Product Specifications

advertisement

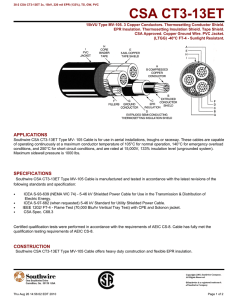

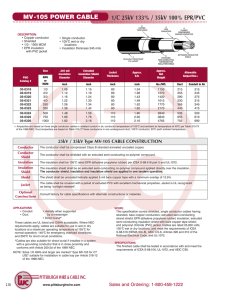

36-26 21XW 1c, 35kV, 420 mil XLP (133%), WS, PVC Simpull® 21XW 35kVU Type MV-90. Copper Conductor. Thermosetting Conductor and Insulation Shield. XLP Insulation. Copper Wire Shield. Simpull® PVC Jacket. RoHS APPLICATIONS Southwire SIMpull 21XW Type MV-90 Cable is for use in aerial, direct burial, conduit, and underground duct installations as permitted by the National Electrical Code. These cables are capable of operating continuously at a conductor temperature not in excess of 90°C for normal operation, 130°C for emergency overload conditions, and 250°C for short circuit conditions, and are rated at 35,000V, 133% (ungrounded system). Maximum sidewall pressure is 1000 lbs. This cable can be installed without the need for pulling lubricant. SPECIFICATIONS Southwire SIMpull 21XW Type MV-90 Cable is manufactured and tested in accordance with the latest revisions of the following standards and specification: UL 1072 • ICEA S-93-639 (NEMA WC 74) • AEIC CS-8 • RoHS • CONSTRUCTION Southwire SIMpull 21XW Type MV-90 Cable offers our patented SIM (Slikqwik ® Infused Membrane) Technology ® for easier pulling, flexible, easy bending insulation, easy cable preparation, fast stripping thermosetting insulation shield, 90°C continuous operating temperature, 100% shield coverage, and it is triple extruded. Cable is sunlight resistant, suitable for direct burial. SOLONON™ low smoke, non halogen polyolefin jackets are available upon request. 21XW 1c, 35kV, 420mil XLP(133%), WS, PVC Product Code Size Conductor Diameter 0.420" (10.67mm) Insulation Diameter Extruded Insulation Shield Diameter Min. Point Jacket Thickness Approximate Overall Diameter Approximate Net Weight Allowable Ampacities+ AWG or kcmil inch* mm inch** mm inch*** mm inch mm inch mm lb./Mft. kg/km Duct Conduit In Air 21-XW-010 1/0 0.362 9.19 1.262 32.1 1.382 35.1 0.08 2.03 1.605 40.8 1126 1675 200 195 21-XW-020 2/0 0.406 10.3 1.306 33.2 1.426 36.2 0.08 2.03 1.649 41.9 1247 1857 230 225 21-XW-030 3/0 0.456 11.6 1.356 34.4 1.476 37.5 0.08 2.03 1.699 43.2 1394 2074 260 260 21-XW-040 4/0 0.512 13 1.412 35.9 1.532 38.9 0.11 2.79 1.755 44.6 1575 2344 295 295 21-XW-250 250 0.558 14.2 1.468 37.3 1.588 40.3 0.11 2.79 1.811 46.0 1742 2592 325 330 21-XW-350 350 0.661 16.8 1.571 39.9 1.731 44.0 0.11 2.79 2.014 51.2 2303 3427 390 395 21-XW-500 500 0.789 20 1.699 43.2 1.859 47.2 0.11 2.79 2.142 54.4 2880 4285 465 480 21-XW-750 750 0.968 24.6 1.888 48.0 2.048 52.0 0.11 2.79 2.331 59.2 3825 5692 565 585 21-XW-100 1000 1.117 28.4 2.052 52.1 2.212 56.2 0.11 2.79 2.495 63.4 4756 7077 640 675 *Nominal diameter per ASTM Standards. **±0.030" ***±0.050" +Ampacities are based on the NEC, 2011 Edition. Duct ampacities are based on Table 310.77 three conductors in one underground duct, 90°C conductor, 20°C earth ambient temperature. Conduit in air ampacities are based on Table 310.73 three cables in isolated conduit in air, 90°C conductor, 40°C ambient temperature. Scope: This specification covers single conductor XLP (cross-linked polyethylene) insulated, shielded, thermoplastic jacketed power cable for use in aerial, direct burial, conduit, and underground duct installations. This cable is capable of operating continuously at a conductor temperature not in excess of 90°C for normal operation, 130°C for emergency overload conditions, and 250°C for short circuit conditions, andA is rated at 35,000V, 133% insulation level (ungrounded system). Standards: The following standards shall form a part of this specification - UL Standard 1072 for Medium Voltage Power Cable and ICEA S-93-639 (NEMA WC 74) 5-46 kV Shielded Power Cable for Use in the Transmission & Distribution of Electric Energy. Conductor: The conductor shall be Class B compressed soft or annealed copper in accordance with ASTM Specs B3 and B8 and ICEA Part 2, Section 2.1 and 2.5. Conductor Shield: The conductor shall be shielded with an extruded semi-conducting thermosetting polymeric layer over the conductor, applied in tandem with and firmly bonded to the insulation. Insulation: The insulation shall be XLP (cross-linked polyethylene) meeting the requirements of the referenced standards. The nominal thickness shall be 0.420". Insulation Shield: The insulation shall be shielded with an extruded layer of semi-conducting thermosetting material which shall be identified as being semi-conducting. Over this layer shall be a helically applied wire shield. Jacket: The cable shall be provided with a jacket of black sunlight resistant PVC conforming to the requirements specified for polyvinyl chloride jackets in ICEA. The average thickness shall be in accordance with Table 7-3 of ICEA. Optional SOLONON low smoke, non halogen polyolefin jackets are available upon request. Identification: Cable shall be identified by surface printing on the jacket. Tests: Qualification tests shall be conducted in accordance with the requirements of AEIC.