Air Handling Units For Radiant Systems

advertisement

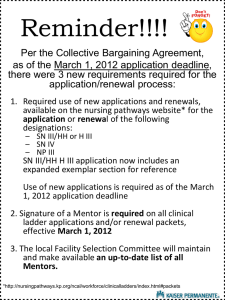

Cod. 9128205.01 - 02/2013 - Copie 2.000 Air Handling Units For Radiant Systems We have been working in an ideal climate for thirty years. A climate that has brought us to a position of leadership in Italy in the field of radiant heating and cooling. RDZ was the first company to receive the management system quality certification (today UNI EN ISO 9001:2008). RDZ has been a quality-oriented company since its very beginning, using the finest materials, developing new solutions, constantly providing excellent service. And also by creating a positive climate in the company to promote the exchange of ideas and stimulate cooperation for constant improvement. CONTENTS Page Introduction Residential applications without air renewal Dehumidifier RNW 204-I Dehumidifier RNW 204-E Dehumidifier RNW 404-CS Dehumidifier RNW 411-CS Dehumidifier RNW 508-CS Dehumidifier RNW 600-CS Residential applications with air renewal Heat recovery unit HR 140 Primary air handling unit UAP 130-C Unit Comfort UC 300-M Unit Comfort UC 300-MHE Air distribution system Commercial applications with air renewal Dehumidifier DA 700 Heat recovery unit SR 700 Dehumidifier DA 1000 Heat recovery unit SR 1000 Dehumidifier DA 2000 Heat recovery unit SR 2000 Unit Comfort UC 700/1000/2000 2 4 6 7 8 9 10 11 12 14 16 19 20 24 26 28 29 30 31 32 33 34 1 Air handling units Air Handling and Radiant Heating and Cooling Systems Modern, more and more hermetical buildings, do not ensure suitable air exchange. In order to guarantee health, comfort and to maintain the building value it is necessary to include ventilation systems for air renewal and humidity control. RDZ solution consists in specific devices defined as dehumidifiers. These are refrigeration units with hydronic coils that thermodynamically treat the air. The air passes through these dehumidifiers, where it is filtered, cooled, further cooled and dehumidified, heated and then post-cooled. The air which is taken in at a certain temperature and with a high humidity value, is thus sent back into a strongly dehumidified room but at the same starting temperature. The combination among a dehumidifier, a properly dimensioned and constructed heat recovery unit and a specific ventilation system creates something which is very similar to the AHU (Air Handling Unit). Yet, this special combination implies additional functions such as dehumidification, renewal, free-cooling, thermoventilation and the integration of sensible heat. These functions are obtained in a very simple way by using both heating and cooling energy with minimum consumption. That is why these units represent the ideal complementary element of a radiant installation. 2 The Comfortable Climate All Year Round Comfort also means air quality: fresh air, rich in oxygen, taken in from outside, filtered and dehumidified. RDZ offers a complete range of units, which can be successfully used in combination with radiant systems for air renewal and for efficient control over summer hygrometric conditions. There are various models available, depending on their use in residential or commercial applications: 1 2 3 4 5 6 Small dehumidifiers for residential applications (RNW) recirculating room air and dehumidify it during summer Small units for residential applications (UAP) for primary air control and air handling during summer Air handling units for residential applications with air renewal and heat recovery (Unit Comfort). Dehumidifiers for commercial applications (DA). Heat recovery units for commercial applications (SR). Handling units with air renewal and heat recovery for commercial applications (Unit Comfort). 3 Air handling units Residential Application without Air Renewal Air vents Air intake duct Dehumidifier RNW 404-CS Kit Easy-Clima Duplex Air to water heat pump Electronic thermohumidistat False ceiling (supply plenum) Cover radiant underfloor system Dehumidifier RNW 404-CS installed in a house The picture shows a house with a radiant underfloor heating/cooling system and RNW 404-CS dehumidifier with air intake duct installed into the false ceiling in the passage (functioning as supply plenum). The dehumidifier recirculates the air within the room and dehumidifies it in summer. The process consists in filtration, cooling, further cooling together with dehumidification, heating and subsequent post-cooling. In this way only the humidity level is reduced, and neutral air is given back into the room. RNW 404 and RNW 411 dehumidifiers, in combination with HR 140 heat recovery unit, make it possible to renew the air in both summer and winter. 4 RNW Dehumidifiers for Relative Humidity Control in Radiant Cooling Systems RDZ radiant systems guarantee maximum summer cooling performance when they are combined with suitable air dehumidification to maintain room comfort and eliminate the risk of condensation. That is why RDZ offers a complete range of machines, called RNW dehumidifiers, specific for radiant systems and available in different models according to actual requirements. Every machine has a refrigeration unit with two additional heat exchangers, exploiting the availability of the cold water (15-18 °C) that is used in the radiant panels. The pre-condenser coil unit, situated immediately before the evaporator, lowers the air temperature, thus reducing the sensible heat on the evaporator coil; the post-condenser coil, positioned after the condenser, reduces the air temperature before giving it back into the room. This process produces dehumidified air at the same temperature as the one in the room. As a result, RNW dehumidifiers basically control “latent heat”. This system also ensures higher efficiency from the chiller, because it can provide the radiant panels with water at a higher temperature than the one which is usually necessary for the dehumidification. 1 2 3 4 5 6 7 8 9 Room comfort during summer. Dehumidification and ventilation functions. Sensible heat integration (RNW 411 / 508 / 600). Summer and winter air renewal (RNW 404 / 411 in combination with heat recovery unit HR 140). No condensation risk. Wide range of models. Installation versatility: Embedded, wall, ceiling versions. Silent functioning. Compact solutions. 