POWER FACTOR CORRECTION

advertisement

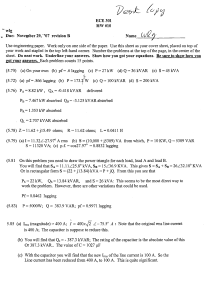

POWER FACTOR CORRECTION Components & Systems August 2002 Table of Contents What is Power Factor 1 ϕ mean What does Cosϕ 1 Disadvantages of Low Power Factor 1 Improving Power Factor 1 Power Factor Correction using Capacitors 2 Centralised Compensation 2 Substantiating Power Factor Costs 2 Calculating Capacitor Requirements 2 Power Factor Components 3 - Capacitors 4-7 - Contactors 4-5 - Fuse Protection 5 - Isolating 6 - Reactive Control Relay 7 Series 4000 Rack System 8-10 Rack System Components 8-10 - Capacitors 9 - Contactors 9 - Fuse Protection 9 - Busbars 9 Series 5000 Power Factor Systems 10 Harmonics 11 What are Harmonics? 11 Series 6000 Harmonic Racks 11 Series 7000 Harmonic Systems 12 Power Factor Correction What is power factor correction? Disadvantages of Low Power Factor Power factor is simply a name given to the ratio of “actual” power (active power) being used in a circuit, expressed in watts or more commonly kilowatts (kW), to the power which is “apparently” being drawn from the mains, expressed in volt-ampere or more commonly kilo volt-ampere (kVA). 1. Increased authorities cost since more current has to be transmitted, and this cost is directly billed to consumers on maximum demand kVA systems. P.F. 2. Causes overloaded generators, transformers and distribution lines within a plant, resulting in greater voltage drops and power losses, all representing waste, inefficiency and needless wear and tear on industrial electrical equipment. Active Power (kW) Apparent Power (kVA) = All modern industries utilise electrical energy in some form or other. Two basic categories of load are encountered in alternate current (AC) networks. 3. Reduces load handling capability of the plants electrical system. Most electrical supply authorities have changed to kVA demand systems from the inefficient kW demand system. Consumers are now billed and penalised for their inefficient systems according to the apparent power being used. In future, consumers will be penalised for plants with power factor below a pre-determined value. 1. Resistive Loads Devices containing only resistance e.g. incandescent lamps, heaters, soldering irons, ovens, etc. The current drawn from the supply is directly converted into heat or light. Since the voltage is assumed to be constant, the actual power (kW) being used is identical to the apparent power (kVA) being drawn from the line. The power factor is therefore unity or 1. In these purely resistive circuits, the current and voltage sinewave peaks occur simultaneously and are said to be “in phase”. Improving Power Factor The most practical and economical power factor improvement device is the capacitor. As stated previously, all inductive loads produce inductive reactive power (lagging by a phase angle of 90°). Capacitors on the other hand produce capacitive reactive power, which is the exact opposite of inductive reactive power. In this instance, the current peak occurs before the voltage peak, leading by a phase angle of 90°. By careful selection of capacitance required, it is possible totally cancel out the inductive reactive power when placed in circuit together. 2. Inductive Loads All motors and transformers depend on magnetism as the basis of their operation. Magnetism is a force and in the physical sense is not consumed. In AC motors and transformers, magnetic forces are only required periodically. Consequently, a permanent magnet cannot be used and the necessary magnetism is produced by electrical means. The electrical current needed for this purpose is not fully utilised. Having produced the magnetic force, the current flows back to the power station again. This current is called the reactive current in contrast to the active current which performs work and is fully utilised in so doing. Although the reactive current is not utilised, it imposes a load on the electrical distribution system and supply authorities demand payment for this load according to specific tariffs. kW ϕ1 KVA2 KV A1 The current drawn from the supply is made up of two separate kinds of current “power producing current” and “magnetising current”. Therefore the current flowing in an AC circuit (unless corrected) is generally larger than is necessary to supply the power being by the expended point. To prevent the continual flow of reactive current back and forth between the load and power station, a capacitor, which is in effect a reactive current storage device, is connected in parallel with the load. The reactive current supplied by the power station and used for the magnetic force when the load is switched on does not now return to the power station but instead flows into the capacitor and merely circulates between the latter and the load. Consequently the distribution lines from the power station are relieved of the reactive current. Reactive power and active power flow through the motor or transformer. Geometrical calculation of these two powers yield the apparent power. The ratio of the active and apparent power is denoted by cosϕ and indicates what fraction of apparent power flowing is actually used by the motor. Active Power (kW) Capacitors can therefore be utilised to reduce kVA and electrical costs. Improved power factor results in: ϕ App aren Inductive Reactive Power (kVAr) t Po wer Capacitor kVAr Required Cosϕ1 is the kVA used before Power Factor Improvement equipment was added to the network. Cosϕ2 is the kVA used after Power Factor improvement equipment was added to the network. ϕ mean? What does Cosϕ Fig. 1 ϕ2 1. Reduced kVA charges (kVA ) 2. Improved plant efficiency 3. Additional loads can be added to the system As can be seen from Fig. 1, the apparent power is greater than the active power and hence the power factor is a value considerably less than unity. 