Finite Element Analysis in Stress Analysis of Elastic Solid Structures Chapter 4

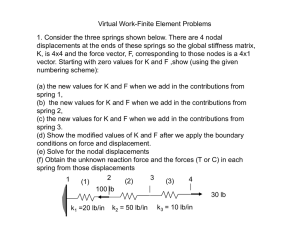

advertisement

San Jose State University

Department of Mechanical Engineering

ME 160 Introduction to Finite Element Method

Chapter 4

Finite Element Analysis in Stress

Analysis of Elastic Solid Structures

Instructor

Tai-Ran Hsu, Professor

Part 1

Introduction to

Fundamentals of Theory of Linear Elasticity

What defines elastic solids?

A solid deforms in response to external actions (e.g., forces, heat, etc.). The deformation is completely reversible – meaning the

solid returns to its original shape after the removal of the external actions.

Two Types of Elastic Solids

Type 1: Linear elasticity of materials:

This type of elasticity occurs to solids undergoing small deformations, such as springs that exhibit linear relationships

between the applied force (F) and the induced elongation (x) that can be represented by a mathematical formula as: F = kx

where k is a constant known as the rate or spring constant. Many metallic materials fall into the category of linear elastic solids

It can also be stated as a linear relationship between stress (σ) and strain (ε) in stretching or compressing a thin rod by

The expression: σ = Eε where E Is known as the elastic modulus or Young's modulus

Type 2: Nonlinear elasticity of materials:

This type of solids behaves as elastic materials as described above, but can exhibit large deformations, such as rubbers and polymers

The FE formulation presented in this course will be based on linear elasticity theory

Linear Elastic Behavior of Solids

Fundamental assumptions

(1) The material is treated as a continuous medium (or a continuum). In the words, the material is homogeneous with no

internal defects or voids of significant sizes

(2) The material is isotropic – meaning its properties are uniform in all directions

(3) The material has no memory

(4) The material exhibits the same properties in tension and compression

Definitions of stress and strain

Uniaxial elongation of a thin rod:

(1) Engineering strain (e):

It is defined with reference to the original shape of the solid. Mathematically it is expressed as:

= ΔL/L0 = L/L0 - 1

(2) True strain (ε):

It is measured on the basis of the immediate proceeding length of the rod sample.

Mathematically it is expressed as:

A0

L0

L

L L L L

LL

1 L 0 2 L 1 ......... L n

0

1

n

(3) Relationship between ε and e:

ΔL

F

(4) Engineering stress (S):

S

L

dL

n

L0 L

L0

L

ε = ℓn(1+e)

Insta tan eous load

P

Original cross sec tional area A0

(5) True stress (σ): σ = P/A

(6) Relationship between S and σ: σ = (1 + e) S

Stress-Strain Curves of Materials

Stretching of thin rods of most engineering materials will exhibit the stress vs. strain relations illustrated in the figure below:

Stresses

True

0

Engineering

Designations:

A’ = proportional limit

A = elastic limit

B = yield point

m =necking point

f = rupture point

S0 = Yield strength of material

Su = ultimate tensile strength of material

Strains

Typical elastic deformation of engineering materials:

(1)

(2)

(3)

(4)

(5)

Very small deformation with strain up to 0.1%

Straight linear relationship between the stress and strain, resulting in a constant stiffness of the .

The slope of line OA’ is called the Young’s modulus (E), representing the stiffness of the material

Completely recoverable strain (or deformation) after the applied load is removed

The yield stress (So) or σy is defined to be the interception of ϵoffset= 0.2% of the σ-ϵ curve. It is a measure of materials

exceeding the elastic limit, and undergoing plastic deformation (an irreversible deformation)

Physics of Deformable Solids subjected to External Forces

Original State:

2 Physical Consequences:

RESPONDES

To Allied

Foreces:

2 things will

happen:

after applied forces:

The Many Components of Displacements and Stresses:

(Element) Displacements:

{U}T: {Ux,Uy,Uz}

in a deformed solid

A small element

located at x,y,z:

See detailed definitions

on the next slide:

Induced Stress Components in Deformable Solids subjected to External Forces

Solid subjected to external forces:

Result in:

Because the forces applied to a general 3-D solid, the induced stresses are MULTI-directional designated by σαβ:

σ = magnitude, subscript α = the axis normal to the plane of action, subscript β = the direction the stress component points to

So, stress component σyy = stress component acting on the plane normal to the y-axis and pointing to the y-direction, whereas

stress component σxy = stress components acting on the face normal to the x-axis but points to the y-direction.

In theory, there are nine (9)

stress components

xx

everywhere

inside the solid: yx

zx

xy xz

yy yz

zy zz

But in reality there

are only six (6)

independent stress

components with:

σxy =σyx , σxz =σzx ,

σyz = σzx

xx

SYM

xy xz

yy yz

zz

1

For FE formulation:

2

3

σ1=σxx,σ2=σyy,,

(4.1)

σ3=σzz, σ4=σxy,

4

σ5=σyz, σ6=σxz

5

6

Induced Stresses in Deformable Solids subjected to External Forces – Cont’d

z

Stress components with same subscripts such as:

σxx, σyy, σzz are called NORMAL stress components,

with unit: psi, or Pascal (Pa) = N/m2 .

σzz

D

σzy

σzx

A

σxz

C

B

σyx

σxy

σyz

G

σxx

E

Stress components with different subscripts such

as: σxy, σxz, σyx, σyz, σzx, σzy are SHEARING stress

components. Shear stress has the unit of change of

y angle from the original right angle to the angle with

the stress, i.e (π/2) – θ. The unit is thus “angle

change” in radians (rad)

σyy

F

x

Effects of Normal and Shear Stresses to Solid Deformation

y

Normal stresses change size:

contraction

-σxx

σxx

Exist NORMAL

to surfaces

Shear stresses change shape:

y

Exist on the SURFACES

-σxy

σxy

elongation

x

x

Relationships between Primary unknown and Secondary Unknowns in FE analyses

Primary Unknown:

Element displacements: {U(x,y,z)} and

Nodal displacements: [N(x,y,z)]{u}T

in FE formulation: {U} = [N]{u}

where {N(x,y,z)} = Interpolation function

Strain-displacement relations

Linkage to the 1st secondary unknown:

Element strains: {ε(x,y,z)}=[B(x,y,z)]{U(x,y,z)} →

corresponding to element stresses: {σ(x,y,z)}

Generalized Hook’s Law

Element strains and stresses, and nodal displacement

are the solutions of FE analyses.

2nd Secondary Unknown:

Element stresses {σ(x,y,z)}=[C]{ε}

Multiaxial Deformations of Elastic Solids

Uniaxial stress with uniaxial deformation:

F

Stress: σxx

Strain: εxx

x

x

L

εxx = ΔL/L

L

ΔL

Uniaxial stress with biaxial deformation with Poisson’s ratio:

y

For solids with significant cross-section, a uniaxial stress may

produce biaxial deformation such as illustrate in the figure in the left.

Lateral contraction:

- εyy

F

The lateral contraction deformation is represented by: - εyy

0

Longitudinal stretching:

+ εxx

x

F

Poisson’s ratio defines as:

yy

Longitudinal stretching strain xx

Lateral contraction strain

● Poisson ratio exists in most multi-axially loaded elastic solids, and this effect needs to be included in all

FE formulations. This effect also leads to the use of Generalize Hooke’s Law for the formulations

Generalized Hooke’s Law for Solids with Multi-axial Stresses:

Stress vs. strain relationship for deformed solids with 3-D deformation

Elongation in one-direction causes contractions

in other directions, and vise versa.

Total strains in three directions induced by the three normal stresses

in x-direction

in y-direction

in z-direction

in which E = Young’s modulus, and γ = Poisson’s ratio of the material

The following expression express the stresses in terms of strains – the Hooke’s law:

1 x y z

xx

E

yy

x 1 y z

1 1 2 1

y

z

zz

x

One may derive the uniaxial stress situation as a special case from the above expression to obtain:

σxx = Eεx

by substituting: σyy = σzz = 0, and εy = -γεx and εz = -γεx in the generalized Hooke’s Law

Element Strain-Displacement Relations for FE Formulation

There are six (6) strain components corresponding to the stress components in interior of the deformed solid.

These strain components are related to the displacements of the solid induced by the external forces.

