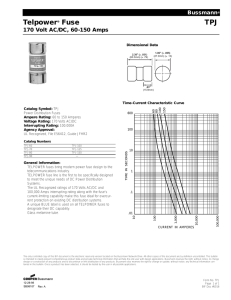

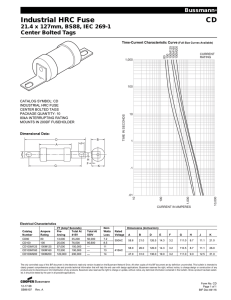

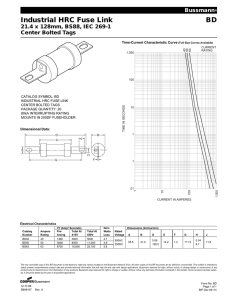

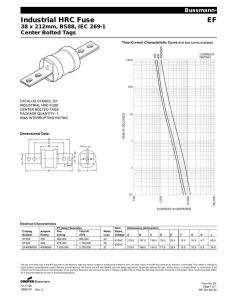

Cooper Bussmann

advertisement