4. Reduced overloading of cables, transformers, switchgear, etc. 5. Improved starting torque of motors P.F. = Reactive Power (kW) Apparent Power (kVA) = ϕ Cosϕ 6. Reduce fuel requirements to generate power due to lower losses. 1 Contents are illustrative only - final details must be checked when placing orders Power Factor Correction Centralised Compensation Power Factor Correction using Capacitors (Automatic Power Factor Correction) Two methods of improving power factor using capacitors are: In large industrial plants where many motors are generally in use or, when the main reason for power factor is to obtain lower electricity bills, then centralised compensation is far more practical and economical than individual motor compensation. a) Individual motor compensation (static capacitors) b) Centralised compensation (automatic capacitor banks) In this instance, large banks or racks of capacitors are installed at the main incoming distribution boards of the plant and are sub-divided into steps which are automatically switched in or out depending on specific load requirements by means of an automatic control system, improving the overall power factor of the network. Individual Motor Compensation Most effective correction is obtained by connecting individual capacitors directly to the terminals of each motor. The motor and capacitor can be controlled jointly by the motor switchgear. The capacitor rating should be matched as closely as possible so that the power factor of the entire plant can be corrected to the optimum value, irrespective of the number of motors switched on. Utilising Table 4 for calculating capacitor kVAr size requirements for power factor correction. The following information must be known beforehand. The size of capacitor required may be determined from Table 3 by taking the motor kW and speed into consideration. Table 3 is a guide only and no guarantee of correct power factor. The correct method of maximum capacitor rating can be determined by using the following formula: where Qc = 0.9Io V√3 Io Qc = = motor magnetising current capacitor power in VAr a) The average plant power factor b) The maximum running load of the plant in kW To avoid ferro-resistance and dangerous voltage rises, the total kVAr required should never exceed 65% of incoming transformer kVA. In practice, to be absolutely safe, this limit should be set at approx. 50%. Generally an automatic power factor system consist of: a) b) c) d) If the magnetising current is not known, 95% of the motor no-load current can be used as an approximate value. Care should be taken not to exceed the value calculated to avoid dangerous overvoltages and possible self excitation of motors at switch-off. a main load-break isolator (or circuit breaker) an automatic reactive control relay power factor capacitors backed by suitable fuse protection suitably rated contactors for capacitor switching The automatic reactive control relay monitors the total network and will switch-in the required capacitor banks at pre-determined intervals compensating for capacitor discharge times and load dependant requirements. Over compensation can cause higher supply voltages which can cause consequent break down of motor insulation and flashover at motor terminals. To be safe, rather use standard capacitor sizes (as indicated below). For this reason, individual motor compensation is not recommended for motors which are rapidly reversed e.g. cranes, hoists, etc. As capacitor switching subjects components to exceptionally high stresses it is imperative to correctly size and rate all components utilised in a system. Table 3 Substantiating Power Factor Correction Costs Individual Capacitor Rating in kVAr to improve Power Factor to 0.95 or better at all loads. Motor Rating kW 2 Pole 3000 rpm 4 Pole 1500 rpm This question can best be answered by an example. Assuming a plant has a total load of 500 kW and a power factor (cosϕ) of say 0.75 lagging. Supply authorities kVA demand charge is approximately R40.00 per kVA (actually above R50.00 in most areas. Johannesburg is currently R53.10). 6 Pole 1000 rpm 0.75 0.5 kVAr 0.5 kVAr 0.5 kVAr 1.1 0.5 kVAr 0.5 kVAr 1.0 kVAr 1.5 0.5 kVAr 1.0 kVAr 1.0 kVAr 2.2 1.0 kVAr 1.0 kVAr 1.5 kVAr 4.0 1.5 kVAr 1.5 kVAr 2.0 kVAr 5.5 2.0 kVAr 2.0 kVAr 3.0 kVAr 7.5 2.0 kVAr 2.0 kVAr 3.0 kVAr 11.0 3.0 kVAr 4.0 kVAr 5.0 kVAr 15 4.0 kVAr 5.0 kVAr 6.0 kVAr 18.5 5.0 kVAr 7.0 kVAr 8.0 kVAr 22 6.0 kVAr 8.0 kVAr 9.0 kVAr 30 8.0 kVAr 10.0 kVAr 12.0 kVAr 37 10.0 kVAr 12.0 kVAr 14.0 kVAr 45 12.0 kVAr 14.0 kVAr 16.0 kVAr 55 16.0 kVAr 22.0 kVAr 25.0 kVAr 75 18.0 kVAr 25.0 kVAr 30.0 kVAr 90 20.0 kVAr 30.0 kVAr 35.0 kVAr 110 25.0 kVAr 30.0 kVAr 40.0 kVAr 132 35.0 kVAr 40.0 kVAr 40.0 kVAr 160 40.0 kVAr 45.0 kVAr 50.0 kVAr kW PF = kVA 500 kW 0.75 PF = 666 kVA Total costs @ R40.00/kVA = R26,640.00/month By installing capacitors to improve power factor (cosϕ) to 0.98 lagging new costs are; 500 kW 0.98 PF = 510 kVA Total costs @ R40.00/kVA = R20,400.00/month therefore savings monthly = R6,240.00 A complete system required to effect power factor from 0.75 to 0.98 (as in above example) would require a system of 360 kVAr which would currently cost approximately R43,000.00 Power factor correction usually pays for itself well within 12 months of the initial purchase (7 months in above example ) and continues saving indefinitely. It therefore stands to reason that more significant savings can be anticipated with the ever increasing escalation costs of electricity in the future. 