Because deformation of the solid CONTINUOUSLY varying throughout the solid, the following relationship exits:

x

xx 0

yy

zz 0

xy

yz y

xz 0

Element Strains

z

Corresponding to

By theory of elasticity:

0

y

0

x

z

0

Element

0

Displacements

U(x,y,z)

0

U x, y, z

x

z U x, y, z (4.2)

y

0 U x, y, z

z

y

x

Element stresses

Example: For uni-axial elongation or contraction of a rod:

Element displacement {U} = {Ux(x)}, The corresponding strain in element is: xx

or: {ε(x,y,z)} = [D]{U(x,y,z)}

x

0

0

D

y

0

z

U x x dU x x

x

dx

0

y

0

x

z

0

0

0

z

0

y

x

(4.3)

(4.4)

Element Stress-Strain Relations – the Generalized Hooke’s Law

According to generalized Hooke’s law for MULTI-Axial stress state,

the following relationship between the element stress and strain exists:

or:

{σ} = [C]{ε}

(4.6)

where [C] is the elasticity matrix with:

0

0

0

1

1

0

0

0

xx

xx

1

0

0

0

yy

yy

1 2

zz

0

0 zz

E

2

1

1

2

1

2

xy

xy

0

yz

yz

2

1 2

xz

SYM

xz

2

Example: For uni-axially loaded rod:

xx E xx E

dU x x

dx

(4.5)

0

0

0

1

1

0

0

0

1

0

0

0

1 2

0

0

E

C

2

1 1 2

1 2

SYM

0

2

1 2

2

where E = Young’s modulus, and γ = Poisson’s ratio

where Ux(x) is the displacement in the rod

(4.7)

Physics of Solid Deformation by

External Forces

Displacements:

{Φ(x,y,z)}T: {Φx(x,y,z,Φy(x,y,z,Φz(x,y,z}

Small element located

at x,y,z:

Total 9 stress components at (x,y,z)

xx xy xz

yx yy yz

zx zy zz

Part 2

FE Formulation of

Deformable Elastic Solids

Derivation of Element Equations

In Step 4, Chapter 3, we derived the element equation using the Rayleigh-Ritz method to take a form:

We will select tetrahedron elements as the basis for FE formulation for general 3-D solid structures

[Ke]{q}= {Q}

(1.27) in the textbook

where [Ke] = Element matrix

{q} = Vector of primary unknown quantities at the nodes of the element

{Q} = Vector of element nodal actions (e.g., forces)

Element equations for each tetrahedron element in the FE model for a

structure are then assembled to establish “overall stiffness equation”

for determining nodal displacements of all nodes in the structure.

[K]{Φ} = {R}

K K em

m

FE Model for s Structure made of

Tetrahedron Elements

where

1

m=total number of elements in the FE model

Derivation of Element Equations-Cont’d Principle of deriving element equation using Rayleigh-Ritz variational principle

From Chapter 2: Let us determine a suitable “functional” to derive the element equation.

A general form of functional:

f

,

,

..........

dv

g

,

,.........

.

ds

v r

s

r

v = volume, s = surface

and then apply the Variational principle on:

1

2 0

from which equations of each element are derived:

0,

0,

0,..............

1

2

3

The “functional” for a deformed solid subjected to external forces is “POTENTIAL ENERGY” (P) in the situation.

The potential energy associated with a deformed solid can be defined as:

P=U-W

(4.8)

where U = the strain energy in a deformed solid, and W = the work done to the deformed solid by external forces acting on

the solid body in the volume and surface of the solid

Derivation of Element Equations-Cont’d

(a)

Strain energy in a deformed solid:

(C)

As we mentioned early in this Chapter that a solid in (a) deforms

into a new shape in (c) – but not indefinitely.

● It stopped further deformation after deformed by certain

amount.

● It reaches a new state of equilibrium. WHY???

Imagine the following phenomenon:

Stretch a free-hung spring by a weight W.

The spring will elongate, but only by a finite amount.

(b)

Ask yourself: WHY?

Answer: the elongation of the spring develops a “resistance,”

which increases as the spring elongates. The spring ceases

further elongation when the “resistance” in the spring balances

the applied weight (force). We say the spring – and the applied

weight reaches a new state of equilibrium, which stop the spring

(d)

From further elongation.

Next: what will happen to the spring after the weight is removed?

You will say that the spring returns to its original length, but WHY??

Answer: because a form of ENERGY was stored in the stretched

spring when it is elongated. This ENBERGY is released to restore

the spring to its original shape after the external force (the weight)

Now, you know why the solid in (a) ceases to deform further after

the application of the system of external forces {p} has been applied was removed.

to the solid in (b). And you would know that there is such ENERGY associated with the solid deformation developed in the solid called

“STRAIN ENERGY.” which is responsible for restoring the solid to its original shape after the applied forces are removed in “ELASTIC” solids.

T

1

Mathematical expression of strain energy in State (c) is:

(3.9) textbook

U dv

2 v

Derivation of Element Equations-Cont’d

The potential energy in a deformed solid is:

Potential energy in a deformed solid subjected to external forces:

P=U-W

(4.8)

Strain energy:

xx

yy

zz

T

1

1

U dv xx yy zz xy yz xz dv

2 v

2 v

xy

yz

xz

1

xx xx yy yy zz zz xy xy yz yz xz xz dv

2 v

(4.9)

Both the strain and stress components are function of (x,y,z), and dv = (dx)(dy)(dz) = the volume of given points

in the deformed solid.

Strain energy is a scalar quantity.

Derivation of Element Equations – cont’d

Work done to deform the solid:

Potential energy in a deformed solid subjected to external forces:

Definition of “work”: Work (W) = Force x Displacement (deformation)

Two kinds of forces: (1) body forces (uniformly distributed throughout the volume of the solid (v)), e.g., the weight,

(2) surface tractions, e.g., the pressure or concentrated forces acting on the boundary surface (s)

Mathematical expression of work: W

v ( x, y, z ) f dv s x, y, z tds

T

x x, y, z y x, y, z

v

T

fx

z x, y, z f y dv

f

z

x x, y, z y x, y, z

s

t x

z x, y, z t y ds

t

z

(4.10)

where {Φ(x,y,z)} = the displacement of the solid at (x,y,z), {f} = body forces, and {t} = the surface tractions , and

ds = the part of the surface boundary on which the surface tractions apply

Derivation of Element Equations – cont’d

Potential energy in a deformed solid subjected to external forces:

So, the potential energy stored in a deformed solid is: P = U – W, or:

T

1

P U W x, y, z x, y, z dv

2 v

x, y, z f dv x, y, z tds

T

v

T

s

(4.11)

Following the Rayleigh-Ritz Variational principle, the equilibrium condition for the deformed solid should

satisfy the following conditions:

P

0

From which, equations for each element may be derived from:

P

P

P

0,

0,

0,..............

1

2

3

Derivation of Element Equations – cont’d

for FE mesh of discretized solids

What we had formulated was for continuum solids. We will now derive the ELEMENT EQUATION for discretized solids in FE mesh:

We need to make distinction between the ELEMENT quantities and the NODAL quantities.

The primary quantity in FE analysis is DISPLACEMENTS. We need teo make distinction between the Element displacements and

the Nodal displacements.

The element displacement is: {Φ(x,y,z)} with three components:

Φx(x,y,z) = the element displacement component along the x-direction

Φy (x,y,z) = the element displacement component along the y-direction, and

Φz(x,y,z) = the element displacement component along the z-direction

Derivation of Element Equations – cont’d

for FE mesh of discretized 3-D solids with tetrahedron elements

We realize that TETRAHEDRON and HEXAHEDRN elements are used in FE models for general 3-D solid structures.

The tetrahedron elements are the “basic elements” for this type of structures, because hexahedron elements

are made up by 4 or more tetrahedron elements.

Our FE formulation for general 3-D solid structures will thus be based on TETRAHEDRON elements

We notice that tetrahedron elements has four (4) associate nodes: Φ1, Φ2, Φ3, and Φ4 with FIXED (specified) COORDINATES.

