MDA Journey to Mission Success March 3, 2008 Randolph Stone

advertisement

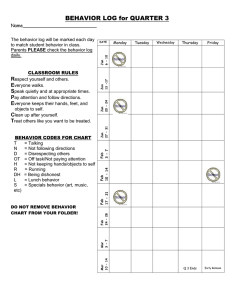

MDA Journey to Mission Success March 3, 2008 Randolph Stone Director-Quality, Safety & Mission Assurance Missile Defense Agency Approved for Public Release 08-MDA-3305 (29 FEB 08) Agenda • Reasons for Quality • Ground-Based Midcourse Defense System (GMD) - History - Major Problems - Impact - Systems Engineering Improvements - Cradle-to-Grave Approach - Lessons Learned - GM Successes • Kinetic Energy Interceptor (KI) - Award Fee - Knowledge Points - MDA Assurance Provisions Approved for Public Release 08-MDA-3305 (29 FEB 08) 2 Reasons for Quality Approved for Public Release 08-MDA-3305 (29 FEB 08) 3 Great Prophet 2 Approved for Public Release 08-MDA-3305 (29 FEB 08) 4 Taepo-Dong-1 Approved for Public Release 08-MDA-3305 (29 FEB 08) 5 Ground-Based Midcourse Defense Sea-Based X Band Radar Approved for Public Release 08-MDA-3305 (29 FEB 08) Ground-Based Interceptor Emplacement 6 GM History • Program Description - National Missile Defense (NMD) Program began in 1996 under BMDO program - Realigned as the Ground-Based Midcourse Defense System (GMD) under MDA in 2002 – A key component of the nation’s multi-layered Ballistic Missile Defense System – The GMD includes sensors, command systems, fire control systems, and Ground Based Interceptors (GBI) - In spiral development – 3 phases simultaneously – Design and Development, Operational, Support Approved for Public Release 08-MDA-3305 (29 FEB 08) 7 GM Major Problems • Directed to produce and field while still in the development & test phase - Rapid deployment – enormous pressure on PD to meet program schedule - Led to high-risk decisions regarding schedule, product quality, and program cost • Acquisition reform – removed Mil Stds, relied on industry “best practices” - Traceability and sub-contractor flow-down - High percentage of issues developed with sub-contractors – Unauthorized changes, poor communication, lack of prime oversight Approved for Public Release 08-MDA-3305 (29 FEB 08) 8 GM Major Problems • EKV team focused on technical aspects of design instead of producability of end item - No production control, constant engineering changes - Schedule slips, nonconformances and quality escapes • Commercial off the Shelf (COTS) - No formal qualification in design and development for COTS flight computer - Computer reset – Root Cause unknown for over a year - COTS became logistically expensive; would have been easier to build Approved for Public Release 08-MDA-3305 (29 FEB 08) “Why Not Not Fly?” Fly?” “Why 9 Impacts • GM experienced a string of failures between 2000 and 2005 - “Interceptor production slowed as the year progressed primarily because technical problems were discovered…these problems were traced back to poor oversight of subcontractors, too few qualification tests, and other quality assurance issues.” GAO Report, March 2006 GMD Test Failures Approved for Public Release 08-MDA-3305 (29 FEB 08) 10 IFT-13c Example Countdown automatically aborted due to a built-in-test anomaly that detected excessive drops of Electronic Control Unit (ECU) messages. Cause: Roundoff error propagation caused a timing mismatch. When the SIGI and FC clocks crossover, timing jitter occurs and occasionally data is sent to the ECU when it is busy, resulting in no responses. To avoid a recurrence, need to raise the tolerance level for missed messages -changing one line of computer software code. IFT-13c – December 2004 Approved for Public Release 08-MDA-3305 (29 FEB 08) 11 IFT-14 Example One of the last steps in the launch sequence is to open the silo doors and retract the horizontal stabilizers that hold the missile in place. Sensors indicated that one of the three lateral support group mechanisms had not retracted, causing the missile to abort launch Cause: Corrosion and dissimilar metals (galvanic corrosion) caused the failure. One mechanism failed to latch due to wrong crush blocks Approved for Public Release 08-MDA-3305 (29 FEB 08) IFT-14 – February 2005 These Tests Tests Were Were Wake-Up Wake-Up Calls Calls These 12 MDA Systems Engineering Improvements • MDA began to take a hard look at its quality practices - Uncovered test and development problems through audits of EKV and OBV – Example: “Functional performance test not consistently conducted during environmental testing” - Commissioned 2005 Independent Review Team (IRT) study – Dr. William Graham, Dr. Bill Ballhaus, MG (R) Bill Nance – Confirmed not enough Ground Testing, Deficiency in performance verification and systems engineering – Recommended: —Strengthen systems engineering —Hold contractors accountable Approved for Public Release 08-MDA-3305 (29 FEB 08) Complete Halttoto Flight Tests These Tests Were Wake-Up Calls Complete Halt Flight Tests 13 MDA Systems Engineering Improvements • MDA began to use a back-to-basics systems engineering approach - Mission Readiness Task Force (MRTF) – Improved readiness through systematic proven processes — System Verification, Critical Design Reviews, System Function Reviews – Improved test rigor & gained confidence in testing procedures - Restructured Contracts & Award Fee Processes – “Paid for Failures” - Program Management began supporting Quality – Strategic Improvements: Infusing quality in contract, empowering Mission Assurance Organization – Tactical Improvements: Test Like You Fly, Dedicated Ground Test Missiles, End-to-End Testing Approved for Public Release 08-MDA-3305 (29 FEB 08) Should It Fly?”Calls These“Why Tests Were Wake-Up 14 MDA Cradle-to-Grave Approach System Functional Review Software Specification Review Continuous Activities -Evaluate human interfaces, controls, displays -S/W safety issues & Audits - Mission Assurance Reps (MARs) on-site Preliminary Design Review Critical Design Review -Subsystem and functional issues Test Design Reviews (TDR) (Gov. & Industry sites) -Voting Member - Mission Assurance Audits Mission Operations Review -Design Performance -Producibility and risk areas System Verification Review Joint Services IM Munition WG Interface Control WG - Award Fee Boards -Interface integration activities --Independent Readiness Review Teams -Ensures integration and compatibility --Mission Readiness Reviews -Resolve technical issues Acquisition Strategy Panel Design Certificate Review -MAP, PMAP on Contract Safety Hazards Assessment -Mission Assurance Criteria Development Test for Risk Reduction -Award Fee Requirements -FMECA, Sneak Analysis Interoperability and/or Integration Test AF TEST LIKE YOU FLY KV DV KI SN AL IP BC AB TH GM SN LAUNCH ACTIVITIES AF INTEGRATED TEST AND EVALUATION PRODUCTION DESIGN AND DEVELOPMENT CONTRACT AF BMDS System Safety Working Group System Requirements Review AF LAUNCH TC Mission Assurance Audits Peer Reviews -Surface correctable problems early -Identify risk -Ensure Best Practices AF Award Fee Board Contract Award Fee Review - Annually Voting Member Approved for Public Release 08-MDA-3305MDA (29Programs FEB 08) -Average 6 MA audits annually Pre-Shipment Reviews Pedigree Review Flight Readiness Review BMDS Parts & Materials Control Board (PMCB) Flight Operations Review -Voting Member -Element PMP Control Boards (PMPCB) Pre-Flight Readiness Review -Voting Member Launch Readiness Review Tests and Inspections Mission Readiness Review -FOD Prevention, NDT, Acceptance Inspection -4 to 6 weeks Prior to launch -Mandatory Gov. Inspections (MGIs) -Voting Member Failure Review Board BMDS Safety Officers (BSOs) Material Review Board -6 BSOs at Colo. Spgs. Supplier Road Maps MDA Executive Level Flight Test Reviews Stakeholder Initiatives -Series of 4 Flight test reviews leading to launch Integrated Product Teams (IPT) -Voting Member 15 FTG-02 Approved for Public Release 