Document 17672419

advertisement

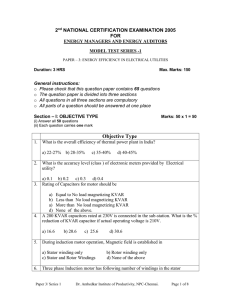

Paper 3 –Set A Solutions Regn No: _________________ Name: ___________________ (To be written by the candidates) NATIONAL CERTIFICATION EXAMINATION 2006 FOR ENERGY MANAGERS & ENERGY AUDITORS PAPER – 3: Energy Efficiency in Electrical Utilities Date: 23.04.2006 Timings: 0930-1230 HRS Duration: 3 HRS Max. Marks: 150 General instructions: o o o o o Please check that this question paper contains 9 printed pages Please check that this question paper contains 65 questions The question paper is divided into three sections All questions in all three sections are compulsory All parts of a question should be answered at one place Section – I: OBJECTIVE TYPE (i) (ii) (iii) 1. Marks: 50 x 1 = 50 Answer all 50 questions Each question carries one mark Put a () tick mark in the appropriate box in the answer book Select the incorrect statement: In system distribution loss optimization, the various options available include a) re-routing and re-conducting such feeders and lines where the voltage drops are higher b) power factor improvement c) optimum loading of transformers in the system d) selection of Aluminium Cored Steel Reinforced (ACSR) lines instead of All Aluminium Alloy Conductors (AAAC) 2. A pure capacitive load in an alternating current (AC) circuit draws a) lagging reactive power c) leading reactive power 3. b) active power d) none of the above Select the incorrect statement: a) harmonics occur as spikes at intervals which are multiples of the supply frequency b) harmonics are multiples of the fundamental frequency c) devices that draw sinusoidal currents when a sinusoidal voltage is applied create harmonics d) transformers operating near saturation level create harmonics _______________________ Bureau of Energy Efficiency 1 Paper 3 –Set A Solutions 4. In a 11 kV feeder, if the voltage is raised from 11 kV to 22 kV for the same loading conditions, the voltage drop in the same feeder system would be lower by a factor of a) 1/4 5. b) 1/2 b) 9 kVAr b) 2980 RPM b) 750 kVAr b) (kW 2+kVAr2)1/2/kW d) kVAr/ (kW 2+kVAr2)1/2 c) 1000 kVAr d) none of the above b) 90% of no-load kVAr of motor d) none of the above A 7.5 kW, 415 V, 14.5 A, 1460 RPM, 3 phase rated induction motor with full load efficiency of 88% draws 10.1 A and 5.1 kW of input power. The percentage loading of the motor is about a) 60 % 11. d) none of the above The approximate size of the capacitor selected for the PF improvement and its installation at the induction motor terminals may be equal to a) No-load kVAr of motor c) full load kVAr of motor 10. c) 2943 RPM The nearest kVAr compensation required for improving the power factor of a 1000 kW load from 0.8 lagging power factor to unity power factor is a) 500 kVAr 9. d) none of the above Power factor is the ratio of a) kW/ (kW 2+kVAr2)1/2 c) kVAr/kW 8. c) 8 kVAr The actual speed of a 2 pole induction motor operating at 49.8 Hz and at a slip of 1.5 % is given by a) 2955 RPM 7. d) none of the above A 10 kVAr, 415 V rated power factor capacitor was found to be having terminal supply voltage of 370 V. The capacity of the power factor capacitor at the operating supply voltage would be approximately a) 10 kVAr 6. c) 1/3 b) 70 % c) 50% d) none of the above Select the wrong statement: a) for every 4°C rise in the air inlet temperature of an air compressor, the power consumption will normally increase by one percentage points for the same output. b) after-coolers remove the moisture in the air before it enters the next stage of compressor to reduce the work of compression c) for every 250 mm WC pressure drop increase across the suction path due to choked filters etc., the compressor power consumption increases by about 2 percent for the same output d) centrifugal compressors are better suited for applications requiring very high capacities, typically above 12,000 cfm 12. The reciprocating air compressor efficiency does not depend on a) discharge pressure c) suction pressure _______________________ Bureau of Energy Efficiency b) flow rate d) system air leakages 2 Paper 3 –Set A Solutions 13. The leak test results show load time of 10 seconds and unload time of 20 seconds in a load-unload reciprocating compressor. If the compressor capacity is 256 cfm, then the approximate leakage would be a) 85 cfm 14. b) 170 cfm c) 256 cfm Dynamic air compressors are mainly of the following type a) two stage reciprocating compressors c) two stage screw compressors 15. b) centrifugal compressors d) none