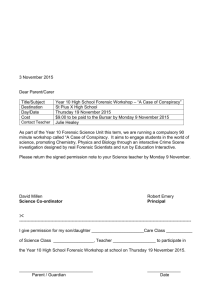

6.4 – Forensic Performance Assessment

advertisement