5 Air handling units Dehumidifier RNW 204-I m 0m 76 619 Code 7040010 Specifications: Power consumption Supply voltage Nominal air flow Water flow at 15 °C Dehumidification capacity Refrigerant R134a Size lxhxd Weight 207 340 W 230 V – 50Hz 200 m3/h 240 L/h 24 L/24h (26°C - RH 65%) 260 g 760x619x207 mm (front panel excluded) 45 Kg mm RNW 204-I dehumidifier is used to control room relative humidity in radiant underfloor, ceiling and wall cooling systems. It is a complete refrigeration unit, equipped with pre- and post-condenser coils fed by the water coming from the radiant panels. It has a zinc-plated sheet metal casing and can be embedded into the wall. It is provided with suitable casing with holes for electrical and plumbing connections and a front panel made of white MDF, which ensures the passage of the air through an anodized aluminium grill. It includes a 3 speed direct coupled centrifugal ventilation fan and a connection box for power supply with PCB. This is a very compact unit, which is particularly noiseless and therefore suitable for residential applications. Features RNW 204-I > Embedded wall installation. > Residential application (80 m2 approx). 6 > Ventilation function. > Dehumidification function. Dehumidifier RNW 204-E m 0m 80 650 230 Code 7040028 Specifications: Power consumption Supply voltage Nominal air flow Water flow at 15 °C Dehumidification capacity Refrigerant R134a Size lxhxd Weight 340 W 230 V – 50Hz 200 m3/h 240 L/h 24 L/24h (26 °C - RH 65%) 260 g 800x650x230 mm 49.6 Kg mm RNW 204-E dehumidifier is used to control room relative humidity in radiant underfloor, ceiling and wall cooling systems. It is a complete refrigeration unit, equipped with pre- and post-condenser coils fed by the water coming from the radiant panels. It has an opaque white MDF casing and is installed on the wall. It includes a 3 speed direct coupled centrifugal ventilation fan and a connection box for power supply with PCB. This is a very compact unit, which is particularly noiseless and therefore suitable for residential applications. Features RNW 204-E > External wall mounting installation. > Residential application (80 m2 approx). > Ventilation function. > Dehumidification function. 7 Air handling units Dehumidifier RNW 404-CS m 1m 71 242 546 mm RNW 404-CS dehumidifier is used to control room relative humidity in radiant underfloor, ceiling and wall cooling systems. It is a complete refrigeration unit, equipped with pre- and post-condenser coils fed by the water coming from the radiant panels. It has a zinc-plated sheet metal casing and it is horizontally installed into false ceilings. Code 7040030 Specifications: Power consumption Supply voltage Nominal air flow Water flow at 15 °C Dehumidification capacity Refrigerant R134a Size lxhxd Weight 360 W 230 V - 50Hz 220 m3/h 240 L/h 26.6 L/24h (26 °C RH 65%) 240 g 711x242x546 mm 36 Kg It includes a 3 speed direct coupled centrifugal ventilation fan and a connection box for power supply with PCB. This is a very compact unit, which is particularly noiseless and therefore suitable for residential applications. Features RNW 404-CS > Horizontal installation into false ceilings. > Residential application (100 m²). > Ventilation function. 8 > Dehumidification function. > In combination with HR 140 heat recovery unit: summer and winter air renewal function. Dehumidifier RNW 411 Code 7041400 r Summe eat h le sensib tion integra 1200 W m m 21 7 247 605 Specifications: Max. power consumption Nominal air flow Integration air flow Water flow at 15 °C Dehumidification capacity Summer sensible heat integration 370 W 220 m3/h 300 m3/h 240 L/h 30.7 L/24h (26 °C RH 65%) 1200 W Size (lxhxd) Weight 721x247x605 mm 37 Kg mm RNW 411 dehumidifier is used to control room relative humidity in radiant underfloor, ceiling and wall cooling systems. It is a complete refrigeration unit, condensed with water and equipped with pre-condenser coils and water-to-gas heat exchanger, which are fed by one hydronic connection to the water coming from the radiant panels. It has a zinc-plated sheet metal casing, and it is horizontally installed into false ceilings. It includes a 3 speed direct coupled centrifugal ventilation fan and a connection box for power supply with PCB. This is a very compact unit, which is particularly noiseless and therefore suitable for residential applications. Features RNW 411 > > > > Horizontal installation into false ceilings. Residential application (100 m²). Ventilation function. Dehumidification function. > Summer sensible heat integration. > In combination with HR 140 heat recovery unit: summer and winter air renewal function. 9 Air handling units Dehumidifier RNW 508-CS Code 7040050 al additionle sensibt hea Specifications: m 0m 84 290 600 Max power consumption Supply voltage Nominal air flow Dehumidification capacity Total head (medium speed) Refrigerant (R134a) Size (lxhxd) Weight 500 W 230 V – 50 Hz 500 m³/h 42.0 L/24h (26 °C - RH 65%) 52 Pa 300 g 840x290x600 mm 47 kg mm RNW 508-CS ductable dehumidifier is used to control room relative humidity in radiant underfloor, ceiling and wall cooling systems in residential and commercial application without air renewal. It has a zinc-plated casing and a stainless steel condensation trap. It includes an alternating compressor which is mounted on suitable rubber anti-vibration supports within a soundproof compartment. The unit is equipped with pre- and post-condenser coils, separately fed by water, and it can supply further sensible heat. It includes a 3 speed direct coupled centrifugal ventilation fan and a connection box for power supply with PCB. Features RNW 508-CS > Horizontal installation into false ceilings. > Residential and commercial applications with a small number of people (200 m2 approx). > Ventilation function. 