High-Temperature Storage and Thermal Cycling

advertisement

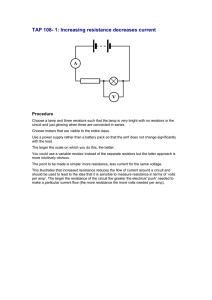

IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 25, NO. 1, MARCH 2002 45 High-Temperature Storage and Thermal Cycling Studies of Thick Film and Wirewound Resistors Jeffrey E. Naefe, R. Wayne Johnson, Member, IEEE, and Richard R. Grzybowski Abstract—The operating ambient temperature for underhood automotive and aerospace applications is increasing. This work was undertaken to evaluate the suitability of thick film and wirewound resistors for distributed aircraft control systems in a 200 C–225 C operating environment. High temperature stability testing of power wirewound and thick film resistors is reported. Dale power wirewound 1 , 100 , and 10 k resistors with power ratings of 5 W and 25 W were tested. The TCR of the 100 , and 10 k resistors was very small, however, the 1 resistor varied by 5% over the temperature range from 25 C to 300 C. Stability with long term storage (10 000 h) at 300 C was measured for the wirewound resistors unpowered and powered at 20% of rated power. With the exception of the 10 k /25W resistor, the change in resistance was less than 4%. Wirewound resistors were also thermal cycled 1000 times over a temperature range from 55 C to 225 C with only one failure due to a broken internal connection. Three 900 Series thick film resistor pastes from Heraeus-Cermalloy were studied: 100 /sq., 1 k /sq., 10 k /sq. The temperature coefficient of resistance (TCR) was measured from 27 C to 500 C in 50 C increments. The change in resistance was 6% up to 300 C. A 2 2 matrix of variables was included in the 300 C storage test: untrimmed resistors, resistors trimmed up 50% in value, unpowered, and powered at 1/8 W. Palladium/Silver was the initial termination choice for these 300 C studies, but silver migration under electrical bias lead to electrical shorts between conductor traces on the substrates with powered resistors. Gold terminated thick film resistors were used for powered storage testing at 300 C. The change in resistance after 10 000 h at 300 C was 3% for all test combinations. Index Terms—High temperature electronics, resistors, thick film, wirewound. I. INTRODUCTION A DVANCES in silicon-on-insulator technology (SOI) and the steady development of silicon carbide based electronics are opening the door for high temperature electronics. Manuscript received August 2, 2000; revised September 10, 2001. This work was supported in part by the National Aeronautics and Space Administration and the Center for Commercial Development of Space Power and Advanced Electronics under NASA Grant NAGW-1192-CCDS-Al, Auburn University, and the Center’s Industrial Partners. This work was presented in part at the 1998 High Temperature Electronics Conference, Albuquerque, NM, June 16–19, 1998. This work was recommended for publication by Associate Editor D. N. Donahoe upon evaluation of the reviewers’ comments. J. E. Naefe was with the Electrical and Computer Engineering Department, Center for Advanced Vehicle Electronics, Auburn University, Auburn, AL 36849 USA. He is now with Raytheon Missile Systems, Tucson, AZ 85705 USA (e-mail: jeffrey-e-naefe@west.raytheon.com). R. W. Johnson is with the Electrical and Computer Engineering Department, Center for Advanced Vehicle Electronics, Auburn University, Auburn, AL 36849 USA (e-mail: johnson@eng.auburn.edu). R. R. Grzybowski was with the United Technologies Research Center, East Hartford, CT 06108 USA. He is now with Corning, Inc., Corning, NY 14830 USA. Publisher Item Identifier S 1521-3331(02)00682-7. High temperature electronics applications include distributed controls for aircraft, automotive electronics, electric vehicles (both civilian and military), and instrumentation for geothermal wells, oil well logging and nuclear reactors [1]. Complete, high temperature electronic systems, however, require more than just semiconductor device technology. Passive components (resistors, capacitors, and inductors) are also required. This work addresses low and medium power resistors. The target application is distributed aircraft control systems with an anticipated maximum ambient temperature of 200 C to 225 C. II. RESISTORS Thick film resistor technology was selected for the low power applications. Thick film resistors are typically rated over the military temperature range of 65 C to 150 C. For higher temperature applications Heraeus–Cermalloy developed the 900 Series resistor inks [2], [3]. These inks are a proprietary ruthenium based formulation. The paste uses a higher softening point glass compared to traditional thick film inks to allow operating higher