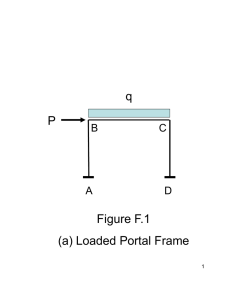

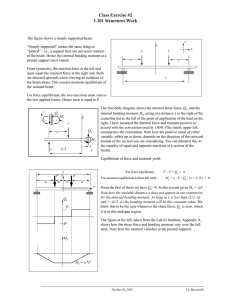

Structural design

advertisement