10 > Dehumidification function. > It can supply additional summer sensible heat. > Ductable solution. Dehumidifier RNW 600-CS Code 7040035 al additionle sensibt hea Specifications: m 0m 69 349 718 Max power consumption Supply voltage Air flow Dehumidification capacity Total head (medium speed) Refrigerant (R407c) Size (lxhxd) Weight 900 W 230 V – 50 Hz 600 m³/h 62.0 L/24h (26 °C - RH 65%) 170 Pa 700 g 690x349x718 mm 53 kg mm RNW 600-CS ductable dehumidifier is used to control room relative humidity in radiant underfloor, ceiling and wall cooling systems in residential and commercial application without air renewal. It has a zinc-plated casing and a stainless steel condensation trap. It includes a hermetically sealed rotary vane compressor mounted on rubber anti-vibration supports within a soundproof compartment. The unit is equipped with pre- and post-condenser coils, separately fed by water, and it can supply further sensible heat. It includes a 3 speed direct coupled centrifugal ventilation fan and a connection box for power supply with PCB. Features RNW 600-CS > Horizontal installation into false ceilings. > Residential and commercial applications with a small number of people (280 m²). > Ventilation function. > Dehumidification function. > It can supply additional summer sensible heat. > Ductable solution. 11 Air handling units Residential Application with Air Renewal RDZ ModulAir distribution system Room air intake (clean rooms) Outside air intake Air exhaust (stale air) Unit Comfort UC 300-M Air supply into the room Room air intake (clean rooms) Unit Comfort UC 300 M - Application in a house The picture shows a house with a radiant underfloor heating and cooling system combined with Unit Comfort UC 300-M. This air handling unit is installed into the false ceiling of the store room, that is in an area ensuring easy positioning of the intake and exhaust ducts towards an outside wall. Unit Comfort 300-M is an air handling unit with high heat recovery efficiency. It ensures summer dehumidification with fresh air flow regulation and partial air recirculation. The features of the unit are as follows: • Ventilation with air renewal • Ventilation with air recirculation • Summer dehumidification • Air renewal in “Boost” mode • Integration of winter sensible heat • Integration of summer sensible heat • Air renewal with heat recovery by means of a high-efficiency heat exchanger (~90%) • Timer programming of different air flow rates (“normal” and “economy”). 12 Ductable Units for Renewal and Dehumidification in Houses In those places where we spend most of our time it is very important for our health to enjoy fresh, clean air. That is why RDZ offers a range of units for forced and controlled room air renewal and heat recovery in residential applications, in addition to traditional dehumidifiers for summer air handling. RDZ solutions are as follows: • HR 140 high-efficiency heat recovery unit (~90%) used in combination with RNW 404 and 411 dehumidifiers for summer and winter air renewal. • UAP 130 primary air handling unit for summer dehumidification, summer and winter room air renewal with high efficiency (~90%) heat recovery and integration of summer and winter sensible heat. The special feature of this unit is its modularity and installation flexibility. • Unit Comfort 300-M is a single unit designed for ventilation, dehumidification, air renewal and summer and winter sensible heat integration. • In addition to the functions provided by Unit Comfort 300-M, Unit Comfort 300-MHE can provide free sensible heat, and it is supplied as standard with four motorized air dampers which regulate air flows so as to optimise their performance. 1 2 3 4 5 6 7 8 9 Residential application. Room comfort and hygiene for all seasons: fresh, clean air. Controlled air renewal function. Ventilation function. Summer dehumidification function. Summer/winter sensible heat integration function (on demand). Free-cooling function for intermediate seasons. No condensation nor mould risk. Modular and compact models. 13 Air handling units Heat Recovery Unit HR 140 Code 7041140 ination In comb 404 W with RN 411 and RNW Specifications: 0 98 mm Max power consumption Supply voltage Air flow High-efficiency heat recovery Size lxhxd Weight HR 140 Kit freecooling 275 60 W 230 V – 50 Hz from 80 to 160 m3/h ~90% 900x275x980 mm 40 kg Adapater Plenum Pa 900 RNW 404-CS mm 242 546 m mm 1m 71 Air handling unit with high efficiency heat recovery (~90%) with countercurrent flows. It shall be used in combination with RNW 404 and RNW 411 standard dehumidifiers for residential applications. It ensures summer and winter air renewal and summer dehumidification and ventilation. View of HR 140 heat recovery unit with RNW 404 dehumidifier This is a very compact unit, which is particularly noiseless and therefore suitable for residential applications. Features HR 140 > Horizontal installation into false ceilings. > In combination with RNW 404 and RNW 411 dehumidifiers. > Residential applications (100 m2 approx). 14 > Summer/winter air renewal with high-efficiency heat recovery (~90%). > Summer dehumidification. > Summer free-cooling with by-pass unit. ACCESSORIES for HR 140 UNIT 1 Adapter Plenum PA 2 Air Supply Plenum 3 HR 140 Free Cooling Code 7041145 Code 7041135 Code 7041148 Sheet-metal component for the combination between HR 140 heat recovery unit and RNW 404 or RNW 411 dehumidifiers. The frontside shall be introduced into the filter box of the dehumidifier, while the backside is equipped with a fitting for pipe Ø 150 mm. The plenum includes a suitable grid for air recirculation and suitable damper. The air supply plenum is made of a zinc-plated sheet metal, and it is insulated inside. It is used to connect Comfort Unit with air supply round ducts. It can be connected with max. 5 supply round ducts: 2 side ducts Ø 150 mm and 3 central ducts Ø 100 mm. 2 collars of 100 mm and 1 collar of 150 mm are supplied as standard. By-pass unit for free-cooling. Optional component with motorized damper diverting the output air for summer free-cooling. HR 140 - Functioning Diagrams These diagrams represent the operation of HR 140 heat recovery unit, combined by means of a Plenum Adapter with RNW 404 dehumidifier and operating in heat recovery and