Highlights of US ITER TBM Technical Plan and Cost Estimates

Highlights of US ITER TBM

Technical Plan and

Cost Estimates

(and Impact of International Collaboration)

Mohamed Abdou and the U.S. Team

TBWG-17

Presented at ITER Test Blanket Working Group (TBWG-17) at

Cadarache, France, April 4-6, 2006

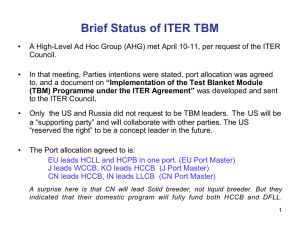

Detailed TBM Planning and Costing Activity for the US TBM Program is Underway

• The activity was requested by DOE and initiated in

August 2005.

• The plan and costing are being developed by technical experts from the community (from Plasma Chamber,

Materials, PFC, Safety and Tritium programs).

– With important support and guidance from costing and project management professionals.

• A very preliminary initial draft of the report was distributed “internally within the team” in early March

2006, for internal discussion and review.

• Revisions are underway.

• Expected:

– Issue Report: May 2006

– “External” Review : July 2006

– “Government” Decision: Summer 2006

– This is the beginning of several steps required by the U.S.

Government for “capital projects.”

Process followed for the US TBM Technical Plan and Cost Estimate

(Some steps were iterative)

• Develop details of test plan in ITER and define “U.S. deliverables”

• Identify the required activities

– R&D

– Design

– Procurement and Fabrication

– Qualification and Acceptance Testing

• Establish WBS

– Assign WBS account numbers to the activities in accordance with the management responsibility for the work and the logical sequence for performing the activities.

– Complete a brief narrative description for each WBS scope and compile a WBS

Dictionary including all WBS levels.

– Add WBS numbers and WBS descriptions

• Determine R&D priorities

• Estimate cost for three different cases based on three different scenarios for international collaboration. These are called “high”, “baseline”, and “low”.

• For the “baseline” case, develop details of the cost estimate, integrated schedule, and yearly expenditures.

• Estimate escalation and contingencies.

• Perform risk assessment and establish contingency

US Selected TBM Concepts (Reference Scenario)

1. The Dual-Coolant Pb-17Li Liquid Breeder

Blanket concept with self-cooled Pb-Li breeding zone and flow channel inserts

(FCIs) as MHD and thermal insulator.

Innovative concept that provides “pathway” to higher outlet temperature /higher thermal efficiency while using ferritic steel.

US lead role in collaboration with other parties (most parties are interested in Pb-Li as a liquid breeder, especially EU and China).

Plan an independent TBM that will occupy half an

ITER test port with corresponding ancillary equipment.

2. The Helium-Cooled Solid Breeder Blanket concept with ferritic steel structure and beryllium neutron multiplier, but without an independent TBM.

Support EU and Japan efforts using their TBM structure & ancillary equipment.

Contribute submodule test articles that focus on particular technical issues.

Cutaway of US DCLL TBM Module

HCCB Submodule Conceptual

Design as of Jan. 2006

Assumptions and Constraints Affecting Strategy,

Technical Planning, and Cost Estimations

The scope of this current planning effort and cost estimation is based on the following assumptions and constraints:

• The DCLL reference scenario assumes the testing of a series of TBMs each of which will occupy an ITER vertical half-port, have dedicated ancillary equipment, and have a PbLi exit temperature limit of 470ºC.

• The HCCB reference scenario assumes a series of sub-modules each of which will occupy 1/3 an ITER horizontal half-port and utilize shared ancillary equipment in-cooperation with the EU or Japan .

• US TBM structures will be fabricated from reduced activation ferritic steel with an assumed temperature limit of 550ºC.

• Detailed planning and cost is for a 10-year period between now and the shipment of the TBM deliverables in 2015 for DAY ONE ITER H-H operation.

• The cost is the total cost for the TBM project including R&D, design, engineering, fabrication, qualification, etc., as well as the cost to interface with ITER and other parties during this period.

• The R&D cost includes all costs related to the Reference Scenarios that occur within the next 10-year period whether they are related to the first

(Day ONE) Test Articles or subsequent test articles.

• Cost of the deliverables includes the cost of the First Test Article and associated equipment (see project deliverables).