2 Contents are illustrative only - final details must be checked when placing orders Power Factor Correction Table 4 Calculating Capacitor Requirements It is imperative that correct capacitor sizes be selected when calculating capacitor requirements. In the case of centralised compensation, it is recommended that the first capacitor step be equal to half the value of the following steps, to allow a smooth overall linear correction system. Existing PF Cosϕ Target Power Factor Required Cosϕ Before applying capacitors 0.80 0.85 0.90 0.92 0.95 0.98 1.0 0.40 1.54 1.67 1.81 1.87 1.96 2.09 2.29 Table 4 (right) will assist in calculating capacitor values in specific applications. 0.42 1.41 1.54 1.68 1.73 1.83 1.96 2.16 0.44 1.29 1.42 1.56 1.61 1.71 1.84 2.04 Prior knowledge of the following is required: 0.46 1.18 1.31 1.45 1.50 1.60 1.73 1.93 0.48 1.08 1.21 1.34 1.40 1.50 1.60 1.83 0.50 0.98 1.11 1.25 1.31 1.40 1.53 1.73 0.52 0.89 1.02 1.16 1.22 1.31 1.44 1.64 0.54 0.81 0.94 1.07 1.13 1.23 1.36 1.56 0.56 0.73 0.86 1.00 1.05 1.15 1.28 1.48 0.58 0.65 0.78 0.92 0.98 1.08 1.20 1.40 a) Power factor before applying capacitors (left vertical column) b) Required power factor (top horizontal row) c) Total consumption in kW The correct capacitor size can be calculated by multiplying the factor when crossing the horizontal and vertical columns in the table below by kW. 0.60 0.58 0.71 0.85 0.91 1.00 1.13 1.33 Example: 0.61 0.55 0.68 0.81 0.87 0.97 1.10 1.30 1. Convert the plant load to kW (kVA x PF = kW) 666 kVA x 0.75 Pf = 500 kW (useful power) 0.62 0.52 0.65 0.78 0.84 0.94 1.06 1.27 0.63 0.48 0.61 0.75 0.81 0.90 1.03 1.23 2. To correct a load of 500 kW at 0.75 PF to 0.98 PF. Follow the 0.75 value (in left vertical column) horizontally until below the 0.98 value (in top horizontal row). The factor value is 0.68. 0.64 0.45 0.58 0.72 0.77 0.87 1.00 1.20 0.65 0.42 0.55 0.68 0.74 0.84 0.97 1.17 0.66 0.39 0.52 0.65 0.71 0.81 0.94 1.14 0.67 0.36 0.49 0.63 0.68 0.78 0.90 1.11 0.68 0.33 0.46 0.59 0.65 0.75 0.88 1.08 0.69 0.30 0.43 0.56 0.62 0.72 0.85 1.05 0.70 0.27 0.40 0.54 0.59 0.69 0.82 1.02 0.71 0.24 0.37 0.51 0.57 0.66 0.79 0.99 0.72 0.21 0.34 0.48 0.54 0.64 0.76 0.96 0.73 0.19 0.32 0.45 0.51 0.61 0.73 0.94 0.74 0.16 0.29 0.42 0.48 0.58 0.71 0.91 0.75 0.13 0.26 0.40 0.46 0.55 0.68 0.88 0.76 0.11 0.24 0.37 0.43 0.53 0.65 0.86 0.77 0.08 0.21 0.34 0.40 0.50 0.63 0.83 0.78 0.05 0.18 0.32 0.38 0.47 0.60 0.80 0.79 0.03 0.16 0.29 0.35 0.45 0.57 0.78 0.80 0.13 0.27 0.32 0.42 0.55 0.75 0.81 0.10 0.24 0.30 0.40 0.52 0.72 0.82 0.08 0.21 0.27 0.37 0.49 0.70 0.83 0.05 0.19 0.25 0.34 0.47 0.67 0.84 0.03 3. Capacitor required to correct from 0.75 to 0.98 (power x capacitor from the table value) 500 kW x 0.68 = 340 kVAr savings: 500 kW @ 0.75 PF 500 kW @ 0.98 Pf Reduction of = = 666 kVA 510 kVA 156 kVA (23.4% less of transformer load) 0.16 0.22 0.32 0.44 0.65 0.14 0.19 0.29 0.42 0.62 0.86 0.11 0.17 0.26 0.39 0.59 0.87 0.08 0.14 0.24 0.36 0.57 0.88 0.06 0.11 0.21 0.34 0.54 0.89 0.03 0.09 0.18 0.31 0.51 0.90 0.06 0.16 0.28 0.48 0.91 0.03 0.85 0.13 0.25 0.46 0.92 0.10 0.22 0.43 0.93 0.07 0.19 0.40 0.94 0.03 0.16 0.36 0.13 0.33 0.95 3 Contents are illustrative only - final details must be checked when placing orders Power Factor Components Power Factor Specifications Components, Systems 3 Phase Monobloc Capacitors 440V “H” Type 440V, 50 Hz, 3 Phase (Maximum Voltage 520V - 50Hz) and Electromechanica have been involved in all aspects of power factor correction in our specific environment for some 20 years now, and it is with this experience gained, that we can confidently recommend, specific components required in power factor correction, and complete ready to connect automatic power factor systems. Alpivar heavy duty capacitors are totally dry units with no impregnation or insulation liquid. Electromechanica offers a complete range of components and equipment for power factor correction viz. a) b) c) d) e) Power factor capacitors 400-550 volt Contactors specifically for capacitor switching Fuse protection components for capacitor banks Automatic reactive control relays Special rack systems incorporating capacitors, contactors, fuse protection and busbars f) Complete power factor systems 30-1500 kVAr Alpivar monoblock capacitors utilise windings insulated by a selfextinguishing casing, immersed in thermosetting polyurethane resin applied under vacuum with excellent heat dissipation qualities (measured internal temperature is <3°C of ambient). Capacitors The unique vacuum potting technique ensures that Alpivar capacitors have excellent resistance over time and much longer service life than conventional capacitors. Traditionally power factor capacitors are made up of single phase metalized polypropylene windings, placed into a plastic cylinder impregnated with epoxy resin. These cylinders (windings) are coupled in a delta configuration (to offer a 3 phase system) and placed into an enclosed sheet metal box which offers desired protection in the event of explosion due to undue stresses placed on the capacitor through potential exposure to overvoltage, increased frequency, harmonic effects and over temperature. Capacitor windings incorporate the following internal protection: • Self