free cooling modes. In both diagrams HR 140 is fitted with both Plenum Adapter and Free-Cooling kit. HR 140 + Kit Free-cooling + RNW 404-CS HR 140 + Kit Free-cooling + RNW 404-CS Free-cooling operation Heat recovery operation Kit Free-cooling Kit Free-cooling Air discharge Air recirculation from clean rooms (passage) Outside air intake Main air supply Air intake from bathrooms and kitchen HR 140 Air recirculation from clean rooms (passage) Air discharge Outside air intake Air intake from bathrooms and kitchen Adapter Plenum RNW 404 or RNW 411 HR 140 Main air supply Adapter Plenum RNW 404 or RNW 411 15 Air handling units Primary Air Handling Unit UAP 130-C Code 7041130 s Split unit m Specifications: 3m 64 420 780 mm Air handling and recovery unit Size lxhxd: 643x270x780 mm Weight: 66 kg Ventilation units 420 Acoustically insulated Size (combined version) lxhxd: 720x420x270 mm. Weight (combined version): 18 kg m 0m 27 720 Max power consumption Supply voltage Dehumification capacity (air renewal) Air flow Renewal air flow with booster function Nominal water flow (at 15 °C) Nominal pressure drop for the hydraulic circuit Summer sensible heat integration High-efficiency heat recovery Total output head Modulating fans Refrigerant 408 W 230 V - 50 Hz 37 l/24h (35 °C RH 50%) from 90 to 150 m3/h 180 m3/h 250 l/h 12 kPa up to 680 thermal W ~90% 70 Pa EC high-efficiency 134 a mm Primary air unit for room air renewal with high efficiency heat recovery (~90%) and summer dehumidification. Operation with fresh air only. The unit consists of two separate modules, which means easier installation and full use of the available space: the fan unit and the heat recovery/handling unit. These can either be installed close together or in separate locations. High-efficiency (~90%) countercurrent air discharge heat exchanger. The system implies the connection with outside fresh air in the fan section (equipped with a filter and a silencer), as well as the connection with the return air from wet rooms (such as bathrooms and kitchen) in the heat recovery and handling unit. The ventilation units can be split into intake and discharge units, which means easier installation and connection even in narrow spaces. UAP 130-C can be managed independently, by external control or by Wi electronic unit. Features UAP 130-C > Horizontal installation into false ceilings. > 2 split units: one air handling/recovery unit and one ventilation unit also for remote installation. > Residential application (120 m2 approx.) > Dehumidification function. 16 > Summer/winter sensible heat integration (on demand). > Summer/winter air renewal with high-efficiency heat recovery (~90%). > Summer free-cooling with by-pass unit. ACCESSORIES UAP 130-C 1 UAP 130 Free Cooling Code 7041138 Code 6600210 By-pass unit for free-cooling. Optional component with motorized damper diverting the output air for summer free-cooling. 2 TH Controller Optional component for UAP autonomous operation, including: • Outside sensor to detect the outdoor climate. • TH-Controller user terminal to detect room temperature and humidity. It displays and controls the parameters of the room and the air handling unit. It also manages the time programming of the different operations. UAP 130-C - Functioning Diagrams These diagrams shows UAP 130-C operating in heat recovery and free-cooling modes. In both examples UAP 130-C is provided with Free Cooling kit. UAP 130-C + Kit Free-cooling UAP 130-C + Kit Free-cooling Free-cooling operation Heat recovery operation Kit Free-cooling Air discharge UAP 130 (main unit) Main air supply Kit Free-cooling Air discharge UAP 130 (main unit) Main air supply Outside air intake Outside air intake UAP 130 (fan unit) Air intake from bathrooms and kitchen UAP 130 (fan unit) Air intake from bathrooms and kitchen 17 Air handling units UAP 130-C Control UAP 130 can be controlled in three different ways as follows: by external control, by Wi controller or completely autonomously with an external sensor and TH control terminal. Outside control Humidistat U Thermostat °C % Switch kitchen/bathroom (Booster) ON F OF Activated carbon cooker hood (Booster) Summer / winter switch Timer or On/Off switch With Wi controllers (digital output from Wi-U) Wi-U Switch kitchen/bathroom (Booster) Activated carbon cooker hood (Booster) ON F OF Autonomous functioning Th Controller* G!!! OLIN -CO FREE Outside sensor TE or duct sensor** °C * It is possible to set remote contacts with: humidistat, thermostat, kitchen/bathroom (booster) switch, On / Off ventilation ** The unit shall work constantly 18 Unit Comfort UC 300-M Code 7041300 Optional modulating valve Code 7041160 Optional motorized dampers Code 7041155 r summe eat h le ib sens on integrati W 0 0 2 1 Specifications: m 0m 77 275 115 0 mm Max power consumption High-efficiency heat recovery Modulating fans Dehumification capacity (recirculation) Dehumification capacity (renewal) Renewal air flow Renewal air flow with booster function Supply air flow Nominal water flow (at 15 °C) Nominal pressure drop for the hydraulic circuit Discharge fan output head Supply fan output head Summer sensible heat integration Refrigerant Size lxhxd Weight 520 W ~90% EC high efficiency 38.7 l/24h (26 °C RH 65%) 51.4 l/24h (35 °C RH 50%) from 80 to 160 m3/h 160 m3/h up to 300 m3/h 400 l/h 13.2 kPa 160 Pa* 154 Pa* 1200 W 134 a 770x275x1150 mm 55 kg *with air flow 160 m3/h Air handling unit with high heat recovery efficiency. It is used for summer dehumidification with fresh air flow regulation or partial air recirculation. The renewal air flow rate, from 80 to 160 m3/h, can be set through the user interface and automatically detected. It consists in a single unit made up of two sections, heat recovery section and air handling section (condensed with water). It is horizontally installed into false ceilings, and it is equipped with air vents on the two shorter sides in order to ensure easier air duct connection and installation even in narrow spaces. The high efficiency (~90%) heat exchanger is situated on the countercurrent air discharge side. The following operation modes can