Principal Mission of the US TBM Program

The principal mission of the US ITER Test Blanket Module (TBM)

Program is to develop, deploy and operate ITER TBM experiments that provide unique experimental data on, and operational experience with, the integrated function of US blanket and first wall components and materials in a true fusion plasma-magneto-nuclear environment.

This data is essential for the:

1. validation of the scientific understanding and predictive capabilities needed to interpret and extrapolate results to subsequent burning plasma experiments, component test facilities, and ultimately energy producing systems;

2. demonstration of the principles of tritium self-sufficiency in practical systems needed to establish the feasibility of the DT fuel cycle;

3. development of the technology necessary to install breeding capabilities to supply ITER with the tritium necessary for operation in its extended phase of operation and help resolve the critical “tritium supply” issue for fusion development (US involvement in the development of this technology with

ITER partners will be essential to understand and influence these partner programs).

4. first integrated experimental results on the reliability, safety, environmental impact, and efficiency of fusion energy extraction systems.

US Test Blanket Project Organized by Subsystem and Deliverables

US TBM Project

Test Module

He Loops

PbLi Loop

Tritium Processing

Design Integration

DCLL TBM

Test Sub-module

Ancillary Equipment

Design Integration

HCCB TBM Predictive Capability

Models and Codes

Databases

Data/Code Integration

Project Support

Administration

TBWG/ITER/Parties

Interface

Codes and Standards

/ QA

Safety and Licensing

Example: DCLL WBS – organized by major systems

1.8.1.1 Test Module

1.8.1.1.1 Administration

1.8.1.1.2 R&D

1.8.1.1.2.1

1.8.1.1.2.2

1.8.1.1.2.3

Thermofluid MHD

SiC/SiC FCI Fab and Properties

SiC/FS/PbLi Compatibility & Chemistry

1.8.1.1.2.4

1.8.1.1.2.5

1.8.1.1.2.6

1.8.1.1.2.7

1.8.1.1.2.8

1.8.1.1.2.9

1.8.1.1.2.10

FM steel fabrication development and materials properties

Helium System subcomponents analyses & tests

PbLi/H2O hydrogen production

Be joining to FS

Virtual DCLL TBM

Advanced Diagnostics

Partially Integrated mockups testing

1.8.1.1.3

Engineering

1.8.1.1.3.1

Preliminary Design and Analysis, Title I

1.8.1.1.3.2

1.8.1.1.3.3

Detailed Design, Title II

Title III

1.8.1.1.4

Prototype TBM design and fabrication

1.8.1.1.4.1 Prototype Call for tender / Contract award

1.8.1.1.4.2

1.8.1.1.4.3

Prototype Manufacturing

Design (tooling and processing)

Prototype TBM Material procurement

1.8.1.1.4.4 PrototypeTBM Fabrication, procurement and shipping

1.8.1.1.5 Prototype TBM Assembly and testing

1.8.1.1.6

TBM design and fabricaton

1.8.1.1.6.1 Call for tender / Contract award

1.8.1.1.6.2

1.8.1.1.6.3

1.8.1.1.6.4

Manufacturing design (tooling and processing)

