Passive Components in CMOS Technology

advertisement

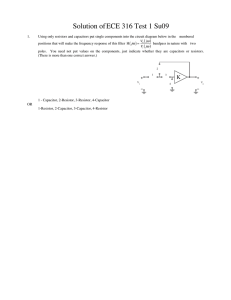

Passive Components in CMOS Technology Valentino Liberali Università degli Studi di Pavia Dipartimento di Elettronica Via Ferrata 1, 27100 Pavia, Italy Phone: +39-0382-505226; Fax: +39-0382-505677 e-mail: v.liberali@ele.unipv.it Contents: Integrated resistors Integrated capacitors EUROPRACTICE Training Course on Analog CMOS Design with Low-Voltage Issues Integrated resistors ,,,, A resistor is made with a given resistive layer. Insulator W L R = 2 Rcont + R WL R (1) is the sheet resistance measured in ohm per square ( = I ) I t W L For a homogeneous layer : L = R L R = Wt W The sheet resistance is: R = t (2) (3) where = resistivity; t = thickness of the material (fixed by technology) W = width; L = length of the resistor (chosen by the designer) INTEGRATED RESISTORS 1 For a non homogeneous layer : R = G1 = R t 1 = R t 1 W = R WL 0 dG 0 (z ) L dz (4) R = Rt 1 0 (z )dz (5) where = conductivity (function of z) INTEGRATED RESISTORS 2 Resistive layers Diffused (or implanted) resistors: n and p doped (n+ or p+ source/drain regions). Nonlinearity effects due to depletion layer modulation are small. Polysilicon resistors (first poly): n doped. Shielding from substrate possible by means of well. With some processes, high-resistivity (i.e. low-doped) poly is available (1 few k = ). Well resistors (n or p, depending on technology). Nonlinearity effects due to depletion layer modulation. Pinched well regions (diffused region on the top of the well increases sheet resistance). Nonlinearity effects due to depletion layer modulation. When available: Second polysilicon resistors (n doped). Shielding possible. Isolation resistors (n and/or p doped). Regions doped with field implantation over an opposite-polarity substrate. INTEGRATED RESISTORS 3 ,,,, , , , , , ,,, , , ,,,, , , ,,,, , , ,,,, , , ,,, , , ,,,, , Diffused resistances n+ p-substrate n+ p+ p-well P-well (or N-well) resistance p+ p+ p-well n-substrate Pinched P-well (or N-well) resistance p+ n+ p+ p-well n-substrate INTEGRATED RESISTORS 4 First poly resistance , ,,, , , , ,,, , ,,, , , , ,,, polysilicon n-substrate polysilicon p+ p-well n-substrate Second poly resistance polysilicon n-substrate polysilicon p+ p-well n-substrate INTEGRATED RESISTORS 5 Properties of integrated resistors Value of R : from few tens = (diffused and polysilicon) to a few k = (well, isolation, low-doped poly). Absolute accuracy: from 25 to 50 %. Voltage coefficient (VC): polysilicon: linear resistors (VC from a few tens to few hundreds ppm/V); diffused: fairly linear (slighltly worse than poly); well and isolation: non linear (VC many thousands ppm/V). Temperature coefficient (TC): from several hundreds ppm/C (diffused, poly) to several thousands ppm/C (well, isolation). INTEGRATED RESISTORS 6 ,, ,,,, , , For small resistors and for matched resistors: attention to terminal contacts. A METAL B METAL R = R WL + 2 Rcont (6) For resistor with large L/W: “serpentine layout”. A B INTEGRATED RESISTORS 7 Accuracy R = t WL (7) Standard deviation of the resistance: 2 2 2 2 2 R t L W (R)2 = R = + t + L + W = = ()2 + (t)2 + (L)2 + (W )2 (8) Accuracy is affected by: process (doping, physical structure, defects) enviroment (stress, temperature) t process (doping, diffusivity, deposition rate) electrical (bias for diffused, well, iso resistors) L litography (mask making, etching) design (choice of L) W litography (mask making, etching) design (choice of W ) generally W L, therefore W L. Absolute accuracy is poor. INTEGRATED RESISTORS 8 Relative accuracy To obtain good matching: use identical structures (including end contacts) place matched elements very close place matched elements with the same orientation make resistors of value nR matched to a resistor of value R (“unity resistor”) by connecting n resistors of value R in series R1 = R R2 = 4R R R R R avoid small width (and length) use interdigitized structures (structures made by a number of “fingers” interleaved to one another) use common-centroid structures (structures having the same “gravity” center) pay attention to boundary effects (use of “dummy” structures around the array) pay attention to physical effects such as: stress (piezoresistance is minimum at 45 in <100> silicon) temperature (especially in power devices). Best resistors for good matching: poly and diffused. Matching within few parts per thousand can be achieved. INTEGRATED RESISTORS 9 , ,, ,, , ,,, ,, , , Side diffusion effect W xj W' Contribution of endings 1 0.5 0 , ,, , , ,, , , ,, ,, , ,, , , , Interdigitized structure