Lab #2: Problem-Solving and Improvement MG/IE 3400 – Production System Design

advertisement

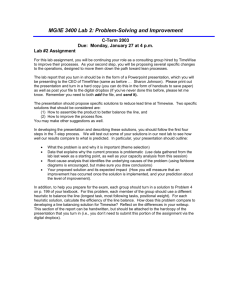

Lab #2: Problem-Solving and Improvement MG/IE 3400 – Production System Design 7-Step Process 1 2 THEME DATA 3 4 5 6 ROOT CAUSE SOLUTION CONFIRM RESULTS 7 STANDARDIZE REFLECT Yes No STEP OBJECTIVE • Describe the Problem • Get the Facts • Brainstorm • One complete sentence • Collect your own data • Ask why 5 times • Customer focused • Go to the site • Involve experts • Supports company/dept. goals • Seek multiple variables • Plan Solution to Address Root Cause • Did Experiment Work? • Run experiment • Construct comparative Paretos for all levels analyzed in Step 2 • Establish schedule for key actions • Document the process • Appropriate level • Stratify/cut data in many ways • Assess positive and negative side effects • Measurable •Look for the “Fat Rabbit” • Show run chart over time with milestones noted • Provide problem overview/magnitude • Identify Strengths/Weaknesses of the 7-Step Process Used • Summarize lessons learned • Train people involved • Confirm results with the customer and those who use the process • Involve affected individuals • Construct Paretos • Weakness oriented • Standardize The New Process Across all Like Processes • Summarize achievements • Monitor the results • Identify next spin/project • Communicate the new standard • Show schedule for spin • How can the team be sure the fix will stick? • Maintain the gain. STANDARD TOOLS Checksheet ¦ High Level Flow Chart Inputs Ishakawa Diagram (a.k.a. Fishbone or Cause & Effect) 1 2 3 4 5 6 7 What When Where How 24 100% 24 20 80% 16 60% 12 Pareto Charts ¦ Run Chart 4 W's & 1H Chart Who Process Outputs 24 100% 20 80% 16 Why is "Fat Rabbit" Happening? 20 16 Who What When Where How Weaknesses ¦ 150% 120% 100% 12 40% 8 Time Line of Experiment 60% Strengths 4 W's & 1H & 1C = Check Before and After Pareto 8 70% 4 20% 4 40% 0 0% 0 0% Countermeasures * * * Old Flow Chart vs. New Flow Chart Positive/Negative Side Effects Next Problem Selection 12 40% 4 20% 0 0% Run Chart Detail Flow Chart of Process Run Chart (Monitor) Item Weakness 8 Gantt Chart Solution Implemented Time Time No fat rabbit: inconclusive Time 1 2 3 4 5 6 7 Plan v. Actual FOLLOW THE LOGIC CHAIN 7-Step Process Flowchart TimeWise Improvement THEME DATA ROOT CAUSE Plan SOLUTION Do Today CONFIRM RESULTS Check Next Week Two Weeks STANDARDIZE Yes Act REFLECT 1. Theme Selection Identify the problem team will address prioritize to identify the most important problem address one of five ‘evils’: defects, delays, mistakes, waste, and accidents A good theme is: measurable customer-focused action-oriented, focused in weakness does not state causes or solutions 2. Data Collection and Analysis Investigate the problem from different viewpoints, establish benchmarks What factors influence the problem? Checksheets for data collection Fishbone diagram Pareto diagram Data from TimeWise Morning session 1 session 2 session 3 Average Cycle Time (min) 9 (others > 15) all > 15 all > 15 # Units in Ending WIP 10 Blue, 10 Black 28 Blue, 60 Black 40 Blue, 42 Black # Units on Time 0 6 5 # Units Shipped Late 3 0 5 # Units in Finished Goods Warehouse 4 Blue, 1 Black 0 5 Blue, 0 Black # Failed 3 lots 3 lots 3 lots # Passed 1 lot 1 lot 1 lot # Orders Outstanding 42 24 Black, 15 Blue 35 # Orders Waiting at Kitting 10 3 1.5 Average Cycle Time (min) # Units in Ending WIP # Units on Time # Units Shipped Late # Units in Finished Goods Warehouse # Failed # Passed # Orders Outstanding # Orders Waiting at Kitting Afternoon session 1 session 2 session 3 greater than shift greater than shift 11:30, 14:20 38 black, 22 blue 56 black, 28 blue 18 black, 16 blue 7 (3 orders) 8 (4 orders) 11 (5 orders) 0 4 (3 orders) 16 (9 orders) 0 0 3 2 3 1 0 1 4 43 (40bk, 30bl) 38 (38bk, 29bl) 29 6 4 6.5 TimeWise: Quality Problems 18 16 14 12 10 8 6 4 2 0 Quadrant Marker Colors Parallelism Ornamental Quadrant - Face and Plate Marker Movement Location Alignment Functional Hand Color Test 3. Causal Analysis Talk to people closest to the work to discover the ‘real’ problem Fishbone diagrams to explore causes more deeply (‘drill down’ to greater levels of detail) Why, why, why, why, why … until you have a root cause, based on data 4. Solution Planning What solutions exist that prevent the recurrence of the root cause? Advantages Disadvantages, impact on other processes Run experiments How will results be measured? Process Analysis Calculate coefficient of variation for each major step in the process CV = std dev/mean Low variability: CV <0.75 Moderate variability: 0.75 < CV <1.33 High variablity: CV >1.33 Process Analysis, cont… What is capacity? Capacity is determined by the bottleneck operation(s). How can you estimate it? Calculate TAKT Time Analyze assembly operations What are sub-elements? Are they necessary? How long do they take? Example Task Time (Sec) Precedence A B C D E F G H I J K 40 55 75 40 30 35 45 70 15 65 40 None None None A A,B B D,E F G,H I C,J 510 Number of Following Tasks Positional Weight 4 4 4 3 3 2 1 0 205 195 225 165 190 120 105 40 Total Task Time Desired production rate = 200/day. Assume 8 hours/day Positional Weights Station Task Time Time so Far Ready Tasks Balance Delay D D = [k* C - ti ] / k* C where C = cycle time k*= number of stations ti = time for task i