Material procurement

Fabrication, procurement and shipping

1.8.1.1.7 Assembly, testing & Installation

1.8.1.2 Helium Flow Loops

1.8.1.2.1 Primary helium loop

1.8.1.2.1.1 Preliminary design of primary helium loop

1.8.1.2.1.2

1.8.1.2.1.3

1.8.1.2.1.4

Detailed design of primary helium loop

Fabrication/Procurement

Assembly, testing & installation

1.8.1.2.2 Intermediate helium loop

1.8.1.2.2.1

1.8.1.2.2.2

1.8.1.2.2.3

1.8.1.2.2.4

Preliminary design of intermediate helium loop

Detailed design of intermediate helium loop

Fabrication/Procurement

Assembly, testing & Installation

1.8.1.3 PbLi Flow Loop

1.8.1.3.1

Preliminary design of the PbLi loop

1.8.1.3.2

Detailed design of the PbLi loop

1.8.1.3.3

Fabrication/Procurement

1.8.1.3.4

Assembly, testing & Installation

1.8.1.4

Tritium Processing

1.8.1.4.1

Administration

1.8.1.4.2

R&D

1.8.1.4.2.1 Modeling tool development and benchmarking

1.8.1.4.2.2

1.8.1.4.2.3

1.8.1.4.2.4

1.8.1.4.3

Engineering

1.8.1.4.3.1

1.8.1.4.3.2

Tritium extraction from PbLi

Tritium extraction from He

Fate of tritium in PbLi

1.8.1.4.4

Fabrication/Procurement

1.8.1.4.5

Assembly/Installation

Detailed Design

Title III

1.8.1.5 DCLL/ITER System Integration

1.8.1.5.1 Administration

1.8.1.5.2

R&D

1.8.1.5.2.1

He and PbLi Conc. Pipe joints

1.8.1.5.2.2

VV Plug bellows design

1.8.1.5.3

TBM System Design Integration

1.8.1.5.3.1

In-Vessel System Integration

1.8.1.5.3.2

1.8.1.5.3.3

1.8.1.5.3.4

Ex-Vessel System Integration and Interface.

RH System integration

Engineering Design and analysis:

1.8.1.5.4

Fabrication, Procurement and Shipping.

1.8.1.5.5

Assembly and on site testing

Deliverables

The main deliverables in March 2015 for the DCLL include:

1. a half-port test module,

2. a primary helium flow loop,

3. a PbLi flow loop,

4. a secondary helium flow loop (and a heat exchanger for PbLi flow loop),

5. tritium processing and measuring systems all capable to meet the quantitative goals and obtain the data sets described above, and

6. predictive capability.

The main deliverables for HCCB are:

1. a test sub-module that has a size of 1/3 of one-half port to be integrated with a host party’s test module,

2. associated ancillary equipment including primary helium flow conditioners, and measuring systems for helium coolant, tritium, and test sub-module performance all capable to meet the quantitative goals and obtain the data sets described above, and

3. predictive capability.

Identified and Prioritized R&D Tasks

• Developed R&D requirements based on TBM technical issues

– Developed system of priorities (cost/risk/benefit)

– Identified potential international collaborations

•

Summarize the main purpose of this subtask. What critical need does this R&D address?

Is it more oriented towards (1) Establishing basic TBM feasibility for fusion (2)

Understanding/predicting TBM performance required for design, or (3) Adding to safety and qualification database.

•

Summarize the risks to the machine or mission if this R&D is not performed.

• Categorize this subtask based on the following system:

– E = Essential for the qualification and successful execution of the TBM experiment, and no other party is doing it.

– I = Important for the qualification and successful execution of the TBM experiment, or Essential but is definitely being done by another party.

–

D = Desirable but the risk is acceptable if not performed.

• Categorize this subtask schedule over the next 10 year period based on the following system.

– B = Beginning 3-4 year s. Needed immediately for preliminary design choices.

–

M = Middle 3-4 years . Needed in the middle of the next 10 years after initial R&D is performed (for instance for qualification or integrated effects tests).

–

E = Ending 3-4 years . Needed before performance of first experiments or is specific for subsequent modules.

US Plan has clearly defined yearly milestones for each R&D indicates attachement to deadline

1

1.8.1.1.2.1 Thermofluid MHD

1.8.1.1.2.1.1 Modeling Tools

1 High Hartmann number flows

2 Non-orthogonal meshes

3 Complex MHD flow and heat transfer

1.8.1.1.2.1.2 Flow Channel Insert Experiments and Modeling

1 Sic/Sic FCI test-section fabrication

2 Experiment 1 - flow development and gap flow

3 SiC/SiC FCI test-section with pressure slots and overlaps

4 Experiment 2 - pressure drop & eq, velocity profile

5

Loop upgrade - vertical magnet orientation and outer wall cooling

6 Experiment 3 - combined heat transfer effects

1.8.1.1.2.1.3 TBM Manifold Experiments and Modeling

1 LM loop modification and Non-conducting test-section

2 Non-conducting wall experiment

3 Conducting test-section fabrication

4 Conducting test-section experiment

5 Optimization test-section experiments

2006

7 1

1, initial review

2007

7 1

2, mid review

2008

7

3, PDR

1

2009

7 1

4, bid pack / MUs

2010

7

5, mod bid package

Cost Range Scenarios

High Cost Range Scenario

• The high cost range scenario is for an Independent US DCLL TBM and an

Independent HCCB TBM; with accounting for known international collaborations.

The high cost scenario is similar in scope to the current EU and Japan TBM programs and gives an indication of total project cost to pursue two blanket options with minimum risk in the sense that the US is responsible for all hardware for half-port sized TBMs for both of its selected blanket options. (Also, space not available on ITER. Practical?)

