3.0 Equipment Description 3.1 Full Assembly Please see Figure 4

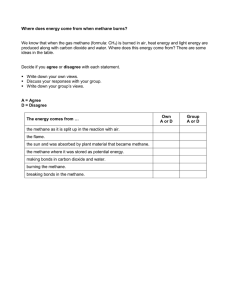

advertisement

3.0 Equipment Description 3.1 Full Assembly Please see Figure 4 below for an illustration of the test apparatus. It should be noted that this figure of the test setup only shows the schlieren setup and does not show the pressure or electrical system. For the descriptions, sizes, and weights of all the internal components, please see Table 1 below. Please note that only major components of the pressure system have been listed in the table. For more detailed information about the pressure system components, please refer to Section 3.4, Pressure/Vacuum System Documentation and the accompanying Table 6. In addition to taking the experiment structure onboard the aircraft, the flight crew was looking ahead to outreach activities by taking a digital camera and a toy gyroscope onboard. It should be noted that this experiment was not a free float experiment. Figure 1 - Experiment Test Apparatus Table 1 - Internal Components Schlieren Component Size [in] 8 in. diameter 1.37 in. thick Spherical Mirrors (x2) Mirror Mounts (x2) Flashlamp Focal Point interrupter (sharp edge) Weight [lbs] Description 5.5 24 in. focal length 10 x 12 x 4 31.94 Aluminum / Bosch 7x5x3 3x3x0.75 5.0 N/A Hard mount to frame Hard mount to frame Weight (lbs) 15 15 N/A N/A 10 N/A N/A Description Sowin TFT Dell CPU Pulnix TMC 9700 Cohu RCA STA-3850 N/A Captain Cook Turbo Igniter Electrical Component Flat Screen Computer Monitor Computer Visual Imaging CCD Camera Schlieren Imaging CCD Camera Amplifier Accelerometer Spark Igniter Component Methane Sample Cylinder Nitrogen Sample Cylinder Pulsed Flame Apparatus Methane Gas Nitrogen Gas Component Digital Camera Gyroscope Toy Size (in) 12x12x4 15x7x20 N/A N/A 14x14x7 N/A N/A Pressure** Size (in) Weight 11x3.5 7.0 lbs 9x2 5.0 lbs N/A 6.0 lbs N/A 4.9 g N/A 4.0 g Size (in) N/A N/A Outreach Weight lbs) N/A N/A **Please see Section 3.4 for more detailed information Description Swagelok (304L-HDF4-1000) Swagelok (316L-HDF4-300) Home built N/A N/A Description Canon Still Camera N/A 3.1.1 Equipment Layout and Flyer Positions Please see Figure 5 for the apparatus layout for flight on the KC-135 used for takeoff, landing, and during parabolas. The general aircraft floor plan used for this figure was taken from the JSC RGO TEDP document number AOD 33896, May 2002. The location of the experiment footprint was chosen as one of the two locations on the airplane that takes advantage of both an overboard vent manifold and a power panel. As shown in the figure, the long axis of the apparatus is aligned with the aft-forward direction and the two flyers were located just in front of the experiment close to the middle of the fuselage. A stress analysis was done on the frame of this apparatus assuming the above aft-forward orientation on the KC-135. Please see Section 3.2.7 of this report, Structural Analysis, for the results of this analysis. Restraints for the flyers were located in the positions marked in the figure. 3.1.2 General Apparatus Hazards Notable hazards include the containment of methane fuel and the integration of pressurized nitrogen and methane gas containers. The schlieren gas density imaging system presents notable hazards regarding the two required glass spherical mirrors and high intensity flash lamp. These hazards were minimized through the design of the experiment and through precautions taken during experimentation. The danger of methane escaping into the test chamber was minimized through the use of kill switches, as well as a manual shutoff valve easily at the flyer’s disposal. In addition, each Swagelok-purchased storage tank was charged to only 100 psi, well below the 1800 psi maximum allowable working pressure. The high-intensity flashlamp was only used during experimentation, was completely enclosed while in use, and placed in a location so as to ensure that no one could look into it. For more information about the schlieren system, please refer to Section 3.5.1. Figure 2 - Experiment layout and flyer positions 3.2 Structure 3.2.1 Design Constraints Several constraints were taken into consideration during the structural design phase of our project’s development. 3.2.2 Footprint Limitation The first item considered was the geometric footprint constraint. The structure must fit within a 20” by 60” rectangular footprint. This constraint was motivated by the layout of bolt anchors in the aircraft cabin floor, which is laid out in a grid of 20” squares as seen in Figure 6. These anchor points are the only points to which our rig can be secured to the aircraft. The structural design centered around this constraint due to its fundamental importance in the interface between the rig and the aircraft. Figure 3 - Aircraft Floor Schematic 3.2.3 Ergonomics Ergonomics was also taken into consideration during the structural design. It was desired to have the main systems (i.e. pressure and schlieren) at waist level and the computer interface (i.e. keyboard, track-pad, and monitor) at shoulder level. It was hoped that this layout would provide easy system operation in all g-level environments. 