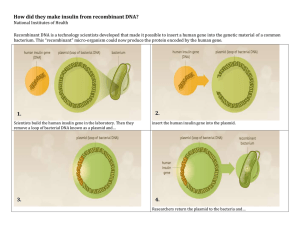

Production of Recombinant Proteins

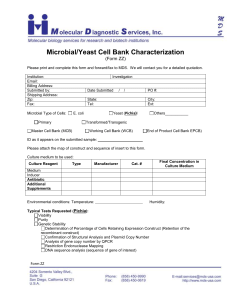

advertisement