superconducting magnetic energy storage factsheet PDF, 178KB

advertisement

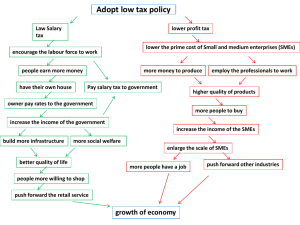

Factsheet to accompany the report “Pathways for energy storage in the UK” Superconducting magnetic energy storage Brief description of technology A Superconducting Magnetic Energy Storage (SMES) system stores energy in a superconducting coil in the form of a magnetic field. The magnetic field is created with the flow of a direct current (DC) through the coil. To maintain the system charged, the coil must be cooled adequately (to a “cryogenic” temperature) so as to manifest its superconducting properties – no resistance to the flow of current. This enables the current to circulate indefinitely with almost zero loss, and therefore, the energy remains stored in the form of a magnetic field. The stored energy can be released back to a connected power system by converting the magnetic energy to electricity, discharging the coil. A typical SMES system structure is given in Figure 1; (1) a superconducting coil, (2) a Power Conditioning System (PCS), and (3) a refrigeration unit [3]. Operationally, SMES is different from other storage technologies in that a continuously circulating current within the superconducting coil produces the stored energy. Most importantly, the only conversion process in the SMES system is from AC to DC in the PCS stage. As a result, there are none of the inherent thermodynamic losses associated with conversion of one type of energy to another, and as a consequence, SMES systems have high cycle efficiency. SMES technology has long been pursued as a largescale technology because it offers many advantages such as instantaneous energy discharge and a theoretically infinite number of recharge cycles. Until recently, however, the material costs for SMES devices have been prohibitively high for all but very small applications. New projects and research collaboration between public and private parties is a key to pave the way to SMES for being competitive with other storage technologies. Figure 1: Schematic of a SMES Technical/economic data See Table 1 Application/markets In comparison with other energy storage technologies, SMES systems exhibit very high storage efficiency (see Table 1) a rapid response (within few milliseconds) and high cyclability, but only for short periods of time. Thus, SMES are suitable for high power and short duration applications, since they are cheap on the output power basis – with a high power density – but expensive in terms of the storage energy capacity. As a result, SMES have attracted attention for applications in solving voltage stability and power quality problems for large industrial customers, electric utilities and the military [1], [3], [5]. More specifically, applications can be classified into; (1) system stability, where SMES can reduce low frequency oscillations to enhance transmission capacity, and boost voltage stability; and (2) power quality, where for instance, SMES systems can offer energy storage for flexible AC transmission system (FACTS) devices [1], [3]. Energy and power Density (Wh/L –W/L) Rated Capacity (MW) Duration (hours) Cycle Efficiency [%] Energy Cost [$/kWh] Power Capacity cost [$/kW] Life (years) 0.2-2.5 Wh/L, 1000-4000 W/L [5], 0.5-5 Wh/L [8] 0.1-10 [4], [5] milliseconds – 8 seconds[5] 97+[5], 90 [3],95[6] 1,000-10,000 [5] 200-300 [5], 350 [10] 20+ [5], 30 [6] Table 1: Technical and economic data for Superconducting Magnetic Storage Systems. 1 Factsheet to accompany the report “Pathways for energy storage in the UK” An on-site SMES is suitable to mitigate the negative impacts of renewable energy in power quality related issues, especially with power converters – needed for solar photovoltaic and some wind farms – and wind power oscillations and flicker. For instance, a SMES system is able to improve a wind farm by stabilizing voltage fluctuations, reducing flicker, and preventing wind farms from tripping during a temporary fault in the grid, allowing a continued wind farm operation [4]. Advantages/disadvantages SMES systems have the ability of fast response; they can switch from charge to discharge state (and vice versa) within seconds, and they can be charged/discharged rapidly and entirely. This is a promising advantage for energy storage systems, which will be expected to quickly stabilize grids when wind or solar resources experience regular and sometimes precipitous plunges in output, especially at a distributed level. These systems are able to be deeply discharged without any influence on either their operational efficiency or service period. The absence of moving parts and high cycling efficiency are some additional advantages [8]. Moreover, the energy output of an SMES is slightly dependent on the discharge rate compared with batteries. SMES also has a high cycle life and, as a result, is suitable for applications that require constant, full cycling and a continuous mode of operation [5]. An important potential advantage of SMES is that it can be deployed in places where other technologies such as pumped hydro or compressed air are not feasible, due to the requirement for a suitable deployment location. On the other hand, the main drawback of the SMES technology is the need of a large amount of power to keep the coil at low temperatures, combined with the high overall cost for the employment of such a unit [8]. Additionally, this technology is economically suitable for short cyclic periods only, with a maximum of hours of duration in storage. This is due to a high self-discharge ratio for longer periods (1015% per day [5]) and mechanical stability problems [3]. Current status The initial proposal of an SMES was brought up by Ferrierin 1969 in France. In 1971 research began in the US by the University of Wisconsin, which led to construction of the first SMES device. At the early stage of SMES research, High Temperature Superconductors (HTS) were not discovered yet, making really expensive and difficult the operation of an SMES. Once commercial HTS appeared in the late 90s, more and more SMES were developed and constructed [3], [5]. The first reported significant size HTS-SMES that had been successfully constructed was developed in 1997 by American