3.2.4 Lean Flammability Ratio Since safety was an ever-present consideration in our design, we wanted to assure that no combustion occurred other than that which took place within the confines of our experiment cycle. To provide this safety, the enclosure was made large enough to allow for the maintenance of the lean flammability ratio for methane. The Lean Flammability Ratio will be discussed in further detail in Section 3.4.2. 3.2.5 Schlieren System Accommodation Most schlieren systems involve long-focal-length spherical mirrors whose focal length must be “folded” by the use of flat mirrors to reduce the size required to house the overall system. The experiment enclosure had to be made large enough to accommodate at least the smallest possible schlieren system. 3.2.6 G-Load Specifications NASA’s Structural Design Requirements section provided us with a set of maximum gloads which the rig must withstand. Table 2 summarizes these g-load specifications. The g-loads were meant to approximate possible worst-case scenarios which may put higher than normal forces on the structure (i.e. severe turbulence, hard-landing, etc.). Figure 7 shows the orientation of the rig relative to the loading directions. Table 2 - G Load Specifications Direction Forward Aft Down Lateral Up 3.2.7 G-Load [g’s] 9 3 6 2 2 Structural Analysis A structural analysis was performed to insure that the preliminary structural design would meet all of the g-load specifications. The analysis was performed on a simplified structural skeleton with all doors and sheet-metal skin removed. Internal system components were approximated as point masses attached at the centers of mass of the appropriate structural member. For each element of the structure, a force was applied which was equivalent to the mass of that element multiplied by the acceleration (g-load) for the case being analyzed. ISMIS, a MatLAB Toolbox, was used to perform the required calculations involved in this analysis. Table 3 shows the result of this analysis. The maximum tensile stress each member can withstand (yield stress) is 250 [N/mm2], therefore no structural member was subjected to a stress that exceeded this limit during any of the loading configurations. Figure 7 shows the orientation of the structure relative to the aircraft and loading directions. The stress analysis results for each load configuration are shown in Figures 8-12. It can be seen from the table and figures that the structure can easily withstand the maximum g-loads. Table 3 - Stress Analysis** Configuration Maximum Stress (N/mm2) Percent of Yield Stress Forward 67.9 27.2% Aft 22.6 9.0% Down 70.9 28.4% Lateral 41.9 16.8% Up 23.6 9.4% ** Maximum stress any member can withstand is 250 N/mm2 Figure 4 - Structure Orientation Figure 5 - Forward Stress Analysis (N/mm2) Figure 6 - Aft Stress Analysis (N/mm2) Figure 7 - Down Stress Analysis (N/mm2) Figure 8 - Lateral Stress Analysis (N/mm2) Figure 9 - Up Load (N/mm2) 3.2.8 Component Attachments Aluminum straps, seen in Figure 13, used along with Velcro, were used to fasten the electrical components to the structure. In addition, the wires were bound to the structure with wire ties. Figure 10 - Component-mounting straps In Figure 13 above, two straps of different sizes are shown that were used for mounting of hardware to the test apparatus. As shown on the right side of Figure 13, rubber has been glued to the inner surface to minimize slippage and stress. The straps were attached to the structure by bolts in a manner that does not allow the component to move relative to the rig. We assumed that there would be no slippage between the strap and the component; therefore we assumed that if the component is subject to the aforementioned g-load specifications, that load would be transmitted directly to the connection bolts in the form of a pure shear force. According to Bosch specifications, the shear strength of the connection bolts is 32 N/mm2, which is many times higher than any shear force that would be applied in any of the g-load cases. 3.2.9 Floor Attachment There were a total of four steel bolts that mount the test apparatus to the aircraft floor. The bolts supplied (NAS 184-6 Steel Studs) were more than adequate to support the fraction of the load that was applied to each mount. 