healing dielectric (metalized s film) • Electrical fuse (per winding) • Effective overpressure disconnecting device (per winding) This conventional system of capacitor manufacture in no way takes heating into consideration, (undoubtedly the single most important factor effecting the overall life of the capacitor). Capacitors have power losses of ±0.05% (0.5 watts per kVAr) which stands to reason that a 60 kVAr capacitor for instance, would have to dissipate ±30 watts of generated heat inside a enclosed sheet metal enclosure. Temperatures measured inside these enclosures could reach 1520°C higher than the ambient temperature that they are exposed to, drastically effecting the overall life of the capacitor. The use of 440V capacitors is highly recommended, which generally accommodate overvoltages in systems due to the presence of harmonics (becoming more prevalent in electrical networks today). This, in effect, permits a permanent 20% overvoltage factor without any negative effects on the capacitor itself. (IEC requirements already anticipate a tolerance of +10%). In the event of element failure, only the effected element is disconnected from the power circuit, ensuring maximum safety conditions and leaving unaffected capacitors still in service. Main Factors Effecting Capacitor Life Care should be taken when calculating capacitor kVAr requirements in 400V systems as the kVAr rating will be slightly lower when 440V capacitors are utilised. Faults Small Faults 15% Selection criteria for suitable capacitors: a) Rated at 440V (in low voltage applications) b) All capacitors utilised within a system should comply fully with requirements of IEC60831-1/2 and CEI-EN60831-1/2 c) Have a tolerance of -5 ÷ +10% d) Be rated for operational temperature of at least 50°C e) Offer permanent overvoltage tolerances of at least 1.15 Un f) Offer permanent overcurrent tolerances of at least 1.7 In g) Capacitors should incorporate effective overpressure disconnector h) Capacitors should be provided with discharge resistors effectively reducing terminal voltages to less than 50V within 1 minute. i) Incorporate internal independent fusing Cause Solution Break down of dielectric within capacitor windings caused by overvoltages. Dielectric is perforated when overvoltage occurs. Manufactured with selfhealing metalized polypropylene film which vapourises the metal around the short circuit to restore electrical isolation. Medium Faults 70% Over current / voltages caused by harmonic presence and over temperature which cannot be overcome by the selfhealing dielectric. Gas build up within the capacitor when emitted caused the deformation of a membrane which effectively disconnects the defective coil from the circuit. High Faults 15% An independent internal electrical fuse disconnects the effected coil. Short circuits. The inclusion of internal fusing does not substitute the necessity of external safety devices such as fuse cut-outs or circuit breakers. Alpivar capacitors associated with patented vacuum potting technique form a highly advanced unit and incorporate all of the above protections. Electromechanica offers a range of Alpivar capacitors far exceeding all of the above requirements. The capacitors comply fully with international requirements of IEC60831-1/2, CEI-EN60831-1/2, NF C54 108/9, CSA 22-2 No.190, UL810. 4 Contents are illustrative only - final details must be checked when placing orders Power Factor Components Contactors Capacitors are rated at 440V to accommodate overvoltages in systems due to the presence of harmonics (becoming more prevalent in electrical networks today). This accommodates a further 10% overvoltage factor above the 10% tolerance anticipated by IEC requirements. Alpivar capacitors withstand overvoltages of 1.18 Un continuously (24h/24) effectively offering a 30% overvoltage factor when applied in a 400V system and can operate effectively up to 520V, 50 Hz. Selection criteria for suitable contactors: a) Contactors utilised within a system should comply fully with requirements of IEC/EN60947-4-1 b) Should be rated for operational temperatures of 50°C (ratings higher than 50°C to 70°C should be reduced by a percentage equal to the difference between the ambient temperature and 50°C) c) It is recommended to underrate the contactors by 10% d) Contactors should be limited to ≤ 120 cycles per hour with an electrical life of 200,000 cycles e) Effective limiting inductances should be incorporated f) Consideration must be made for capacitor discharge times and reactive control relays should incorporate sufficient delay to ensure that capacitors are sufficiently discharged before they are reconnected. Standard maximum permissible current requirements for conventional capacitors is 1.3 In. Alpivar capacitors are designed to withstand up to 2.0 In. Specifications Rated Voltage Internal Protection : : Tolerance Max. Voltage Overload Max. Current Overload Loss Factor : : : : Operating Temperature Insulation Class : : Discharge Resistors Standards : : Type VCB1544 VCB2044 VCB2544 VCB3044 VCB4044 VCB5044 VCB6044 VCB7544 VCB8044 VCB9044 VCB10044 (1) kVAr 440V 15 20 25 30 40 50 60 75 80 90 100 (2) kVAr 400V 12 17 21 25 33 41 50 62 66 74 83 440V, 50 Hz three-phase - Self Healing Dielectric - Electric Fuse (per element) - Overpressure disconnecting device (per element) ±5% capacitance 1.18 Un continuous (24h/24) 2.0 In <0.3W per kVAr (including discharge resistors) -40 - +55°C 6 kV for 1 minute at 50 Hz (25kV 1.2/50mµS shockwave) Incorporated (<50 