Each node has three (3) displacement components too. These nodal displacement components are:

T 1x

1 y 1z 2 x 2 y 2 z 3 x 3 y 3 z 4 x 4 y 4 z T

where Φ1x, Φ1y, Φ1z = displacements in Node 1 in 3 directions; Φ2x, Φ2y, Φ2z = displacements in Node 2 in 3 directions;

Φ3x, Φ3y, Φ3z = displacements in Node 3 in 3 directions; Φ4x, Φ4y, Φ4z = displacements in Node 4 in 3 directions

Derivation of Element Equations – cont’d for FE mesh of discretized 3-D solids with tetrahedron elements

We mentioned previously that the functional that we will use to derive the element equations in FE formulation of solid structures

Is the potential function in the solid as show below:

P U W

T

1

x, y, z dv

x

,

y

,

z

v

2

x, y, z f dv x, y, z tds

T

v

T

s

(4.11)

Now because the ELEMENTS in discretized solid) Also, these elements are interconnected by the NODES to simulate the original

solid structures. This “link” requires the FE formulation involves the functional with both the ELEMENT and NODAL quantities in

the formulation.

This “link” is established using the INTERPOLATION FUNCTION that relates the

element quantities with the corresponding nodal quantities such s:

The 12 nodal displacements:

The 3 element displacements: x x, y, z

x, y, z y x, y, z N x, y, z

x, y, z

z

The INTEERPOLATION function

T 1x

1 y 1z 2 x 2 y 2 z 3 x 3 y 3 z 4 x 4 y 4 z T

Derivation of Element Equations – cont’d

Key equations to construct the functional - the potential energy

1. The element displacements vs. nodal displacements via Interpolation function:

{Φ(x,y,z)} = [N(x,y,z)] {Φ}

2. Element strain vs. nodal displacements:

{ε(x,y,z)} = [D]{Φ(x,y,z)}

in which [D] in Equation (4.4)

(4.3)

Hence

{ε} = [D][N(x,y,z)]{Φ}= [B(x,y,z)]{Φ}

with [B(x,y,z)] = [D][N(x,y,z)]

(4.12)

(4.13)

3. Element stresses vs. nodal displacements:

{σ} = [C]{ε}

in which the elasticity matrix [C] in Equation (4.7)

Hence

{σ} = [C] [B(x,y,z)]{Φ}

Typical tetrahedron element

for 3-D FE models

4. Strain energy with nodal displacements:

T

1

U dv

v

(4.6)

(4.14)

(4.9)

2

Hence

or

U

U

1

Bx, y, z T C Bx, y, z dv

v

2

T

1

T

C B( x, y, z ) dv

B

(

x

,

y

,

z

)

2 v

(4.15)

(4.16)

Derivation of Element Equations – cont’d

The functional for Variational process

We mentioned that the functional for deriving the element equations for

discretized solid structure is the POTENTIAL ENERGY (P) as shown below:

P U W

T

1

x, y, z dv

x

,

y

,

z

2 v

x, y, z f dv x, y, z tds

T

v

T

s

(4.11)

By substituting the Strain energy expressed in Equation (4.16) into the above equation, we get:

P( )

1

T

T

C B( x, y, z ) dv

B

(

x

,

y

,

z

)

2 v

N ( x, y, z ) f dv N ( x, y, z ) tds

T

T

T

v

T

(4.17)

s

Due to the fact that nodal displacement {Φ} have “fixed value” but not a function og (x,y,z), so they can be factore

Out of the integration with respect to (x,y,z). We thus have the following:

T1

T

T

P( ) B( x, y, z ) C B( x, y, z )dv

2 v

T

T

T

T

N ( x, y, z ) f dv N ( x, y, z ) tds

v

s

(4.18)

Derivation of Element Equations – cont’d

Element equation by Variational process

All elements in discretized solids subjected to external force require to satisfy

the following condition that:

P

1

P

P

2 0

By substituting the potential energy P in Equation (4.18) into the above equation:

T1

T

T

B( x, y, z ) C B( x, y, z )dv

v

P

2

0

T

T

T

T

N ( x, y, z ) f dv N ( x, y, z ) tds

v

s

(4.19)

Derivation of Element Equations – cont’d

Element equation by Variational process

The above variation results in:

B( x, y, z ) C B( x, y, z )dv

N ( x, y , z ) f dv

T

v

N ( x, y, z )T tds

T

v

s

0

Upon moving the last two items to the right-hand side:

B( x, y, z ) C B( x, y, z )dv

N ( x, y , z ) f dv

T

v

T

v

s

N ( x, y, z )T tds

(4.20)

We may represent Equation by the following element equation:

(4.21)

[Ke] {Φ} = {q}

where

K e vB( x, y, z )T C Bx, y, z dv

= Element stiffness matrix

(4.22)

Nodal displacement copmponents

q vN x, y, z T f dv sN x, y, z tds

T

Nodal force matrix

{f} = Body forces

{t} = Surface tractions

[N(x,y,z)] in Step 3, Chapter 3, [B(x,y,z)] in Equation (4.13), [C] in Equation (4.7)

(4.23)

Examples of FE Stress Analysis of Solid Structures

NOTE: In FE stress analysis of solid structures, it is customer to represent the element displacements by:

and nodal displacements by: {u}.

U x x, y, z

U ( x, y, z ) U y x, y, z

U x, y, z

z

The relationship between the element displacements and the nodal displacements are:

{U} = [N(x,y,z)] {u}

where [N(x,y,z)] = the Interpolation function. It is a row matrix for 1-D bar elements,

rectangular matrices for 2- or 3-D elements.

● Interpolation function enables the determination of the primary quantities in the element with specified coordinate (x,y,z)

with the same primary quantities of the associate nodes

Part 3

Finite Element Formulation for

One-dimensional Bar elements

1. Bar elements subjected to unidirectional load

2. Truss bar elements

3. Beam bending elements

One-Dimensional Stress Analysis of Bar Elements

Derive the interpolation function using general formulation:

We will need first to derive the [h] matrix in Equation (1.13) by the following computations:

x 1 2 x

Φ1

We have:

●

L

x1 = 0

x2 = L

Figure 1.6 Linear Interpolation Function

of a Bar Element

and

2 1 2 x2

From which we will have

Φ2

●

1 1 2 x1

x

1 1 x1 1

Aa

1

x

2 2

2

with the matrix [A] to be:

1 x

A 1 and

1 x2

A

1 x1

x2 x1

1 x2

1 x2 x1

h

x2 x1 1 1

By following Equation (1.15), we have the interpolation function of a bar element to be:

The inverse matrix of [A] is:

A1

1 x2 x1 1

T

N x R h 1 x

1 1 L x2 x x1 x

x

x

2 1

For the present case with x1 = 0, and x2 = L, we have the interpolation function to be:

x x

N x 1

L L

(1.7)

Derive the element equation for a typical 1-D bar element: a bar element made of one material with Young’s modulus E.

The bar is subjected two forces F1 and F2 as shown in the figure below. Establish the element equation

u1 Node 1

●

F1

Node 2

L

x=x1

●

u2

F2

x

Because the bar is made of one material, and the applied forces are along

the length of the bar. So the bar will only deform along the length of the bar

e.g., the element displacement U is a function of coordinate x only:

x=x2

We thus have the element displacement to be U = U(x). The corresponding displacements at the two nodes are:

{u}T = {u1

u2}.

The relationship between the element displacement and the corresponding nodal displacements are:

{U(x)} = {N(x)} {u}

(4.24)

in which {N(x)} is the interpolation function for one-D bar element. It is a row matrix with two columns

We had derived this interpolation function before with assumption that the element displacement {U(x)} follows

a linear polynomial function: U(x)= α1 + α2x, and found the interpolation function using this liner function to be

In the same form as in Equation (1.7) we derived using general formulation method:

N x 1 x x

(4.25)

L L

with L = x2 – x1

Because the bar element is subjected to force along the x-coordinate only, and both the induced stress and strain are

in the direction of x-coordinate only. We thus obtain from Equation (4.4) and obtain:

D

d

x dx

From Equation (4.13), we thus have the [B] matrix to be:

B( x) DN ( x)T d 1 x x 1

dx L L L

1 1

1 1

L L

For the same reason of being uniaxial stress distribution, i.e., σxx = Eεxx by uniaxial Hooke’s law, we have the

elasticity matrix [C] = E – the Young’s modulus from Equation (4.7) with Poisson’s ratio γ = 0. We thus has the

element equation of the deformed bar expressed in the form:

(4.26)

[Ke] {Φ} = {q}

with

K e vB( x, y, z ) C Bx, y, z dv x Bx EBx ( Adx)

T

x2

T

1

x2 1

EA x2 1

1

T

1 1 E 1 1 Adx 2 1 1dx

x1

L x1 1

L

L

EA x2 1 1

EA x2 x1 x2 x1 EA 1 1

2

dx 2

L x1 1 1

L x2 x1 x2 x1 L 1 1

(4.27)

Example 4-1 Show the element equation for the bar element in the figure, and determine displacement at Node 2

u1

F1

●

The nodal forces {q} for the bar element are expressed as: {q}T = {-F1

Node 1

x=x1

Node 2

L

●

u2

F2

x

F2}

We may thus express the element equation for the bar element to be:

x=x2

EA 1 1 u1 F1

L 1 1 u2 F2

(a)

Because there is only one bar element in the structure, the overall stiffness equation in Equation (1.28)

is identical to that of element equation in Equation (4.24).