be set through the user remote control: air renewal, ventilation, dehumidification, summer and winter sensible heat integration. The unit is equipped with one pre-installed and electrically connected motorised damper for automatic recirculating air flow control. It can be optionally combined with two additional motorised dampers to avoid annoying draughts of fresh air (e.g. very cold unprotected windy locations). Another optional is a valve with modulating servomotor to control air temperature in winter through UC 300-M. It also controls air temperature in summer when the compressor is off. Comfort UC 300-M unit can be controlled by Wi electronic control unit, by external control or autonomously (work in progress). Features UC 300-M > Horizontal installation into false ceilings. > Single unit including two parts: heat recovery part and air handling part (condensed with water). > Residential application (120 m2 approx). > Ventilation function. > Dehumidification function. > Summer/winter air renewal with high-efficiency heat recovery (~90%). > Summer/winter sensible heat integration (on demand). > Free-cooling control. > (Optional) 2-way valve with servocontrol on air temperature. 19 Air handling units Unit Comfort UC 300-MHE Code 7041350 mmer Free su heat le sensib 1200 W Optional modulating valve Code 7041160 Specifications: m 0m 85 275 120 0m m Max power consumption High-efficiency heat recovery Modulating fans Dehumification capacity (recirculation) Dehumification capacity (renewal) Renewal air flow Renewal air flow with booster function Supply air flow Nominal water flow (at 15 °C) Nominal pressure drop for the hydraulic circuit Discharge fan output head Discharge fan output head Supply fan output head Summer sensible heat integration Refrigerant Size lxhxd Weight 520 W ~90% EC high-efficiency 34.0 l/24h (26 °C RH 65%) 49.3 l/24h (35 °C RH 50%) from 80 to 200 m3/h 200 m3/h up to 300 m3/h 300 l/h 7.4 kPa 148 Pa* renewal+integration 203 Pa* renewal+dehumidif. 128 Pa* 1200 W (free) 134 a 850x275x1200 mm 60 kg *flow rate 200 m3/h Air handling unit with high heat recovery efficiency. It is used for summer dehumidification with fresh air flow regulation or partial air recirculation. The fresh air flow rate, from 80 to 200 m3/h, can be set via the user panel and automatically detected. Air handling machine built as a single unit made up of two sections, heat recovery and air treatment (condensed with air). It is horizontally installed into false ceilings, and it is equipped with air vents on the two shorter sides in order to ensure easier air duct connection and installation even in narrow spaces. The high efficiency (~90%) heat exchanger is situated on the countercurrent air discharge side. The following operation modes can be set through the user remote control: air renewal, ventilation, dehumidification, summer and winter sensible heat integration. In particular, summer sensible heat integration and part of the condensed latent heat are supplied costlessly, i.e., without using further energy from the chiller. The unit includes four preinstalled and electrically connected motorised dampers for automatic function control. The heat discharge unit within the exhaust duct reduces energy consumption both during dehumidification and integration modes. Another optional is a valve with modulating servomotor to control air temperature in winter through UC 300-MHE. It also controls air temperature in summer when the compressor is off. Comfort UC 300-MHE unit can be controlled by Wi electronic control unit, by external control or autonomously (work in progress). Features UC 300-MHE > Horizontal installation into false ceilings. > Single unit including two parts: heat recovery part and air handling part (water-condensed). > Residential application (150 m2 approx). > Ventilation function. > Dehumidification function. 20 > Summer/winter air renewal with high-efficiency heat recovery (~90%). > Summer/winter sensible heat integration (on demand). > Free summer sensible heat (min. 1200 W). > Free-cooling control. > (Optional) 2-way valve with servocontrol on air temperature. UC 300-MHE Components G R SET H F E I J K D C L B M A Q N P O Unit Comfort UC 300-MHE Details Unit Comfort UC 300-MHE includes some very important structural details: • It consists in a single unit made up of two sections: heat recovery part and air handling part (condensed with air). • The unit has a rectangular shape with air vents placed on the two shorter opposite sides, which means easier air duct connection and installation even in narrow spaces. • The unit is equipped with four pre-installed and electrically connected motorised dampers for automatic function control. • The heat discarge unit is situated in the air exhaust duct. In this way energy consumption is reduced both during dehumidification and integration modes. • Compared to Unit Comfort UC 300-M, Unit Comfort UC 300-MHE has a different refrigeration circuit including an additional condensation coil in the air exhaust duct. This means free summer sensible heat (at least cooling 1.2 KW) without using further energy from the chiller. Ref. A B C D E F G H I J K L M N O P Q R Description Air supply vent Air supply fan Optional free-cooling vent 1 Finned coils Optional free-cooling vent 2 Heat exchanger Motorised dampers Room intake vent for air recirculation Room intake vent for air renewal Fresh air intake vent Renewal air exhaust vent Air discharge fan Condensation coil in the exhaust duct Compressor Hydraulic connections Condensation outlets Switchboard Control unit • A self-control PCB is supplied as standard. Considering the air flow characteristics of the distribution system, this board keeps air flow setting even when the filters are clogged, thus signalling the need for cleaning. 