Chapter 6: Fundamentals of Convection Yoav Peles

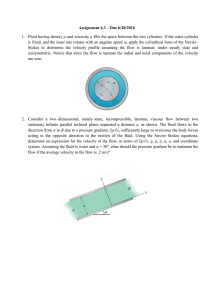

advertisement

Chapter 6: Fundamentals of Convection Yoav Peles Department of Mechanical, Aerospace and Nuclear Engineering Rensselaer Polytechnic Institute Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. Objectives When you finish studying this chapter, you should be able to: • Understand the physical mechanism of convection, and its classification, • Visualize the development of velocity and thermal boundary layers during flow over surfaces, • Gain a working knowledge of the dimensionless Reynolds, Prandtl, and Nusselt numbers, • Distinguish between laminar and turbulent flows, and gain an understanding of the mechanisms of momentum and heat transfer in turbulent flow, • Derive the differential equations that govern convection on the basis of mass, momentum, and energy balances, and solve these equations for some simple cases such as laminar flow over a flat plate, • Nondimensionalize the convection equations and obtain the functional forms of friction and heat transfer coefficients, and • Use analogies between momentum and heat transfer, and determine heat transfer coefficient from knowledge of friction coefficient. Physical Mechanism of Convection • Conduction and convection are similar in that both mechanisms require the presence of a material medium. • But they are different in that convection requires the presence of fluid motion. • Heat transfer through a liquid or gas can be by conduction or convection, depending on the presence of any bulk fluid motion. • The fluid motion enhances heat transfer, since it brings warmer and cooler chunks of fluid into contact, initiating higher rates of conduction at a greater number of sites in a fluid. • Experience shows that convection heat transfer strongly depends on the fluid properties: – – – – – dynamic viscosity m, thermal conductivity k, density r, and specific heat cp, as well as the fluid velocity V. • It also depends on the geometry and the roughness of the solid surface. • The rate of convection heat transfer is observed to be proportional to the temperature difference and is expressed by Newton’s law of cooling as qconv h Ts T (W/m2 ) (6-1) • The convection heat transfer coefficient h depends on the several of the mentioned variables, and thus is difficult to determine. • All experimental observations indicate that a fluid in motion comes to a complete stop at the surface and assumes a zero velocity relative to the surface (no-slip). • The no-slip condition is responsible for the development of the velocity profile. • The flow region adjacent to the wall in which the viscous effects (and thus the velocity gradients) are significant is called the boundary layer. • An implication of the no-slip condition is that heat transfer from the solid surface to the fluid layer adjacent to the surface is by pure conduction, and can be expressed as qconv qcond k fluid T y (W/m2 ) (6-3) y 0 • Equating Eqs. 6–1 and 6–3 for the heat flux to obtain h k fluid T y y 0 Ts T (W/m2 C) (6-4) • The convection heat transfer coefficient, in general, varies along the flow direction. The Nusselt Number • It is common practice to nondimensionalize the heat transfer coefficient h with the Nusselt number hLc Nu (6-5) k • Heat flux through the fluid layer by convection and by conduction can be expressed as, respectively: T qconv hT (6-6) qcond k (6-7) L • Taking their ratio gives qconv hT hL Nu (6-8) qcond k T / L k • The Nusselt number represents the enhancement of heat transfer through a fluid layer as a result of convection relative to conduction across the same fluid layer. • Nu=1 pure conduction. Classification of Fluid Flows • • • • • • • Viscous versus inviscid regions of flow Internal versus external flow Compressible versus incompressible flow Laminar versus turbulent flow Natural (or unforced) versus forced flow Steady versus unsteady flow One-, two-, and three-dimensional