of the above The flow output of which of the following changes with the discharge pressure a) screw compressor c) reciprocating compressor 16. d) 128 cfm b) centrifugal compressor d) none of the above Higher chiller COP can be achieved with a) higher evaporator temperature and lower condensing temperature b) lower evaporator temperature and higher condensing temperature c) lower evaporator temperature and lower condensing temperature d) none of the above 17. In water cooled refrigeration systems, condenser cooling water temperature should be closest to a) ambient dry bulb temperature c) dew-point temperature 18. The refrigeration load in TR when 20 m3/hr of water is cooled from a 13 about a) 33 19. b) 80.3 C is d) none of the above b) 3516 W c) 200 BTU/min d) all of the above b) condenser c) expansion valve d) evaporator b) 882 rpm c) 294 rpm d) none of the above For centrifugal fans, the relation between Power (kW) and Speed (N) is given by kW1 N 1 a) = kW2 N 2 23. o A fan with 25 cm pulley diameter is driven by a 1470 rpm motor through a v-belt system. If the motor pulley is reduced from 20 cm to 15 cm at the same motor rpm and fan pulley diameter, the fan speed will reduce by a) 1176 rpm 22. C to 8 In a vapour compression refrigeration system, the component where the refrigerant fluid experiences no heat loss or gain is a) compressor 21. c) 39.6 o One ton of refrigeration (TR) is equal to a) 50.4 kcal/min 20. b) ambient wet bulb temperature d) none of the above 2 kW1 N 1 b) = kW2 N 2 2 3 kW1 N 1 c) = kW2 N 2 3 d) none of the above The pressure flow characteristic curve of a centrifugal fan changes with the following flow control method a) inlet guide vane _______________________ Bureau of Energy Efficiency b) inlet damper c) outlet damper d) none of the above 3 Paper 3 –Set A Solutions 24. The hydraulic power of a motor pump set is 6.9 kW. If the power drawn by the motor is 14.0 kW at a 88% efficiency, the pump efficiency is given by a) 43.4% 25. b) 49.3% c) 56% d) none of the above Which of the following is not true of air receivers? a) smoothen pulsating air output c) a source for draining of moisture 26. If inlet and outlet water temperatures of a cooling tower are 42 oC and 36oC respectively and atmospheric DBT and WBT are 39 oC and 32 oC respectively, then the effectiveness of cooling tower is a) 85.7% 27. b) 60% b) lower d) none of the above b) 16.8 kW c) 25.2 kW c) 40 m b) decrease b) 160 m3/hr c) not change d) none of the above c) 140 m3/hr d) none of the above Which of the following ambient conditions will evaporate maximum amount of water in a cooling tower a) 40oC DBT and 37oC WBT c) 35 oC DBT and 29 oC WBT 34. d) none of the above A water pump is delivering 200 cubic metres per hour at ambient conditions. The impeller diameter is trimmed by 10%. The water flow at the changed condition is given by a) 180 m3/hr 33. b) 70 m Lowering the Cycles of Concentration (C.O.C) in circulating water in a cooling tower, the blow down quantity will a) increase 32. b) both head and flow decreases d) none of the above In a pumping system the static head is 10 m and the dynamic head is 15 m. If the pump speed is doubled, then the total head will be a) 50 m 31. d) none of the above What is the impact on flow and head when the impeller of a pump is trimmed? a) both flow and pump head increases c) flow decreases and pump head increases 30. d) none of the above The motor efficiency is 0.9 and pump efficiency is 0.6. The power transmitted to the water is 15.11 kW. The input power to the motor driving the pump is about a) 28.0 kW 29. c) 75% The efficiency of forward curved fans compared to backward-inclined fans is__ a) higher c) same 28. b) storage of large volumes of air d) increases the pressure of air b) 38 oC DBT and 37 oC WBT d) 35 oC DBT and 30 oC WBT The L/G ratio of a cooling tower does not depend on a) range c) outlet wet bulb temperature _______________________ Bureau of Energy Efficiency b) enthalpy of inlet air d) dry bulb temperature 4 Paper 3 –Set A Solutions 35. The lowest theoretical temperature to which water can be cooled in a cooling tower is a) average DBT and WBT of the atmospheric air b) WBT of the atmospheric air c) DBT of the atmospheric air d) difference between DBT and WBT of the atmospheric air 36. The unit of lux is a) 1000 lumens per square feet c) one lumen per square metre 37. b) 10 lumen per square metre d) one lumen per square feet If voltage is reduced for gas discharge lamps to its optimum value, it will result in a) reduced