Vermont Electric Energy Efficiency Potential Study Draft

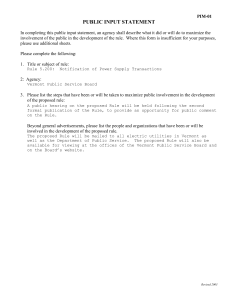

advertisement