B100-95023 OEM Product Guide - Kriz

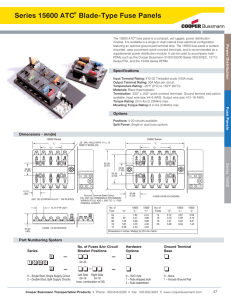

advertisement