flows Velocity Boundary Layer • • • • • • • • Consider the parallel flow of a fluid over a flat plate. x-coordinate: along the plate surface y-coordinate: from the surface in the normal direction. The fluid approaches the plate in the x-direction with a uniform velocity V. Because of the no-slip condition V(y=0)=0. The presence of the plate is felt up to d. Beyond d the free-stream velocity remains essentially unchanged. The fluid velocity, u, varies from 0 at y=0 to nearly V at y=d. Velocity Boundary Layer • The region of the flow above the plate bounded by d is called the velocity boundary layer. • d is typically defined as the distance y from the surface at which u=0.99V. • The hypothetical line of u=0.99V divides the flow over a plate into two regions: – the boundary layer region, and – the irrotational flow region. Surface Shear Stress • Consider the flow of a fluid over the surface of a plate. • The fluid layer in contact with the surface tries to drag the plate along via friction, exerting a friction force on it. • Friction force per unit area is called shear stress, and is denoted by t. • Experimental studies indicate that the shear stress for most fluids is proportional to the velocity gradient. • The shear stress at the wall surface for these fluids is expressed as u (6-9) ts m (N/m 2 ) y y 0 • The fluids that that obey the linear relationship above are called Newtonian fluids. • The viscosity of a fluid is a measure of its resistance to deformation. • The viscosities of liquids decrease with temperature, whereas the viscosities of gases increase with temperature. • In many cases the flow velocity profile is unknown and the surface shear stress ts from Eq. 6–9 can not be obtained. • A more practical approach in external flow is to relate ts to the upstream velocity V as rV 2 (6-10) ts Cf (N/m2 ) 2 • Cf is the dimensionless friction coefficient (most cases is determined experimentally). • The friction force over the entire surface is determined from rV 2 (6-11) Ff C f As (N) 2 Thermal Boundary Layer • Like the velocity a thermal boundary layer develops when a fluid at a specified temperature flows over a surface that is at a different temperature. • Consider the flow of a fluid at a uniform temperature of T∞ over an isothermal flat plate at temperature Ts. • The fluid particles in the layer adjacent assume the surface temperature Ts. • A temperature profile develops that ranges from Ts at the surface to T∞ sufficiently far from the surface. • The thermal boundary layer ─ the flow region over the surface in which the temperature variation in the direction normal to the surface is significant. • The thickness of the thermal boundary layer dt at any location along the surface is defined as the distance from the surface at which the temperature difference T(y=dt)-Ts= 0.99(T∞-Ts). • The thickness of the thermal boundary layer increases in the flow direction. • The convection heat transfer rate anywhere along the surface is directly related to the temperature gradient at that location. Prandtl Number • The relative thickness of the velocity and the thermal boundary layers is best described by the dimensionless parameter Prandtl number, defined as Molecular diffusivity of momentum mc p Pr (6-12) Molecular diffusivity of heat k • Heat diffuses very quickly in liquid metals (Pr«1) and very slowly in oils (Pr»1) relative to momentum. • Consequently the thermal boundary layer is much thicker for liquid metals and much thinner for oils relative to the velocity boundary layer. Laminar and Turbulent Flows • Laminar flow ─ the flow is characterized by smooth streamlines and highly-ordered motion. • Turbulent flow ─ the flow is characterized by velocity fluctuations and highly-disordered motion. • The transition from laminar to turbulent flow does not occur suddenly. • The velocity profile in turbulent flow is much fuller than that in laminar flow, with a sharp drop near the surface. • The turbulent boundary