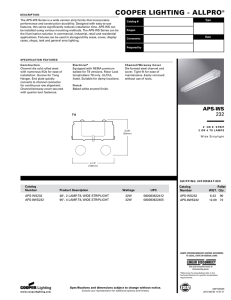

Installation Instructions

advertisement

IC Installation Instructions ! CAUTION • All wiring should be done by a licensed electrician in accordance with state codes, local codes and National Electric Code (NEC) standards. • Improper installation may result in serious injury and void warranty. • Contains parts and assemblies susceptible to damage by electrostatic discharge (ESD). • Operate lamps ONLY with proper ballast. • In event of lamp failure, replace lamp or disconnect primary power to the ballast within two weeks at the very most. This will prevent damage to electrical components from dielectric stresses, which may result from the high voltage starting pulses unique to High Pressure Sodium circuits. • Use protective gloves and eye equipment when replacing lamps. • If outerlamp glass is broken, turn off lamp and replace it promptly to avoid exposure to ultraviolet energy. Even with the outer lamp glass broken, the arc tube may continue to fire. • The arc tubes contain mercury and/or sodium. Use appropriate care in disposal of failed or broken lamps. Wiring To gain access to the wiring compartment, loosen all captive screws on the ballast end cover nearest to the conduit hole. Remove cover and gasket. Wiring instructions and electrical ratings are shown on the label inside the compartment. Install 1/2 inch NPSI strain relief plug (located inside of wiring compartment) in conduit hole located on ballast assembly. Connect lamp cord from end of socket housing to ballast assembly by running cord through strain relief plug and into wiring compartment. Make proper electrical connections as shown on the wiring diagram. Connect black lead to lamp lead, white lead to com lead, and green lead to ground stud. When making supply lead connections, the mast fitter cover must be removed to gain access to the wiring compartment. Loosen the four (4) 10-24 screws and remove the cover. Connect the black supply lead to the proper voltage lead and the white supply lead to the ballast lead marked “com”. Connect the ground lead to the green ground wire inside of the mast fitter. On quad-volt ballasts, unused voltage leads must be insulated with a proper connector. Fixture Assembly Select desired mounting position and attach arm assemblies to mast fitter/ballast assembly using two (2) 1/2-20 x 1 inch hex head bolts and 1/2 inch split-lock washers (Items 10 and 11). Tighten loosely. The arms incorporate 45 degree angles at the ends that mate to the mast fitter. These angles allow the arms to be assembled in differrent positions as appropriate for the installation. Position lamp housing assembly between the two arm assemblies and attach with two (2) 1/2-13 x 1-3/4 inch hex head bolts and 1/2 inch split lock washers (Items 5 and 6). Tighten all 1/2 inch bolts. Install lamp in socket housing, and assemble to bottom of lamp housing aligning with four (4) 1/4-20 machine screws. Make sure socket housing is seated properly on gasket and is mounted in correct position (labeled “front”). For proper lamp installation, see “lamping” section. Lamping This fixture is designed to accept either High Pressure Sodium BT-37 (1000W) or Pulse Start Metal Halide BT-56 (up to 1000W). Removal of the socket housing provides easy access to the lamp compartment. The top end of the lamp must seat securely in the spring loaded retainer when the lamp base is screwed tightly into the socket. This prevents lamp breakage. When re-lamping, it is recommended that cover glass and reflector be cleaned to maintain fixture efficiency (see “Cleaning” page 2). Phoenix Lighting 8711 West Port Avenue Milwaukee, WI 53224 USA Phone: +1 414.973.3300 Toll Free: 800.438.1214 Fax: +1 414.973.3210 www.phoenixlighting.com IC Installation Instructions Cleaning If the interior surface of the cover glass or reflector surface becomes dirty, it is recommended that they be cleaned to maintain maximum output. The glass may be cleaned with any non-abrasive conventional glass cleaner. The reflector should be cleaned with a soft cloth using soapy water or special reflector cleaners. To prevent gaskets from sticking at sealing surfaces, it is recommended that a petroleum jelly be lightly applied to gaskets when replacing any of the access covers. Best results are achieved when one application is wiped dry (to clean the gasket surface) and a second application remains wet. Repair Parts List Item Qty Description Part No. 1 1 fixture shell assembly contact factory 2 1 glass cover 4602400 3 1 glass cover gasket 5002800 4 1 glass retaining frame 2753991 5 2 1/2-13 x 1-3/4 inch hex cap screw 6033500 6 2 1/2 inch split lockwasher 6311900 7 1 port gasket 5003000 8 1 right arm assembly 1092080 9 1 ballast assembly contact factory 10 2 1/2-20 x 1 inch hex cap screw 6038014 11 2 1/2 inch split lockwasher 6311900 12 contact factory ballast mounting strap contact factory 13 1 mast fitter cover contact factory 14 1 mast fitter contact factory 15 1 1/2 inch cord grip 4032800 16 1 socket housing assembly contact factory 17 1 left arm assembly 1092081 18 1 lamp retainer assembly contact factory Phoenix Lighting 8711 West Port Avenue Milwaukee, WI 53224 USA Phone: +1 414.973.3300 Toll Free: 800.438.1214 Fax: +1 414.973.3210 www.phoenixlighting.com IC Installation Instructions Repair Parts 1 2 3 5 6 4 13 8 7 17 16 10 11 9 14 18 12 15 Product design and specifications are subject to change without notice. N5610609C 08.08.16 Phoenix Lighting 8711 West Port Avenue Milwaukee, WI 53224 USA Phone: +1 414.973.3300 Toll Free: 800.438.1214 Fax: +1 414.973.3210 www.phoenixlighting.com