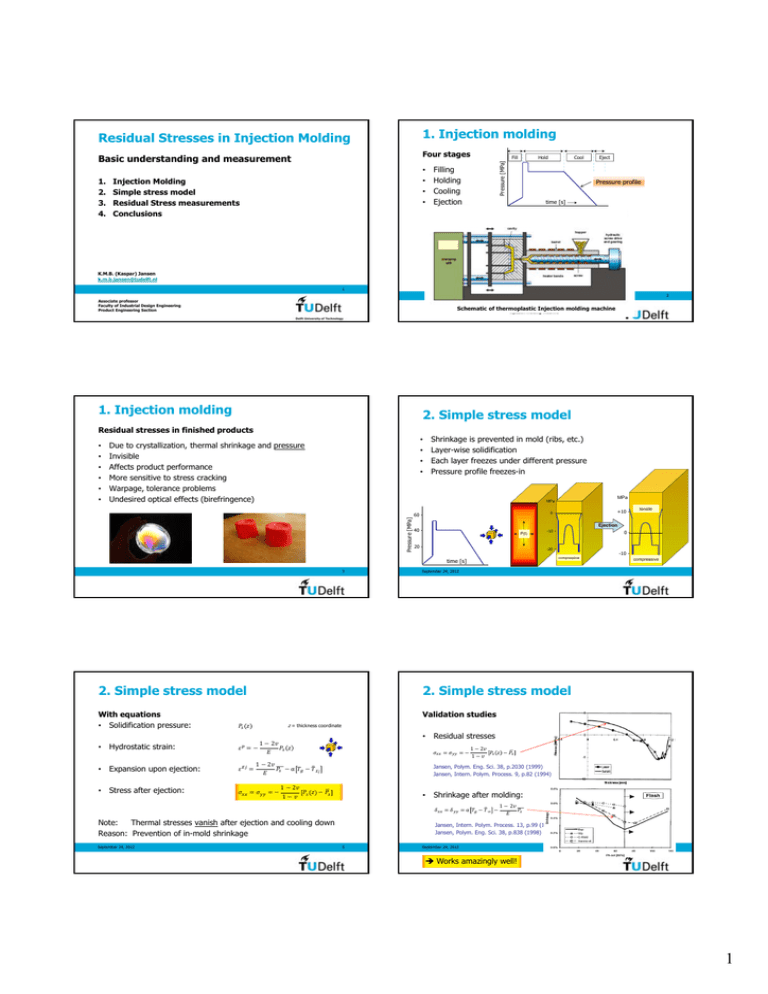

Residual Stresses in Injection Molding 1. Injection molding 1

advertisement

1. Injection molding Residual Stresses in Injection Molding Four stages 1. 2. 3. 4. • • • • Injection Molding Simple stress model Residual Stress measurements Conclusions Fill Hold Cool Pressure [MPa] Basic understanding and measurement Filling Holding Cooling Ejection Eject Pressure profile time [s] K.M.B. (Kaspar) Jansen k.m.b.jansen@tudelft.nl 1 2 Associate professor Faculty of Industrial Design Engineering Product Engineering Section Schematic of thermoplastic Injection molding machine 1. Injection molding 2. Simple stress model Residual stresses in finished products • • • • • • • • • • Due to crystallization, thermal shrinkage and pressure Invisible Affects product performance More sensitive to stress cracking Warpage, tolerance problems Undesired optical effects (birefringence) Shrinkage is prevented in mold (ribs, etc.) Layer-wise solidification Each layer freezes under different pressure Pressure profile freezes-in Pressure [MPa] 2. Simple stress model 40 - P(t) 20 - -10 - • Stress after ejection: -10 compressive compressive September 24, 2012 Validation studies z = thickness coordinate 1 1 • Residual stresses 2 2 1 2 1 Jansen, Polym. Eng. Sci. 38, p.2030 (1999) Jansen, Intern. Polym. Process. 9, p.82 (1994) α 1 2 1 • Shrinkage after molding: α Note: Thermal stresses vanish after ejection and cooling down Reason: Prevention of in-mold shrinkage September 24, 2012 0- -20 - 2. Simple stress model With equations • Solidification pressure: • Expansion upon ejection: tensile Ejection time [s] 3 +10 - 0- 60 - • Hydrostatic strain: MPa MPa 1 2 ∞ Jansen, Intern. Polym. Process. 13, p.99 (1998) Jansen, Polym. Eng. Sci. 38, p.838 (1998) 5 September 24, 2012 6 Works amazingly well! 1 2. Simple stress model 2. Simple stress model Warpage due to uneven cooling Warpage due to uneven cooling • Injection Molded plate - Low hold pressures warp to hot side; high to cold side curvature 12 1 2 • Injection molded corner product tensile Hot Cold • / Intern. Polym. Process. 13, p.417 (1998) / compressive - Model predicts correct trends, but - underpredicts warpage by factor 2 Intern. Polym. Process. 13, p.417 (1998) Fine tuning of angle with Ph and ΔTw possible! September 24, 2012 7 September 24, 2012 2. Conclusions about stress model • Model is simple and gives a clear understanding • For simple geometries model works as good as simulation tools • Frozen-in cavity pressure profile determines stresses and shrinkage (not the thermal stresses!) • Surface layer and core are in tension; sub-surface layer in compression 3. Residual Stress Measurements Overview of methods • MPa • +10 - tensile 0- • Shrinkage and warpage follow from same model • Shrinkage and warpage can be tuned with holding pressure and mold temperatures 8 • • -10 compressive September 24, 2012 9 birefringence • Sensitive to both orientation and stress (PC, PMMA more for stress, PS more for orientation) • Stresses relieve near cutting surface not useful Layer