Development of standard methods for the collection

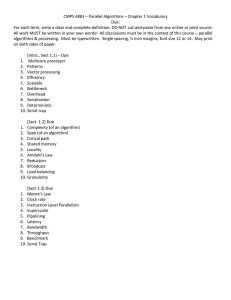

advertisement