Reverse Recovery Time (TRR)

advertisement

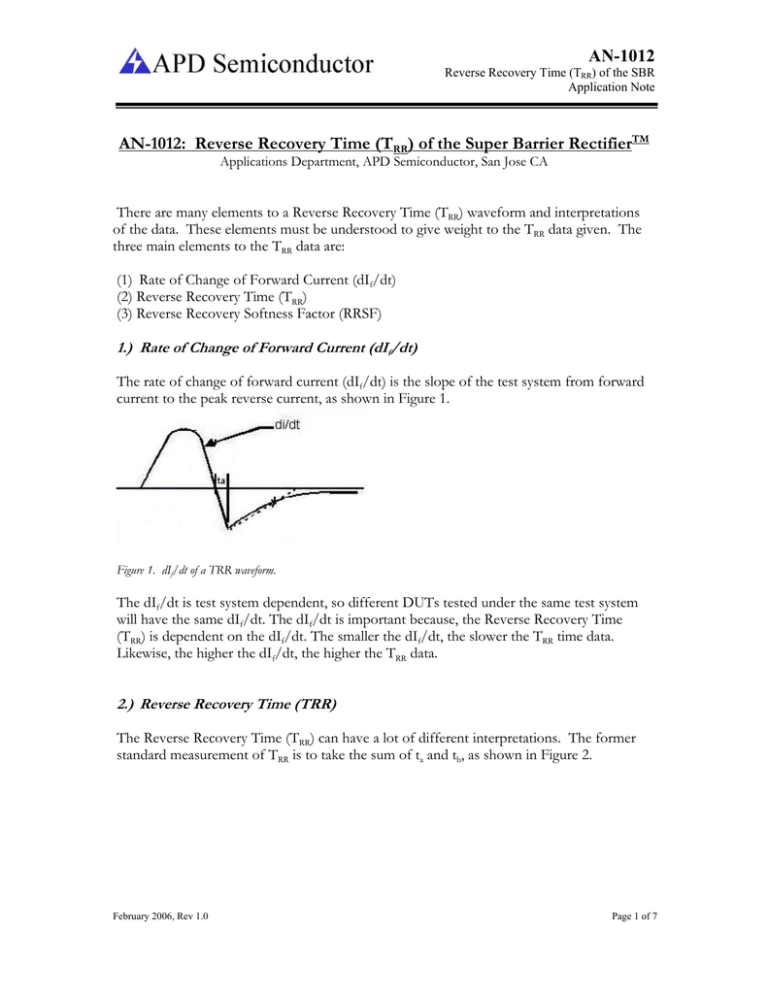

AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note AN-1012: Reverse Recovery Time (TRR) of the Super Barrier RectifierTM Applications Department, APD Semiconductor, San Jose CA There are many elements to a Reverse Recovery Time (TRR) waveform and interpretations of the data. These elements must be understood to give weight to the TRR data given. The three main elements to the TRR data are: (1) Rate of Change of Forward Current (dIf/dt) (2) Reverse Recovery Time (TRR) (3) Reverse Recovery Softness Factor (RRSF) 1.) Rate of Change of Forward Current (dIf/dt) The rate of change of forward current (dIf/dt) is the slope of the test system from forward current to the peak reverse current, as shown in Figure 1. Figure 1. dIf/dt of a TRR waveform. The dIf/dt is test system dependent, so different DUTs tested under the same test system will have the same dIf/dt. The dIf/dt is important because, the Reverse Recovery Time (TRR) is dependent on the dIf/dt. The smaller the dIf/dt, the slower the TRR time data. Likewise, the higher the dIf/dt, the higher the TRR data. 2.) Reverse Recovery Time (TRR) The Reverse Recovery Time (TRR) can have a lot of different interpretations. The former standard measurement of TRR is to take the sum of ta and tb, as shown in Figure 2. February 2006, Rev 1.0 Page 1 of 7 AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note Figure 2. Standard TRR For SBR devices, such method cannot be used because of the soft recovery characteristics. Instead, as defined by JEDEC, a more precise method of measuring TRR with a soft recovery is shown in Figure 4 where a line is drawn from IRM to 0.25 IRM. Because of this soft recovery profile, most automated test equipment that uses the former standard way to measure TRR will measure the SBR TRR 5-10nS higher than the “real” TRR as defined by JEDEC. Figure 3. JEDEC Soft Recovery Method of TRR 3.) Reverse Recovery Softness Factor (RRSF) The Reverse Recovery Softness Factor (RRSF) is a new parameter introduced by JEDEC to better define the characteristics of soft switching. The RRSF is a defined as the absolute value in ratio of dIf/dt slope in the ta region divided by the greatest magnitude of dIR/dt slope in the tb region. An example of RRSF is shown below in Figure 4. February 2006, Rev 1.0 Page 2 of 7 AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note Figure 4. RRSF Measurement This is important to reduce EMI and large voltage spikes in the system that is cause by the product of stray inductance and a fast dir/dt. So, it is not only important to have a fast recovery, but one that is also a soft recovery. An ideal fast soft recovery is when RRSF is equal or close to 1. An abrupt recovery occurs when the RRSF is less than 0.5. This parameter was taken from the latest JEDEC 282 standard. Applications defining Reverse Recovery Time (TRR): A.) TRR Comparison of SBR Technology versus Fast Recovery Diode (FRED) Performance Below is a simplified circuit of a typical flyback power supply used in an application like a laptop power supply/charger. (Flyback Converter) Standard DC Voltage Output Output Rectifying Diode Figure 5. Schematic of typical flyback power supply February 2006, Rev 1.0 Page 3 of 7 AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note In such an application, the forward voltage (Vf) of the diode constitutes for the majority of the power loss through the diode. The power loss from the switching is very minimal, as long as the TRR is faster than 25nS at 25C. The more important key parameter is the softness of the recovery, or RRSF. If the recovery is abrupt and has a violent snap-back, this may cause potential problems from ringing and other oscillations in a practical application circuit. The summary table below is the TRR results from an enclosed laptop power supply application comparing the SBR20200 versus an Onsemi 20ETF02 Fast Recovery Diode (FRED) with the key parameters. Product di/dt TRR RRSF SBR20200 80A/uS 50nS .60 Onsemi 20ETF02 (FRED) 80A/uS 75nS .52 Table 1. SBR vs. FRED TRR in a laptop power supply Vf@ 10A .81V 1.1V Ambient Temp, Ta 80 80 Efficiency 90.48% 89.70% From the summary table, it can be seen that with a dIf/dt of 80A/uS and switching at 1A of current, the TRR of