PV Connector UTX and UTX-XL Series

advertisement

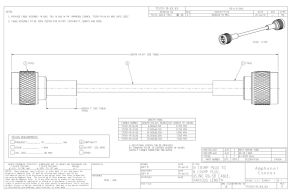

INSTRUCTION MANUAL PV Connector UTX and UTX‐XL Series UTX PV CONNECTOR UTX‐XL PV CONNECTOR Prepared by: Johnny Wang Checked by: Allen Wan Date: Aug/15/2015 Date: Aug/15/2015 File Name: PV‐692999‐000 Page 1 of 13 INSTRUCTION MANUAL Electrical rating: Current rating: 1500V DC (UL/IEC/TUV/JET) 1000V DC (ETL) TUV: 31A @85℃; 29A @90℃; (2.5mm²/14AWG) 42A @85℃; 39A @90℃; (4.0mm²/12AWG) 53A @85℃; 49A @90℃; (6.0mm²/10AWG) 75A @85℃; 69A @90℃; ( 10mm²/ 8AWG) JET: 30A (2.5mm²/14AWG) 40A (4.0mm²/12AWG) 50A (6.0mm²/10AWG) ETL/UL: 15A (14AWG) 20A (12AWG) 30A (10AWG) 50A (8AWG) Protection degree: IP68 mated and IP2X unmated Safety class: II Operation Temperature Range: ‐40℃ to +90℃ License holder Full Address Amphenol Technology (Shenzhen) Co., Ltd. Building C, 2nd Industrial Zone of Xia Shi Jia, Jiangshi Community, gongming Sub‐district, Baoan, Shenzhen, Guangdong, 518103 P. R. China CAUTION: 1) The connector must be isolated and disconnected from the power supply during the assembling or disassembling process. 2) Do not disconnect under load. 3) The use of PV cable is recommended. 4) The use of tin plated cable is recommended. 5) The connectors are IP68 rated, and can be positioned for short time under 1MT of water. 6) The connector is considered to be in compliance with UL 6703 only when assembled in the manner specified by assembly instructions. 7) This connector is suitable for use only with Class B and C stranded copper conductors (See NFPA NEC 70 Chapter 9, Table 10)”. If the connector is found to be suitable for use with other stranding classes, the connector shall be marked with those class conductors. See the Standard for Wire Connectors, UL 486A-486B. 8) Some chemicals should be avoided to contact with body of UTX and UTX‐XL PV connector, refer to the following table. Table 1: Chemical Chemical Name Manufacture Critical strain Rank Grease Z260 HASCO 1.2 A A7002 HASCO 1.2 A Dow Corning Molykote EM‐30L >1.5 A Dow Corning Molykote EM‐50L 0.44 C Molykote PG-641 Dow Corning 0.87 B Oils Silicone Oil KF96 ShinEtsu Silicones >1.5 A Silicone Oil SH200 ShinEtsu Silicones >1.5 A File Name: PV‐692999‐000 Page 2 of 13 INSTRUCTION MANUAL Dia Cut Machine Oil KV46 Mould Release Agent Pelicoat B Pelicoat S‐6 Binder Chemlok Surfactant Charmy VQuick Alcohols Ethyl Alcohol Isopropyl alcohol(IPA) Acid, Alkali Sulfuric acid(50% sol) Ammonia water(25% sol) Phosphoric acid(60% sol) Sodium Chloride (sat.) Other TBP(plasticizer) Gasoline OELHELD Nippon Oil 0.6 0.56 C B Chukyo-Kasei Chukyo-Kasei >1.5 0.39 A C LORD 0.08 D Kao 1.0 A / / 1.2 0.9 A B / / / / >1.5 >1.5 >1.5 >1.5 A A A A / / 0.11 <0.10 D D Table 2 : Adhesion bond & potting resin ShinEtsu Silicones ShinEtsu Silicones Momentive Momentive Dow Chemical Dow Chemical Wacker Chemical Critical strain 23℃ >1.5 >1.5 >1.5 >1.5 >1.5 >1.5 0.6 3M >1.5 Application Product Name Manufacture Adhesion Sealant Potting Material KE45W KE4828W TSE382W TSE392W PV 804 PV 8101 APF125 VHB TAPE 4941 KE‐200 CX‐200 KE‐210F CAT‐210 PV7010 ShinEtsu Silicones ShinEtsu Silicones ShinEtsu Silicones A A A A A A B A 0.41 C >1.5 A 1.5 A Table 3: Explanation of the critical crack point Critical strain (%) Remark >1.0 Rank Not primary factor of cracking, May be secondary Rating A factor in some case of cracking. 1.0~0.5 File Name: PV‐692999‐000 May be a primary factor of stress cracking at the B Page 3 of 13 INSTRUCTION MANUAL stress concentrated region. Special care of chemical use is required. 