper use Improper discharge of pool and spa water Potable water discharged to storm drains Soil erosion Copper pesticides 6 Provision C.13 Copper Control Identify commercial/industrial businesses likely to use copper or have sources of copper and include them in the inspection programs Inspectors need to ensure that proper BMPs are in place to minimize discharge of copper to storm drains Special emphasis on roof runoff that might accumulate copper deposits from on-site ventilation systems at industries or businesses that use copper 7 Industrial/Commercial Sources Electroplating Semiconductor manufacturing Metal finishers Auto dismantlers Car Washes Automotive Services 8 From BASMAA Stormwater Inspectors’ Guidance Manual: SIC 7549 (Vehicle service shops) and SIC 7542 (Car wash facilities) can also contribute copper to stormwater runoff if proper BMPs are not in place 9 Copper in Roof Runoff Metal finishing, electroplating and semiconductor manufacturing industries Processes - copper chloride etchers, ammonia etchers, and acid plating bath exhaust vents 10 Inspection for Copper Deposition Look for chemical deposition around vents, pipes, and other roof surfaces to determine if there is a potential source of copper and if safe access is possible If discolorations or deposits are seen, implement BMPs to minimize the contamination of roof runoff 11 Inspection for Copper Deposition (cont.) If roof top access not possible, check downspout discharge areas 12 Best Management Practices Install vent covers and drip pans Prevent leaks in pipe fittings and containment vessels with routine maintenance Properly dispose of condensate from ventilation Promote condensation of ammonia etchant vapor Install scrubber system to treat ammonia etchant vapors 13 Pollutant of Concern MERCURY 14 MERCURY San Francisco Bay is considered to be “impaired” by mercury because some types of fish caught in the Bay contain mercury at concentrations that may threaten the health of humans consuming them. TMDL adopted in SF Bay Basin Plan Feb 2008 15 Provision C.11 Permittees shall promote, facilitate, and/or participate in collection and recycling of mercury containing devices and equipment at the consumer level 16 Industrial/Commercial Sources Facilities that use mercury in processes and equipment metal finishing/electroplating facilities auto dismantlers/recyclers. Facilities that have mercury containing products that need to be disposed properly 17 From BASMAA Stormwater Inspectors’ Guidance Manual: 18 Mercury Containing Products Fluorescent Bulbs Tubular and Circular lamps Compact Fluorescent bulbs Tanning Lamps Germicidal Lamps High Intensity Discharge (HID) Lights Metal Halide lamp High Pressure Sodium Lamps Mercury Vapor Lamps Source: Northeast Waste Management Official’s Association (www.newmoa.org)19 Mercury Containing Products Other Types of Lighting Mercury Short Arc Metal Halide Lamp Mercury Capillary Lamps Mercury Xenon Short-arc Lamps Neon Lights Source: Northeast Waste Management Official’s Association (www.newmoa.org)20 Mercury Containing Products Relays and Tilt Switches Root Switch from Sump Pump Mercury Wetted Relay Tilt Switch from Washing Machine Flame Sensor from Gas Range Mercury Displacement Relay Mercury Contact Relay Source: Northeast Waste Management Official’s Association (www.newmoa.org)21 Mercury Containing Products Batteries – Standard Mercury Batteries, Alkaline Batteries Zinc Air Miniature Batteries Mercury Thermostat Silver Oxide Button Cell Batteries Mercury Switch inside Thermostat Alkaline Manganese Oxide Button-Cell Mercury Thermostat Source: Northeast Waste Management Official’s Association (www.newmoa.org)22 Best Management Practices Proper Disposal Spill Management 23 Proper Disposal Regulated by recycling and disposal requirements of the universal hazardous waste rules in the State of California Small business may qualify as a Conditionally Exempt Small Quantity Universal Waste Generator (CESQUWG) CESQUWGs can recycle their lamps at their local government sponsored Hazardous Waste Recycling and Disposal Program’s sites or they can contract with a hazardous water hauler to properly dispose of their hazardous waste 24 Spill Management Never touch mercury with bare hands Never use vacuum cleaners or brooms to clean up mercury spills Use cardboard pieces, a squeegee, or an eyedropper to gather and draw up the mercury Place the mercury and the items used to clean up the spill in a bag and dispose off as hazardous waste. See EPA website at http://www.epa.gov/hg/spills/ for more detailed information on cleaning up spills/breakage of products that contain mercury Provide facilities with EPA guidance on clean-up for broken fluorescent lamps, CFLs, and thermometers, if needed (See handout examples) 25 Pollutant of Concern PCBs 26 PCBs Synthetic chemicals: Poly-chlorinated biphenyls Manufacture of PCBs was stopped in the U.S. in 1977 because of evidence they build up in the environment and can cause harmful health effects PCBs continued to be imported into the U.S. until 1979, when they were banned Regulated under the Toxic Substances Control Act (TSCA) 27 TSCA Regulations (Toxic Substances Control Act – 1976) Designed to ban the manufacture of PCBs and ensure the proper disposal of PCBs and PCB equipment, while minimizing the risk posed by the storage, use, and handling of the substance. 