However, adjustments of the now overall stiffness equation with the three matrices in Equation (4.24) would be required,

as expressed:

K aa

K

ba

K ab qa Ra

K bb qb Rb

where {qa} = specified (known) nodal quantities; {Rb} = specified (known) applied resulting actions, from which we may obtain:

{qb} = [Kbb]-1 ({Rb} – [Kba]{qa})

(6.12) (PRINCIPAL REF)

The specified nodal unknown {qa} in this case is u1 = 0 and F1=0, the required unknown {qb} is u2, We thus need no adjustment of the

Matrices in the overall stiffness equation in (4.24). The required unknown quantity u2 is obtained from Equation (6.12, REF) to be:

u2

EA 1

F2 10 EA F2

L 1

L

Example 4-2 Deformation and stress in a compound bar made of two different materials

Use the FEM to determine the displacements at the joint of a compound road made of copper and aluminum induced by a

uniaxial force P = 30000 N at of the end of the rod as shown in the Figure A below:

Figure A Compound Rod subjected to a Uniaxial Force

The compound rod has a cross-sectional area A = 650 mm2 and the Young’s moduli Ecu = 10300 MPa and Eal =69000 MPa.

Solution:

The situation shown in Figure A indicates that the rod is expected to elongate along the same direction in the x-axis, as shown in Figure B.

Figure B FE model for a Compound Bar

Example 4-2 – Cont’d

The FE model in Figure B indicates the following:

(1) There are total 3 nodes in the structure

(2) Nodal coordinates:

Node 1 at x1 = 0; Node 2 at x2 = 915 mm, and Node 3 at x3 = 1220 mm

(3) The length of Element 1 = L1 = 915 mm; the length of Element 2 = L2 = 305 mm

(4) Both elements have a cross-sectional area: A1 =A2 = A = 650 mm2

(5) Displacements at the 3 nodes are: {u}T = {u1 u2 u3} with u1 = 0

Our solution begins with developing the “element equations” for both elements in the FE model:

Element 1 made of copper:

Coefficient matrix for Element 1:

K

1

e

E1 A1 1 1 10300 x 650 1 1 7.317 7.317 6

x10 N / m

L1 1 1

915 x103 1 1 7.317 7.317

Element equation for Element 1:

7.317 x106

6

7.317 x10

7.317 x106 u1 p1

6

u

7.317 x10 2 p2

where p1 and p2 are forces art Node 1 and 2 respectively

(a)

Example 4-2 – Cont’d

Element equation for Element 1:

7.317 x106

6

7.317 x10

7.317 x106 u1 p1

6

7.317 x10 u2 p2

Element 2 made of aluminum:

Coefficient matrix for element 2:

K ELA

2

e

2

2

2

1 1 69000 x650 1 1 147.05 147.05 6

1 1 305 x103 1 1 147.05 147.05 x10 N / m

(b)

Element equation for Element 2:

147.05 x106

6

147.05 x10

147.05 x106 u2 p2

6

u

147.05 x10 3 p3

Due to the fact that the present case involves TWO elements with Node 2 being common to both these element,

we need to assemble the coefficient matrices by following the established rule by summing up the values of Node 2

from both element coefficient matrices.

Example 4-2 – Cont’d

We thus assemble the overall stiffness matrix by adding K e1 In Equation (a) and K e2 in Equation (b) in the following way:

7.317

K 106 0

0

7.317

0

7.317 147.05 147.05 106

0

147.05

0

7.317 7.317

0

154

.

367

147

.

05

0

0

147.05

(c)

The numbers in boldface in Equation (c) are those associated with Node 2.

The overall stiffness equation for the bar structure with specified loading/boundary conditions is thus expressed in the

following partitioned matrices as:

0 u1 0 p1 0

7.317 7.317

106 0

154.367 147.05 u2 p2 0

0

0

147.05 u3 p3 30000

(d)

The two unknown nodal displacements u2 and u3 may be obtained by the following equations using the partitions

in Equation (d):

154.367 147.05 u2 0

106

u

0

147

.

05

30000

3

resulting in the displacement of the compound bar at the joint (Node 2) to be u2 = 1.94 mm and the displacement

at the free end u3 = 2.04 mm. The total elongation of the rod is 3.98 mm.

Example 4-2 – Cont’d

Strain in Elements

Now that we have solved the displacements at the 3 nodes, we may use the train-displacement relations to

determine the induced strains in both these elements:

T

1xx

xx2

1

2

where xx and xx are the strains in Element 1 and 2 respectively

The strain-displacement relationship is available from the expression: {ε} = [B]{u} in Equation (4.3), in which the matrix {B} is:

Bx

d

N x d x x2

dx

dx x1 x2

x x1 1

x1 x2 x1 x2

1

x1 x2

We have: Node 1 at x1 = 0; Node 2 at x2 = 915 mm, and Node 3 at x3 = 1220 mm, leading to: the length of

Element 1 = L1 = 915 mm; the length of Element 2 = L2 = 305 mm. We may thus express the [B(x)] for both

elements to be:

B1

1

915

1

1

, and B2

915

305

1

305

Example 4-2 – Cont’d

From the [B] matrices for both elements, we may compute the strains in Element 1 and 2 as follows:

1

xx

1

915

1

305

xx2

1 u1 0

1

1.94

u2

0.21%

915 u2 915

915

for element 1, and

1 u2

u2

u3

1.94 2.04

0.1

0.033%

305 u3

305 305

305 305

305

for element 2

Stresses in elements

We may use the Hooke’s Law to determine the stresses in each of these two elements from their corresponding strains

For element 1 with Ecu = 10300 MPa:

1xx C1 1xx Ecu 1xx 10300 x0.0021 1.03MPa

For element 2 with Eal = 69000 MPa:

xx2 C2 xx2 Eal xx2 69000 x0.00033 22.77 MPa

Finite Element Formulation of Elastic Solid Structures

One-Dimensional Bar Elements

for Truss Structures

FE Formulation of Truss Elements Using 1-D Bar Elements

Common Trusses

FE Formulation of Truss Elements Using 1-D Bar Elements - Cont’d

The characteristics of a truss element can be summarized as follows (a quote from Dr. Agarwal’s

lecture notes):

1. Truss is a slender member (length is much larger than the cross-section).

2. It is a two-force member i.e. it can only support an axial load and cannot support a

bending load. Members are joined by pins (no translation at the constrained node,

but free to rotate in any direction). Being a two-force member, the force acting in the member is in the

length-direction only.

3. The cross-sectional dimensions and elastic properties of each member are constant along its length.

4. The element may interconnect in a 2-D or 3-D configuration in space.

We will formulate 2-D configuration only. Meaning the truss member deforms in a plane

defined by x-y coordinates.

5. The bar elements for truss structures is mechanically equivalent to a spring, since it has

no stiffness against applied loads except those acting along the axis (the length direction) of the member.

6. However, unlike a spring element, discussed in previous chapters, a truss element can be oriented in any

direction in a plane, and the same element is capable of tension as well as compression along its longitudinal

directions.

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Simple Bridge Structure:

FE model with 1-D bar elements with designated element and node numbers. All elements are

interconnected by “frictionless hinges”:

3

ο

Element (1)

(3)

Node 1

ο

(2)

ο2

P1

5

(6)

(5)

(4)

ο

(7)

ο

4

P2

(8)

(11)

(9)

ο6 (10)

P3

ο7

ο ο οο

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

A fundamental phenomenon in Statics is that “hinged” joint of any member in

A frame or truss cannot resist moment. Consequently, any member in s truss

As shown in the figure at the left with hinge joints (as illustrated in the lower

Figure will have forces acting along the length of the member.