0.5~0.2 Risk of cracking under static or dynamic strain C during assembly, transportation, or use. Special care for no contact to chemical is required part design. High risk of cracking only contact with chemical. 0.2> 1) Product picture: UTX cable Connector (TUV&UL&JET&ETL APPROVALS): D UTX‐XL cable Connector (TUV&UL APPROVALS): 2) Connector part numbering: File Name: PV‐692999‐000 Page 4 of 13 INSTRUCTION MANUAL 3) Stamping forming Contact part numbering for reel: Note: cold forming contact are supplied standard with the connectors. Stamping forming contact Cold forming contact 4) Required tools: Crimp tool for cold forming contact: Crimp die for cold forming contact: Crimp tool stamping forming contact: Crimp die for stamping forming contact: File Name: PV‐692999‐000 H4TC0001 H4TD0001 H4TC0002 H4TD0002 Page 5 of 13 INSTRUCTION MANUAL Strip tool for 2.5/4/6mm² PV cable: H4TS0000 Wrench tool for UTX: UTXTWA001 Wrench tool for UTX‐XL: UTXTWL001 Open‐end back cap spanner: H4TTW1000 5) Cable preparation and stripping process: Amphenol specified strip tool (H4TS0000) can be used in this step. Strip cable and be careful NOT to nick conductors. Adjust the striper stopper and put the cable in corresponding notch to strip the length of 7mm. See below pictures 1 to3. Strip length cable L=7mm Picture 1 Picture 2 Picture 3 6) Crimp process for 8AWG cold forming contacts: Amphenol specified crimp tool (H4TC0001) can be used in this step. Insert striped cable into contact barrel and insure all conductor strands are captured in the contact barrel. See below pictures 1 and 2. Picture1 Picture2 File Name: PV‐692999‐000 Page 6 of 13 INSTRUCTION MANUAL Crimp contact barrel by using the 4‐ident crimping die, by putting the contact barrel with striped cable in the corresponding crimping notch or locator, 8AWG cold contact of UTX‐XL share with 10AWG of crimping notch. The pull‐out force have to meet below table 1 requirement. See below picture 3 and 5. Female contact Male contact Picture 3 Picture 4 Table 1 Cable pull‐out Position Cable size force requirement 3 8AWG/10.0 mm² Min. 401 N Position 3 Picture 5 See below pictures 6 and 7 for crimping result. Picture6 Picture7 7) Crimp process stamping forming contact: Amphenol specified crimp tool (H4TC0002) can be used in this step. Insert striped cable into contact barrel and insure all conductor strands are captured in the contact barrel. See below pictures 1 and 2. Picture 1 Picture 2 File Name: PV‐692999‐000 Page 7 of 13 INSTRUCTION MANUAL Crimp contact barrel by using the crimping die, the pull‐out force have to meet below table 1 requirement. Table 1 Position 1 Cable pull‐out force Position Cable size requirement 1 14AWG/2.5 mm² Min. 223 N Position 2 2 12AWG/4.0 mm² Min. 312 N Position 3 3 10AWG/6.0 mm² Min. 356 N Picture 3 See below pictures 4 and 5 for crimping result. Picture 4 Picture 5 If the customer wants to use the automatic crimping machine, we suggest that the contact crimping dimensions should meet the table 2 requirement. Table 2 Cable Size Crimping Height(A) Crimping Width(B) 14AWG/2.5 mm² 2.50±0.05mm 3.30±0.10mm A 12AWG/4.0 mm² 2.65±0.05mm 4.00±0.10mm 10AWG/6.0 mm² 2.75±0.05mm 4.25±0.10mm B Picture 6 The dimensions of crimp tool as below picture 7 and 12 (Unit: mm), 2.5mm²/14AWG Up Blade Picture 7 File Name: PV‐692999‐000 2.5mm²/14AWG Down Blade Picture 8 Page 8 of 13 INSTRUCTION MANUAL 4.0mm²/12AWG Up Blade 4.0mm²/12AWG Down Blade Picture 9 Picture 10 6.0mm²/10AWG Up Blade 6.0mm²/10AWG Down Blade Picture 11 Picture 12 8) Assembly process: Insert contact cable assembly into back of male and female connector. A “click” should