temperatures. The increase in softening point should permit operation to 500 C, however the stability with time at 500 C would need to be determined. The minimum in the temperature coefficient of resistance (TCR) was shifted from room temperature to approximately 150 C. The Heraeus-Cermalloy thick film resistor pastes used were: R951 (100 k /sq.), R941 (10 k /sq.), R931 (1 k /sq.), and R921 (100 /sq.). Two thick film conductors were used, a palladium–silver (Heraeus-Cermalloy C1003) and a gold (Ferro FX-30-052). The test samples were fabricated on 96% alumina substrates by first printing the resistor ink, then firing it at 950 C. Next the conductor was printed and fired at 850 C. The firing profile used was one hour with 12–14 min at the peak temperature. The dried print thickness of the resistors obtained was 24 2 m with the fired thickness of 12 2 m. The post-fired resistor values were between two to five times the nominal paste value. This likely relates to a combination of factors including the firing sequence (resistor first then conductor instead of vice versa), the time–temperature profile and the conductors used. The fired resistor values were repeatable and the resistor geometry could have been adjusted to obtain specific resistor values if required. Commercially available RH Series high reliability, wirewound power resistors manufactured by Dale Electronics were selected for the medium power applications. These resistors are CuNi or NiCr wire wound on a ceramic (alumina or steatite) core. The wire and core used depends on the resistor value and power rating. In these tests, 1 /25 W, 1 /5 W, 100 /25 W, 1521–3331/02$10.00 © 2002 IEEE 46 IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 25, NO. 1, MARCH 2002 Fig. 1. Macro view of cross sectioned 10 k /5 W wirewound resistor. Fig. 3. Normalized change in resistance as a function of temperature for the 1 k /sq. thick film resistor paste. Fig. 2. Normalized change in resistance as a function of temperature for the 100 /sq. thick film resistor paste. 100 /5 W, and 10 k /5 W values were studied. The 1 /25 W, 1 /5 W, 100 /25 W are manufactured with CuNi wire, while the 100 /5 W and 10 k /5 W use NiCr. The resistance wire is welded to a copper plated steel end terminal that exits the package for electrical interconnection. Silicone is used to insulate between the wire and the aluminum chassis mount housing. The aluminum housing includes mounting holes for direct attachment to a heat sink for heat removal. A cross section is shown in Fig. 1. The resistors are derated to zero power dissipation at 275 C for continuous use by the manufacturer. At 200 C, the resistors are derated by the manufacturer for constant operation with power dissipation at 20% of the room temperature power rating. The temperature limitation as identified by the manufacturer was the silicone insulation. While the specific silicone used by Dale is not known, the manufacturers of high temperature silicones typically rate their materials for a maximum use temperature between 250 C and 300 C. III. TEMPERATURE COEFFICIENT MEASUREMENT OF RESISTANCE For testing the thick film resistors at temperature, a clamping fixture was constructed [4]. Various resistor geometries were printed and measured. Figs. 2–4 plot the normalized change in resistance versus temperature from 25 C to 500 C for the three resistor pastes with PdAg conductor terminations as a function Fig. 4. Normalized change in resistance as a function of temperature for the 10 k /sq. thick film resistor paste. of resistor geometry. Three to four resistors were measured for each data point and averaged. As expected, the minimum resistance is in the 150–200 C temperature range for the 100 /sq. and the 1 k /sq. pastes. The 10 /sq. paste shows a continuing downward shift in resistance with increasing temperature, but there is an inflection point at approximately 200 C. None of the resistors in this test were trimmed or powered. From room temperature to 300 C, the resistor geometry did not significantly affect the variation of resistance with temperature. With the exception of the intentional shift in minimum resistance, the behavior of the resistors from room temperature to 300 C is similar to conventional thick film resistors over the 55 C to 125 C temperature range. The temperature coefficient of resistance (TCR) of the wirewound resistors was measured by a four-wire measurement and technique to increase accuracy particularly for the 1 values. The results are plotted in Fig. 5. Each data 100 point represents the average of five samples. The 100 and 10 k resistors varied by less than 0.2% over the temperature range from 27 C to 