(DSM) study - Ethiopian Energy Authority

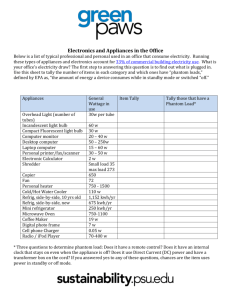

advertisement