Modelisation of the engine coolant warming

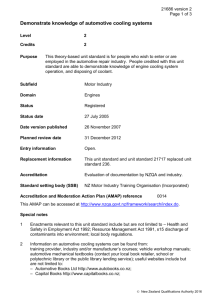

advertisement