Exhaust Gas Scrubber Systems

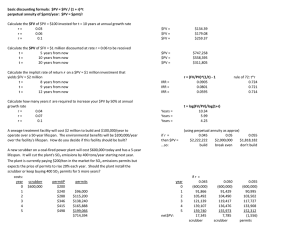

advertisement