300 C. The 1 varied significantly over NAEFE et al.: THICK FILM AND WIREWOUND RESISTORS 47 Fig. 6. Silver migration paths in the 100 k /sq. sample. Fig. 5. TCR measurements of Dale chassis mount power wirewound resistors. the temperature range and the characteristic was unexpected. The measurement was repeated and the results were verified. The coefficient of variation was less than 1% for all of the 1 resistance measurements. The effect was similar for 1 resistors at both power ratings. While the exact mechanism for the resistance as a function of temperature characteristic measured is not known, the fact that the end terminal is nonnegligible portion of the total 1 resistance must be considered. The TCR is thus a function of the two material systems: the CuNi wire and the copper plated steel end terminal. For larger value resistors, the contribution due to the end terminal is insignificant and its TCR does not measurably effect the TCR of the overall resistor. IV. THE 300 C STORAGE STABILITY The application of primary interest in this work was distributed controls for aircraft with a design ambient temperature of 200 C to 225 C. To accelerate the life testing of the resistors, a storage temperature of 300 C was used. For the thick film resistors, a 2 2 matrix of variables was studied in the 300 C storage test. The test conditions were: laser trimmed or untrimmed and powered to 1/8 watt or unpowered. All of the resistors in this test were 1.5 mm 1.5 mm in size. After the sequential firing of the resistor and conductor inks, plunge cuts were used to increase the value of the laser trimmed resistors by 50%. A Quantrad Nd : YAG laser trimmer was used to trim the resistors. The trim speed and laser power were set to ensure a clean kerf with no microcracking. Five resistors were tested per test matrix cell. The original thick film resistors tested at 300 C were 100 /sq., 1 K /sq., and 100 k /sq., and were terminated with the thick film Pd/Ag conductor. In the powered samples, silver migration quickly became a failure mode. The 100 k /sq. sample (Fig. 6) showed many more migration paths compared to the 100 sq. sample (Fig. 7). The 100 k /sq. test vehicles migrated to failure in 24 h, while the 1 k /sq. and 100 /sq. samples failed after 700 and 2500 h, respectively (Fig. 8). Fig. 7. Silver migration paths in the 100 /sq. sample. The data is a near linear fit of log time to failure versus bias voltage. Increasing bias voltage (1/8 watt power dissipation at higher resistor values) increased the silver migration rate at 300 C. Silver migration in the presence of bias and moisture is a well know phenomena. However, silver migration was not anticipated at 300 C in air. The increased temperature increases the mobility of the Ag under bias. The exact point for initiation of Ag migration could be related local printing irregularities that reduce the spacing (increase the electric field) between adjacent traces. Pointed irregularities could also serve as electric field concentrators. The edges of screen printed thick film conductor traces are not smooth due to the nature of the screen printing process. Unencapsulated PdAg conductors can not be used at 300 C. The powered testing of these inks was terminated when this failure mode was discovered. Unpowered testing of the Pd/Ag terminated 100 /sq. and 1 k /sq. resistors was continued to 10 000 h. Gold terminated (Ferro FX-30-052) samples were fabricated for the powered resistor testing. Extensive tests were performed on the R951 (100 k /sq.) paste, but it proved to be very unstable at temperatures 300 C. Since the 100 k /sq. paste was deemed unusable, the 10K /sq. paste was added in its place. In addition to the powered samples fabricated with gold terminations, unpowered gold terminated 10 k /sq. samples were also printed. The resistors were placed in a Blue-M oven, and wires were run through feed-throughs to provide power and to allow resistance measurement in-situ. The oven was ramped to 300 C in 48 Fig. 8. IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 25, NO. 1, MARCH 2002 Silver migration time to failure as a function of bias voltage. Fig. 9. Normalized change in resistance with storage time at 300 C for unpowered, 100 /sq. thick film resistors. The resistors were terminated with PdAg conductors. air. This storage test ran for 10 000 h. The change in resistance is plotted as a normalized shift using Normalized Change In Resistance Value Value Value (1) Each data point plotted is based on the average of the five samples. The resistance measurements were made in-situ. Fig. 10. Normalized change in resistance with storage time at 300 C for 1/8 W powered, 