3.3 Electrical System The methods that were used for the electrical components to work together and ensure proper operation of the experiment are described in detail in this section. The experiment requires several electrical components to be synchronized so that accurate data can be obtained. Furthermore, the electrical system was designed to be autonomous so that the synchronization could be achieved with minimal crew interaction, thus reducing possible errors. Finally, the electrical system was designed with many redundant safety measures in mind, ensuring that the researchers onboard the KC-135 would not lose power from their experiments or be in danger of excess methane releasing into the aircraft. 3.3.1 Electrical Analysis The interaction of the electrical components with one another is detailed in the schematic shown below (Figure 14). The specifications for each wire, which include the maximum current flowing through that wire and the thickness of the wire, are given in Table 4. Table 4 shows that each wire can adequately contain the current flowing through the wire. Figure 11 - Schematic of Electrical System Table 4 - Wire Specifications Wire ID PP P1 P3 P4 P5 P6 P7 PC C1 C2 D1 F G L MA MB PR R1 R2 S1 S2 B1 B2 VA VB PS A Description Aircraft Power Panel Flashlamp Power 12V DC Power Supply Audio Amplifier Power UPC Power Computer Monitor 24V DC Power Supply UPS Power to Computer Visual Camera Power Supply to Camera Schlieren Imaging Camera Power Supply to Camera Accelerometer Flash Processor to Flashlamp Igniter Ground Lead Igniter Hot Lead Visual Camera to Switch Schlieren Camera to Switch 24V DC Power to Gas Relays DAQ Board to N2 Purge Relay DAQ Board to Methane Relay Nitrogen Purge Relay to Solenoid Methane Fuel Relay to Solenoid AA Battery to Igniter Relay Igniter Relay to Igniter Switch Visual Camera to IMAQ Board Schlieren Camera to IMAQ Board Audio Amplifier to Speaker DAQ Board to Audio Amplifier Max. Current 8.6 A 3.5 A 2.0 A 1.0 A 6.0 A 2.0 A 1.0 A 4.35 A 0.6 A Wire Gauge 12 18 direct 18 18 18 direct 18 20 0.35 A 20 0.01 A 0.01 A 0.01 A 0.01 A 0.01 A 0.01 A 1.0 A 0.025 A 0.025 A 0.5 A 0.5 A 0.2 A 0.01 A 0.01 A 0.01 A 3.16 A 0.1 A 20 20 X 8C 20 20 20 (BNC) 20 (BNC) 18 X 2 20 20 18 18 20 20 20 20 18 18 The schematic shows that six components are grounded to the surge protector. The surge protector attaches to the aircraft power panel to ensure zero potential difference between the electrical components and frame of the apparatus. The loads that are carried through the components to the surge protector are detailed in the next section and in Table 4. In addition, it should be noted that the flashlamp we will use is not a laser, but does produce strong pulses of light. Thus, the flashlamp is configured in such a way that the light is not directed at anyone’s eyes. Furthermore, the flashlamp will not be turned on until the apparatus is closed. 3.3.2 Load Table In accordance with NASA guidelines, the load table shown below was created (Table 5). The load table describes the electrical power drawn from each power source to verify that the experiment will not draw more current than is available. Table 5 - Load Tables Power Source Name: Power Cord A Voltage: 115 V AC, 60 Hz Wire Gauge: 12 Max. Outlet Current: Power Source Name: AA Battery Voltage: 1.5 V DC Wire Gauge: 18 Max. Battery Current: 3.3.3 20 Amps Load Analysis Flash Lamp 24 V DC Power Supply 12 V DC Power Supply Amplifier Computer UPS Computer Monitor Total Current Draw: Load Analysis Electronic Igniter 0.2 Amps Total Current Draw: 3.5 A 1.0 A 2.0 A 1.0 A 6.0 A 2.0 A 15.5 Amps 0.16 A 0.16 Amps Automation It is evident from this schematic that due to the number of electrical components being used for this experiment, having the experiment run autonomously is a necessity. The synchronization of the components includes having the flashlamp and schlieren imaging camera starting operation at the same time and continuing operation at the same frequency so that the rates the flashlamp is emitting light and the camera is recording data are equal. Furthermore, both the luminosity imaging camera and the schlieren imaging camera must begin operation at the same initial time and frequency so that the luminosity and schlieren images align with one another and can be used to describe the flame at the same instant in time. The final part of the synchronization includes having the speaker begin pulsing at the instant the cameras start recording data so that it will be known when the pulsing is occurring. Due to its ability to allow user-friendly control over electrical components, LabVIEW was used to automate the experiment. LabVIEW is able to synchronize the electrical components described in the previous paragraph, as well as collect data through Data Acquisition (DAQ) and Image Acquisition (IMAQ) cards. For this experiment, we acquired a DAQ card and two IMAQ cards from a generous donation by National Instruments. The DAQ card is used to record the accelerometer data, communicate the desired