R2 Dummy strip Dummy strip R1 R1 R2 INTEGRATED RESISTORS 10 Typical resistor properties Layer R = Accuracy % n+ 2050 2550 p+ 50150 2550 poly (no silicide) 30100 2550 high- poly 1kfew k 2550 n-well 1k3k 2550 p-well 2k8k 2550 pinched well > well 3050 n-iso 2k6k 2550 p-iso 2k8k 2550 TC ppm/C 2001.5k 2001.5k 2001.5k 2001.5k several k several k several k several k several k VC ppm/V 50300 50300 20200 20200 several k several k several k several k several k Actual values depend on the specific technology. INTEGRATED RESISTORS 11 Integrated capacitors A capacitor is made with two conductive layers (electrodes) insulated by means of a dielectric layer. Different kinds of capacitors are available in CMOS technology: poly 1 to poly 2 (dielectric is thin silicon dioxide or other, e.g. thin sandwich of silicon dioxide, silicon nitride, silicon dioxide); poly to implanted region (high-dose implantation under poly; dielectric is thin silicon dioxide); poly to metal 1 (dielectric is intermediated CVD oxide); metal 1 to diffused active area (dielectric is intermediated CVD oxide); metal 1 to metal 2 (dielectric is the intermetal insulator). Additional (not good) capacitors: MOS capacitor (i.e. gate-to-channel MOS capacitance; dielectric is the gate oxide) , nonlinearities; reverse-biased junction (dielectric is the depletion region) , high nonlinearities. INTEGRATED CAPACITORS 12 ,, ,,, , ,, , ,,, , ,, ,,, ,,,, , , ,,, ,, Exmples of integrated capacitors polysilicon p+ or n+ diffusion polysilicon I polysilicon II shielding well INTEGRATED CAPACITORS 13 For parallel-plate capacitors: C = "r"t0A (9) where A is the electrode area; t is the dielectric thickness; "0 is the permittivity of free space; "r is the relative permittivity of the dielectric. The capacitance per unit area CS = "rt"0 (10) depends on the dielectric properties and thickness. INTEGRATED CAPACITORS 14 Properties of integrated capacitors Value of CS : from few hundredths to 2 fF/m2. Absolute accuracy: from 10 to 20 %. Voltage coefficient: in the range of few tens to few hundreds ppm/V (much higher for MOS and junction capacitors). Temperature coefficient: in the range of a few tens ppm/C. INTEGRATED CAPACITORS 15 Accuracy C = "r"t0A = "r "0tWL (11) Standard deviation of the capacitance: 2 2 2 2 2 C " t W L r (C )2 = C = " + t + W + L = r = (" )2 + (t)2 + (W )2 + (L)2 r (12) Accuracy is affected by: " r process (oxide quality) enviroment (stress, temperature) operating point (voltage bias; hysteresis can be present with some kinds of dielectric) t process (growth or deposition conditions; bottom-electrode structure) W , L litography (mask making, etching) design (choice of W and L) Absolute accuracy is better than for resistors. INTEGRATED CAPACITORS 16 Relative accuracy To obtain good matching guidelines similar as for resistors (and transistors) should be followed: use identical structures (including terminals) place matched elements very close place matched elements with the same geometrical orientation make capacitors of value nC matched to a capacitor of value C (“unity capacitor”) by connecting n capacitors of value C in parallel; for non-unity capacitors, keep the same perimeter-to-area ratio as the unity capacitor (to reduce effects due to overetching or underetching) avoid small width or length (use square capacitors) use suitable shape for unity capacitor use common-centroid structures use interleaved structures made by a number of unity capacitors placed in parallel pay attention to boundary effects (use “dummy” structures around the matched array). Best capacitors for good matching: poly 1 to poly 2 or poly to implanted region. Matching better than one part per thousand can be achieved. INTEGRATED CAPACITORS 17 , , ,, ,,,,, ,, ,, , ,,,,, ,, ,,, , ,, ,, ,, , ,, ,, , , , ,, ,, , , ,, ,, , , , ,, ,, , , ,, ,, , ,, ,, , , , ,, , , , Layout example for common-centroid structures C1 C2 1 C3 1 C4 2 C5 4 8 Unity capacitor C5 INTEGRATED CAPACITORS C4 C1 C3 C2 18 Parasitic capacitances When using capacitors, attention must be paid to parasitic (i.e. undesired) capacitances of the electrodes. ,,, ,,,,, ,,,,, CONNECTION TOP C P,T C BOTTOM C P,B SUBSTRATE Equivalent circuit C TOP C P,T BOTTOM C P,B SUBSTRATE Bottom-plate parasitic capacitance CP;B is a non negligible fraction of the desired capacitance C . From this point of view, the best capacitor is poly 1 to poly 2, followed by poly to implanted region. The top plate parasitic capacitance CP;T is smaller. Connect top plate to parasitic-sensitive nodes. Pay attention also to stray capacitances due to connections. INTEGRATED CAPACITORS 19