layer can be considered to consist of four regions: – – – – Viscous sublayer Buffer layer Overlap layer Turbulent layer • The intense mixing in turbulent flow enhances heat and momentum transfer, which increases the friction force on the surface and the convection heat transfer rate. Reynolds Number • The transition from laminar to turbulent flow depends on the surface geometry, surface roughness, flow velocity, surface temperature, and type of fluid. • The flow regime depends mainly on the ratio of the inertia forces to viscous forces in the fluid. • This ratio is called the Reynolds number, which is expressed for external flow as Inertia forces VLc rVLc Re (6-13) Viscous forces m • At large Reynolds numbers (turbulent flow) the inertia forces are large relative to the viscous forces. • At small or moderate Reynolds numbers (laminar flow), the viscous forces are large enough to suppress these fluctuations and to keep the fluid “inline.” • Critical Reynolds number ─ the Reynolds number at which the flow becomes turbulent. Heat and Momentum Transfer in Turbulent Flow • Turbulent flow is a complex mechanism dominated by fluctuations, and despite tremendous amounts of research the theory of turbulent flow remains largely undeveloped. • Knowledge is based primarily on experiments and the empirical or semi-empirical correlations developed for various situations. • Turbulent flow is characterized by random and rapid fluctuations of swirling regions of fluid, called eddies. • The velocity can be expressed as the sum of an average value u and a fluctuating component u’ u u u' (6-14) • It is convenient to think of the turbulent shear stress as consisting of two parts: – the laminar component, and – the turbulent component. • The turbulent shear stress can be expressed as t turb r u ' v ' • The rate of thermal energy transport by turbulent eddies is qturb r c p v ' T ' • The turbulent wall shear stress and turbulent heat transfer t turb u r u ' v ' mt y ; qturb T r c p vT kt (6-15) y • mt ─ turbulent (or eddy) viscosity. • kt ─ turbulent (or eddy) thermal conductivity. • The total shear stress and total heat flux can be expressed as u u m mt r t y y (6-16) T T k kt r c p t y y (6-17) t turb and qturb • In the core region of a turbulent boundary layer ─ eddy motion (and eddy diffusivities) are much larger than their molecular counterparts. • Close to the wall ─ the eddy motion loses its intensity. • At the wall ─ the eddy motion diminishes because of the no-slip condition. In the core region ─ the velocity and temperature profiles are very moderate. In the thin layer adjacent to the wall ─ the velocity and temperature profiles are very steep. Large velocity and temperature gradients at the wall surface. The wall shear stress and wall heat flux are much larger in turbulent flow than they are in laminar flow. Derivation of Differential Convection Equations • Consider the parallel flow of a fluid over a surface. • Assumptions: – – – – steady two-dimensional flow, Newtonian fluid, constant properties, and laminar flow. • The fluid flows over the surface with a uniform freestream velocity V, but the velocity within boundary layer is two-dimensional (u=u(x,y), v=v(x,y)). • Three fundamental laws: – conservation of mass continuity equation – conservation of momentum momentum equation – conservation of energy energy equation The Continuity Equation • Conservation of mass principle ─ the mass can not be created or destroyed during a process. • In steady flow: Rate of mass flow into the control volume = Rate of mass flow out of the control volume • The mass flow rate is equal to: ruA ruA (6-18) The fluid leaves the control volume from the left surface at a rate of ru dy 1 the fluid leaves the control volume from the right surface at a rate of u r u dx dy 1 x Repeating this for the y direction (6-19) v+∂v/∂y·dy and substituting the results into Eq. u 6–18, we obtain dy u+∂u/∂x·dx r u dy 1 r v dx 1 r u u v x,y dx dy 1 r v dy