CBA 390 (H/R) Chapter 5 Outline Design of Goods and Services

advertisement

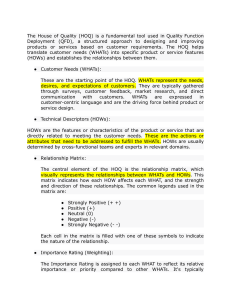

CBA 390 (H/R) Chapter 5 Outline Design of Goods and Services I. GENERATION OF NEW PRODUCTS A. Opportunities 1. Economic Change 2. Sociological and demographic change 3. Technological change 4. Political/legal change 5. Changes in a. market practice b. professional standards c. suppliers and distributors B. Product Strategy Options 1. Product differentiation 2. Low cost 3. Rapid response C. Product Life Cycle 1. Introduction - (R & D), process modification, supplier development 2. Growth – stabilize design, effective forecasting, enhanced capacity 3. Maturity – competitors established, cost control, paring down product line 4. Decline – plan to terminate offering D. Product Development Stages 1. Idea generation 2. Assessment of firm’s ability to carry out 3. Customer requirements 4. Functional specifications 5. Product specifications 6. Design review 7. Test market 8. Introduction to market 9. Evaluation 10. Success rate = 1/1750 ideas II. PRODUCT-BY-VALUE ANALYSIS A. Lists products in descending order of their individual dollar contribution to the firm. B. Help management evaluate alternative strategies. III. QUALITY FUNCTION DEPLOYMENT A. Identify customer wants B. Identify how the goods/service will satisfy customer wants C. Relate customer wants to product hows D. Identify relationships between the firm’s hows E. Develop importance ratings F. Evaluate competing products IV. MANUFACTURABILITY AND VALUE ENGINEERING A. Benefits: 1. reduced complexity of products 2. additional standardization of products 3. improved functional aspects of product 4. improved job design and job safety 5. improved maintainability of the product 6. robust design V. ISSUES FOR PRODUCT DEVELOPMENT A. Robust design B. Time-based competition C Modular design D. Value analysis E. Environmentally friendly design (recycle, less energy, less harmful ingredients) VI. TIME-BASED COMPETITION A. Product life cycles are becoming shorter. Therefore, quickly developing a new product helps to obtain a competitive advantage VII. PRODUCT DOCUMENTS A. Engineering drawing 1. Shows dimensions, tolerances & materials 2. Shows codes for Group Technology B. Bill of Material 1. Lists components, quantities & where used 2. Shows product structure VIII. PRODUCT DOCUMENTS A. Assembly drawings B. Assembly chart C. Route sheet D. Work order IX. MAKE-OR-BUY DECISIONS A. Decide whether or not you want (or need) to produce an item B. May be able to purchase the item as a “standard item” from another manufacturer X. GROUP TECHNOLGY CHARACTERISTICS A. Parts grouped into families – Similar, more standardized parts B. Uses coding system – Describes processing & physical characteristics C. Part families produced in manufacturing cells – Mini assembly lines XI. GROUP TECHNOLOGY BENEFITS A. Improved product design B. Reduces purchases C. Reduced work-in process inventory D. Improved routing & machine loading E. Reduced setup & production times F. Simplified production planning & control G. Simplified maintenance