21 Air handling units UC 300-MHE - Functioning Diagrams These diagrams show some possible operations with UC 300-MHE: air renewal, dehumidification, integration with air renewal and partial recirculation. Air renewal only (e.g. in winter) Damper 2 4 Damper 1 Coils Heat recovery Fan 1 Filter Recirculation from clean rooms (passage) Switchboard Condenser Damper 3 Damper 4 3 Bathroom and kitchen air intake 130 m3/h Filter Outside air intake Filter Filter Fan 2 Air discharge Dehumidification and integration with air renewal and partial recirculation Air discharge 140 m3/h 22 Condenser Switchboard Damper 3 Damper 4 2 3 Coils Air supply 240 m3/h Heat recovery Fan 1 Damper 2 4 Recirculation from clean rooms (passage) Damper 1 100 m3/h Filter Outside air intake Filter 80 m3/h or as appropriate Filter Outside air intake Filter Fan 2 180 m3/h or as appropriate UC 300-M and UC 300-MHE Control System UC 300-MHE and UC 300-M can be controlled in three different ways: by external control, by Wi control unit or autonomously (work in progress). External control Humidistat Thermostat User interface U °C % Kitchen/bathroom switch (Booster) ON F OF Activated carbon cooker hood (Booster) Summer/Winter switch RECIRCULATION contact RENEWAL contact Wi controller (digital output from Wi-U module) Wi-U User interface Kitchen/bathroom switch (Booster) Activated carbon cooker hood (Booster) ON F OF Independent functioning (WORK-IN-PROGRESS) Outside sensor TE Room sensor TA-H User interface °C NG!!! OOLI -C FREE or Duct sensor TA-H Kitchen/bathroom switch (Booster) ON Activated carbon cooker hood (Booster) F OF 23 RDZ ModulAir Distribution Systems RDZ ModulAir is a flexible modular air distribution system including a plenum and semi-rigid ducts which are used for air intake and discharge, thus ensuring balanced air flow distribution in all rooms. The system consists in 150 mm ducts to connect the unit with the distributor, a modular plenum with 9 or 15 vents, flexible ducts made of PE-HD DN 63 and room supply and intake vents. If you connect one or more distributor vents, you can balance the air flow rate, room by room, according to the need, without using complex dimensioning and specific installation, as usually happens with traditional sheet metal ducting. Connections are installed in a very easy and fast way thanks to an automatic “click and go” joint system which ensures tight seals. Since it consists of small diameter pipes, the air distribution system can be installed into the ceilings, under the floors, into the walls, or even between steel reinforcing bars before casting the concrete. All components are treated with antibacterial and anti-static additives to ensure perfect cleanliness and easy maintenance as mentioned by European standards. One of the main advantages is the reduction in transmitted noise because all materials are made of plastic. 1 2 3 4 5 24 Easy and fast modular installation. Reduced number of necessary components. Reduced noise transmission. Easy maintenance and cleaning. It can be installed into ceilings, under floors and into walls. Plenum fitting with 15 outlets Plenum fitting with 9 outlets Room air intake (wet rooms) Intake vents Supply vents Unit Comfort UC 300-MHE Air exhaust (stale) Duct for RDZ ModulAir System Outside air intake Room air intake (clean rooms) Room air supply Rendering of a ventilation system featuring Comfort 300-MHE and RDZ ModulAir, room by room, as air distribution system. Cover undefloor heating sytem Components 1 RDZ ModulAir Duct Flexible duct DN 63 for RDZ ModulAir System. Package: 50-m roll. Code 2 3 7045000 Plenum Fitting 9 outlets Air supply or intake plenum with 9 outlets for duct DN 63 + plenum fitting Ø 125 mm (5 closing plugs are supplied as standard). Code 5 7045225 Plenum fitting Ø 125 mm + 3 outlets for duct DN 63. 7045135 Vent with 3 Outlets (Upright or Horizontal) Air supply or intake square vent for wall installation with 3 upright or horizontal round outlets DN 63. Code Code 6 Air supply or intake plenum with 9 outlets for duct DN 63 + plenum fitting Ø 125 mm (5 closing plugs are supplied as standard). Fitting with 3-outlet Module Code 7045125 Plenum Fitting 15 outlets Code 4 7045072 7045076 Double-Wall Duct Eco-friendly flexible ducts for air conditioning, made of resin mixture with additives. In the version with insulation, the insulating layer is made of polystyrene fibre, thickness 25 mm. Package: 10 m. Code Code Code Code Ø 100 Ø 125 Ø 150 Ø 200 7045210 7045212 7045215 7045220 25 Air handling units Commercial Application with Air Renewal Unit Comfort UC 1000 Supply duct Temperature/humidity room sensor User interface Manifold cabinet Radiant ceiling system Intake duct Unit Comfort UC 1000 in offices This picture shows a building with offices, where a radiant heating and cooling system have been installed into the false ceiling. Unit Comfort UC 1000 has been placed into the machine room, and it has been provided with air intake and supply ducts. Unit Comfort UC 1000 is made up of DA 1000 dehumidifier and SR 1000 heat recovery unit. It is ideal for medium-sized commercial applications with a medium number of people. It contains motorised dampers to control dehumidification, ventilation, air renewal (with heat recovery) and summer and winter sensible heat integration. In this way, b!klimax radiant ceiling system combined with one or more Unit Comfort modules becomes a DOAS radiant system (Dedicated Outdoor Air System). It is not only considered as a highly efficient system, but it also ensures excellent quality in terms of room comfort, because it combines room temperature control (sensible heat), through the radiant installation, with air handling in terms of primary air supply and humidity control. Thanks to the cross-flow heat exchanger, some energy can be saved, while additional sensible heat can be supplied on demand. 