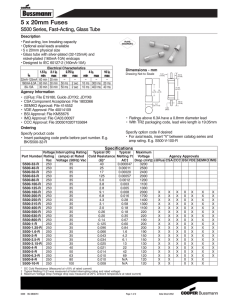

HIGH SPEED FUSES Applications Guide

advertisement