within 1 min) IEC60831-1 and 2 EN60381-1 and 2 NFC54108-9 CSA22-2No.190 UL810 (3) Current (A) per phase 20 26 33 39 52 66 79 98 105 118 131 The contactor during the closing transition is influenced by electrical currents having high frequencies and high amplitudes. The frequencies of these currents range between 1 and 10 kHz; the amplitudes must have values lower than the maximum permissible current peak of the contactor to be used. If this condition cannot be verified, it is necessary to use limiting inductances or special capacitor switching contactors. Lovato contactors utilised in our systems are specially designed for capacitor switching and are equipped with earlymake contacts which introduce resistors to limit the connecting current of capacitors for a very brief interval, (2-3 ms) during the contactor closing. These resistors are then disconnected from the circuit once the contactor closing operation is completed and the current capacity is then conveyed through the main contacts of the contactor, dramatically reducing wear of contactors, capacitors and fuses, ensuring longer life and reliability of the system. Dimension H x W x D 275 x 90 x 225 275 x 90 x 255 275 x 90 x 225 275 x 180 x 225 275 x 180 x 225 275 x 180 x 225 275 x 270 x 225 275 x 270 x 225 275 x 360 x 225 275 x 360 x 225 275 x 360 x 225 L1 L2 L3 1 3 5 A1 A2 2 4 6 T1 T2 T3 (1) Actual Capacitor Rating (2) Equivalent kVAr Rating (3) Supply Voltage is 440V Lovato BF..K Contactors type Max. operating Power at 230V 400V 440V kVAr kVAr kVAr Rated Current (A) Fuse gG (A) 40 BF25K00 11 20 22 30 BF40K00 17 30 33 43 63 BF65K00 26 45 50 70 100 BF80K00 34 60 65 90 125 5 Contents are illustrative only - final details must be checked when placing orders Power Factor Components Fuse Protection Mains Isolators The use of a main incoming isolator is highly recommended, preferably door interlocked to prevent opening of the enclosure with power applied to the components. As circuit breakers have been known to cause unnecessary nuisance tripping in many instances the use of fuses or a fuse switch should be considered if protection of the mains supply cable is required additionally. Selection criteria for suitable fuses: a) Should conform fully to requirements of IEC60269-1, IEC60269-2-1 b) Should be gl-gG type high rupturing capacity c) Offer protection for overcurrents and short circuits with fault levels of up to 50kA d) Fuse bases should be highly resistant to temperature withstand up to 120°C and be self-extinguishing - UL94Vo with a creepage resistance of CTI = 600V. DF DIN type (knife) fuses have been found to be particularly suitable for protection of capacitor banks in systems. Specific fuse protection is essential for each capacitor bank of a system. Exposure to overvoltage, increased frequency and the effects of harmonics, permit capacitors to be continuously overloaded at up to 1.35 times their nominal rating. This overload as well as high initial switching currents of the capacitors must be considered when calculating fuse requirements for capacitor bank protection. Table 5 (below) will assist in correctly specifying standard fuses as well as recommended cable sizes for capacitor banks. Selection criteria for suitable mains isolator: a) Must be fully compliant with requirements of IEC60947-1/3 as well as IEC60664, 60269 and 60204 b) Control circuit should be wired through a mounted “early makelate break” auxiliary, effectively allowing the making and breaking action of the isolator to switch “off-load” thus preventing potential operation of the isolator on fully charged capacitors. c) Should be door interlocked with enclosure, preventing opening of enclosure door with live components exposed. d) Must be sized correctly to accommodate total system current carrying capacity. Fuse Bases Table 5 Rating kVAr 2 2.5 3 4 5 7.5 10 15 20 25 30 35 40 50 60 70 80 Rated Voltage 440VAC Rated Current A 2.9 3.6 4.3 5.8 7.2 8.6 14.4 21.5 28.5 33.0 39.2 46.5 53.5 66.0 80.0 93.0 108.0 Fuse Rating A 10 10 10 10 16 20 25 40 40 63 63 80 80 100 125 160 160 Selection criteria for fuse bases: Cable Cross Section mm2 1.5 1.5 1.5 1.5 2.5 2.5 4 10 10 16 25 35 35 50 70 70 95 a) Should be fully compliant with the requirements of IEC/EN 60269-1/2, VDE0636, DIN43620. b) Should be made of self-extinguishing material UL94 VO. c) Be rated for voltages up to 690V. The df range of polyester fuse bases offer a very high insulation and are able to withstand extremely high temperatures. The insulation (IP) protection can be enhanced by additional fuse and terminal covers. 6 Contents are illustrative only - final details must be checked when placing orders Power Factor Components The capability of performing complex calculations regarding reactive power, permits the rapid switching of capacitor banks in a timeous, explicit manner, resulting in a drastic reduction in the number of operations and their homogeneous use. Reactive Control Relay Selection criteria for suitable control relays: a) Must be compliant with requirements of IEC/EN60255-5/6, IEC60068-2-61/6 b) Should incorporate an accurate power factor indicator c) Offer clear indication of steps switched-in d) Must facilitate a suitable delay between disconnection and reconnection of the same step (min 60 sec) even when operated in manual mode e) Have a contact rating of at least Ith: 5A-250V (AC1) f) Ensure balanced/equally distributed use of switching steps g) Be configurable for stepping 1-1-1.../1-2-2.../1-2-4 h) Allow accurate readings and indication