Baseline Cost Range Scenario

• The baseline scenario is defined as an Independent US DCLL TBM accounting for known international collaboration, and a supporting international partnership on the HCCB TBM.

This baseline cost scenario most closely matches the DOE guidance presented in Chapter 3.3.

Lower Cost Range Scenario

• The lower cost range scenario is defined as a Leading international partnership on DCLL TBM and a supporting international partnership on the HCCB TBM . The low cost range scenario represents the minimum level of investment where the US will still acquire the knowledge, and develop the capabilities and skills, in the many areas necessary for fusion blanket development and fabrication in the US of components for a future

CTF and fusion DEMO. There is however more risk associated with this scenario due to the level of international collaboration.

US ITER TBM Total Project Cost Breakdown until March 2015

Estimates as of Mar 29, 2006

WBS

1.8.2

1.8.2.1

1.8.2.1.1

1.8.2.1.2

1.8.2.1.3

1.8.2.1.4

1.8.2.1.5

1.8.2.2

1.8.2.3

1.8.3

1.8.3.1

1.8.3.2

1.8.3.3

1.8.3.3.1

1.8.3.3.2

1.8.3.3.3

1.8.1

1.8.1.1

1.8.1.1.1

1.8.1.1.2

1.8.1.1.3

1.8.1.1.4

1.8.1.1.5

1.8.1.1.6

1.8.1.1.7

1.8.1.2

1.8.1.3

1.8.1.4

1.8.1.5

1.8

WBS Description

Dual Coolant Lead Lithium (DCLL)

Test Module

WBS Administration

Research and Development

Engineering

Prototype Fabrication/Procurement

Prototype Assembly and Testing

TBM Fabrication/Procurement

TBM Assembly and Testing

Helium Flow Loops

Lead Lithium (PbLi) Flow Loop

Tritium Processing System

DCLL/ITER System Integration

Helium Cooled Ceramic Breeder (HCCB)

Test Submodule

WBS Administration

Research and Development

Engineering

Prototype/Submodule Fab & Testing

Integration and Packaging

Ancillary Equipment

HCCB/ITER System Integration

Project Support

Project Administration / Project Controls

TBWG/Parties Interface & Collaborations

Safety and Regulatory Support

Regulatory Support

Safety Analysis and Reporting

Safety Design Integration

US ITER-TBM Estimated Cost

Est. Escalation and Contingency

US ITER-TBM Total Project Cost

Low Range (k$)

$16,764

$14,656

$1,684

$7,377

$3,900

$1,385

$311

$813

$1,295

$7,881

$2,000

$2,300

$3,581

$840

$1,356

$1,385

$35,747

$28,284

$2,500

$17,859

$6,338

$771

$102

$670

$45

$2,412

$2,094

$943

$2,014

$60,392

$16,241

$76,633

Baseline ($k)

$16,764

$14,656

$1,684

$7,377

$3,900

$1,385

$311

$813

$1,295

$8,785

$2,000

$2,300

$4,485

$840

$2,260

$1,385

$64,127

$53,031

$2,500

$36,780

$10,578

$1,540

$203

$1,340

$89

$4,021

$3,490

$1,571

$2,014

$89,676

$23,271

$112,947

High Range (k$)

$44,512

$39,412

$2,500

$25,037

$8,365

$3,460

$50

$3,159

$1,941

$11,028

$2,000

$2,300

$6,728

$1,260

$3,390

$2,078

$64,127

$53,031

$2,500

$36,780

$10,578

$1,540

$203

$1,340

$89

$4,021

$3,490

$1,571

$2,014

$119,666

$32,522

$152,188

US ITER TBM Total Project Cost Summary until March 2015

Estimates as of Mar 29, 2006

WBS

1.8.1

1.8.2

1.8.3

WBS Description

Dual Coolant Lead Lithium

(DCLL)

Helium Cooled Ceramic Breeder

(HCCB)

Project Support

Low Range

(k$)

$35,747

$16,764

$7,881

Baseline

($k)

$64,127

$16,764

$8,785

High Range

(k$)