Removal • Elaborative • Stress relaxation due to milling heat Hole drilling method • Only “average” stress level possible not useful Environmental Stress Cracking test • Only “average” stress level possible not useful September 24, 2012 10 3. Residual Stress Measurements 3. Residual Stress Measurements Outline of Layer Removal test Example of Layer Removal method 1. Mill top layer (50-200 µm) 2. Residual stresses are no longer balanced zr 3. Release from vacuum rig h(x) 4. Measure curvature κ Back-Calculate stress distribution 6 1 4 2 Treuting and Read, J Appl Phys 22, p.130 (1951) September 24, 2012 11 deflection profiles curvature profile September 24, 2012 stress distribution 12 Hastenberg et al., Pol Eng Sci 32, p.506 (1992) Zoetelief et al., Pol Eng Sci 36, p.1886 (1996) 2 3. Residual Stress Measurements 3. Residual Stress Measurements Layer Removal method: Problems and solutions • Stress relaxation after production Why Excimer laser ablation • KrF has high energy photons (3.5-8 eV) Store in freezer before use • Melting and stress release during milling 0 C-O 3.6 C-C bond strength 6.2 10 eV Use sharp tool and speed < 1500 rpm • Creep effects after milling KrF excimer laser Due to flattening in test rig! Wait 10 min (96% recovery) Nd:YAG laser CO2 laser • Resolution: milling <0.1 mm is difficult Will give problems near surface curvatures data • Data analyis of κ(zr) curve: differentiation error Polyfit 4 • direct bond breaking; no melting! • Pulsed operation: shockwaves remove debris • Ultra thin layers possible (< 1 µm) Polyfit 6 Do not fit a polynomial over all data points but use a sliding window fit September 24, 2012 13 1 September 24, 2012 0.5 Jansen, Polym. Eng. Sci. 38, p.2030 (1999) 14 Note: only works well with Polycarbonate 0 3. Residual Stress Measurements 3. Residual Stress Measurements Comparison with model predictions Comparison between standard milling and laser ablation • Stress levels of 5 MPa tensile to -10 MPa compression • Typical error margin: ± 0.5 MPa • Good consistency; differences only near surface (200 µm) • 500-1000 rpm milling similar to laser ablation • 2000 rpm not OK: surface stresses changed High viscosity; high Ph - small surface stress compressive sub-surface layer good match with model High viscosity; low Ph - large compressive surface stress almost quenching like stress profile reasonable match with model Low viscosity; high Ph September 24, 2012 - large tensile surface stress - “inversion” of stress profile 2012 -September low24,stresses in core - good match with model 15 16 4. Conclusions MPa • Stresses in injection molding are mainly due to frozenin pressure variations • Warpage is due to asymmetric stress distribution • Stress profile, warpage and shrinkage can be estimated is a relatively simple way tensile +10 - 0- -10 compressive • Layer Removal method is suitable to measure stress profiles but carefulness is required • Depending on viscosity and holding pressure the frozen-in stress profiles can be tuned from compressive to tensile! September 24, 2012 ‐1 ‐0.5 0 0.5 1 17 3