Advanced Maritime Emissions Control System (AMECS®)

advertisement

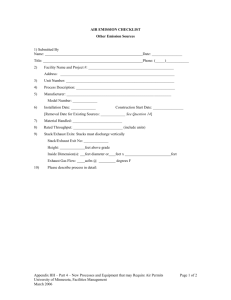

Creating a better Environment through Science Advanced Maritime Emissions ® Control System (AMECS ) Advanced Cleanup Technologies, Incorporated Hazardous Waste Management & Emissions Control Specialists Environmental Systems Development Division The Problem The PROBLEM (continued) Depiction of Various Ship Stack Configurations The Exhaust Capture System must Can Accommodate Various Stack Shapes accommodate various stack geometries The PROBLEM (continued) The system must be able to treat various fuel types, handle various exhaust flows and exhaust temperatures The Solution Emissions Control Technology ACTI’s Emissions Control Technology consists of two types of systems: • Advanced Locomotive Emissions Control System (ALECS) designed to capture and treat the exhaust emissions from railroad locomotives • Advanced Maritime Emissions Control System (AMECS) designed to capture and treat the exhaust emissions from ocean-going vessels – Barge-Based System – Shore-Based System – Multi-Capture and Treatment System Emissions Treatment Subsystem Picture of the Actual System Demonstrated and Tested in Roseville, California Successful Demonstration Program • The objective of the tests at Union Pacific Railroad’s J. R. Davis rail-yard in Roseville, California was to demonstrate ALECS capability to: - Remotely attach to a railroad locomotive around the exhaust opening - Capture the exhaust gas and direct it via the overhead manifold system into the Emissions Treatment Subsystem Successful Demonstration Program (continued) - Maintain attachment and exhaust capture while the railroad locomotive is underway within designated area within the rail yards • The test of ALECS was a success, meeting all the goals described above and more • The same treatment system is used on AMECS Successful Demonstration Program (continued) Shore-Based AMECS Configuration Barge-Based AMECS Configuration Emissions Treatment Subsystem Outlet Gas Preconditioning Chamber (PCC) Cloud Generation Chambers (CGC) System ID Fan Inlet Gas Heat-Exchanger Heater (Burner) Selective Catalytic Reduction (SCR) Emissions Treatment Subsystem Removal of Sulfur Dioxide (SO2) Using Sodium Hydroxide Captured Exhaust Gas Cooled Removal of Particulate Matter and Hydrocarbons Inlet Gas Removal of Oxides of Nitrogen (NOX) using Urea as the active agent Waste-Water Reservoir Emissions Capture Subsystem Maximum Envelope 125 Feet Maximum Envelope 125 Feet Articulating Arm & Placement Tower shown with Exhaust Intake Bonnet (EIB) Depiction of station keeping supporting bonnet attachment (30 foot radius) Articulating Arm & Placement Tower Articulating Arm (for EIB placement) Peacock Assembly Expandable Boom Cable Drive Assembly Placement Tower Counter Balance Emissions Intake Bonnet (EIB) Side Views of EIB, shown in closed position with Shroud withdrawn High temperature Shroud Carbon Fiber Ribs EIB Station Keeping Wire Sensors • Three fixed stack points connected to floating arm measure stack position (EIB shown in closed position) • Wire sensors allow for rapid and accurate arm adjustment Soft Tri-Pod Stack Interface EIB Exhaust Control Heat Sensing Device Intake Exhaust Control, EIB shown in open position Location of Intake Control Damper Hot Thermal Zone Intermediate Thermal Zone Damper Full-Open Temperature Control Threshold Control Sections (Zones) Damper Partially Opened Coolest Thermal Zone EIB Wire Position Sensors (Station Keeping) • Three fixed stack points connected to floating arm measuring stack position • Wire sensors allow for rapid and accurate arm adjustment • Wire Sensor designed and manufactured by Micro-Epsilon Soft Tri-Pod Standoff Stack Interface Wire Sensors (Set of Three) EIB