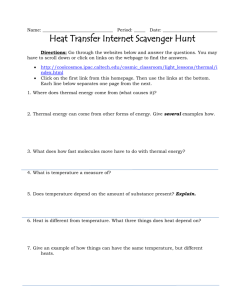

open file - MacLean Power Systems

advertisement