even in the presence of high harmonic content or waveform distortions. Besides instantaneous power factor indication, the large LED digital display also indicates: • Voltage (True RMS) • Current (True RMS) • ∆ kVAr (Indicating the required reactive power to correct to pre-set value) A configurable alarm function indicates the following: Over/Under Voltage (A.HU/A.LU) Over/Under Current (A.HI/A.LI) Over/Under Compensation (A.HC/A.LC) The Lovato DCRE range of reactive control relays more than meet the above requirements. They perform the control and adjustment functions in a totally digital manner and incorporating latest microprocessor technology, facilitating accurate, reliable power factor control. An appropriate algorithm ensures accurate operation even in systems characterised by high harmonic content. The trend in the market place is to supply systems with separate auto-off-man selector switches and pilot lights. This trend should be strongly discouraged as this method of switching overrides the inherent safety delays incorporated in the controller (which is able to perform the same function) and exposes contactors to undue stress and a potentially dangerous situation when operated inadvertently on fully charged capacitors. DCRE12 L1 L2 L3 VOLTAGE 1 2 3 4 5 6 7 8 9 10 11 12 C 1 2 3 4 5 6 7 8 9 10 11 12 13 /5A OV 380-415V CURRENT S1 S2 14 15 QS1 Technical Characteristics DCRE5 DCRE7/12 FU2 FU1 FU13 Supply Circuit FU12 R FU14 KM1 R KM2 KM12 R Supply Voltage Ue Operating Limits Rated Frequency Maximum Power Consumption 380-415 VAC -15% ... +10% Ue 50 (or) 60Hz (self configuring) 5.4 VA 2.6 VA LOAD R R R TC1 K1 K2 K12 Current Limit Rated Current Ie Operating Limits Overload Capacity Overload Peak Note 5A 0.125 ... 5.5A 1.1 Ie 10 x Ie 1s 1) Always ensure that C.T. is connected to the phase not utilised for supply voltage to controller. 2) Ensure that C.T. is correctly rated for system requirements and connected in the correct direction. Reading and Control Range Voltage Reading Limits Current Reading Limits Type of Voltage/Current Reading Power Factor Adjustment Re-connection Time of Same Step Switching Sensitivity -15% ... +10% Ue 2.5 ... 110% Ie True RMS 0.85 Inductive - 0.95 Capacitive 5-240 sec 5-600 sec Relay Output No. of Outputs (1 x Isolated can be Alarm Relay) Contact Arrangement Rated Capacity Ith Rated Operating Voltage Maximum Switching Voltage 5 7 or 12 1 x NO 5A-250V (AC1) 250 VAC 440 VAC Housing Version Dimensions Protection (IP54 with t/parent cover) Type of Termination Flush Mounting 96x96x62mm 144x144x32mm IP41 Plug-in / screw 7 Contents are illustrative only - final details must be checked when placing orders Series 4000 Rack The Series 4000 rack system is a convenient all-in-one component kit for mounting into a standard enclosure to complete a system. The system incorporates latest developments in capacitor, contactor and fuse technology. Contactors Are special capacitor switching type equipped with early make contacts which introduce limiting resistances during the contactor closing operation, whereafter they are completely disconnected from the circuit. Drastically reducing stress and wear of the contactors, capacitors and fusegear, ensuring longer life and overall reliability. Busbars Are incorporated on the racks by insulated supports, offering very high fault levels suitable for currents of up to 630A. The system is expanded by merely coupling to busbars of another rack Capacitors Fuseholder Are potted in thermoset polyurethane resin under vacuum offering excellent heat dissipation qualities. They are mounted onto the rack exposed, permitting effective airflow from all sides. The capacitors incorporate the following internal protections: • Self Healing Dielectric • Electrical Fuse • Overpressure Disconnecting Device Capacitors are rated at 55°C and can operate at voltages of up to 520V and are designed to withstand up to 2.0 In. Discharge Resistors Fuses utilised in the rack system provide effective protection from short circuits and overload conditions. They are specially designed for direct mounting onto busbars, which are incorporated in the rack. Enable the capacitors to be discharged in compliance with applicable standards. They are mounted externally to enable ease of visual inspection. 8 Contents are illustrative only - final details must be checked when placing orders Power Factor Components As contactors are wired in the delta loop, current requirements are lower, thereby decreasing the contacting ratings by √3. Series 4000 Rack System The Series 4000 rack system has recently been developed as a convenient all-in-one component for inclusion into a standard enclosure or as a complete system. The design combines many years experience gained in power factor and its application in very harsh local conditions. Incorporating latest up-to-date technology in capacitor, contactor and reactive control relay developments. The table below indicate contactor requirements with 6 terminal capacitors and conventional 3 phase capacitors. kVAr 415V 12.5 25 30 40 50 60 75 100 Standard 3ph Capacitor BF12K10 BF40K10 BF40K BF65K BF65K BF80K 6 Terminal Capacitor BF9K10 BF20K10 BF25K10 BF40K BF40K BF65K BF65K BF80K Fuses and Fuse Bases Fuses utilised in the 4000 series rack system are DIN (blade type) Class gl-gL-gG HRC fuses. They provide effective protection from short circuits and overload conditions for all 3 phases of the capacitor bank and conform fully to requirements of IEC60269, CEE16, VDE0636 and DIN57363. Racks