100 /sq. thick film resistors. The resistors were terminated with Au conductors. followed by a gradual decrease after 1000 h. The powered 3.5% over 10 000 h. Laser trimming resistor group shifted appeared to have little effect on either group of 100 /sq. samples. The different behavior with time at temperature for the powered versus unpowered resistors is believed to be related to the difference in termination metallurgy. B. 1 k /sq. Thick Film Resistors A. 100 /sq. Thick Film Resistors 3.5% after The unpowered 100 /sq. resistors drifted 10 000 h at 300 C (Fig. 9). The powered (Fig. 10) group exhibited a rapid increase in resistance during the first 250 h The untrimmed, unpowered 1 k /sq. resistors (Fig. 11) shifted 0.6% during the first 2500 h at 300 C, while the trimmed, unpowered resistors (Fig. 12) shifted 0.35% during the first 2500 h. After 2500 h a positive exponential drift takes NAEFE et al.: THICK FILM AND WIREWOUND RESISTORS 49 Fig. 11. Normalized change in resistance with storage time at 300 C for unpowered, 1 k /sq. thick film resistors. The resistors were terminated with PdAg conductors. Fig. 13. Normalized change in resistance with storage time at 300 C for unpowered, 10 k /sq. thick film resistors. The resistors were terminated with Au conductors. Fig. 12. Normalized change in resistance with storage time at 300 C for 1/8 W powered, 1 k /sq. thick film resistors. The resistors were terminated with Au conductors. Fig. 14. Normalized change in resistance with storage time at 300 C for 1/8 W powered, 10 k /sq. thick film resistors. The resistors were terminated with Au conductors. place in both the trimmed and untrimmed samples. Laser trimming appears to have little effect in the unpowered stability of these resistors. Additionally, it should be noted the total shift after 10 000 h of storage is 3.5% for both the trimmed and untrimmed resistors. The powered 1 k /sq. resistors drifted 1% and laser trimming did not degrade stability. The by different behavior observed for the powered versus unpowered resistors was similar in trend to that observed for the 100 /sq. resistors. Ferro Au conductor and the behavior as a function of time at temperature was similar to the other resistors (100 /sq. and 1 k /sq.) values terminated with Au under power. This provides evidence that the termination metallurgy has a significant affect on the stability behavior of these resistors. The powered 10 k /sq. resistors (Fig. 14) drifted less than 2.5% after 10 000 h at 300 C. The laser trimmed resistors did drift more with time compared to the untrimmed resistors. The higher resistance values have a higher glass content and the potential for microcracking during laser trimming increase. The conduction mechanisms in thick film resistors are still not completely understood. The fired ink is a nonhomogeneous mixture of conductive particles in a glass matrix. Even the TCR of thick film resistors exhibits both metallic (positive TCR) and C. 10 k /sq. Thick Film Resistors The unpowered 10 k /sq. resistors (Fig. 13) drifted less than 2% after 10 000 h at 300 C. Laser trimming did not significantly affect stability. These resistors were terminated with the 50 IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 25, NO. 1, MARCH 2002 Fig. 15. Average resistance of Dale chassis mount power wirewound resistors stored at 300 C and powered to 20% of room temperature power rating. The resistance value and rated power are indicated in the legend. semiconductor or insulator (negative TCR) characteristics over the temperature range, providing no clear indication of the conduction process. Changes in resistance with high temperature storage can result from a combination of mechanisms including annealing of the glass, diffusion within the resistor matrix, diffusion between the resistor and the termination metallization and microcrack growth. These mechanisms can have competing effects on the change in resistance. The direction and magnitude of the changes will depend on the dominant mechanism at a given time. While the behavior of the drift in resistance varies with time at temperature and resistance value, the thick film resistors maintained a 5% tolerance during the 10 000 of storage. D. Wirewound Resistors The wirewound resistors were bolted to an aluminum heat sink. Indalloy Easy-Flo 45 was used to braze Brim wire (inorganic braid with a silicone varnish over a stranded nickel-plated copper conductor) to the resistor terminals. Five resistors of each type were powered at 20% of the room temperature rated power level (powered at 1 W or 5 W). In addition, five 100 /5 W and five 10 k /5 W resistors were tested unpowered. The