Station Keeping Sensor System Positioning Sensors • Wire sensors accurate to within ± .1 inches • Determines arm position relative to stack within one inch Wire Sensors Positioning Standoffs (three) Emissions Intake Bonnet Depiction of the EIB being placed onto a typical strait ships stack Soft Tri-Pod Standoff Stack Interface Emissions Intake Bonnet Depiction of the EIB being placed onto lip style stack Station Keeping Wire Sensors Minimal Impact, if any, on Port Operations Ease of access to stack Unobtrusive Barge Location Depiction of Attachment While Anchored Unobtrusive barge attachment while OGV is anchored Vertical Compensator Articulating Arm Emissions Intake Bonnet (EIB) shown unfurled Typical Attachment Shown for Single Stack Vessel Vertical Compensator Typical Attachment Shown for Dual-Stack Vessel Pair of Emissions Intake Bonnet’s (EIBs) shown furled SUMMARY Advanced Maritime Emissions Control System (AMECS®) Advantages: • No ship modification required • Substantial Reduction of Harmful Pollutants – Removal percentages of sulfur dioxide (SO2), particulate matter (PM), oxides of nitrogen NOX) all above 95%, depending on fuel type – Over 60% removal of Hydrocarbons • Can capture and treat exhaust emissions while ships are berthed and anchored waiting to be berthed • Provides a Cost-Effective solution Questions & Answers Advanced Cleanup Technologies, Incorporation Hazardous Waste Management Specialists 18414 South Santa Fe Avenue Rancho Dominguez, California 90221-5612 310 763-1423 Supporting Data The following slides contain additional information regarding ACTI’s Advanced Maritime Emissions Control System (AMECS), and will only be used as required to respond to questions EIB Light Wind Applications Bellows Bonnet Designed for Light Wind Applications Top-View Side-View EIB Stack Interface System Swivels (four) Tri-Pod Standoff Stack Interface System Soft Interface Pads EIB Securing & Release System Securing System Cinching Cables (sown in blue) after attachment Cinching Cables (shown in red) prior to attachment SCR Reactor, Injection System & Burner Directed into front of system Catalyst NOx NOxNOx Exhaust Gas NH3 NH3 H2O NH3 NOx NH3 Heater Diesel Control Fuel Urea 20 NH 2 20 NH 2 20 NH 2 20 NH 2 Cleaned Gas Thermal Management System Captured Hot Engine Exhaust Cloud Chamber Scrubber Diesel Generator Scrubbed Gas Hot Exhaust Hot Exhaust Heat Exchanger SCR Reactor Urea Hot Exhaust Clean Exhaust Stream SCR Reactor – Argillon Catalyst • Titanium – Vanadium Oxide Ti-V2O5 Based • Ceramic Substrate • Homogeneous • Honeycomb SCR Catalyst Performance NOx Removal Efficiency vs. Operating Temperature o o (Design Temperature = 600 to 680 F) NOx Removal Efficiency (%) 100.0 90.0 80.0 Designed input input temperature temperature Designed range range 70.0 60.0 50.0 400 450 500 550 600 650 Operating Temperature (F) 700 750 800 AMECS Improvements Under Lessons Leaned: The following two improvements are under consideration as a result of the Demonstration and Testing Program in Roseville, California • Create one common housing partition between the Selective Catalyst Reduction (SCR) Reactor and the Thermal Management System (shown in the next slide). This would increase thermal efficiency and reduce the system cost. • Continuous Emissions Monitoring System (CEMS); the system deployed seems to require a greater amount of technical skill then we believe is necessary. In addition, the system cost seems to be high. We will evaluate other systems. • We developed a much better understanding of rail yard operations and the type of exhaust capture system that would most likely work without interfering with railroad operations. AMECS Improvements (continued) Thermal Management System Old Design New Design SCR Reactor & Burner Assembly Heat-Exchanger