amplitude and frequency to the speaker, and control the methane and nitrogen solenoids. On the other hand, one IMAQ card records the luminosity image data while the other IMAQ card records the schlieren image data. The LabVIEW interface is shown below in Figure 15. From this figure, it is seen that in addition to controlling the electrical components of the experiment, LabVIEW also controls many other aspects of the experiment. These include the ability to alter the frequency and amplitude of the pulse in real-time, meaning that those parameters can change while the flame is pulsing. In addition, the rate that the accelerometer is recording data can be altered so that changes in gravitational acceleration can be recorded to the desired precision. Furthermore, the LabVIEW interface allows us to have the option to save the data so that it can be analyzed. Figure 12 - LabVIEW interface Moreover, the LabVIEW program was created so that when the experiment is operating, two windows will pop up showing both the luminosity and schlieren images that are being recorded (Figure 16). These windows allow the users to make any modifications to the cameras, such as focusing or calibrating, in real time. Figure 13 - LabVIEW interface during experiment operation 3.3.4 Safety In addition to providing automation, LabVIEW provides many safety features for our experiment. These include limiting the amount of time the methane gas will flow before the flame is ignited. If the flame does not ignite after this time, it is assumed that something is prohibiting the flame from igniting, so the setup should be examined for any possible problems. In most cases where the flame does not light in the specified amount of time, it can be assumed that the amplitude and frequency of the pulse are not allowing a sufficient amount of methane to accumulate in the ignition area. Therefore, on the next test run, different values for the pulse amplitude and frequency should be tried. Limiting the ignition time ensures that if there is a problem that prohibits the flame from igniting, excess methane will not be wasted. Another LabVIEW safety feature includes the option to purge the system of the methane gas before any given trial run. Purging the system ensures that the pressure lines as well as the test chamber are free of the combustible methane gas since there is not enough oxygen available for the gas to combust. In the event of an emergency, there are several options available to the crew to shutdown the experiment. The most accessible method is a master on/off kill switch located on the exterior of the structure (Figure 17). This kill switch can easily be reached by the crewmember operating the computer. However, if for some reason he is unable to activate the kill switch, the other crewmember will also be able to reach it. Another option for the crew to shutdown the experiment will be to manually turn off the surge protector. For a closer look at the kill switch, please see Figure 18. master kill switch Figure 14 - Master kill switch on top of structure If activated, either of these methods will cause both the fuel and purge solenoids to deactivate (lose power) and move to a default state. The default state of the solenoids will immediately close the fuel supply to extinguish the flame, and initiate flow of the purge gas to prevent any combustion from taking place. Once the purge gas has ensured that the test chamber is safe, the crew members can manually shut it off to preserve the nitrogen. In addition, if the kill switch is activated, it will turn off all the electrical components with the exception of the CPU and monitor, which are powered by an Uninterruptible Power Supply (UPS). The UPS is basically a battery that allows the computer to operate without electrical power from the plane for approximately five minutes. Furthermore, the UPS prevents data loss if there is a temporary power loss, such as a black out or brown out. The UPS will beep if there is a power loss so that the crew members will recognize the situation and ensure that the computer is shut off properly. Having the computer remain active during a situation in which the kill switch must be activated cannot cause any event that would compromise the safety of those onboard the KC-135. LabVIEW also provides an abort option through a large “STOP EXPERIMENT” button and “QUIT” button on the LabVIEW virtual instrument panel (Figure 15). If the experiment is running, the “STOP EXPERIMENT” button simply closes the methane solenoid and leaves the nitrogen solenoid in the closed position. However, the “QUIT” button puts both solenoids in their default positions and quits the LabVIEW program. A final safety feature links what LabVIEW perceives is the state of the solenoids (open or close) and the actual state of the solenoids. This