08-MDA-3305 (29 FEB 08) 16 GM Lessons Learned • Good Quality practices from the beginning will benefit in the long run Intercept • It is hard to change once the program has started - Hard to change culture - Costly to change design NO INTERCEPTOR FAILURES These Tests Were Wake-Up SINCE Calls 2005 17/17 Successful Intercepts Approved for Public Release 08-MDA-3305 (29 FEB 08) 17 KEI – Kinetic Energy Interceptor KEI Launcher • Mission Assurance Philosophy Built-In - Contracts & Program Culture • In Design and Development Phase - 1st and 2nd stage static fire tests - KEI Fire Control and Communication • First Flight Test – FY09 KEI Command Center Kinetic Energy Interceptor Approved for Public Release 08-MDA-3305 (29 FEB 08) MDA’s New Program BuiltWake-Up with Mission Assurance These Tests Were Calls 18 Kinetic Energy Interceptor • Contract integrated with high-level of Mission Assurance - Program Integration with Mission Assurance Government Personnel – Matrixed People from MA Organization – KIQ: QS Direct Line - Contractors held fully accountable for mission success - Real-time incorporation of lessons learned – Not sitting in a database – Experience from across BMDS utilized - Early Integration Product Team (IPT) Approach with all suppliers • Contract Structured with Award Fees Government Involvement from theCalls Beginning These Tests Were Wake-Up Approved for Public Release 08-MDA-3305 (29 FEB 08) 19 KEI Award Fee Boards • Unique Award Fee Criteria – Based on Knowledge Points and Mission Assurance Mission Assurance Actions and Metrics - Schedule comes 2nd • Find problems and identify issues early and often • Increased scrutiny on performance - No longer “paid for failures” • Set of steps to determine accurate award fee - Performance Monitor – Including Mission Assurance Personnel - Award Fee Review Board – Including Mission Assurance Personnel - Award Fee Advisory Board – Including Mission Assurance Management - Fee Determining Official – MDA Director Incentives to “Get It Right the First Time” These Tests Were Wake-Up Calls Approved for Public Release 08-MDA-3305 (29 FEB 08) 20 Award Fee Criteria – Knowledge Points Kinetic Energy Booster • MDA Director’s Knowledge points - Preplanned event that provides objective evidence for key decision making - Each added commitment hinges on knowledge gained about critical risks • Completed KEI Knowledge Points - Demonstrate ONIR Accuracy for Boost Phase Fire control (April 2006) - Successful 1st and 2nd stage static firings • Future Knowledge Points - Booster Flight Tests (2008) Approved for Public Release 08-MDA-3305 (29 FEB 08) 21 Award Fee Criteria – MDA Assurance Provisions MAP Requirements Sections MAP Rev A 3.1 Management 3.2 Design and Development 3.3 Software and Firmware 3.4 Technical and Mission Assurance Reviews 3.5 Reliability, Maintainability, Availability 3.6 Parts and Materials Control Program 3.7 Integrated Test and Evaluation Program 3.8 Test, Measuring, and Diagnostic Equipment and Standards 3.9 Interface Management 3.10 Configuration Management 3.11 Control of Nonconforming Items and Materials 3.12 Fabrication and Quality 3.13 Supplier Management 3.14 Safety 160These Pages Tests – Over 1800Wake-Up “Shall” Statements Were Calls Approved for Public Release 08-MDA-3305 (29 FEB 08) 22 Mission Assurance Toolbox CEO Days Supplier Roadmaps Pedigree Reviews Lessons Learned Mission Assurance And Safety Audits MDA Assurance Provisions MDA Pedigree Review Certification Government / Industry Partnerships Industry Stakeholder Initiatives MDA Mission Assurance Representatives MDA Advisories Approved for Public Release 08-MDA-3305 (29 FEB 08) MDA Parts, Materials And Processes Plan Memorandum Of Agreement (MOA) DCMA QA Letter of Delegation QSMA Unfettered Access 23 FTG-03a Approved for Public Release 08-MDA-3305 (29 FEB 08) 24 Questions? Approved for Public Release 08-MDA-3305 (29 FEB 08) 25