28 TSCA Regulations Include numerous exceptions and authorized activities Allowed uses of PCBs include servicing of PCBs in various PCB-containing equipment, such as transformers, capacitors, natural gas pipelines, and hydraulic systems 29 TSCA Regulations Owners of PCB Transformers must register transformers with EPA There are requirements for marking, storage, record keeping and disposal of PBC-containing equipment EPA Data bases can be found at http://www.epa.gov/osw/hazard/tsd/pcbs/pubs/ data.htm 30 Provision C.12.a Develop training materials Train municipal building inspectors to identify PCBs or PCB-containing equipment Integrate PCB inspections into existing stormwater inspections of facilities Reporting requirements 31 Identification of PCB Containing Equipment Equipment will be marked 32 Identification of PCBs Containing Equipment Look at Records Recordkeeping Requirements include PCB weights identification and numbers of items storage, transfer, and disposal dates identification of shippers and receivers Manufacturer’s label/PCB Fluid trade names Aroclor, Askarel, Eucarel, Pyranol, Dykanol, Clorphen, Clorinol, Chlorextol, Diaclor, Hyvol, Asbestol, Inerteen, Elemex, Saf-T-Kuhl, No-Flanol, Nepolin, EEC-18, and others 33 Transformers PCB Transformer Source: EPA 34 Where Are Transformers Found? Industrial and other sectors: Commercial Buildings: Inside commercial buildings (may be owned by a utility) Neon signs (older ones manufactured prior to 1977-78) Utilities Electrical substations Inside, around, or on top of buildings In powerhouses that generate and distribute electrical power throughout a facility In underground vaults Distribution Substations Power generating facilities See handouts for list of registered facilities in Bay area 35 Capacitors PCB Capacitor Source: EPA 36 Where Are Capacitors Found? Utilities: Manufacturing: Located in distribution substations Located in banks or individually Found in underground pump stations Used for power factor correction on motor control units and part of circuitry for electric induction furnaces Used for power correction start up of large motors (e.g., water pumps for air conditioning systems or lift stations) Used for start up of any large motor associated with manufacturing (e.g., drills, saws) See handouts for list of facilities in Bay Area that generate or handle PCB wastes 37 Transformer and Capacitor Manufacturers and PCB Fluid Trade Names See Tables in Handouts from EPA’s PCB Inspection Manual for manufacturer names and fluids they contain 38 Hydraulic Systems Hydraulic Systems Source: EPA 39 Hydraulic Fluid Manufacturers and Trade Names Main manufacturer was Monsanto Pryradraul (Many numerical versions – See table in handouts for a listing) Santovac Turbinol See handouts for list of facilities in Bay Area that generate or handle PCB wastes 40 Fluorescent Light Ballasts Source: National Lamps and Components 41 Fluorescent Light Ballasts PCBs are located in the light ballasts’ small capacitor or in the potting material (the insulating material inside the ballast) If inspectors observe light ballasts that were manufactured before 1978, it should be assumed they contain PCBs Light ballasts manufactured between 1978 and 1998 were marked with the message “No PCBs” Ballasts manufactured after July 1, 1998 are not required to have that message on them, which can lead to confusion 42 Other Equipment Containing PCBs Heat Transfer Systems Electric Motors Electromagnets 43 Other Products/Materials These will be unmarked and possibly found in older facilities (before the 1979 ban): Carbonless copy paper General sealants and coatings, including windshield sealant and silo sealant Investment casting wax Lubricants, used motor oil, hydraulic fluid, and additives to transmission fluids Plastics Floor finish Old electrical devices or appliances with PCB capacitors Paint, including marine paint Electrical cable insulation (If electrical cable contains liquids or damp insulation, PCBs should be suspected.) Gaskets Roofing materials Thermal insulation materials, including fiberglass, felt, foam, and cork Oil-based paint Caulking materials Old electrical equipment such as: voltage regulators, switches, re-closers, bushings, and electromagnets 44 Best Management Practices Employee Awareness Spill Containment Provisions in Work Area Proper Storage Proper Disposal No Leaks 45 INSPECTION FORMS Cities/Agencies should modify existing stormwater inspection forms to include a reminder to inspect for POCs 46 Sample Form from Sunnyvale Note for inspector to remind them to check for POC sources. “Other sources determined to have a potential to contribute to pollution of stormwater runoff; e.g., PCBs, Copper, Mercury” 47 Examples of Problems to Report Observed in a Stormwater Inspection A PCB transformer that is not registered in the EPA database (see Table 2 in handouts for list of facilities in Bay Area); PCB-containing equipment that does not have the proper labeling; Leaking PCB-containing equipment or storage drum; or Improper storage of PCB-containing materials 48 If You Observe a Problem... The MRP requires permittees to document incidents and “refer to appropriate regulatory agencies” as necessary. BASMAA suggests that if stormwater inspectors find a problem related to PCBs or PCB-containing equipment during a stormwater inspection that the agency fax the inspection report, or notify by e-mail or phone, the following three agencies: EPA Region 9: Steve Armann, Regional PCB Coordinator, email: armann.steve@epa.gov, phone: 415-972-3352, FAX: 415-947-3530 Industrial Inspection contact for Alameda, San Mateo and Santa Clara Counties, Cecil Felix, email: CFelix@waterboards.ca.gov, phone: 510-622-2343, fax: 510-622-2460 County Department of Environmental Health or local CUPA agency 49 WRAP UP POC inspections need to be integrated into existing stormwater inspection programs. Use BASMAA Technical Memorandum and Guidance Manual for reference Use Outreach Material for educating business operators Complete Inspection Forms 50 Questions? Kristy McCumby Hyland City of Sunnyvale 408-730-7274 kmccumby@ci.sunnyvale.ca.us 51