Design and Characterization of a Concentrating Solar Simulator

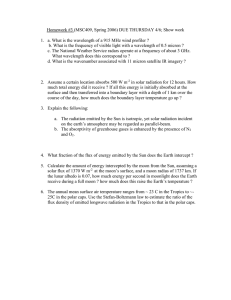

advertisement