dx 1 x y (6-20) dx v Simplifying and dividing by dx·dy u v 0 x y (6-21) The continuity equation The Momentum Equation • The differential forms of the equations of motion in the velocity boundary layer are obtained by applying Newton’s second law of motion to a differential control volume element in the boundary layer. • Two type of forces: – body forces, – surface forces. • Newton’s second law of motion for the control volume Acceleration Net force (body and surface) (6-22) (Mass) X in a specified direction = acting in that direction or d m ax Fsurface, x Fbody , x (6-23) • where the mass of the fluid element within the control volume is d m r dx dy 1 (6-24) • The flow is steady and two-dimensional and thus u=u(x, y), the total differential of u is du u u dx dy x y (6-25) • Then the acceleration of the fluid element in the x direction becomes du u dx u dy u u ax u v dt x dt y dt x y (6-26) • The forces acting on a surface are due to pressure and viscous effects. • Viscous stress can be resolved into two perpendicular components: – normal stress, – shear stress. • Normal stress should not be confused with pressure. • Neglecting the normal stresses the net surface force acting in the x-direction is Fsurface , x t t P P dy dx 1 dx dy 1 dx dy 1 x y y x 2u P m 2 dx dy 1 x y (6-27) • Substituting Eqs. 6–21, 6–23, and 6–24 into Eq. 6–20 and dividing by dx·dy·1 gives u u 2u P r u v m 2 y y x x Boundary Layer Approximation Assumptions: 1) Velocity components: The x-momentum equation (6-28) u>>v 2) Velocity gradients: ∂v/∂x≈0 and ∂v/∂y≈0 ∂u/∂y >> ∂u/∂x 3) Temperature gradients: ∂T/∂y >> ∂T/∂x • When gravity effects and other body forces are negligible the y-momentum equation P 0 (6-29) y Conservation of Energy Equation • The energy balance for any system undergoing any process is expressed as Ein-Eout=Esystem. • During a steady-flow process Esystem=0. • Energy can be transferred by – heat, – work, and – mass. • The energy balance for a steady-flow control volume can be written explicitly as E in Eout by heat Ein Eout by work Ein Eout by mass 0 (6-30) • Energy is a scalar quantity, and thus energy interactions in all directions can be combined in one equation. Energy Transfer by Mass • The total energy of a flowing fluid stream per unit mass is estream enthalpy kinetic potential 2 2 C pT gz V 2 u v 2 2 • Noting that mass flow rate of the fluid entering the control volume from the left is ru(dy·1), the rate of energy transfer to the control volume by mass in the x-direction is mestream x Ein Eout by mass,x mestream x mestream x x dx (6-31) r u dy 1 c pT u T dx r c p u T dxdy x x x • Repeating this for the y-direction and adding the results, the net rate of energy transfer to the control volume by mass is determined to be E in Eout by mass T u v T rcp u T T dxdy dxdy r c p v x y x y T T rcp u v dxdy y x (6-32) • Note that ∂u/∂x+∂v/∂y=0 from the continuity equation. Energy Transfer by Heat Conduction • The net rate of heat conduction to the volume element in the x-direction is E in Eout by heat , x Qx T Qx Qx dx k dy 1 x x x 2T k 2 dxdy x dx (6-33) • Repeating this for the y-direction and adding the results, the net rate of energy transfer to the control volume by heat conduction becomes E in Eout by heat 2T 2T 2T 2T k 2 dxdy k 2 dxdy k 2 2 dxdy x y y x (6-34) Energy Transfer by Work • The work done by a body force is determined by multiplying this force by the velocity in the direction of the force and the volume of the fluid element. • This work needs to be considered only in the presence of significant gravitational, electric, or magnetic effects. • The work done by pressure (the flow work) is already accounted for in the analysis above by using enthalpy for the microscopic energy of the fluid instead of internal energy. • The shear stresses that result from viscous effects are usually very small, and can be neglected in many cases. The Energy Equation • The energy equation is obtained by substituting Eqs. 6–32 