26 Ductable Units for Commercial Application with Air Renewal and Dehumidification DA 700, 1000 and 2000 dehumidifiers are air handling units specifically designed for radiant heating and cooling systems for floors, ceilings and walls in commercial application. They contain a direct expansion refrigeration cycle, and they are equipped with additional heat exchangers for preand post- air treatment. In summer these units dehumidify the room air, reintroducing it into the room at a neutral temperature; if necessary, they can also supply additional sensible heat in combination with the radiant system. SR 700, 1000 and 2000 heat recovery units are combined with the relevant dehumidifiers in buildings, where room air renewal is necessary. They are equipped with high-efficiency aluminium-plate heat exchangers to save the sensible energy from the exhaust air flow. 1 2 3 4 5 6 7 8 9 Commercial applications. Room comfort and hygiene all year round: fresh, clean air. Controlled air renewal. Ventilation. Summer dehumidification. Summer/winter sensible heat. Free-cooling in spring and autumn. No condensation nor mould risk. Installation into false ceilings. 27 Air handling units Dehumidifier DA 700 Code 7041700 r Summe eat h le ib s n se on integrati 3000 W Specifications: m 5m 77 342 675 Max power consumption Dehumidification capacity Nominal air flow Pre-treatment water flow (at 15 °C) Condensation water flow Total output head Summer sensible heat integration max Size lxhxd Weight 1214 W 84.4 l/24h (26 °C RH 65%) 700 m3/h 700 l/h 100 l/h 87 Pa 3016 W 775x342x675 mm 61 kg mm DA 700 dehumidifier for radiant heating and cooling systems for floors, ceilings and walls is suitable for commercial applications. It is used for air handling in medium-sized buildings with a medium number of people. Summer operation is combined with a radiant cooling system or at least a system operating with water at 15°C. The galvanized steel casing of the unit contains a set of finned coils for air treatment, a refrigeration circuit for dehumidification, an air intake filter, a condensation trap, an air supply fan and a PCB. DA 700 dehumidifier is equipped with a display showing the different operation icons. The supply vent air temperature and other parameters can be also read and set, while input / output stata and any alarms can be displayed and managed. Features DA 700 > Horizontal installation into false ceilings. > Commercial application (small volume). > Dehumidification function. 28 > Ventilation function. > Summer sensible heat integration. Heat Recovery Unit SR 700 Code 7041710 y Efficienc 59% Specifications: m 6m 96 Max power consumption Nominal air flow Air dampers Discharge fan output head Supply fan output head Heat recovery efficiency Size lxhxd Weight 778 W 700 m³/h supplied as standard 48 Pa 149 Pa 59% 966x342x926 mm 52 kg *In combination with DA 700 342 926 mm SR 700 cross-flow heat recovery unit with aluminium-plate heat exchanger has been designed to be used with DA 700 dehumidifier. It is equipped with two double suction centrifugal fans, one in the supply duct and one in the exhaust duct. DA 700 controls the operation of SR 700 by means of a suitable connector which guarantees reliable intercommunication. By default the unit starts up in recirculation mode, while air renewal is activated through the remote input on DA 700 dehumidifier. SR 700 heat recovery unit is equipped with ON/OFF motorised dampers which can be also partially opened to control air flow. Features SR 700 > Horizontal installation into false ceilings. > Commercial application. > Ventilation function. > Renewal function can be enabled by relevant remote input on DA 700. 29 Air handling units Dehumidifier DA 1000 Code 7041100 le r sensib Summetegration heat in 0 W 450 Specifications: m 3m 90 393 705 Max power consumption Dehumidification capacity Nominal air flow Pre-treatment water flow (at 15 °C) Condensation water flow Total output head Summer sensible heat integration max Refrigerant R410a Size lxhxd Weight 1192 W 127.5 l/24h (26 °C RH 65%) 1000 m3/h 1000 l/h 130 l/h 116 Pa 4498 W 1250 g 903x393x705 mm 70 kg mm DA 1000 dehumidifier for radiant heating and cooling systems for floors, ceilings and walls is suitable for commercial applications. It is used for air handling in medium-sized buildings with a large number of people. Summer operation is combined with a radiant cooling system or at least a system operating with water at 15°C. The galvanized steel casing of the unit contains a set of finned coils for air treatment, a refrigeration circuit for dehumidification, an air intake filter, a condensation trap, an air supply fan and a PCB. DA 1000 dehumidifier is equipped with a display showing the different operation icons. The supply vent air temperature and other parameters can be also read and set, while input / output stata and any alarms can be displayed and managed. Features DA 1000 > Horizontal installation into false ceilings. > Commercial application (medium volume). > Dehumidification function. 30 > Ventilation function. > Summer sensible heat integration. Heat Recovery Unit SR 1000 Code 7041110 y Efficienc 59% Specifications: m 3m 9 11 393 Max power consumption Nominal air flow Air dampers Discharge fan output head Supply fan output head Heat recovery efficiency Size lxhxd Weight 605 W 1000 m³/h supplied as standard 92 Pa 228 Pa 59.1% 1193x393x1056 mm 72 kg *In combination with DA 1000 105 6m m SR 1000 cross-flow heat recovery unit with aluminiumplate heat exchanger has been designed to be used with DA 1000 dehumidifier. It is equipped with two double suction centrifugal fans, one in the supply duct and one in the exhaust duct. DA 1000 controls the operation of SR 1000 by means of a suitable connector which guarantees reliable intercommunication. By default the unit starts up in recirculation mode, while air renewal is activated through the remote input on DA 1000 dehumidifier. SR 1000 heat recovery unit is equipped with ON/OFF motorised dampers which can be also partially opened to control air flow. Features SR 1000 > Horizontal installation into false ceilings. > Commercial application. > Ventilation function. > Renewal function can be enabled by relevant remote input on DA 1000. 