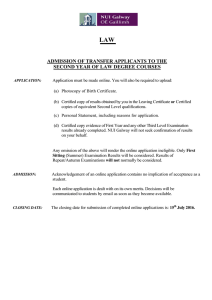

guide information for canadian certified equipment

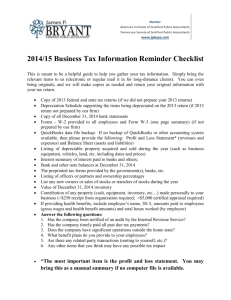

advertisement