are supplied with capacitor sizes from 25 to 100 kVAr in various configurations. They incorporate capacitors, special capacitor switching contactors and fuse protection. Fuse bases are directly mounted onto a suitably rated, incorporated busbar system suitable for capacities up to 500 kVAr, offering simple expansion capabilities by merely coupling to busbars of another rack. Fuse-link Type 300063 300100 300160 300160 Capacitors Capacitors utilised in the Series 4000 rack system are the Alpivar heavy duty types. They are self-healing and incorporate independent internal fusing, overpressure protection facilities and are able to withstand permanent overvoltages up to 520V and over current at 2.0 x In (see pages 4 and 5 for detailed technical specifications). Capacitors are designed to withstand undue stresses caused by potential exposure to overvoltage, increased frequency and limited harmonic effects. In (A) 63A 100A 160A 160A Capacitor Size (kVAr) 25 kVAr 50 kVAr 75 kVAr 100 kVAr Breaking Capacity 80 kA 80 kA 80 kA 80 kA Capacitors are mounted, exposed, offering all-round ventilation with excellent heat dissipation, ensuring longer life. The specially designed 6 terminal capacitors utilised in the rack system allow contactors to be wired in the delta loop, reducing current carrying by 30% on contactors. L1 5 6 T1 L1 3 4 T2 L2 1 2 T3 L3 Fuse bases are specially designed to directly mount onto busbars which are incorporated in the rack system. They provide independent fuse protection of all three phases of each capacitor bank (up to two banks per rack). R L2 S L3 T Busbars Busbars are incorporated on the racks and supported by high class insulated 3 phase supports, incorporating termination at the top or bottom of the rack. Standard supplied busbars are suitable for currents in excess of 630A. Systems are expanded by merely coupling busbars to those of another rack. Contactors Contactors utilised on the 4000 Series rack system are specifically designed for capacitor switching. They are equipped with earlymake auxiliary contacts which temporarily introduce limiting resistances (effectively absorbing peak in-rush currents) during the contactor closing operation. These resistors are disconnected from the circuit once the contactor closing operation has been completed and the capacitor current capacity is then conveyed through the main contacts of the contactor. This method of operation drastically reduces wear of contactors, capacitors and fuses, ensuring longer life and overall reliability of the entire system. 9 Contents are illustrative only - final details must be checked when placing orders Power Factor Components Series 4000 Rack System Series 5000 Complete Power Factor Systems kVAr The Series 5000 Power Factor Correct System encompasses all the advantages of the 4000 Series rack system in a purpose built, floor standing enclosure. The racks are securely mounted into the enclosure (measuring 550mm wide x 400mm deep) and coupled together via the incorporated busbars of the racks. A mains isolator is included (for top or bottom entry) and the reactive control relay, door mounted and connected to the circuit. Configurable (kVAr) Type 440V 400V 40025 25 21 1 x 25 40050 50 41 1 x 50 42050 50 41 1 x 25 + 1 x 25 40075 75 62 1 x 75 42075 75 62 1 x 25 + 1 x 50 40100 100 83 1 x 100 42100 100 83 1 x 50 + 1 x 50 The panel is supplied as a complete floor standing “ready to connect” system providing effective ventilation and dissipation of heat build-up within the panel. An additional fan cooling facility can be included for applications where the environment provides very low airflow. Dimensions 160 240 525 500 248 400 150 200 550 Advantages of the 4000 Series Rack a) The rack offers good, effective ventilation for capacitors b) Capacitor windings (cells) are incased in thermosetting resin, housing forming (better heat dissipation) longer life c) Windings independently 1) Internally fused 2) Equipped with an effective internal overpressure device effectively disconnecting only a damaged cell from the system leaving remaining good cells still operational (minimum reduction in overall capacitance) d) Alpivar heavy duty capacitors are rated at 55°C. 1.18 Un (30% overrating in 400V systems) 2.0 In e) Special capacitor switching contactors incorporating initial limiting resistances increase contactor and capacitor life f) Busbar system incorporated onto rack convenient expansion capabilities by simply coupling to busbars of another rack g) Easy access to all components for maintenance and repair purposes Series 5000 Floor Standing Complete Systems Type kVAr 440V kVAr 400V 50150 50175 50200 50250 50275 50300 50350 50375 50400 50450 50475 50500 150 175 200 250 275 300 350 375 400 450 475 500 124 145 165 207 227 248 289 310 331 372 393 413 Steps (kVAr) 25-25-50-50 25-50-100 25-25-50-100 25-25-50-50-100 25-50-100-100 50-50-100-100 50-3 x 100 25-50-3 x 100 50-50-3 x 100 50-4 x 100 25-50-4 x 100 50-50-4 x 100 Dimension H x W x D 1500 1500 1500 1500 1500 1500 2100 2100 2100 2100 2100 2100 x x x x x x x x x x x x 600 600 600 600 600 600 600 600 600 600 600 600 x x x x x x x x x x x x 500 500 500 500 500 500 500 500 500 500 500 500 * Larger sizes available on request Sizes above 540 kVAr are readily available but in this case two standard systems with their independent isolators are utilised, with only one reactive control relay to maintain the current ratings of incorporated busbars on the racks. 