power consumption b) increased power consumption c) increased light levels d) no change in power consumption 38. Which is the most energy efficient lamp? a) LPSV 39. b) HPMV d) GLS The ratio of luminous flux emitted by a lamp to the power consumed by the lamp is ___. a) Illuminance c) Luminous Efficacy 40. c) FTL b) Lux d) Colour Rendering Index Which of the following is the best definition of illuminance? a) time rate of flow of light energy b) luminous flux incident on an object per unit area c) flux density emitted from an object without regard for direction d) flux density emitted from an object in a given direction 41. Typical exit flue gas temperature of a 5 MW DG set operating above 80% load is in the range of a) 340 to 370 deg C c) 200 to 230 deg C 42. In a DG set, the generator is consuming 150 litre per hour diesel oil. If the specific fuel consumption of this DG set is 0.25 litres/ kWh at that load, then what is the kVA loading of the set at 0.6 PF? a) 300 kVA 43. b) 250 to 280 deg C d) none of the above b) 600 kVA c) 1000 kVA d) none of the above The factors affecting Waste Heat Recovery from exhaust flue gases of DG set are: a) DG set loading b) Temperature of exhaust flue gases after turbo charger c) Back pressure on the DG set 44. d) all of the above The jacket cooling water in a diesel engine flows at 12.9 m 3/hr with a range of 10oC and accounts for 30% of the engine input energy. The power output of the engine will be a) 430 kW _______________________ Bureau of Energy Efficiency b) 500 kW c) 387 kW d) none of the above 5 Paper 3 –Set A Solutions 45. The maximum back pressure drop (mmWC) allowed in a DG set is a) 100-150 46. b) 150-200 c) 250-300 d) none of the above The electronic ballast in lighting application does not have one of the following characteristics a) lower operational losses than conventional ballasts b) tuned circuit to deliver power at 28-32 KHz c) requiring a mechanical switch (starter) d) low temperature rise 47. Energy savings potential of variable torque applications in comparison to constant torque application is: a) higher 48. b) lower c) equal d) none of the above The function of soft starter includes a) delivers a controlled release of power to the motor b) provides smooth, stepless acceleration and deceleration. c) extension of motor life d) all of the above 49. The occupancy sensors in a lighting installation are best suited for a) large production shops/hangars b) conference halls c) street lighting d) entrances of offices/buildings 50. The blowdown quantity required in cooling towers is given by a) evaporation loss/ (cycle of concentration –1) b) (cycle of concentration –1)/ evaporation loss c) evaporation loss/ (1 - cycle of concentration) d) evaporation loss/ (cycle of concentration +1) ……. End of Section – I ……. _______________________ Bureau of Energy Efficiency 6 Paper 3 –Set A Solutions Section – II: SHORT DESCRIPTIVE QUESTIONS (i) (ii) S-1 Marks: 10 x 5 = 50 Answer all Ten questions Each question carries Five marks Calculate the transformer total losses for a 100 kVA transformer for an average loading of 40%. Assume no load and full load losses as 1.70 kW and 10.50 kW respectively. Ans: Transformer losses = S-2 No load losses + (% loading)2 x Full load losses = 1.70+ (0.4)2 x 10.5 = 3.38 kW Fill in the blanks a) Slip ring induction motors are normally less efficient than squirrel cage induction motors b) Low speed Squirrel cage induction motors are normally less efficient than high speed Squirrel cage induction motors c) The capacitor requirement for PF improvement at induction motor terminal increases with decrease in rated speed of the induction motor d) Induction motor efficiency increases with increase in its rated capacity e) Totally-enclosed, fan cooled (TEFC) motors are more efficient than Screen – protected, drip-proof (SPDP) induction motors S-3 Calculate the free air delivery (FAD) capacity of a compressor in m 3/hr for the following observed data: Receiver capacity: Initial pressure (with empty receiver): Final pressure: Initial air temperature: Final air temperature: Additional holdup volume: Compressor pump up time: Atmospheric pressure: _______________________ Bureau of Energy Efficiency 0.3 m3 0 kg/cm2 (g) 7 kg/cm2 (g) 35oC 50 oC 0.05 m3 4.1 minutes 1.026 kg/sq. cm absolute 7 Paper 3 –Set A Solutions Ans: = P2 P1 V 273 t1 P0 t 273 t 2 = 7 0 (0.3 0.05) 273 35 1.026 4.1 273 50 = 0.555 m3/min S-4 The COP of a vapour compression refrigeration system is 3.0. If the compressor motor