31 Air handling units Dehumidifier DA 2000 Cod. 7041500 le r sensib Summe gration heat inte W 8450 Specifications: m 2m 5 10 535 798 Max power consumption Dehumidification capacity Nominal air flow Pre-treatment water flow (at 15 °C) Condensation water flow Total output head Summer sensible heat integration max Refrigerant R410a Size lxhxd Weight 3533 W 242.7 l/24h (26 °C RH 65%) 2000 m3/h 2000 l/h 250 l/h 214 Pa 8456 W 2500 g 1052x535x798 mm 114 kg mm DA 2000 dehumidifier for radiant heating and cooling systems for floors, ceilings and walls is suitable for commercial applications. It is used for air handling in large-sized buildings with a large number of people. Summer operation is combined with a radiant cooling system or at least a system operating with water at 15°C. The galvanized steel casing of the unit contains a set of finned coils for air treatment, a refrigeration circuit for dehumidification, an air intake filter, a condensation trap, an air supply fan and a PCB. DA 2000 dehumidifier is equipped with a display showing the different operation icons. The supply vent air temperature and other parameters can be also read and set, while input / output stata and any alarms can be displayed and managed. Features DA 2000 > Horizontal installation into false ceilings. > Commercial application (large volume). > Dehumidification function. 32 > Ventilation function. > Summer sensible heat integration. Heat Recovery Unit SR 2000 Code 7041510 y Efficienc 62% Specifications: 14 12 mm 535 Max power consumption Nominal air flow Air dampers Discharge fan output head Supply fan output head Heat recovery efficiency Size lxhxd Weight 1621 W 2000 m³/h supplied as standard 170 Pa 425 Pa 61.8% 1214x535x1266 mm 116 kg *In combination with DA 2000 126 6m m SR 2000 cross-flow heat recovery unit with aluminiumplate heat exchanger has been designed to be used with DA 2000 dehumidifier. It is equipped with two double suction centrifugal fans, one in the supply duct and one in the exhaust duct. DA 2000 controls the operation of SR 2000 by means of a suitable connector which guarantees reliable intercommunication. By default the unit starts up in recirculation mode, while air renewal is activated through the remote input on DA 2000 dehumidifier. SR 2000 heat recovery unit is equipped with ON/OFF motorised dampers which can be also partially opened to control air flow. Features SR 2000 > Horizontal installation into false ceilings. > Commercial application. > Ventilation function. > Renewal function can be enabled by relevant remote input on DA 2000. 33 Air handling units Unit Comfort UC 700/1000/2000 L Size LxhxD UC 700 UC 1000 UC 2000 h 966x342x1585 mm 1193x393x1745 mm 1214x535x2048 mm P Unit Comfort UC 700 / 1000 / 2000 are designed as the combination between DA 700 / 1000 / 2000 dehumidifiers and SR 700 / 1000 / 2000 heat recovery units. These combinations are used in commercial applications in medium-sized buildings with a medium number of people. Unit Comfort modules are supplied as standard with motorised dampers to control dehumidification, ventilation, air renewal (with heat recovery) and summer and winter sensible heat integration. Since they are condensed with water, hydraulic connection is very easy. For specific technical details see relevant data sheets for DA 700 / 1000 / 2000 and SR 700 / 1000 / 2000. Features UC 700/1000/2000 > > > > 34 Horizontal installation into false ceilings. Commercial application. Dehumidification function. Ventilation function. > Air renewal with heat recovery. > Summer/winter sensible heat integration. > Air dampers supplied as standard. Unit Comfort UC 700/1000/2000 Unit Comfort 700 / 1000 / 2000 can work at the following operating modes: ventilation only, dehumidification, summer and winter sensible heat integration, air recirculation and air renewal. • Ventilation function with Unit Comfort activates two standard fans, one in DA and one in SR unit. This ensures larger head to exhaust air. • By closing the Dehumidification contacts, the unit begins to dehumidify and keep the same neutral supply temperature as the intake one. The temperature is preset at 26°C but this value can be changed. • The Integration function in summer is activated by closing the integration contacts. The units start dehumidifying the room air by introducing a certain degree of sensible heat into the room. The parameter of the room temperature can be set by the user. The Integration function in winter just activates the ventilation or air renewal functions thereby causing hot water to circulate. In this mode the dehumidification operation is disactivated. • Recirculation is the default operating mode of the two combined DA and SR units guaranteeing dehumidification and integration by recirculating room air. • Air Renewal function is activated by closing the renewal contacts. The units move the dampers so as to change air flow and after a while they turn on the discharge fan. At this point, during summer, the units begin to dehumidify or integrate, totally renewing the air (or partially renewing it in case of partialised dampers). During winter the units take some air from outside, which passes through SR heat exchanger before being supplied into the room. Functioning Diagrams Unit Comfort UC 700 / 1000 / 2000 operating in air recirculation and air renewal mode. Air recirculation Air renewal Supply Supply DA Fan DA Fan Compressor Compressor Coils Coils Fan 1 SR Damper Fan1 SR Damper Damper Room intake Switch board Heat exchanger Switch board Room intake Filter Filter Damper Heat exchanger Fan 2 SR Damper Filter Fan 2 SR Damper Filter 35 RDZ S.p.A. Viale Trento, 101 (S.S. 13 Km 64,5) - 33077 Sacile, PN - ITALY Tel. +39 0434.787511 - Fax +39 0434.787522 www.rdz.it - rdzcentrale@rdz.it 36 Da trent’anni lavoriamo in un clima ideale. Un clima che ci ha portato ad essere leader in Italia nel riscaldamento e raffrescamento radianti e ad ottenere, per primi, la Certificazione di Qualità (oggi UNI EN ISO 9001:2008) per il nostro sistema di gestione. Perchè, sin dalla fondazione di RDZ, abbiamo sempre scelto di lavorare bene. Utilizzando i materiali migliori, ricercando e sviluppando le soluzioni più innovative, fornendo costantemente un servizio di altissima qualità ai nostri clienti. Ma anche instaurando in azienda un “clima“ positivo, aperto, che favorisce il flusso di idee e stimola la collaborazione reciproca. Per lavorare sempre meglio e raggiungere ogni giorno nuovi traguardi di eccellenza. Cod. 9128205.01 - 02/2013 - Copie 2.000 Air Handling Units For Radiant Systems