Superconductor, and then connected to a scaled grid in Germany. The successful design and testing of this HTS-SMES proved that HTS conductors could be used in commercial products [3]. Micro-SMES devices in the range of 1–10 MW are commercially available, and over 30 devices with approximately 50 MW of total capacity are installed in different parts of the United States for power quality or uninterruptible power supply. The largest installation includes six or seven units in upper Wisconsin by American Superconductor in year 2000. These units of 3 MW/0.83 kWh are currently operated by the American Transmission Company, and are used for power quality applications and reactive power support where each can provide 8 MVA [4]. It is estimated that over 100 MW of SMES units are now in operation worldwide [5]. An important and recent project that aims to prove that SMES can work at the grid level is under the sponsoring of the U.S. Department of Energy Advanced Research Projects Agency for Energy (ARPA-E). Via a US$4.2 million grant, the Swiss-based engineering firm ABB outlined plans for a 3.3 kilowatt-hour proof-of-concept SMES prototype. ABB is collaborating with superconducting wire manufacturer SuperPower, Brookhaven National Laboratory, and the University of Houston. The group's ultimate goal is to develop a 1-to-2megawatt-hour commercial-scale device that is costcompetitive with lead-acid batteries [2]. Some other SMES projects have also been proposed. In High Energy Accelerator Research Organization in Japan, researchers intend to combine liquid hydrogen refrigeration-based SMES with a hydrogen-fuel cell system [3], [9]. The envisioned concept behind is that, at a power failure, the fast response of an SMES will immediately supply electric power in the first few seconds. Later on, the fuel cell will substitute SMES for power supply. This device has not yet been constructed, but the simulation and design have been studied. However, liquid hydrogen is not yet considered as a safe cryogen coolant and safety is always the essential concern with this system. 2 Factsheet to accompany the report “Pathways for energy storage in the UK” http://www.technologyreview.com/energy/350 69/page1/ Time to commercialisation and R&D needs SMES is a developed technology and commercially available; however, when compared to other technologies, SMES is still costly. Competitiveness and reliability still need more trials by the electricity industry and the market to become a mature energy storage technology [5]. The actual applications, especially for large-scale utility, are still not widespread. At the larger scale the projected development of a 100 MWh load levelling system could be completed during 2020-30. In the decade 2030-40 it is projected that a 1 GWh class system for daily load leveling could be available [11]. The present maximum size is 10MW but the estimated theoretical potential is 2000 MW [12]. An important possibility to reduce costs and increase competitiveness of SMES is the integration into existing FACTS, since this combination eliminates the cost for the inverter unit (part of the PCS), which is typically the largest portion of the cost for the entire SMES system. The development of higher temperature superconductors should also make SMES cost effective due to reductions in refrigeration needs [1]. Safety, security, environmental and public perception issues Most of the environmental concerns associated with energy storage technologies are not present in SMES; it does not use or produce harmful chemicals, does not implies radical changes to the landscape, and its silent in its operation. However, the intensive magnetic field –in which SMES stores its energy –, needs to be examined, in terms of its impacts on the environment and human health [5], [13], specially before developments of large scale applications. Additionally, extremely low temperatures are required for the superconducting system, which represents also a safety issue when managing the refrigeration systems [10]. References [1] [2] Ribeiro, P.F.; Johnson, B.K.; Crow, M.L.; Arsoy, A.; Liu, Y.Energy storage systems for advanced power applications. Proceedings of the IEEE, Vol. 89, Nº 12, December 2001. Phil Mckenna. Superconducting Magnets for Grid-Scale Storage. Technology Review, Energy. March. 2011. Available [Online] [3] Weijia Yuan. Second-Generation HighTemperature Superconducting Coils and Their Applications for Energy Storage. Springer Theses, Doctoral Thesis accepted by the University of Cambridge, Cambridge, UK. 2011. [4] M. Beaudin; H. Zareipour; A. Schellenberglabe; W Rosehart. Energy storage for mitigating the variability of renewable electricity sources: An updated review. Energy for Sustainable Development 14 (2010) 302–314. [5] H. Chen et al. Progress in electrical energy storage system: A critical review/ Progress in Natural Science 19 (2009) 291–312 [6] Shoenung SM. Characteristics and technologies for long- vs. short-term energy storage.United States Department of Energy; 2001. March. [7] Schaber C, Mazza P, Hammerschlag R. Utilityscale storage of renewable energy. Electr.J. 2004;17(6):21–9 (July). [8] J. K. Kaldellis. Stand-alone and hybrid wind energy systems. Technology, energy storage and applications. Woodhead Publishing Series in Energy: Number 6. 2010 [9] Makida Y, Hirabayashi H, Shintomi T, Nomura S (2007) Design of SMES system with liquid hydrogen for emergency purpose. Appl Supercond IEEE Trans 17(2):2006–2009 [10] European Parliament’s committee on Industry Research and Energy (ITRE). Policy Department Economic and Scientific Policy. Outlook of Energy Storage Technologies. 2006 [Online]. Available:http://www.europarl.europa.eu/docu ment/activities/cont/201109/20110906ATT260 09/20110906ATT26009EN.pdf [11] The Scottish Government. “Energy Storage and Management Study: Inventory of Energy Storage Technologies” 2010. Available [Online] http://www.scotland.gov.uk/Publications/2010/ 10 [12] Cheung K.Y.C, Cheung S.T.H, Navin De Silvia R.G, Juvonen M.P.T, Singh R, Woo J.J. “Large-Scale Energy Storage Systems”. Imperial College London: ISE2, 2002/2003. [13] Janie Page Blanchard. Environmental Issues Associated With Superconducting Magnetic Energy Storage (SMES) Plants. 1989 IEEE. 3