resistors were placed in a Blue-M oven, and wires were run through feed-throughs to provide power and to allow resistance measurement in-situ. The oven was ramped to 300 C in air and the storage test ran for 10 000 h. The resistance was periodically measured in-situ and the results are plotted in Figs. 15 and 16. All of the powered resistor measurements were four point measurements, while the unpowered resistor measurements were two point measurements. Each data point is based on the average of the five samples. At 4 520 h the oven was shutdown for a period of three weeks to allow wiring of the Au terminated thick film resistors into the oven. A significant jump in resistance was noted in the 10 k /5 W and the 1 /5 W. The 1 /5 W returned to pre-shutdown values very quickly, but the 10 k /5 W had a permanent shift associated with the Fig. 16. Average resistance of Dale chassis mount power wirewound resistors stored at 300 C without power applied. The resistance value and rated power are indicated in the legend. Fig. 17. Cross section of 10 k /5 W Dale resistor after 10 000 h at 300 C unpowered showing a crack in the silicone. shutdown. As a possible explanation, a thermal cycling study was performed to examine the effects of thermal cycling on these resistors and is discussed in a later section. With the exception of the 10 k /5 W resistor, all shifts in resistance value were less than 4%. A thermal study was conducted at 300 C to measure the case temperatures on three Dale power wirewound resistors. The three resistors (100 /5 W, 100 /25 W, and 10 k /5 W) were powered to 20% of rated power. A thermocouple was placed into a hole drilled into the aluminum case on each resistor. The measured case temperature was 320 C indicating a temperature rise of 20 C due to power dissipation. E. Cross-Sectioning of Wirewound Resistors After 10 000 h Three 10 k /5 W resistors were cross-sectioned and analyzed upon completion of 10 000 h of storage at 300 C. The silicone had changed color from black to light gray. Cracks were found in the silicone between the ceramic core and the aluminum housing (Fig. 17) and delamination occurred between the silicone and the aluminum housing (Fig. 18). During storage for 10 000 h, the silicone continues to cure and harden. With NAEFE et al.: THICK FILM AND WIREWOUND RESISTORS 51 Fig. 18. Cross section of 10 k /5 W Dale resistor after 10 000 h at 300 C powered to 20% of rate power showing delamination. Fig. 20. Closeup of failed wire connection. VI. CONCLUSIONS Fig. 19. Failed wire of the aged 10 K /5 W Dale resistor after 100 thermal cycles ( 55 C to 225 C). 0 continued curing and potential mass loss (outgassing) during the extended high temperature storage, volumetric contraction of the silicone could lead to cracking and delamination. While cracking and delamination of the silicone was observed, there were no catastrophic failures during the 10 000 h of storage at 300 C. The delamination and cracks could potentially provide a path for moisture egress in humidity testing, but humidity test were not performed in this series of experiments. Normalized resistance shifts of 4.0% were found for all wirewound resistors except the 10 k /5 W resistors. The 20% power dissipated in the power wirewound resistors only increased the case temperature from 300 C to 320 C. This indicates the resistors could be operated at higher power levels at lower temperature (200 C). With only one power wirewound resistor failing after 10 000 h of lifetime testing plus 1000 thermal cycles from 55 C to 225 C, these wirewound resistors are a viable solution for the medium power resistive needs. The thick film resistors are an acceptable choice for low power resistor needs at higher temperatures. The Heraeus–Cermalloy R900 pastes could be used to achieve the range of to 100 k . The tests run on these thick values from 100 film pastes show that the resistors should be able to meet 5% tolerance requirements necessary for most applications in the high temperature range (175 C–250 C). Gold terminations are required to operate these resistors at these elevated temperatures. Even the addition of palladium to the silver conductor is not sufficient to curb the inherent silver migration. REFERENCES V. THERMAL CYCLING Thermal cycling between 55 C and 225 C was used to simulate engine startup and cool down. After completing 10 000 h of storage at 300 C, the wirewound resistors were shipped to United Technologies Research Center for thermal cycling. Both aged resistors and identical, new resistors were included in the thermal cycling study. The thermal cycle range was from 55 C to 225 C. Only one failure (at 100 cycles) was found