Caterpillar Machine Fluids Recommendations

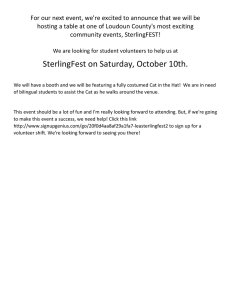

advertisement