Laboratory Safety Lecture 1 Chemical & Fuels Engineering 1

advertisement

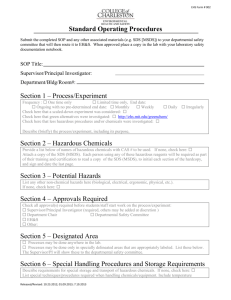

Laboratory Safety Lecture 1 Chemical & Fuels Engineering 1 OHSA Hazard Communication Standard from 1988. Employer responsibility Provide Information Chemical Hygiene Plan Permissible Exposure Limits established Symptoms associated with exposure Reference materials on hazards, safe handling, storage and disposal Training Physical and health hazards of chemicals used Contents of Chemical Hygiene Plan Methods to detect of hazardous chemical release 2 Employee Responsibilities (this is you, the student) Plan work in accordance Personal responsibilities with Chemical Hygiene Plan Use equipment for designed Work so that others (e.g., purpose coworkers, the public) will Be familiar with emergency not be harmed. equipment and procedures Know and use appropriate protective equipment Be alert to unsafe conditions and actions call attention to them correct them 3 Chemical Hygiene Plan - www.ehs.utah.edu/programs/chp.htm Training and Documentation Standard Operating Procedures i. Reactive Chemicals ii. Corrosive Chemicals iii. Acids and Bases iv. Carcinogens and Toxins v. Compressed Gasses Exposure Control Monitoring 4 Chemical Hygiene Plan – Sections Roles & Responsibilities Information and Training Prior Approval Circumstances Standard Operating Procedures Appendix Power Outage Emergency Response Carcinogenic Chemical List 5 Lab is scheduled from 1:00 to 5:00 PM on assigned afternoons. You are expected to manage your time and productivity to make the best use of your allotted time. Your employer will have the same expectation. Make-up time will usually not be granted. Students may not work in the lab unless an instructor, teaching assistant, or lab technician is present. 6 We start the semester with the lab clean and well organized. It is up to you to keep it that way. Clean-up is everyday at 4:30 PM, plan on this in your project schedule. Failure to clean-up everyday and at the end of your project will result in a reduction in your grade and the ire of Bob Cox. 7 You are responsible for the safety of your project, your team and your neighbors. A safety review will be part of your preliminary oral exam. Violations of safe practice will result in a reduction of your grade or suspension from the lab. As an engineer you are responsible for your own safety, the safety of your co-workers, and the safety of the public and the environment. Safety equipment is available in each lab. There is no excuse for not using it. 8 Safety glasses are required whenever you are handling chemicals or operating machinery. (PERIOD) Hard-hats are required when working on the grating area. Please do not drop tools on the students below! Use the fume hoods to reduce your chemical exposure. When handling strong corrosives such as full strength acids and bases, use a face shield, gloves, and splash apron. 9 Gloves Choose the type of Glove that will protect against the chemical you are handling Glove Materials Permeation Test Data Take glove off so that your skin does not make contact with contaminated area See www.labsafety.com 10 Glove Material Butyl Neoprene Nitrile PVC polyvinyl chloride PVA polyvinyl alcohol Viton7 Applications A synthetic rubber material that offers the highest permeation resistance to gas and water vapors. Especially suited for use with esters and ketones. A synthetic rubber material that provides excellent tensile strength and heat resistance. Neoprene is compatible with some acids and caustics. It has moderate abrasion resistance. A synthetic rubber material that offers chemical and abrasion resistance - a very good general duty glove. Nitrile also provides protection from oils, greases, petroleum products, and some acids and caustics. A synthetic thermoplastic polymer that provides excellent resistance to most acids, fats and petroleum hydrocarbons. Good abrasion resistance. A water-soluble synthetic material that is highly impermeable to gases. Excellent chemical resistance to aromatic and chlorinated solvents. This glove cannot be used in water or waterbased solutions. A fluoroelastomer material that provides exceptional chemical resistance to chlorinated and aromatic solvents. Viton7 is very flexible, but has minimal resistance to cuts and abrasions. ~ Cost $12-20/pair $30-55/12pr $11-12/100pr disposable (Chemistry) $16-60/12pr reusable $15/100 pr disposable $30-55/12 pr reusable $37/10pr $35-100/pair 11 Do not eat or drink in the lab. These are chemical handling areas. Do not pipette by mouth! Do not