safety feature is an essential tool because it ensures that the LabVIEW program is operating correctly. If there is any ambiguity in the state that LabVIEW identifies the solenoids to be in and the actual state of the solenoids, then the kill switch will be activated. Linking the virtual interface with the actual event is accomplished by using Light Emitting Diodes (LEDs) on the LabVIEW interface and on the top of the experiment structure (Figure 18). In both cases, the red light shows the state of the fuel solenoid and the blue LED shows the state of the purge solenoid. If the red LED is on, then the fuel solenoid is open and the methane gas is flowing. The figure below is showing this case. Conversely, if the red LED is off, then the solenoid is closed and the methane gas is not flowing through the pressure lines. Likewise, if the blue LED is on, then the purge solenoid is open and the nitrogen gas is flowing through the lines. However, if the blue LED is off, then the purge solenoid is closed and no nitrogen is flowing through the lines. At no point should both the red and blue LEDs be on. Should this happen, then the experiment will be aborted. Also, if LabVIEW is operating correctly, then the LEDs on the virtual interface should correspond exactly to those on the structure. If the LEDs do not correspond to one another, then the kill switch will be activated. LEDs Figure 15 - LED states during experiment operation (fuel flow on) 3.4 Pressure/Vacuum System Documentation The pressure system that was re-designed and flown in the 2003 RGSFOP operated nominally and successfully demonstrated its robust design. At the conclusion of the 2002 RGSFOP in which a pulsed methane-flame was first studied by a UT Austin student team, many lessons were learned that led to the new design for this year’s flight campaign. Being the central system of the project, changes to the pressure system affected the design of both the structural and electrical systems. Descriptions of all aspects of the pressure system as well as descriptions of the changes that were implemented are described below. Please see Figure 19 for an AutoCAD illustration of the pressure system that was used for design and development and Figure 20 for a photograph of the system that was subsequently flown. 3.4.1 System Description and Fluid Quantities For a schematic showing all pressure system components used in the final system design, please refer to Figure 21. For descriptions of all components labeled in Figure 21, also refer to Table 6. A methane storage cylinder (Swagelok, model 304L-HDF4-1000) was used with a volume of 1 liter and a pressure rating of 1800psi but was only charged to 100 psi to hold the required 4.6 grams of fuel. For information regarding measures taken to ensure safety in the unlikely event of gas escape, please see the next section regarding the lean flammability limit of methane fuel. A nitrogen purge system was used to eliminate the chance of creating a fuel-air mixture in the methane line. The purge gas was stored in a small storage cylinder (Swagelok, model 316L-HDF4-300) with a volume of 0.33 liters and a pressure rating of 1800 psi but was only charged to 100 psi which was more than enough gas for the entire campaign. Pressure relief valves set at 125 psi were placed just downstream of the gas storage cylinders so that the cylinders could not be overpressurized while being charged on the ground prior to flight. Manual shut-off valves were placed just after the relief valves, and were then followed by pressure regulators that reduced the pressure to 40 psi. For the methane fuel line, the next component was a micro-metering control valve with an accompanying Vernier handle that was used to set the desired methane flow rate. The Vernier handle allowed precise flow rates to be set and reset to allow repeatable conditions for ground and flight testing. The next methaneline component was a solenoid valve that was computer-controlled through LabVIEW allowing the automatic control necessary to initiate several experiments in the short time given on each parabola on the KC135. Lastly for the Methane line, a check valve was in place that ensured no nitrogen or air could enter the methane line or cylinder, thus again avoiding a fuel-air mixture. For the nitrogen line, the component after the pressure regulator was a solenoid valve that was computer-controlled through LabVIEW. At this point, the two gas lines merge into a tee connector. Please note that all lines before the tee connector consist of ¼” stainless steel tubing with Swagelok stainless steel fittings. A ¼” stainless steel flex tube then connects between the tee connector and an emergency relief valve set at 4 psi installed downstream of all components and directly connected to the PFA. The Pulsed Flame Apparatus (PFA) is not