in the 1000 cycle study. The resistor that failed was a 10 k /5 W resistor that had previously been powered to 20% for 10 000 h at 300 C. SEM photographs were taken of the failure. The resistive wire broke at the heel of the resistance weld to the end termination (Fig. 19). The roundness of the end of the broken wire suggested the wire was badly fatigued before failure (Fig. 20). Aging and hardening of the silicone encapsulant, coupled with delamination of the silicone from the aluminum housing likely resulted in stress on the wire during thermal cycling. [1] G. Shorthouse and S. Lande, “The global market for high temperature electronics,” in Proc. 3rd Int. High Temp. Electron. Conf., Albuquerque, NM, June 1996, pp. I-3–8. [2] H. W. Imhof and B. E. Bertsch, “Thick film materials for hi-temperature operation,” in Proc. High Temp. Electron. Instrum. Conf., Dec. 1981, p. 83. [3] B. L. Draper and D. W. Palmer, “Extension of high temperature electronics,” in Proc. 29th Electron. Comp. Conf., May 1979, pp. 40–46. [4] W. Dillard, J. Naefe, M. Palmer, and R. W. Johnson, “A test fixture for high-temperature, low noise testing of electronic components,” in Proc. 3rd Int. High Temp. Electron. Conf., Albuquerque, NM, June 1996, pp. XIV-9–14. Jeffrey E. Naefe received the B.Eng. degree (with honors) and the M.S. degree from Auburn University, Auburn, AL, in 1995 and 1998, respectively. His thesis research was concentrated in high temperature resistors and component attach materials. Upon graduation, he took a job in the Commercial Wireless Communications Division, Raytheon, Dallas, TX. His primary work was concentrated in developing terrestrial wireless communication systems. He left Raytheon in October 2000 and is currently employed by NERA Telecommunications, Inc., Dallas. His work continues in the development of point-to-multipoint terrestrial communications systems. 52 IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 25, NO. 1, MARCH 2002 R. Wayne Johnson (M’82) received the B.E. and M.Sc. degrees from Vanderbilt University, Nashville, TN, in 1979 and 1982, respectively, and the Ph.D. degree from Auburn University, Auburn, AL, in 1987, all in electrical engineering. He has worked in the microelectronics industry for DuPont, Eaton, and Amperex. He is an Alumni Professor of electrical engineering at Auburn University and Director of the Laboratory for Electronics Assembly and Packaging (LEAP). At Auburn, he has established teaching and research laboratories for advanced packaging and electronics assembly. Research efforts are focused on materials, processing, and modeling for multichip packages and high temperature electronics. He has worked in MCM design, MCM-L, -C, and -D substrate technology as well as SMT, wire bond and flip chip assembly techniques. He has published and presented numerous papers at workshops and conferences and in technical journals. He has also co-edited one IEEE book on MCM technology and written two book chapters in the areas of silicon MCM technology and MCM assembly. Dr. Johnson received the 1997 Auburn Alumni Engineering Council Senior Faculty Research Award for his work in electronics packaging and assembly, the 1993 John A. Wagnon, Jr. Technical Achievement Award from ISHM, the Daniel C. Hughes Memorial Award in 1997. He is a Fellow of ISHM and a member of SMTA and IPC. He was the President of the International Society for Hybrid Microelectronics in 1991. Richard R. Grzybowski received the B.S. degree from Yale University, New Haven, CT, the M.S. degree from Rensselaer Polytechnic Institute, Troy, NY, and the Ph.D. degree from the University of Connecticut, Storrs, all in electrical engineering. He is Manager of Systems Engineering Research Department, Corning, Inc., Erwin, NY, where he is responsible for the development and growth of this new department in Integration technology. He came to Corning in September 2000 from the United Technologies Research Center (UTRC), East Hartford, CT, where he was Manager of the Electronics Design and Analysis Department. His areas of responsibility included wireless communications systems, power electronics electric machines, and predictive reliability. He was previously Technical Manager for Harsh Environment Electronics, Packaging, and Reliability, UTRC. In that role, his responsibilities included microcircuit fabrication and packaging for high temperature environments (to 600 C ), reliability prediction based on probabilistic physics of failure, advanced electronics packaging, and wireless technology. He has five patents, more than 60 publications, and is a coauthor of the book High Temperature Electronics (Orlando, FL: CRC, 2001). +