and 6–34 into 6–30 to be 2 2 T T T T rcp u v k 2 2 y y x x (6-35) 2T 2T T T rcp u v k 2 2 m y y x x (6-36) • When the viscous shear stresses are not negligible, • where the viscous dissipation function is obtained after a lengthy analysis to be u 2 v 2 u v 2 2 x y y x (6-37) • Viscous dissipation may play a dominant role in highspeed flows. Solution of Convection Equations for a Flat Plate (Blasius Equation) • Consider laminar flow of a fluid over a flat plate. • Steady, incompressible, laminar flow of a fluid with constant properties • Continuity equation u v x y (6-39) • Momentum equation u u 2u u v 2 x y y (6-40) • Energy equation T T 2T u v 2 x y y (6-41) Boundary conditions • At x=0 • At y=0 • As y∞ u 0, y V , u x,0 0, T 0, y T v x,0 0, T x,0 Ts u x, V , (6-42) T x, T • When fluid properties are assumed to be constant, the first two equations can be solved separately for the velocity components u and v. • knowing u and v, the temperature becomes the only unknown in the last equation, and it can be solved for temperature distribution. • The continuity and momentum equations are solved by transforming the two partial differential equations into a single ordinary differential equation by introducing a new independent variable (similarity variable). • The argument ─ the nondimensional velocity profile u/V should remain unchanged when plotted against the nondimensional distance y/d. • d is proportional to (x/V)1/2, therefore defining dimensionless similarity variable as y V x might enable a similarity solution. (6-43) • Introducing a stream function y(x, y) as y u y ; y v x (6-44) • The continuity equation (Eq. 6–39) is automatically satisfied and thus eliminated. • Defining a function f() as the dependent variable as y f V x /V (6-45) • The velocity components become y y x df V df u V V y y V d x d (6-46) y x df V 1 V df v V f f x V d 2 Vx 2 x d (6-47) • By differentiating these u and v relations, the derivatives of the velocity components can be shown to be u V d2 f u V d2 f 2u V 2 d 3 f ; V ; 2 2 2 x 2 x d y x d y x d 3 (6-48) • Substituting these relations into the momentum equation and simplifying d3 f d2 f 2 3f 0 2 d d (6-49) • which is a third-order nonlinear differential equation. Therefore, the system of two partial differential equations is transformed into a single ordinary differential equation by the use of a similarity variable. • The boundary conditions in terms of the similarity variables f 0 0, df 0, d 0 df 1 (6-50) d • The transformed equation with its associated boundary conditions cannot be solved analytically, and thus an alternative solution method is necessary. • The results shown in Table 6-3 was obtained using different numerical approach. • The value of corresponding to u/V=0.99 is =4.91. • Substituting =4.91 and y=d into the definition of the similarity variable (Eq. 6–43) gives 4.91=d(V/x)1/2. • The velocity boundary layer thickness becomes d 4.91 4.91x V x Re x (6-51) • The shear stress on the wall can be determined from its definition and the ∂u/∂y relation in Eq. 6–48: u tw m y y 0 V d2 f mV x d 2 (6-52) 0 Substituting the value of the second derivative of f at h=0 from Table 6–3 gives 2 rmV t w 0.332V x 0.332 rV Re x (6-53) Then the average local skin friction coefficient becomes C f ,x tw rV / 2 2 0.664 Re x 1/ 2 (6-54) The Energy Equation • Introducing a dimensionless temperature q as q x, y T x, y Ts (6-55) T Ts • Noting that both Ts and T are constant, substitution into the energy equation Eq. 6–41 gives q q 2q u v 2 x y y (6-56) • Using the chain rule and substituting the u and v expressions from Eqs. 6–46 and 6–47 into the energy equation gives df dq d 1 Vy df dq d d q V f 2 d d dx 2 x d d dy d y 2 2 (6-57) • Simplifying and noting that Pr=/ gives d 2q dq 2 2 Pr f 0 d d Boundary conditions: (6-58) q 0 0, q 1 • Obtaining an equation for q as a function of alone confirms that the temperature profiles are similar, and thus a similarity solution exists. • for Pr=1, this