spill any chemicals. Spill containment and clean-up materials are located in lab 3520A. The removable gratings between floors must not be removed. Near fatal injuries have occurred in the past. Shorts and sandals are not appropriate attire in the laboratories. You can change before lab. 12 Keep your work area clean and well organized, clean up any spills. ALL chemical containers must be labeled. After Consulting Guidelines for Drain Disposal of Chemicals, Contact your instructor or Bob Cox for disposal of chemicals and hazardous waste. Be aware of the danger of long hair, loose clothing and jewelry around rotating or moving equipment. Secure your long hair. 13 Safety Considerations Exposure Limits OSHA Average over 40 hr work week – Sickness – Death Flamibility/Explosion Flamibility Limits Explosion Limits Threshold Limit Value Threshold of smell 14 Hazardous Operations Develop a plan of operation for hazardous experiments/equipment Get plan approved Document all operations to meet the guidelines of the plan 15 OTHER LABORATORY AREA HAZARDS Compressed gas cylinders. A. Past accidents, projectile Hazard capable of penetrating concrete walls. B. Tanks must be securely belted or chained in place. C. Oxygen tanks must be segregated. D. Oxygen connections and lines must be oil free. E. Either a regulator or a safety cap must be in place at all times. F. The safety cap must be in place when moving the tank. 16 OHSA Chemical Hygiene Plan (CHP) for Senior Lab For University MSDS Container Labeling 17 MSDS Cornerstone of Chemical Safety Identification Ingredients and Hazards Reactivity Data Spill/Leak Procedures Special Protection Info. Special Precautions Glossary of Terms used in MSDS 18 http://www.che.utah.edu go to the SAFETY page http://www.chem.utah.edu contents frame go to the MSDS link on the http://www.ehs.utah.edu go to the LINKS page 19 MSDS 20 21 22 23 Rating Summary Health (Blue) 4 3 2 1 Danger Warnin g Warnin g Caution 0 May be fatal on short exposure. Specialized protective equipment required NFPA Chemical Hazard Labels Corrosive or toxic. Avoid skin contact or inhalation May be harmful if inhaled or absorbed May be irritating No unusual hazard Flammability (Red) 4 Danger Flammable gas or extremely flammable liquid 3 Warning Flammable liquid flash point below 100° F 2 Caution Combustible liquid flash point of 100° to 200° F 1 Combustible if heated 0 Not combustible Reactivity (Yellow) 4 Danger Explosive material at room temperature 3 Danger May be explosive if shocked, heated under confinement or mixed with water 2 Warning Unstable or may react violently if mixed with water 1 Caution May react if heated or mixed with water but not violently 0 Stable Not reactive when mixed with water Special Notice Key (White) W Water Reactive Oxy Oxidizing Agent 24 Chemical Labels B C E F+ F Xn Xi N O R T T+ Biohazard Corrosive Explosive Extremely Flammable Highly Flammable Harmful Irritant Dangerous for the En Oxidizing Radioactive Toxic Very Toxic 25 Each lab/work area must have appropriate spill containment and clean-up materials sufficient for the chemicals in use. Minor spills dealt with in the Lab. Two types of packs Acid Base Major spills require assistance, call University dispatch 5-2677 COPS). Life threatening situations, ring fire alarm and evacuate. (5- 26 What to do in Power Outage Close Fume Hoods Secure Chemical Containers Caps, Covers, etc. Close cylinders at tank valve Turn off non-essential equipment and large power draw equipment Check all sensitive or reactive materials maintain cover gases or seals 27 What to do in Fire Pull the nearest fire alarm and evacuate. University policy is that students should not attempt to fight fires. Any person having first hand knowledge of an alarm situation should report to the emergency response personnel in the parkinc7 lot at the northwest comer of MEB. Close lab and hallway doors on your way out. Never disregard a fire alarm. 28 Have an alternate escape route planned. What to do in Earthquake. Routinely close cabinet doors. Hide under a heavy desk or door frame. Evacuate cautiously, watch for falling glass. 29 Emergency Response 30 Many lab projects will generate hazardous waste streams. As part of your project planning, discuss the disposal issues with Instructor. Some hazardous wastes may be treated and neutralized. Guidelines for Drain Disposal of Chemicals http://www.che.utah.edu/~geoff/writing/index.html Some hazardous wastes must be collected for disposal. All waste containers must be kept closed. Annual EPA inspections. Fines from past infractions. 31