draws power of 10.5 kW at 91% motor efficiency, find out the tonnage of the refrigeration system. Ans: Power input to compressor = = 0.91 x 10.5 9.555 kW Cooling effect = = = 9.555 x 3.0 28.665 kW 24652 kcals/hr = = 24652/3024 8.15 Tonnes 28.665 kW x 860 kcal/kwh Refrigeration tonnage S-5 Estimate the cooling tower capacity (TR) and approach with the following parameters Water flow rate through CT Specific heat of water Inlet water temperature Outlet water temperature Ambient WBT = 130 m3/hr = 1 kcal/kg °C = 42 °C = 37 °C = 31 °C Ans: Cooling tower capacity (TR) = (flow rate x density x sp.heat x diff. temp)/ 3024 = 130 x 1000 x 1.0 x (42-37)/ 3024 = 215 TR Approach _______________________ Bureau of Energy Efficiency = 37- 31 = 6oC 8 Paper 3 –Set A Solutions S-6 How do you calculate the velocity of air/gas in a duct using the average differential pressure and density of the air/gas? Ans: Velocity V, m/s = CP x (2 x 9.81 Δp x γ)1/2 γ Cp = Pitot tube constant, 0.85 (or) as given by the manufacturer Δp = Average differential pressure (velocity pressure) measured by pitot tube by taking measurement at number of points over the entire cross section of the duct. γ = Density at air/ gas at test condition S-7 Briefly explain the benefit of installing servo stabilizer for lighting feeder Ans: In many plants, during the non-peaking hours, the voltage levels are on the higher side. During this period, voltage can be optimized, without any significant drop in the illumination level. The servo stabilizer will provide stabilized voltage for the lighting equipment. The performance of “gears” such as chokes, ballasts, will also improved due to the stabilized voltage. Further, servo stabilizer can maintain optimum voltage, which would help in saving electricity. S-8 A 180 kVA, 0.80 PF rated DG set has diesel engine rating of 220 BHP. What is the maximum power factor which can be maintained at full load on the alternator without overloading the DG set? (Assume alternator losses and exciter power requirement as 5.60 kW and there is no derating of DG set) Ans: Engine rated Power = 220 x 0.746 = 164 kW Rated power available for alternator = 164 – 5.6 = 158.4 kW Maximum power factor possible = 158.4 /180 = 0.88 S-9 A pump is delivering 50 m3/hr of water with a discharge pressure of 35 metre. The water is drawn from a sump where water level is 5 metre below the pump centerline. The power drawn by the motor is 9.5 kW at 91% motor efficiency. Find out the pump efficiency. _______________________ Bureau of Energy Efficiency 9 Paper 3 –Set A Solutions Ans: Hydraulic power Ph = Q (m3/s) xTotal head, hd - hs (m) x (kg/m3) x g (m/s2) / 1000 Q = 50/3600 m3/s , hd - hs = 35 – (-5) = 40 m Hydraulic power Ph = (50/3600) x 40 x 1000 x 9.81 / 1000 = 5.45 kW Pump shaft power = 9.5 kW x 0.91 = 8.65 kW Pump efficiency = hydraulic power / pump shaft power = 5.45 /8.65 = 63 % S-10 What are the technical aspects of energy efficient motors with respect to insulation life, slip and starting torque? Ans: Lower temperatures in energy efficient motors translate to long lasting insulation. Generally, motor life doubles for each 10°C reduction in operating temperature. The lower the slip, the higher the efficiency. Less slippage in energy efficient motors results in speeds about 1% faster than in standard counterparts. Starting torque for efficient motors may be lower than for standard motors. ……. End of Section - II ……. Section – III: LONG DESCRIPTIVE QUESTIONS (i) (ii) Marks: 5 x 10 = 50 Answer all Five questions Each question carries Ten marks _______________________ Bureau of Energy Efficiency 10 Paper 3 –Set A Solutions L-1 The contract demand of a process plant is 5000 kVA with the electricity supply utility company. The average monthly recorded maximum demand of the process plant is 4600 kVA at a power factor of 0.80. The utility bill analysis provides the following tariff structure. a) Minimum monthly billing demand is 75% of the contract demand or the actual recorded maximum demand whichever is higher. b) Monthly maximum demand (MD) charge is Rs. 300 per kVA. Find out the optimum limit of power factor capacitor requirement entirely from the view of reducing maximum demand so that no excess demand charges are paid to the supply company. Also work out the simple payback period, assuming cost of power factor capacitor installation along with automatic power factor correction controller is as Rs. 500 per kVAr. Ans: Minimum payable demand = 5000 x 0.75 = 3750 kVA Margin available for reduction