considered a pressurized vessel because it is open to the ambient air around it. Please see below for more specific information about the PFA. Figure 16 - Pressure System AutoCAD Design Figure 17 - Photograph showing actual pressure system 3.4.2 Lean Flammability Limit of Methane Fuel It is important to note that if all methane fuel is released into the test chamber and then the igniter is activated, there is no chance of an explosion. This is because even though the methane will combine with the ambient air in the test chamber and form a fuel-air mixture, combustion cannot occur because the mixture will contain less than the critical amount of fuel. This critical limit is known as the lean flammability limit of a combustible gas [10]. The lean flammability limit of methane fuel is 5%. If all the stored methane were to escape into the test chamber, the gas would expand to only 7.6 liters and, given that the volume of free space in the chamber can be conservatively estimated to be 250 liters (total enclosure volume less the approximate volume of all inside components), it is found that the ratio of methane fuel to total free volume would be less than the above limit: V (CH 4 ) 7.6 Liters ≅ = 3% < 5.0% V ( free _ space) 250 Liters (1) When designing the new structure in AutoCAD, it was ensured that the volume of area around the flame experiment was large enough to meet the lean flammability limit as explained above including a very conservative factor of safety. The entire structural volume was found to be approximately 900 liters. The flame test area occupies the upper half of this volume, however, the many components that have been placed around the flame nozzle must be taken into account when doing this computation. The volume of interest was then very conservatively estimated to be 250 liters, resulting in a flammability limit of roughly 3 percent. Therefore, all built-in safety measures (kill switch, purge gas, and the fact that the flame will be operating in non-premixed mode as described above) are redundant in terms of safety because the system will not exceed the lean flammability limit. As a result, these measures are most useful as a monitoring tool for gas leaks or flame-extinction and will be used to save gas in the event of fuel release. 3.4.3 Operating Procedures Following arrival at Ellington Field, our pressure system was attached to the supply bottles of Methane and Nitrogen. The two sample cylinders attached to the apparatus were then charged for ground testing. Ground operation was begun by first flushing the pressure system with nitrogen purge gas. Then the electrical system was initiated and both computer-controlled solenoid valves were set to the “closed” position. Next, the manual on/off valves were opened and the pressure regulator was set to 30psi. Tests (both ground and flight) then commenced by setting the desired flow rate with the Vernier handle and running the experiment with the computer-controlled solenoid valves. When the test matrix was completed, the manual on/off valves were closed, all remaining methane in the tubing was burned off, and the system was purged with nitrogen once again to ensure that excess methane did not remain in the lines. Figure 18 - Schematic of Pressure System Table 6 - Pressure System Design Specifications*** Schematic Reference 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Component Description Pressure Setting (psi) MAWP (psi) Quick-Connect Stem Methane Sample Cylinder Relief Valve Manual Shutoff Valve Pressure Regulator Needle Valve CH4 Solenoid Valve (default closed) Check Valve 1/4” stainless steel tubing Stainless steel flex tubing Relief Valve Pulsed Flame Apparatus Quick-Connect Stem Nitrogen Sample Cylinder Relief Valve Manual Shutoff Valve Pressure Regulator N2 Solenoid Valve (default- open) N/A 112 Regulator Setting (psi) 250 1800 Relief Valve Setting (psi) N/A N/A N/A N/A Swagelock Swagelock Cert. Test / Calib. Date 3/25 3/25 125 N/A 3000 2500 125 N/A N/A N/A Swagelock Swagelock 3/25 3/25 N/A N/A N/A 3000 3000 500 N/A N/A N/A 40 N/A N/A Victor Swagelok ASCORed Hat 3/25 3/25 3/25 N/A N/A 6000 ?? N/A N/A N/A N/A Hoke Swagelok 3/25 3/25 N/A 3000 N/A N/A Swagelock 3/25 4 N/A 3000 N/A 4 N/A N/A N/A 3/25 3/25 N/A 100 250 1800 N/A N/A N/A N/A Swagelok House Built Swagelock Swagelock 125 N/A 3000 2500 125 N/A N/A N/A Swagelock Swagelock 3/25 3/25 N/A N/A 3000 500 N/A N/A 40 N/A Victor ASCORed Hat 3/25 3/25 *** Note: All fittings will be Swagelok stainless steel fittings Built By 3/25 3/25 3.4.4 Pulsed Flame Apparatus The Pulsed Flame Apparatus (PFA) is essentially a methane exit nozzle that is mounted by screws to a speaker purchased at Radio Shack. It is the only home-built component involved in the pressure system and is not considered a pressurized vessel because it is open to ambient air. Please