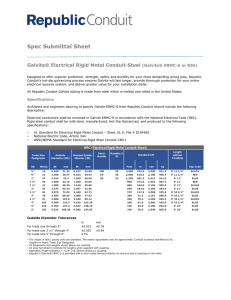

FLEXIBLE ELECTRICAL CONDUIT

advertisement