of MD = 4600 – 3750 = 850 kVA Present load in kW = = 3680 kW = 0.9813 4600 x 0.80 Desired power factor = 3680/ 3750 Power factor capacitor requirement to achieve the desired power factor = 3680 [tan (Cos-1 0.8) – tan (Cos-1 0.9813)] = 2038 kVAr (say 2050 kVAr) Cost of power factor capacitor installation = Rs. 500 per kVAr x 2050 kVAr = 10.25 lakhs Monthly savings due to MD reduction = 850 kVA Yearly savings = 850 x 300 x 12 = Rs. 30.60 lakhs Simple payback period = investment cost / yearly savings = 10.25/ 30.6 = 0.335 years = 4 months L-2 A 7.5 kW, 415 V, 14.5 A, 4 pole, 50 Hz, 3 phase rated squirrel cage induction motor has a full load efficiency and power factor of 89% and 0.88 respectively. An energy auditor measures the following operating data of the motor (a) (b) (c) (d) (e) Supply voltage Current drawn PF Supply frequency RPM = = = = = 410 V 9.5 A 0.8 49.8 Hz 1480 Find out the following at the motor operating conditions: _______________________ Bureau of Energy Efficiency 11 Paper 3 –Set A Solutions 1. 2. 3. Power input in kW % motor loading % slip Ans: 1. Power input = 1.7321 x 0.410 x 9.5 x 0.8 = 5.397 kW 2. % motor loading = power input/ rated power input x 100 = 5.397/ (7.5/0.89) = 5.397/ 8.4269 = 64% 3. Synchronous RPM at 49.8 Hz, NS = 120 f/ P = 120 x 49.8/ 4 = 1494 RPM % slip = (Ns – N)/ Ns x 100 = (1494 – 1480) / 1494 = 14/ 1494 x 100 = 0.93% L-3 (a) A fan is delivering 20,000 Nm3/hr. of air at static pressure difference of 70 mm WC. If the fan static efficiency is 55%, find out the shaft power of the fan. (b) Explain briefly the difference between static and dynamic head of a centrifugal pumping system. Ans: (a) Q = 20,000 Nm3 / hr. , Pst = 70 mmWC, St = 55% , P = ? = 20,000/3600 = 5.56 m3/sec Fan static St = 0.55 5.56 x 70 102 x P = Volume in m3/sec x Pst in mmWc 102 x Power input to shaft Shaft power drawn = 6.94 kW (b) Static head is simply the difference in height of the supply and destination reservoirs and it is independent of flow. Dynamic head is the friction loss, on the liquid being moved, in pipes, valves and equipment in the system. The friction losses are proportional to the square of the flow rate. _______________________ Bureau of Energy Efficiency 12 Paper 3 –Set A Solutions L-4 List down any 10 energy conservation opportunities in compressed air system. Ans: Ensure air intake to compressor is not warm and humid by locating compressors in well-ventilated area or by drawing cold air from outside. Every 40C rise in air inlet temperature will increase power consumption by 1 percent. Clean air-inlet filters regularly. Compressor efficiency will be reduced by 2 percent for every 250 mm WC pressure drop across the filter. Keep compressor valves in good condition by removing and inspecting once every six months. Worn-out valves can reduce compressor efficiency by as much as 50 percent. Install manometers across the filter and monitor the pressure drop as a guide to replacement of element. Minimize low-load compressor operation; if air demand is less than 50 percent of compressor capacity, consider change over to a smaller compressor or reduce compressor speed appropriately (by reducing motor pulley size) in case of belt driven compressors. Consider the use of regenerative air dryers, which uses the heat of compressed air to remove moisture. Fouled inter-coolers reduce compressor efficiency and cause more water condensation in air receivers and distribution lines resulting in increased corrosion. Periodic cleaning of inter-coolers must be ensured. Compressor free air delivery test (FAD) must be done periodically to check the present operating capacity against its design capacity and corrective steps must be taken if required. If more than one compressor is feeding to a common header, compressors must be operated in such a way that only one small compressor should handle the load variations whereas other compressors will operate at full load. The possibility of heat recovery from hot compressed air to generate hot air or water for process application must be economically analyzed in case of large compressors. Consideration should be given to two-stage or multistage compressor as it consumes less power for the same air output than a single stage compressor. _______________________ Bureau of Energy Efficiency 13 Paper 3 –Set A Solutions If pressure requirements for processes are widely different (e.g. 3 bar to 7 bar), it is advisable to have two separate compressed air systems. Reduce compressor delivery pressure, wherever