Consequently, the derivation of the interpolation function in the FE formulation of

these members may begin with the bar element in Example 4-1

y

Truss members along x-direction of y-direction only:

x

The element equations for these elements will be in similar forms

as for the 1-D bar elements in Examples 4-1 and 4-2.

Inclined Truss Members:

The element equation for those truss members that are inclined with the x-coordinate with angle θ,

however, will be in different forms, as will be derived in the following procedures.

FE Formulation of Inclined Truss Elements Using 1-D Bar Elements

Inclined truss bar element in x-y plane: Element (1), (5), (7) and (11):

y

vj

Fj

j

(xj,yj)

vi

The inclined truss bar elements such as shown in the figure at right

may have TWO displacement components, but these elements can only

elongate or contract in the LONGITUDINAL direction only.

i

Fi

The same applies to the induced strain and stress.

So, These are regarded as “a special bar elements.”

uj

ui

(xi,yi)

0

These bar elements remain having two nodes: Node i and Node j

Located at specified coordinates (xi, yi) and (xj, yj) respectively.

Each node has two displacement components:

ui and vi = displacement of Node i in respective x- and y- directions

uj and vj = displacement of Node j in respective x- and y-directions

Fi and Fj are the forces acting at Node I and Node j respectively

x

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Derivation of element equation

[Ke]{Φ} = {q}

(4.21)

The situation in the bar element in truss structures is unique in the way that these bar elements are solid element of “two-force members”

– meaning that the force is acting along the length of the bar only. Consequently, the induced displacements that ae effective to the

elongation or contraction of the bar (truss) member elements are the ones in the length-direction only. The strain and stress in the truss

members are along the length of the bar too.

The displacement components in an inclined bar element in the plane defined by the (x,y) coordinate system in the figure below do not

contribute in producing the displacement, strain and stress in the bar element for this reason . However their “equivalence” to the ones

along the length direction of the bar element do.

Consequently, we need to convert the current situation in the inclines bar element in the left to the equivalent situation in the right

of the figure through a coordinate transformation process of the nodal displacement components and the applied nodal forces

Equivalent Typical Bar Element

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Derivation of element equation – Cont’d

Transformation of Nodal displacement components: From the “global coordinates” to “Local coordinates”- The latter

is used for the FE formulation as with 1-D bar elements

Truss bar element:

Typical bar element:

Converting

“truss bar element”

to equivalent “typical

bar element”

By referring to the above figure, we have the following relationship in transforming the nodal displacement components from

The global coordinates (x,y) in the left figure to the local coordinate (x) in the right of the figure:

at Node i:

i ui cos vi sin cui svi

(4.28a)

at Node j:

j u j cos v j sin cu j sv j

(4.28b)

ui

i c s 0 0 vi

Equations (4.28a,b) may be expressed in matrix form:

u

0

0

c

s

j

j

or in a shorthand version of: {δ} = [T]{u}

v j

with the matrix [T] being the transformation matrix

where c = cosθ and s = sinθ

(4.29a)

(4.29b)

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Derivation of element equation – Cont’d

Transformation of Nodal force components:

From “global coordinates” to “Local coordinates”

Transformation of nodal forces can be done in a similar way as we did with nodal displacements. However, it would be easier to do it using

the work done to the element by these forces, as work done is a scalar quantity, which is easier to transform in space than the vector

quantities such as displacements.

Since the work done to the element by nodal forces may be expressed as: W T f uT F for the same element in both local and global

coordinate systems, or in a long-hand form:

Fix

F

f1

iy

T

T

W 1 2 ui vi u j v j or f u F

f2

F jx

F jy

Substituting {δ} = [T]{u} in Equation (26b) into the above expression, we get: ([T]{u}])T{f} = {u}T{F}, leading to:{u}T[T]T{f} = {u}T{F}

We will thus have the nodal force transformation by the following relationship:

[T]T {f} = {F}

where {f} = nodal forces in “typical bar element”, {F} = nodal forces in “inclined truss element”

(4.30)

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Derivation of element equation – Cont’d

Element equation in Local Coordinate System

Now that we have made the real situation in the “Global” coordinates (x,y) to be equal to the situation in 1-D “Local” coordinate (x) situation

through a “transformation” process:

Inclined truss bar element:

Transformation

Matrix:

T

Equivalent bar element:

=

c s 0 0

0 0 c s

(4.26a)

Previously derived interpolation function:

N x

Real situation in

“Global” coordinates

Coordinate Transform:

x

1

L

x

L

Previously derived “element equation”

with modified notation of nodal quantities:

EA 1 1 i f i

(4.24)

f

1

1

L

j j

or K e f

AE

AE

L

L

with K e

AE

AE

L

L

(4.27)

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Derivation of element equation – Cont’d

Element equation in Local Coordinate System

EA 1 1 i f i

L 1 1 j f j

(4.24)

AE

AE

L

L (4.27)

K e f with K e AE

AE

L

L

Relationship of nodal forces between the two coordinate systems: {F} in global coordinate system = [T]T{f} in Local coordinate system .

The element equation in global coordinate system thus have the form:

K e f

(4.31)

The nodal forces in the Local coordinate system {f} can be viewed as a transformed forces {F} rom the global coordinate systems with

the relationship: [T]T {f} = {F} as shown in Equation (4.27), or {f} = ([T]T)-1, leading to:

[Ke]{δ} = ([T]T)-1 {F}

But we also have already derived the following relationships: {δ} = [T]{u} in Equation (4/26b), and [T]T = {F} in Equation (4.27).

By substituting these relationships into the above expression, we will get the following “reversed transformation” of element equation

from the Local coordinate system to Global coordinate systems:

(4.32)

REAL inclined truss members: [K ][T]{u} = ([T]T)-1 {F} Equivalent 1-D bar elements

e

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Derivation of element equation – Cont’d

Element equation in Local Coordinate System

The Element Equation of inclined truss elements is: [Ke][T]{u} = ([T]T)-1 {F}

(4.33)

We realize the fact that the transformation matrix: [T]T = [T]-1 (Reference No. 2). Thus Equation (4.33) has a new form of:

[Ke][T]{u} = ([T]-1)-1 {F} leads to: [Ke][T]{u} = [T]{F} with ([T]-1)-1 = [T] in the last expression.

Now, if we multiply both sides by [T]-1, and use the relationship of [T]-1 = [T]T, we have the element equation of

the inclined truss element (i.e., the bar element in the global coordinate system) to be:

The element Equations for

inclined truss members:

AE

AE

L

AE

L

L

where K e AEL

[T]T[Ke][T]{u} = {F}

(4.34)

c s 0 0 with A, L= cross-sectional area and the length of the truss element

0 0 c s respectively, c=cosθ and s=sinθ

and [T ]

FE Formulation of Truss Elements Using 1-D Bar Elements – Cont’d

Element equation for Inclined Truss Members

where

The stiffness matrix:

K e u F

ui

v

u i

u j

v j

and

Fix

F

iy

F

F jx

F jy

c2

cs c 2 cs

s 2 cs s 2

AE cs

K e 2

2

cs

L c cs c

2

2

cs

s

cs s

(4.35)

(4.36a)

(4.36b)

(4.37)

1) This stiffness matrix represents the stiffness of a single element with incline angle θ

2) It is symmetric about the diagonal line of the square matrix

3) Since there 4 unknown nodal displacements - meaning 4 degree-of-freedom (dof), the matrix is of the size

of (4x4)

4) The terms c and s represent the cosine and sine values of the orientation of the element with the

horizontal plane, rotated in a counter clockwise direction (+ve direction)

Example 4-3 FE Stress Analysis of a Truss Structure:

A truss with 3 members joined by frictionless hinges as shown in the figure.

Element 1 and 2 are made of aluminum, and element 3 is made of steel.

Materials

Cross-sectional

Area (A) (10-6m2)

Young’s Modulus (E)

(106 N/m2)

Yield Strength (σy)

(106 N/m2)

Member (1)

Aluminum

200

70,000

170

Member (2)

Aluminum

200

70,000

170

Member (3)

Steel

100

200,000

21,000

Solution:

We realize the fact that there are 3 members, each has its own dimension, and material with properties listed in the above table.

