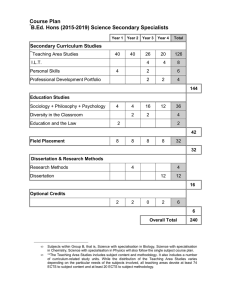

2 Course Delivery

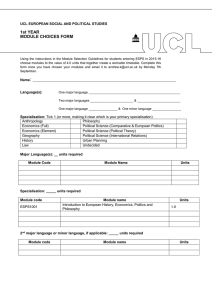

advertisement