possible, to save energy. Provide extra air receivers at points of high cyclic-air demand which permits operation without extra compressor capacity. Retrofit with variable speed drives in big compressors, say over 100 kW, to eliminate the `unloaded’ running condition altogether. Keep the minimum possible range between load and unload pressure settings. Automatic timer controlled drain traps wastes compressed air every time the valve opens. So frequency of drainage should be optimized. Check air compressor logs regularly for abnormal readings, especially motor current cooling water flow and temperature, inter-stage and discharge pressures and temperatures and compressor load-cycle. Compressed air leakage of 40- 50 percent is not uncommon. Carry out periodic leak tests to estimate the quantity of leakage. Install equipment interlocked solenoid cut-off valves in the air system so that air supply to a machine can be switched off when not in use. Present energy prices justify liberal designs of pipeline sizes to reduce pressure drops. Compressed air piping layout should be made preferably as a ring main to provide desired pressures for all users. A smaller dedicated compressor can be installed at load point, located far off from the central compressor house, instead of supplying air through lengthy pipelines. All pneumatic equipment should be properly lubricated, which will reduce friction, prevent wear of seals and other rubber parts thus preventing energy wastage due to excessive air consumption or leakage. Misuse of compressed air such as for body cleaning, agitation, general floor cleaning, and other similar applications must be discouraged in order to save compressed air and energy. Pneumatic equipment should not be operated above the recommended operating pressure as this not only wastes energy bus can also lead to excessive wear of equipment’s components which leads to further energy wastage. _______________________ Bureau of Energy Efficiency 14 Paper 3 –Set A Solutions L-5 Pneumatic transport can be replaced by mechanical system as the former consumed about 8 times more energy. Highest possibility of energy savings is by reducing compressed air use. Pneumatic tools such as drill and grinders consume about 20 times more energy than motor driven tools. Hence they have to be used efficiently. Wherever possible, they should be replaced with electrically operated tools. Where possible welding is a good practice and should be preferred over threaded connections. On account of high pressure drop, ball or plug or gate valves are preferable over globe valves in compressed air lines. Briefly explain the step-by-step approach for conducting Energy Performance Assessment of DG set on shopfloor. Ans: Routine energy efficiency assessment of DG sets on shopfloor involves following typical steps: 1) Ensure reliability of all instruments used for trial. 2) Collect technical literature, characteristics, and specifications of the plant. 3) Conduct a 2 hour trial on the DG set, ensuring a steady load, wherein the following measurements are logged at 15 minutes intervals. a) Fuel consumption (by dip level or by flow metre) b) Amps, volts, PF, kW, kWh c) Intake air temperature, Relative Humidity (RH) d) Intake cooling water temperature e) Cylinder-wise exhaust temperature (as an indication of engine loading) f) Turbocharger RPM (as an indication of loading on engine) g) Charge air pressure (as an indication of engine loading) h) Cooling water temperature before and after charge air cooler (as an indication of cooler performance) i) Stack gas temperature before and after turbocharger (as an indication of turbocharger performance) 4) The fuel oil/diesel analysis is referred to from an oil company data. 5) Analysis: The trial data is to be analysed with respect to: a) Average alternator loading. _______________________ Bureau of Energy Efficiency 15 Paper 3 –Set A Solutions b) Average engine loading. c) Percentage loading on alternator. d) Percentage loading on engine. e) Specific power generation kWh/liter. f) Comments on Turbocharger performance based on RPM and gas temperature difference. g) Comments on charge air cooler performance. h) Comments on load distribution among various cylinders (based on exhaust temperature, the temperature to be 5% of mean and high/low values indicate disturbed condition). i) Comments on housekeeping issues like drip leakages, insulation, vibrations, etc. ……. End of Section - III ……. _______________________ Bureau of Energy Efficiency 16