So, we may conveniently construct the FE model of the truss structure by using 3 elements 1 with node pair 1-3, element 2

with node pair 2-1, and element 3 with node pair 2-3, as shown in the figure.

We will derive the element equations for all these 3 elements by using the formulations for truss elements with: Equation (4-24) for

the horizontal Element 1, and Equations (4.35) and (4.37) for the inclined elements 2 and 3.

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Derivation of element equations

Element 1:

L1 = 0.26 m, E1 = 70000 MPa, A1 =200x10-6 m2:

(1)

u1x

Being horizontal, we have the incline angle θ = 0, which leads to:

c = cosθ=1, c2 = 1, s=sinθ = 0, s2 = 0 and cs = 0

v3y

v1y

Node 3

Node 1

u3x

We also calculate the coefficient of the stiffness matrix of element 1 as follows:

E1 A1 70000 106 200 10 6

53.84 106 N m

L1

0.26

L1 = 0.026 m

Using Equation (4.37), the stiffness matrix for Element 1 is thus:

c2

cs c 2 cs

1

0

2

2

cs

s

cs

s

E

A

53.84 106

K e1 1 1 2

1

L1 c cs c 2

cs

2

2

cs

s

cs

s

0

0 1

0 0

0 1

0 0

0

0

0

0

(a)

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Derivation of element equations

Element 2:

L2 = 0.15 m, E2 = 70000 MPa, A2 =200x10-6 m2:

v1y

u1x

L2=150 mm

Node 1

c = cos 90o = 0, c2 = 0; s = sin 90o = cos0o = 1, s2 = 1 and cs = 0 ,

and

u2x

v2y

E2 A2 70000 106 200 10 6

31.06 106 N m

L2

0.15

(2)

Node 2

In this Element 2, we have the inclined angle θ=90, which lead to:

Hence the stiffness matrix for Element 2 is:

0 0

0 1

K e2 31.06 106

0 0

0 1

0 0

0 1

0 0

0 1

(b)

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Derivation of element equations

Element 3:

L3 = 0.3 m, E3 = 200,000 MPa, A3 =100x10-6 m2:

v3y

y

Node 3

Element 3 has an inclined angle θ = 30o leading to:

u3x

v2y

u2x

Node 2

X

c= cos 30o = 0.866, c2 = 0.75, s = sin 30o = 0.5, s2 = 0.25 and cs = 0.433;

Also the coefficient of the stiffness matrix:

E3 A3 200000 106 100 10 6

66.67 106 N m

L3

0.3

The stiffness matrix for element 3 is:

0.433

0.75 0.433

c2

cs c 2 cs

0.75

0.433

2

2

0

.

25

0

.

433

0

.

25

cs

s

cs

s

E

A

66.67 106

K e3 3 3 2

2

0.75 0.433 0.75

0.433

L3 c cs c

cs

2

2

0.433

0.25

cs

s

cs s

0.433 0.25

(c)

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Derivation of element equations

From Equation (4.21):

[Ke] {Φ} = {q} with a general expression for element equations, we are now in the position to express the

same equations for the 3 elements in the current truss structure as follows.

The 3 Element equations for the truss structure:

Element (1) with Node 1 and 3

53.84

0

106

53.84

0

0 53.84

0

0

0 53.84

0

0

0 u1x f1x

0 v1 y f1 y

0 u3 x f 3 x

0 v3 y f 3 y

Element (2) with Node 1 and 2

0

0

31.6

6 0

10

0

0

0 31.6

0

0 u1x f1x

0 31.6 v1 y f1 y

0

0 u2 x f 2 x

0 31.6 v2 y f 2 y

Element (3) with Node 2 and 3

28.87

50

28.86 u2 x f 2 x in which u1x, u2x and u3x = displacement components in x-direction

50

of Node 1, 2 and 3 respectively

28.87

v f

16

.

67

28

.

87

16

.

67

v1y, vy2 and v3y = displacement components in y-direction

2 y 2 y

106

of Node 1, 2 and 3 respectively

50

28.87

50

28.87 u3 x f 3 x

f1x, f2x and f3x = Nodal force at Node 1, 2 and 3 respectively

16.67 v3 y f 3 y

28.87 16.67 28.87

f1y, f2y and f3y = Nodal force at Node 1, 2 and 3 respectively

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Assembly of element equations for Overall Stiffness Equation

By following the description on “assembly of element stiffness matrices” in Step 5 with diagram of Chapter 3 Steps in Finite

Element Analysis, we may assemble the three (3) truss element stiffness matrices shown above in the following form:

or in a neat form as shown in the next slide:

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Element stiffness matrix and Overall Stiffness Equation of the Truss Structure

The overall stiffness matrix of the truss structure:

(d)

With this overall stiffness matrix, we may establish the overall stiffness equation for the truss structure as shown below:

(e)

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Boundary and Loading conditions of the Truss Structure

We recognize the following specified conditions for the discretized truss structures:

The boundary conditions (displacement at nodes):

1) With Node 1 being completely fixed: u1x = v1y = 0

2) Node 2 is allowed to move in vertical (y) direction: u2x = 0

The loading conditions:

All except Node 3 has one force acting in the y-direction:

f1x = f1y = f2x = f2y = f3x = 0 and f3y = 0.4 kN = 400 N

The overall stiffness equation in Equation (e) after the substitution of the above specified boundary and loading conditions has the form:

0

0

0

53.84

0 u1x 0 f1x 0

53.84

0

v 0 f 0

31

.

6

0

31

.

6

0

0

1y

1y

0

0

50

28.87

50

28.87 u2 x 0 f 2 x 0

6

10

v

f

0

0

31

.

6

28

.

87

48

.

27

28

.

87

16

.

67

2 y 2 y

53.8

0

50

28.87 103.84 28.87 u3 x f 3 x 0

0

28.87 16.67 28.87

16.67 v3 y f 3 y 400

0

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Overall Structure Stiffness Equation with given Boundary and Loading Conditions for the Truss Structure

0

0

0

53.84

0 0 0

53.84

0

0 0

31

.

6

0

31

.

6

0

0

0

0

0

50

28.87

50

28.87 0

106

v

0

31

.

6

28

.

87

48

.

27

28

.

87

16

.

67

0

2 y

53.8

0

50

28.87 103.84 28.87 u3 x 0

0

28.87 16.67 28.87

16.67 v3 y 400

0

(f)

Now, if we follow Step 6 in Chapter 3 on Steps in FE Analysis, we may partition Equation (f) in the following way:

where {qa} = specified (known) nodal

quantities;

{Rb} = specified (known) applied resulting

actions, from which we may obtain:

{qb} = [Kbb]-1 ({Rb} – [Kba]{qa})

qa 0

v2 y

qb u3 x

v

3y

Ra 0

0 31.6 28.87

48.27 28.87 16.67

6

0 K 10 53.8

0

50 K bb 106 28.87 103.84 28.87

ba

Rb 0

16.67 28.87

0

16.67

0 28.87

400

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of 3 unknown nodal displacements in truss structure

We will get the 3 unknown nodal displacements from the portioned over

stiffness equation by the expression: {qb} = [Kbb]-1 {Rb}:

v2 y

48.27 28.87 16.67

6

u3 x 10 28.87 103.84 28.87

v

16.67 28.87

16.67

3y

1

3.1646

867.36 10 19

0

8

19

0

10

1.86

867.36 10

400

3.1646

3,2166

3.1646 0

3.2166 0

14.734 400

Solve for the unknown displacement components at Node 2 and 3:

u2y = -12.65x10-6 m, u3x = 12.86x10-6 m and v3y = -58.94x10-6 m with negative signs meaning downward direction

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure

We will determine the strain components and then stress components in each of the 3 elements

in the truss structure.

We should bear in mind that truss members are “two force members,” in which only the in-line

displacement components will produce strains and stresses.

Element 1:

u1x

ο

X=0

L1

ο

X=L1

u3x

with Node 1 and Node 3

We have the relationship between the element displacement U(x) and the

x corresponding nodal displacement components {u1x u3x}T along the line of

the bar element in the figure I the left:

x

x u1x

x

x

U x N x u 1

1 u1x u3 x

L1

L1 L1 u3 x L1

where the interpolation function of this simplex bar element is given in Equation (1.5) textbook

We will use Equation (4.3): the element strain {ε} = [B(x)]{u} to compute the only strain, εxx in the element by using Equation (4.12):

x xx Bx u

d

in which the matrix [B(x)] is given in Equation (4.13) to be: [B(x)] = [D][N(x)], with D x dx for the

present one-dimensional case. We thus have: Bx d 1 x

dx

L1

x

L1

We thus have the strain εxx in element 1 to be:

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure

We will determine the strain components and then stress components in each of the 3

elements in the truss structure.