see Figure 22 for an AutoCAD image of the PFA. As shown, gas enters the PFA through the fuel inlet on the right. The flow then passes through a one-inch layer of honeycomb where it is straightened to a more uniform and predictable flow. Then, after passing through a mesh screen that is used to eliminate possible flame flashback, the fuel is ignited just outside of the converging nozzle at the top. It should be noted that there is a relief valve directly connected to the inlet that is set at 4 psi. Methane Fuel Nozzle Flashback Protection Screen Flow-Straightening honeycomb Methane Fuel inlet Pulsing Loudspeaker Figure 19 - Pulsed Flame Apparatus 3.4.5 Flame Ignition System A new ignition system was implemented for the current flight campaign. In 2002, a piezo-electric igniter was used that was directly mounted to the PFA. This igniter was both unpredictable and poorly mounted. It failed to light the flame on several occasions and, because of its placement, caused flow disruption as methane exited the nozzle. This disruption caused undesirable instabilities in the flame. This year, flame-ignition was achieved through the use of a battery-powered high voltage spark igniter generously donated by Barbeques Galore Inc. The igniter has a variable-width spark gap enabling flexible configuration. The igniter assembly is mounted on a swivel arm that is manually actuated by pulling or pushing on a cable taken from a bicycle brake system. When the cable is pulled, the igniter swings over the nozzle exit. Once in place, a button on the igniter is depressed, causing a continuous spark until the button is released. 3.5 Schlieren Flow Imaging System The schlieren system consists of two spherical concave mirrors, one high-speed flash lamp, one CCD camera with neutral density filters, and a knife-edge. Schlieren imaging techniques can show first-order density gradients in the vertical or horizontal direction through the test section. In our case, by placing a flame in the test section, important visual information about the internal structure of the flame can be discerned. With this technique the relatively “cold” methane gas can be seen pulsing up through the middle of the hot flame. Also, the flame’s hot combustion products can be seen interacting with the ambient air. Figure 23 shows the setup used for our schlieren system. Figure 20 - Schlieren Imaging System Schematic 3.5.1 How schlieren works The schlieren imaging technique utilizes the fundamentals of spherical mirror optics. If a divergent light source (i.e. point source) is placed at the focal point of a spherical mirror, the spherical mirror will reflect a perfectly collimated light beam. This means that all of the light rays are parallel (i.e. not converging nor diverging). Conversely, perfectly collimated light is focused by a spherical mirror down to one point (i.e. the focal point of the mirror). In addition, imperfectly collimated light (i.e. some rays are diverging, and some are converging) will focus in the vicinity of the focal point but will not converge to a single discrete point. a.) b.) Figure 21 – Schlieren Schematic a.) Perfectly collimated light rays throughout the test section; uniform neutral image, b.) Collimated light is refracted by density gradients within the flame; light, dark, and neutral regions within the image. Figure 24a shows the test section with perfectly collimated, non-deflected light passing through it. Figure 24b show the test section with a flame present. The density gradients within the flame refract the parallel light rays by various amounts. Because these light rays are no longer parallel, they do not all focus down to one point. The light rays that are deflected downward are blocked by the knife edge, and the light rays that are deflected upward make it past the knife edge and are recorded by the camera. This creates an image of light, dark, and neutral regions that represent the amount in which the collimated light was deflected by the density gradients. The intensity of the light and dark regions suggest the severity of the density gradients within the flame. 3.5.2 Fabricated Schlieren Components The mirror mounts consist of an 8” diameter cylindrical housing attached to a 10” by 10” flat plate. An 8” concave spherical mirror will be secured inside the cylindrical housing using four ¼”-20 thread per inch screws, and a ¼” steel and a ¼” rubber washer. The flat plate backing of the mirror mounts will attach to another plate that has special profiles that accommodate the insertion of a Bosch profile. This profile will be attached to swivel hanger brackets that allow the profile to pivot about its longitudinal axis. This mirror mount design allows for rotational and vertical adjustments. A schematic drawing of the mirror mount is shown in Figure 25. Figure 22 - Mirror Mounts