$64,127

$44,512

$11,028

1.8

US ITER-TBM Estimated Cost $60,392 $89,676 $119,666

Est. Escalation and Contingency

US ITER-TBM Total Project Cost

$16,241

$76,633

$23,271 $32,522

$112,947 $152,188

Estimated DCLL Baseline R&D Costs until March 2015 in 2006 k$

Total is $49,129k

$10,574, 21%

$1,455, 3%

$321, 1%

$7,203, 14%

$2,718, 6%

$2,911, 6%

Estimation as of

Mar 29, 2006

$6,621, 13%

$2,768, 6%

$844, 2%

$10,688, 21%

$840, 2%

$799, 2%

$1,387, 3%

Thermofluid MHD

SiC/SiC FCI Fab

SiC/FS/PbLi Compatibility

RAFS Fab. Devel.

Helium Subcomponent Tests

PbLi/H2O Reaction

Be Joining to RAFS

Virtual TBM

TBM Diagnostics

Mockups Fac.& Testing

Design Integration

Tritium Control

Known Int. Collaborations

Note: Includes TBM, Ancillary Loop, Tritium Systems and Design

Integration R&D

Estimated DCLL Cost Savings for Known Int. Collaborations in 2006 k$

Total is $10,574

Virtual TBM , $1,065

RAFS Fab. Devel.

PbLi/H2O Reaction

Be Joining to RAFS

Virtual TBM

Be Joining to RAFS ,

$2,816

RAFS Fab. Devel. ,

$5,095

PbLi/H2O Reaction ,

$1,598

Estimation as of

Mar 29, 2006

Additional R&D savings may be possible in diagnostics development and test facilities

Additional Hardware savings may be possible by joint design and fabrication of He and PbLi ancillary systems

Estimated HCCB Baseline R&D Costs until March 2015 in 2006 k$

Total is $7,377k

$2,708, 37%

Estimation as of

Mar 29, 2006

$886, 12%

$845, 11%

$792, 11%

$178, 2%

$788, 11%

He Flow & Manifold Tests

SB Thermomechanics & T Recovery

T Control and Predictive Capability

Breeder pebble knowledge base

Diagnostics and Instrumentation

Partially Integrated Tests

In-Pile Pebble Bed Assembly Tests $1,180, 16%

"Dual-Use" costs with DCLL including RAFS fabrication development and

Integrated Test Facilities included under DCLL only

Estimated yearly spending profile for US TBM Project through shipment of deliverables, March 2015

$22,500

$20,000

$17,500

Estimation as of

Mar 29, 2006

Contingency (k$)

Escalated Cost (k$)

$15,000

$12,500

$10,000

$7,500

$5,000

$2,500

$0

FY06 FY07 FY08 FY09 FY10 FY11 FY12 FY13 FY14 FY15

Contingency (k$) $295 $1,072 $1,634 $2,157 $2,253 $1,900 $1,375 $877 $432 $123

Escalated Cost (k$) $2,454 $8,923 $13,592 $17,943 $18,749 $15,807 $11,443 $7,299 $3,597 $1,021

Lessons Learned from U.S. Technical

Plan and Cost Estimate for ITER-TBM

• The largest uncertainties in developing the technical plan and cost estimate is the lack of a well-defined agreement among the Parties on the specifics of the ITER-TBM.

• Particular examples of uncertainties:

– How much space is available to the U.S. (or to any party) in

ITER test ports?

– Is it practical for the U.S. to assume space is available to test two independent TBM concepts? (Is it practical for any Party to make such assumptions?)

– What specific framework for international collaboration is practical to assume?

• “Joint Partnership” on test modules and ancillary equipment?

Assigning of Tasks?

• “Sharing” of R&D tasks?

• Schedule is very tight. Phasing of tasks for the next 10 years is a challenge.

Urgent Actions Needed

1.

There needs to be an agreement among the ITER parties on

“Major Principles” of the ITER Test Program.

e.g. assignment of port space, how many concepts per party, which concepts are actually tested jointly by several parties.

TBWG is the logical entity to deal with the challenge of reaching agreement on a well defined, practical test program to which all parties agree.

2.

Developing and signing of a LEGAL agreement among ITER parties on the TBM Program (either as part of ITER agreement or as an amendment).

3.

Need to formalize agreement(s) among the parties into Legal

Agreement(s) (multi-lateral, tri-lateral, and/or bi-lateral) on specifics of collaborations on TBM R&D, construction of test module, construction and sharing of ancillary equipment, etc.