10 Contents are illustrative only - final details must be checked when placing orders Power Factor Systems (curve x c). For the 5th harmonic there is an absorption effect which is more intense at a resonance frequency of 204 Hz than at 189 Hz. HARMONICS What are harmonics? For the 7th harmonic (=350 Hz) and even more for higher frequencies there is a block effect caused by the filter circuit as can be seen on the diagram. Harmonics are undesired signals which are present in electrical networks that have a frequency multiple of the fundamental: as they overlap they create a new distorted wave shape which is no longer sinusoidal. Electromechanica offer combined solutions for harmonics in our Series 6000 racks which incorporate capacitors with high overvoltage and overcurrent capabilities allowing application into networks, with a degree of interference up to 25%, without the need for reactance. Should the interference be higher, racks incorporating inductances are also offered. Most modern factories are making increasing use of modern power electronics. A feature of semi-conductor controlled devices and drives is to generate a high content of harmonics in the mains. The result is that resonance occur which leads to dangerous excess currents which overload capacitors, cables, fuses and especially contactors. Degree of Interference Harmonics do not originate from power generators but are produced by non-linear loads which can be divided into three main groups: SH ST • Loads with variable impedance i.e. arc furnaces, fluorescent lighting, etc. • Loads with saturated magnetic circuits i.e. reactors, saturation transformers, induction furnaces, etc. • Loads that make use of semi-conductor devices i.e. static rectifiers, static frequency converters, static uninterruptible power supplies, static induction regulators. ≤ 25% > 25% H SAH SH (kVA) The weighted total of the harmonic generators present at the transformer secondary. Non-linear loads are therefore typical harmonic generators. ST (kVA) The power rating of the HV / LV transformer Harmonic currents are load independent and are caused by the harmonic generator which is dependent on the phase angle of the power supply. The frequencies occurring form multiples of the mains rated frequency, since impedance of the line system rises during increased frequency (whereas te impedance of capacitors falls). The harmonic current flow through capacitors installed in the vicinity of the harmonic generator. Series 6000 Rack incorporate: • • • • • As a remedy each capacitor can be in series with a reactance. The inductance is so designed that series resonance frequency below the 5th harmonic results. Usual values are 189 Hz or 205 Hz. capacitors 25-50-100 kVAr capacitor switching contactors anti-harmonic reactor with thermal protection fuses and fuse holders suitably rated busbars The capacitor / reactance combination is inductive at any frequency above the series resonance. Consequently, a resonance between mains reactance and capacitor can no longer occur at a higher mains harmonic. Reactance XC in Relation to Frequency f Fig. 3 XC (%) 100 Z (%) 90 z 9H 80 70 60 Z 18 Z z 4H 20 The Series 6000 racks slide into position and are designed with metallic shielding of the reactor from the capacitors. 50 40 kVAr 30 20 10 X C(%) Type 440V 400V Dimensions H x W x D 60025 25 21 325 x 700 x 460 60050 50 41 325 x 700 x 460 60100 100 83 325 x 700 x 460 50 100 150 200 250 300 350 400 450 500 550 600 650 700 f (Hz) The racks can be simply mounted into standard enclosures of 800mm width to be included into systems to be manufactured or added to existing systems and can be expanded by merely coupling to busbars of another rack. Fig. 3 above indicates the reactance x c in relation to frequency f. From this it can be seen that in the range of the 5th harmonic (=250 Hz) the reactance of the capacitor and filter circuit is lower than that of a capacitor without filter circuit 11 Contents are illustrative only - final details must be checked when placing orders Power Factor Systems The Series 7000 Floor Standing Complete Systems (incorporating anti-harmonic reactors) Is a complete ready-to-connect enclosed system control relay, mains isolator all mounted into a suitably ventilated enclosure ready for installation. Series 7000 Complete System Type 440V kVAr 400V Dimensions H x W x D 7125 125 103 2100 x 800 x 600 7150 150 124 2100 x 800 x 600 7175 175 145 2100 x 800 x 600 7200 200 165 2100 x 800 x 600 7250 250 207 2100 x 800 x 600 7275 275 227 2100 x 800 x 600 7300 300 248 2100 x 800 x 600 7350 350 289 2100 x 800 x 600 7400 400 331 2100 x 800 x 600 Larger sizes available on request 12 Contents are illustrative only - final details must be checked when placing orders Power Factor Equipment • Low Voltage Equipment • Capacitor Switching Contacts • Fusegear • Reactive Control Relays • Load-break Switches • Capacitor Rack Systems • Anti-harmonic Reactors • Capacitor Rack Systems incorporating Harmonic Reactors • Complete Power Factor Systems • Complete Power Factor Systems incorporating Harmonic Reactors (www.em.co.za) (Gauteng) (Cape Province) (Kwazulu Natal) 9/11 Data Crescent, Ormonde Ext 8 P O Box 38980, Booysens 2016 2 Woodbridge Business Park Koeberg Road, Montague Gardens P O Box 200, Milnerton 7435 17 Mc Donald Rd, Congella P O Box 17317, Congella 4013 Telephone: (011) 249-5000 / 496-2773 Telefax: (011) 496-2779 E-mail: info@em.co.za Telephone: (021) 529-7000 Telefax: (021) 552-0331 E-mail: info@em.co.za Telephone: (031) 205-1571 Telefax: (031) 205-1625 E-mail: info@em.co.za