the SBR20200 is 50% faster than the Onsemi Fast Recovery Diode with a RRSF that is closer to 1. The Onsemi Fast Recovery diode has a much higher Irrm which can possibly cause an undesired reverse voltage peak that can exceed the breakdown voltage of the device. The correct measurement of TRR and the parameters are shown graphically in Figure 6. Figure 6. SBR and BYQ28E TRR Waveforms The typical forward voltage (Vf) for the Onsemi 20ETF02 Fast Recovery Diode is 1.1V at 10A. The SBR20200 has a Vf typical value of 0.81V at 10A. When compared on a power loss and efficiency basis, the power loss of the SBR20200 will be much less, thus causing the efficiency of the overall power supply efficiency to be 0.78% higher than the Fast Recovery Diode. February 2006, Rev 1.0 Page 4 of 7 AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note B.) TRR Comparison of SBR Technology versus Schottky Performance The reverse recovery time (TRR) and the reverse recovery softness factor (RRSF) are very important elements in high frequency applications like the energy recovery circuit in plasma television displays (PDP). The operating frequency of this type of circuit is in the range of 100-200 kHz. Therefore, it is critical that the recovery of the high energy recovery diodes is fast and soft. Otherwise, such ringing can cause spikes and excessive EMI that will cause detrimental effects on the performance of the circuit. Figure 7 shows a simplified version of a high energy recovery circuit in a typical Plasma Television display. Vs = 180V p-p (100-200 kHz) High Energy Recovery Diodes High Energy Recovery Diodes Figure 7. High Energy Recovery Circuit from Plasma (PDP) Television To duplicate the same type of switching, a very fast test pulse was used to compare the SBR20300 to the MBR40250 Schottky device. Below is a summary table of the TRR data taken from a very fast 400A/uS TRR tester. Table 2. TRR comparison of SBR versus Schottky Product dif/dt TRR SBR20300 Onsemi MBR40250 400A/uS 400A/uS 12nS 10nS RRSF Recovery Type Ambient Temp, Ta 0.9 Soft Recovery 25 0.4 Abrupt Recovery 25 From the results, the SBR20300 has a RRSF that is twice greater than the MBR40250 Schottky device. The reverse recovery waveform of the SBR20300 is very closely identical to the “ideal” fast soft switching waveform. Figure 8 shows the fast soft SBR reverse recovery waveform. February 2006, Rev 1.0 Page 5 of 7 AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note Figure 8. Onsemi MBR40250 Schottky Abrupt Recovery TRR Waveform As shown in Figure 7, the reverse recovery of the Schottky diode is abrupt with excessive ringing that may cause EMI disruptions. The sharp slope of the recovery, dIf/dt, may cause a large unwanted spike from stray inductances. These dangerous voltage spikes may potential peak pass the breakdown voltage, thus damaging or failing the diodes. Figure 9. Onsemi MBR40250 Schottky Abrupt Recovery TRR Waveform Summary: As demonstrated from this paper, it is not only important to have a fast recovery, but one that is also a soft recovery. When compared in real world applications, it is critical that the diodes have a fast recovery time along with having the least amount of ringing, measured by a RRSF value closest to 1. The physics of the SBR technology (see apps notes, Reverse Recovery Time (TRR) in Super Barrier Rectifier) lends itself to have these switching characteristics and makes the SBR perfectly suited for today’s applications. February 2006, Rev 1.0 Page 6 of 7 AN-1012 Reverse Recovery Time (TRR) of the SBR Application Note Information furnished is believed to be accurate and reliable. However, APD Semiconductor assumes no responsibility for the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of APD Semiconductor. Specifications mentioned in this publication are subject to change without notice. This publication superseded and replaces all information previously supplied. APD SEMICONDUCTOR products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the APD SEMICONDUCTOR product could create a situation where personal injury or death may occur. APD logo and SBR are registered trademarks of APD Semiconductor. All other names are the property of their perspective owners. © 2006 APD Semiconductor – All rights reserved www.apdsemi.com February 2006, Rev 1.0 Page 7 of 7