equation reduces to Eq. 6–49 when q is replaced by df/d. • Equation 6–58 is solved for numerous values of Prandtl numbers. • For Pr>0.6, the nondimensional temperature gradient at the surface is found to be proportional to Pr1/3, and is expressed as dq 0.332 Pr1/ 3 d 0 (6-59) • The temperature gradient at the surface is dT dy y 0 q T Ts y y 0 dq d T Ts d 0 dy y 0 (6-60) V x • Then the local convection coefficient and Nusselt number become 0.332 Pr1/ 3 T Ts and k T y y 0 qs V 1/ 3 hx 0.332 Pr k Ts T Ts T x (6-61) hx x (6-62) Nu x 0.332 Pr1/ 3 Re1/ 2 Pr>0.6 k • Solving Eq. 6–58 numerically for the temperature profile for different Prandtl numbers, and using the definition of the thermal boundary layer, it is determined that d d t Pr1/ 3 Nondimensional Convection Equation and Similarity Continuity equation u v 0 x y (6-21) x-momentum equation u u 2u P r u v m 2 y y x x (6-28) Energy equation 2T 2T T T rcp u v k 2 2 (6-35) y y x x • Nondimensionalized variables T Ts x y u v P * * * * * x ; y ; u ; v ; P ; T 2 L L V V rV T Ts * • Introducing these variables into Eqs. 6–21, 6–28, and 6–35 and simplifying give u* v* * 0 * x y Continuity equation (6-64) x-momentum equation * * 2 * * u u 1 u P u * * v* * * *2 x y Re L y x (6-65) Energy equation * * 2 * T T 1 T u * * v* * x y Re L Pr y*2 (6-66) with the boundary conditions u* 0, y* 1 ; u * x* , 0 0 ; u * x* , 1 ; v* x* , 0 0 T * 0, y* 1 ; T * x* , 0 0 ; T * x* , 1 (6-67) • For a given type of geometry, the solutions of problems with the same Re and Nu numbers are similar, and thus Re and Nu numbers serve as similarity parameters. • A major advantage of nondimensionalizing is the significant reduction in the number of parameters. • The original problem involves 6 parameters (L, V, T, Ts, , ), but the nondimensionalized problem involves just 2 parameters (ReL and Pr). 6 parameters L, V, T, Ts,, Nondimensionalizing 2 parameters ReL, Pr Functional Forms of the Friction and Convection Coefficient • From Eqs. 6-64 and 6-65 it can be inferred that u * f1 x* , y* , Re L (6-68) • Then the shear stress at the surface becomes u ts m y y 0 mV u * L y * y* 0 mV L f 2 x* , Re L (6-69) • Substituting into its definition gives the local friction coefficient, C f ,x ts mV L 2 * * * f x , Re f x , Re f x , Re L 2 L 2 L 3 2 2 rV 2 rV 2 Re L (6-70) • Similarly the solution of Eq. 6-66 T * g1 x* , y* , Re L , Pr (6-71) • Using the definition of T*, the convection heat transfer coefficient becomes k T y y 0 k T T T * k T * s (6-72) h * * Ts T L Ts T y y 0 L y y 0 * * • Substituting this into the Nusselt Number relation gives * hL T Nu x * k y g 2 x* , Re L , Pr y* 0 (6-73) • It follows that the average Nu and Cf depends on Nu g3 Re L , Pr ; C f f 4 Re L (6-74) • These relations are extremely valuable: – The friction coefficient can be expressed as a function of Reynolds number alone, and – The Nusselt number as a function of Reynolds and Prandtl numbers alone. • The experiment data for heat transfer is often represented by a simple power-law relation of the form: Nu C RemL Pr n (6-75) Analogies Between Momentum and Heat Transfer • Reynolds Analogy (Chilton─Colburn Analogy) ─ under some conditions knowledge of the friction coefficient, Cf, can be used to obtain Nu and vice versa. • Eqs. 6–65 and 6–66 (the nondimensionalized momentum and energy equations) for Pr=1 and ∂P*/∂x*=0: x-momentum equation * * 2 * u u 1 u * * u v * * x y Re L y*2 (6-76) Energy equation * * 2 * T T 1 T * * u v * * x y Re L y*2 (6-77) • which are exactly of the same form for the dimensionless velocity u* and temperature T*. • The boundary conditions for u* and T* are also identical. • Therefore, the functions u* and T* must be identical. u * y* Reynolds analogy C f ,x y* 0 T * * y Re L Nu 2 (6-78) y* 0 (6-79) (Pr=1) • The Reynolds analogy can be extended to a wide range of Pr by adding a Prandtl number correction. C f , x 0.664Rex1/ 2 (6-82) C f ,x Nu x 0.332 Pr1/ 3 Re1/ 2 Re Nu x Pr1 3 2 0.6 Pr 60 Pr>0.6 (6-83)