We should bear in mind that truss members are “two force members,” in which only the

in-line displacement components will produce strains and stresses.

Element 1:

u1x

ο

X=0

with Node 1 and Node 3

in global coordinates

L1=0.26 m

ο

u3x

x

[T]

with θ=0o

X=L1

1 0 0 0

0 0 1 0

The transformation matrix: T

ui

i 1 0 0 0 vi

The relationship of nodal displacements in Local coordinate system

u

0

0

1

0

j

and the corresponding global coordinate systems is: {δ} = [T]{u}, or:

j

v j

But we obtained the nodal displacements from the previous calculations to be:

ui = u1x =0, vi = v1x =0, uj = u3x = 12.86x10—6m, vj = v3y = -58.94x10-6m

= Element 1

in local coordinate

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure

0

i 1 0 0 0

0

0

6

6

j 0 0 1 0 12.86 10 12.86 10

58.94 10 6

We have the strain in the element is obtained by using Equation (4.12): {ϵ} = [B(x)]{Φ}, and [B(x)] = [D]{N(x)] (3.13)

We thus have:

B DN x d 1 x x 1 1

dx

The strain in Element 1 is thus:

xx 1

L1

L1

L1 L1

L1

1 i 1

L1 j 0.26

0

1

49.46 10 6 m / m

6

0.26 12.86 10

The corresponding stress in Element 1 can be obtained from Equation (4.6): {σ}=[C]{ϵ}=(70000x106)(49.46x10-6)=3.43 MPa

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure - Cont’d

Element 2:

with Node 1 and Node 2

We have computed that u1 = v1 = 0, u2 = 0 and v2 = u2y = -12.65x10-6 m

Let us transform the coordinate system in the lower left figure to one-dimensional bar

element using Equation (4.29) to the following situation:

ui

Node i = Node 2

Node j = Node 1

i c s 0 0 vi

δi

δj

j 0 0 c s u j

v j

We have : c = cos 90o =0, and s = sin 90o = 1.0, leading to:

y

v1

u1

Node 1

u2

Node 2

v2

ui u 2 0

6

i 0 1 0 0 vi v2 u2 y 12.65 10

u

u

0

0

0

0

1

j

j

1

v j v1 0

i 12 10 6

The above expression leads to: δi = -12x10-6 m and δj = 0 or:

x

0

j

We have the strain in the element is obtained by using Equation (4.12): {ϵ} = [B(x)]{Φ}, and [B(x)] = [D]{N(x)] (3.13)

d

x

x 1

1

We thus have: B DN x 1

dx

The strain in Element 2 is thus:

L2

L2 L2

xx 1

L2

L2

1 i 1

L2 j 0.15

1 12 10 6

6

80 10 m / m

0.15

0

The corresponding stress in Element 2 can be obtained from Equation (4.6): {σ}=[C]{ϵ}=(70000x106)(80x10-6)=5.6 MPa

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure - Cont’d

Element 3:

with Node 2 and Node 3

We obtained the nodal

Displacements from

The previous calculation

to be as shown

v3j = -58.94x10-6

y

Node 3

v2i = -12.65x10-6

Node 2

Transformation matrix

[T]

x

u2i = 0

δi=u2x

ο

L3=0.3 m

The transformation matrix [T] has the following form with θ = 30o:

cos 30o

T

0

sin 30

0

0

cos 30o

u3j=12.86x10-6

0

0

0 0.866 0.5

0 0.866 0.5

sin 30o 0

ο

δj=u3x

x

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure - Cont’d

Element 3:

with Node 2 and Node 3

The nodal displacements in the equivalent Element 3 in the Local coordinates can be related to the real Element 3 in the global

coordinates by the transformation matrix to be:

ui u 2 i 0

6

i 0.866 0.5

0

0 vi v2i 12.65 10

6.325 6

6.325 10 6

x10

u u 12.86 10 6

6

0

0

0

.

866

0

.

5

18

.

3332

11

.

1368

29

.

47

10

3j

j

j

6

v j v3 j 58.94 10

But since the interpolation function of the equivalent Element 3 in the local coordinate is:

And the matrix [B(x)] = [D][N(x,y,z)] from Equation (4.13) in the present case to be:

Bx

N x 1

d

x

1

dx L3

x

L3

x 1

L3 L3

x

L3

1

L3

(1.7)

Example 4-3 FE Stress Analysis of a Truss Structure - cont’d

Solution of secondary unknowns of induced strains and stresses in all three elements in the truss structure - Cont’d

Element 3:

with Node 2 and Node 3

The strain {ε} in terms of nodal displacements in Element 3 may be obtained by using Equation (4.12): {ε}=[D]{N(x)}:

1

xx

L3

1 i 1

L3 j 0.3

1 6.325

6

10

0.3 18.3332

(21.0833 61.1107) 10 6 82.194 10 6 m

The induced stress in Element 3 is {σ} can be computed by using Equation (4.6), or {σ} = [C]{ε} with [C] = E3 = 200,000x106 Pa (N/m2)

We thus have the stress in element 3 to be:

{σ} = σxx = E3εxx = (200000x106)(-82.194x10-6) = - 16438800.33 N/m2 or -16.44 MPa (a compressive stress)

Finite Element Formulation of Elastic Solid Structures

One-Dimensional Bar Elements

for Bending of Beams

Quick Review of Simple Beam Theory

1) Like truss members, beams are slender members (length is much larger than the cross-section) in structures.

2) However, unlike the truss members, beam members can resist forces applied laterally or transversely to their axes.

y

Original straight beam:

Induced

deflection by

applied forces

P – concentrated force

W(x) – distributed load

y

per unit length

x

x

x

Deflected state

Induced deflection: y(x)

3) Beams can also resist the applied moments that cause the beams to bend, i.e. beams can have deflection

induced by applied moments (e.g., torque in the x-y plane)

4) Beams may be straight or curved. We will focus on straight beams only .

5) The application of unilateral forces or moments will not only cause the beam to bend in shapes, but also

having deflections, y(x) perpendicular to the beam axes, as shown in the above figure.

6) So, the actions to beam can be: concentrated forces, distributed load and moments

The induced reactions are: Deflection of the beam y(x), bending moments M(x) and shear forces V(x),

and the bending stresses (normal stress σn(x) – normal to the cross- section of the beam, and the shear

stress σs(x) - acting on the cross-section of the beam)

Quick Review of Simple Beam Theory – Cont’d

Construction of induced bending moment and shear force distributions (diagrams)

y

y

Uniform distribution load: w N/m

P

B

A

Ra

Pb

L

a

b

L

x

Rb

Pa

L

B

A

Ra

wL

2

x

L

Rb

x

wL

2

Bending Moment Diagram:

M(x)

M x

Pb

x

L

M x

M(x)

Pa

L x

L

Pab

L

wL2

8

x

V(x)

Shear Force Diagram:

pb

L

pa

L

x

x

V(x)

wL

2

wL

2

x

Quick Review of Simple Beam Theory – Cont’d

Induced Shear Stresses in Bent Beams by Applied Force

There are two types of stresses induced to the beam subjected to external forces:

(1) The normal stress along the x-coordinate. It exists in perpendicular to the

cross-section of the beam (σxx), and

(2) The shear stress (σxz) that exists on the surfaces of the beam cross-section.