be heard or felt when the contact cable assembly is seated in correct position. Contacts cannot be removed once seated. See below pictures 1 and 8. UTX Female PV Connector Picture 1 File Name: PV‐692999‐000 Picture 2 Page 9 of 13 INSTRUCTION MANUAL UTX Male PV Connector Picture 3 UTX‐XL Female PV Connector Picture 5 UTX‐XL Male PV Connector Picture 7 Picture 4 Picture 6 Picture 8 UTX PV connector back cap must be screwed up with a properly torque range 3.5 to 4.0 N∙m and UTX‐XL PV connector back cap must be screwed up with a properly torque range 4.0 to 4.5 N∙m. Notes: 1> The cable range of UTX PV connector is from ø5.3mm to ø7.65mm, UTX‐XL is from ø7.9mm to ø9.3mm. 2> The number of conductor strands for UTX is from 19 to 105. The number of conductor strands for UTX‐XL is from 19 to 84. 3> These torque force apply to Amphenol PV cable only. The cable assembly should pass IP68 and Pullout test (20Lb, 1Min, without contact) which UTX and UTX‐XL PV connector assembled with different PV cable. 4> A statement that the conductor type is limited to copper wire only ( "Copper" or "CU" are acceptable). Amphenol has already tested UTX and UTX‐XL PV connector whether the samples were screwed cap or body, there is no any effect on the functionality, customer can choose the different screwed method according to their manufacturing processes. See the acting point when connector was screwed body below picture 9 and 10. Picture 9 Picture 10 File Name: PV‐692999‐000 Page 10 of 13 INSTRUCTION MANUAL See the acting point when connector was screwed cap below picture 11 and 12. Picture 11 Picture 12 Amphenol specified wrench tool (UTXTWA001 for UTX and UTXTWL001 for UTX‐XL) can be used in this step or electric torque controlled wrench tool with as well the Amphenol open‐end back cap spanner (H4TTW1000). See below picture 13 and 16. Picture 14 Picture 15 Picture 13 Picture 16 File Name: PV‐692999‐000 Page 11 of 13 INSTRUCTION MANUAL 9) Connector mating and un‐mating: For mating align the 2 half connectors and mate them together by hand until a “click” is heard and/or felt. For un‐mating, since the Amphenol UTX and UTX‐XL PV connector complies with the NEC 2008 690.33, a tool is required to disconnect the connector once mated. Amphenol specified wrench tool (UTXTWA001 for UTX and UTXTWL001 for UTX‐XL) or Universal tool (H4TU0000) should be used in this step. See below picture 1 and 3. WRENCH TOOL DISCONNECT UNIVERSAL TOOL DISCONNECT UTX Picture 1 WRENCH TOOL DISCONNECT UTX Picture 2 UTX‐XL Picture 3 10) Cable routing: The forces must not create a visible deformation in the sealing portion of the insulation. See below picture 1 and 2. Refer to cable manufacturers specification for minimum bending radius. File Name: PV‐692999‐000 20mm 20mm Page 12 of 13 INSTRUCTION MANUAL REVISION RECORD DESCRIPTION DATE REV A FIRST RELEASE May/13/2014 B Update information for UTX‐XL Aug/19/2014 C Update information for UTX and UTX‐XL AUG/15/2015 Amphenol Industrial Operations Amphenol Industrial Operations Europe Amphenol Middle East Enterprises FZE Amphenol Technology Shenzhen Ltd 40-60 Delaware Avenue Via Barbaiana 5 Office C-37 PO Box 21107 Building C, 2nd Industrial Zone of Xia Shi Jia, Sidney, NY 13838-1395 I-20020 Lainate (MI) Ajman Free Zone Jiangshi Community, Gongming Sub-district, Guangming New District, Shenzhen, PRC USA ITALY UAE CHINA Tel: 1-520-285-5114 1-888-364-9011 Tel: +39 02 93254.204 Tel: +9716-7422494 Tel: +86 755 2881 8389 Fax: 1-520-397-7169 Fax:+39 02 93254.444 Fax:+9716-7422941 Fax:+86 755 2991 831 File Name: PV‐692999‐000 Page 13 of 13