It also exists on the face along the x-coordinate (σyx) with the same magnitude

Expression for normal stress (σxx): xx x M x y

I

(4.38)

where M(x) = bending moment at location x, y = distance from center of the beam

cross-section to the depth of the cross-section in y direction, and I = section

y

moment of inertia

b

3

bh

For beams with rectangular cross-section:

I

z

H

12

For beams with circular cross-section:

I

d 4

y

64

Section moment of inertia for beams of other cross-sections, including I-cross-sections

are available from mechanical engineering handbooks

z

d

Quick Review of Simple Beam Theory – Cont’d

Induced Shear Stresses in Bent Beams by Applied Force

Expression for shearing (σxz) or (σyx):

These stresses are induced by the shear force V(x) at the various cross-sections along the beam

y

c1

z

dA

y

y1 H

yx

b

V x

Ib

c1

y1

ydA

V x

Q

Ib

(4.39)

where Q=shear moment

For beams with rectangular cross-sections, dA = bdy, resulting in:

by 2

2

Q bydy

y1

2

h

We have

V x h 2

y12 with

yx x

2I 4

h

2

y1

b h2

y12

2 4

yx max

3V

bh

at the center line of the beam where y1=0

Quick Review of Simple Beam Theory – Cont’d

Euler-Bernoulli Theory of Beam Bending

This theory relates the induced deflection (deformation of beams) and the applied forces

y

Original straight beam:

Induced

deflection by

applied forces

P – concentrated force

w(x) – distributed load

y

per unit length

x

x

x

Deflection and Bending Moment M(x)

and Shear force V(x) relations:

d 2 v x M x

2

dx

EI

Applied

Forces

Deflected state

Induced deflection: v(x)

d 2 v x

d 3v x

M x EI

and V x EI

2

dx

dx 3

Induced Deflection v(x) may e obtained by solving the 4th order differential equation:

d 4 v x

EI

0

4

dx

where E = Young’s modulus of the beam material

I = Section moment of inertia

Induced

Deflection v(x)

& M(x), and V(x)

(4.40a,b)

FE Formulation of Beam Elements

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

y

Uniform distribution load: w N/m

y

B

A

x

Beam

Element

B

A

v(x)

x

L

ρ

Node i

ρ = Radius of curvature

deflection curve at x

Θ = slope of deflection

curve at x

V(x) = Deflection at x

Node j

x

x

v(x)

L

Primary Quantities

x=0

vi

In the element: The deflection v(x)

i

At the nodes: The deflections v and slope θ, or as expressed as: d at Node i and Node j

v j

j

x

Datum

line

L

x=L

FE Formulation of Beam Elements

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Beam elements

Contrary to the “truss elements,” beam elements deforms from its original straight shape into curved bent shape due to lateral

(or transverse) forces or applied couples (moments).

Actions and Induced Reactions in Beam Elements

Mi

Deformed shape

Node i

vi

Vi

X=0

Original shape

x

L

Node j

θ(x)

X

vj

Vj

X=L

Mj

in the element

Induced

Reactions

at Node i

at Node j

Linear

displacement

v(x)

Linear

displacement

vi

Linear

displacement

vj

Rotation

θ(x)

Rotation

θi

Rotation

θj

Actions

Lateral forces Vi

and Vj

Moments Mi and

Mj

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Derive Interpolation Function

We assume the traverse displacement of the beam element follows a linear

polynomial function o the form:

vx a1 x 3 a2 x 2 a3 x a4

(4.41)

in which a1, a2, a3 and a4 are constant coefficients

By substituting the coordinates of Node I and Node j into the assumed

element deflection in Equation (4.38), we get:

x=0

dv x

a3

dx x 0

At Node i:

vi v x x 0 a4

At Node j:

v j v x x L a1 L3 a2 L2 a3 L a4

x=L

i

2

j

dv x

3a1 L2 2a2 L a3

dx x L

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Derive Interpolation Function

We may thus express the element deflection v(x) in terms of the nodal deflections by

substituting the 4 constant coefficients into Equation (3.38) and after re-arranged terms

to yield:

1

2

v x 3 vi v j 2 i j x 3

L

L

1

3

2 vi v j 2 i j x 2 i x vi

L

L

The above expression can also be expressed as: v x N iv

where

N iv

1

3

2

3

2

x

3

x

L

L

L3

1

N jv 3 2 x 3 3 x 2 L

L

We thus have:

v(x) = [N(x)]{d}

The element

deflections

The nodal

deflections

N i

N j

N i

N jv

1 3

2 2

3

x

L

2

x

L

xL

L3

1

3 x 3 L x 2 L2

L

with Interpolation function: N x N iv

vi

i

N j

v j

j

(4.43)

N i

(4.42)

N jv

N j

(4.44)

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Derive Element Strain εxx – Displacement v(x) Relation

We realize the fact that the rotation (or the slope) of the deflected beam is: dvx for 0 x L

dx

An expanded view of a deformed beam in x-direction:

Contracted top edge

-u

Undeformed neutral axis

Rotation of the beam section at x

Stretched bottom edge

X

dx

We may find from the above diagram of expanded beam that the stretch u can be obtained by: u ( x) y y

But from theory of elasticity:

du

d dv x

d 2 v x

xx

or xx x, y y

y

dx

dx dx

dx 2

(4.45)

dv( x)

dx

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Derive Element Stress σxx – strain εxx Relation

We will have the normal stress σxx= Eεxx

and the shear stress:

yx x

M x y

I

(4.38)

V x

Q (4.39) with Q to be the shear moment

Ib

The relationships between the bending moment M(x) and Shear force V(x) are expressed in Equation (4.40a) and (4.40b) respectively:

d 2 v x

d 3v x

M x EI

and V x EI

dx 2

dx 3

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Derive the Element Stiffness Equations

We may express the applied actions to the beam element in applied forces fiy, fjy and moments mi, mj in terms of the

element deflections V(x) represented by the assumed polynomial function in Equation (4. 41) to be:

The beam element:

mi

Deformed shape

Node i

vi

Original shape

vj mj

L

X=0

d 3v x

EI

12vi 6Li 12v j 6L j

f iy V EI

3

3

dx x 0 L

d 3v x

EI

f jy V EI

3 12vi 6 L i 12v j 6 L j

3

dx x L L

Nodal moments:

X

θ(x)

x

fiy

Nodal forces:

Node j

-fjy

X=L

d 2 v x

EI

2

2

mi M EI

6

Lv

4

L

6

Lv

2

L

j

i

i

j

dx 2 x 0 L3

d 2 v x

EI

m j M x EI

6 Lvi 2 L2 i 6 Lv j 4 L2 j

2

3

dx x L L

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Derive the Element Stiffness Equations

The above expressions may e express in the following matrix form for the element stiffness equations:

6 L 12 6 L vi f iy

12

2

2

EI 6 L 4 L 6 L 2 L i mi

3

L 12 6 L 12 6 L v j f jy

2

2

6

L

2

L

6

L

4

L

j m j

Stiffness matrix [Ke] x

Nodal unknown

quantities(transverse

displacements & rotations

=

(4.46)

Applied nodal transverse forces

& moments

We thus have the stiffness equation of a beam element to be:

6 L 12 6 L

12

2

2

EI 6 L 4 L 6 L 2 L

ke 3

L 12 6 L 12 6 L

2

2

6

L

2

L

6

L

4

L

(4.47)

FE Formulation of Beam Elements – Cont’d

Principal reference: “A First Course in the FEM” 6th Edition, Cengage Learning by Daryl Logan, 2017

Determine the deflection of a cantilever beam at the half span and at the point under the load. Dimensions and

Example 4

applied lateral force are shown in the figure. The beam is made of a material with Young’s modulus E = 10000 MPa

ℓ/2=0.5 m

Node 1

•

•

x

Node 2

P = 20 N

•

Node 3

We realize the fact that we are seeking solutions at the mid-span and at the point

under the applied force. It id reasonable to discretize the beam into to two (2) elements,

as shown below:

ℓ=1m

Beam Cross-section:

b = 1 cm

h = 2 cm

Section moment of inertia (I) is:

bh 3 10 2 2 10 2

I

12

12

Solution:

3

0.667 10 8 m 4

EI = (1010)(0.667x10-8) = 66.7

Element 2:

Element 1:

Node 1

v1,, θ1

Node 2

• L = 0.5 m •

v2,θ2

Node 2

v2,, θ2

Node 3

• L = 0.5 m •

v3,θ3

We will first derive the element equations given in Equation (4.46) with element stiffness

matrices shown in Equation (4.47) for both Element 1 and 2.

FE Formulation of Beam Elements – Cont’d

Example 4

For Element 1 with L1 = 0.5 m:

6 L1

12

2

EI 6 L1 4 L1

1

ke 3

L1 12 6 L1

2

6

L

2

L

1

1

12

6 L1

12

6 L1

6 L1

3 12 3

12

3

2 L12

1

3

0

.

5