Hazardous Materials & Hazardous Waste Training September 10, 2008

advertisement

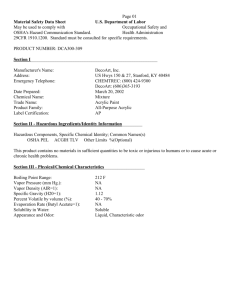

Hazardous Materials & Hazardous Waste Training September 10, 2008 Drug & Laboratory Disposal, Inc. 331 Broad Street Plainwell, MI 49080 There are many training requirements with which to comply under various Federal regulations. EPA, DOT & OSHA are the primary agencies that enforce specific training requirements related to management of hazardous waste. EPA – Environmental Protection Agency Provides a systematic approach to managing hazardous waste DOT – Department of Transportation Regulates hazards during transportation OSHA – Occupational Safety and Health Administration Regulates workplace conditions and practices EPA Training Requirements 40 CFR 262.34 (d)(5)(iii) Hazardous waste management RCRA in 1976 EPA Training Requirements Anyone who could cause non-compliance at a facility Anyone with duties which ensure the facility’s compliance Annual review of written training plan EPA Training Requirements Must include job-specific waste management procedures Must be completed within 6 months of assignment to the facility Must have supervision until trained Training must be reviewed annually DOT Training Requirements 49 CFR 172.700; 173.1 (b) Hazardous materials transportation DOT Training Requirements Employees who directly affect transportation safety Repeated at least every 3 years Change in rules requires additional training. DOT Training Requirements General awareness Function-specific training Security training Safety training DOT Training Requirements Must include test and be kept for 3 years Training completed within 90 days of employment, during which they may not work with hazardous materials unless under supervision of trained and knowledgeable employee OSHA Training Requirements 29 CFR 1910.1200(h) Hazardous chemicals workplace safety OSHA Training Requirements Any employee who could be exposed to any physical or health hazard Recognize hazards and protect employees from hazards through proper communication Establish a written hazardous communication program OSHA Training Requirements Must be trained how to work with hazardous chemicals to prevent illnesses, injuries, or death Must include container management techniques, safe chemical use, proper protective equipment use, and spill response training OSHA Training Requirements Labels on incoming containers of hazardous chemicals Have MSDS readily accessible for each work shift For waste shipment, have containers labeled Initial training and whenever new physical or health hazards are introduced Most important; everything hinges on generator knowledge, materials, and processes used. What is it and is it a hazardous material Must determine the type of hazard and the degree of hazard We need to know the physical and chemical properties. -Physical state (liquid, solid, gas) -Flashpoint or boiling point -Will it kill people (toxicological effect) -What does it do to your skin -Is it reactive to air, water, other chemicals -Is it radioactive Get information from: MSDS Text books Manufacturer’s data Analytical results 3 ways to become a hazardous material: Meets a hazard class definition from 1 – 8 The DOT says so with a “+” entry Miscellaneous class 9 Hazard class definitions Hazard class definitions The DOT says so with a “+” entry About 50 chemicals from a list of 3000 Must be shipped under this classification Examples: phenol, magnesium arsenate Miscellaneous Class 9 If it doesn’t meet a hazard class and meets one of the following; It has airplane hazards (Crew safety) It is a hazardous waste (EPA number) Marine pollutant Separate list by DOT Elevated temperature material Molten or hot Forbidden materials May not legally be offered for transportation or transported Usually have to meet specific conditions for safety before transportation Determine the degree of hazard: PGI indicates greater danger PGII indicates medium danger PGIII indicates minor danger Indicated by packing group, used in packaging the material Some hazard classes don’t have packing groups. (2, 7) Not safe to over classify. (responders and employees safety) Division 3 Packing Groups Packing Group Flash Point Initial Boiling Point ≤ 35°C (95°F) I II ≤ 23°C (73°F) > 35°C (95°F) III ≥ 23°C (73°F) but ≤ 60.5°C (141°F) > 35°C (95°F) Division 6.1 Packing Groups Oral toxicity LD50 (mg/kg) Dermal toxicity LD50 (mg/kg) Inhalation toxicity by dusts and mists LC50 (mg/L) I ≤5 ≤ 40 ≤ 0.5 II > 5 but ≤ 50 > 40 but ≤ 200 > 0.5 but ≤ 2 III solids: > 50 but ≤ 200; liquids: > 50 but ≤ 500 > 200 but ≤ 1000 > 2 but ≤ 10 Packing Group A material may meet the defining criteria for more than one hazard class but is assigned to only one hazard class. Lots of chemicals are toxic. Select from column 2 Be accurate Be specific (technical names, chemical family, end use, n.o.s. use) Waste characteristics and waste code numbers -Characteristic D codes -F listed solvents -P & U toxic waste codes -Act 451 industrial liquid codes Characteristic D Codes D001 Ignitable waste code D002 Corrosive waste code D003 Reactive waste code D004 – D011 Toxic heavy metals waste codes D012 – D043 Toxic organic codes F Listed Solvents F001 - Used in degreasing (6 solvents) F002, F003, F004, F005 - Spent Solvents (28 solvents) Examples: methanol, xylene, methylene chloride P & U Toxic Waste Codes Commercial chemical products – pure P codes - acutely toxic U codes – toxic Examples: nickel cyanide, bromoform Act 451 Industrial Liquid Codes Act 451 Part 121 liquid industrial wastes Not EPA waste codes Can be DOT shipping name Examples: Antifreeze, crankcase oil Act 451 Codes Mixed Solvents (Solvent Solutions) Pharmaceutical Automotive Oil Coolants and Water Soluble Oils Other Oil Polychlorinated Biphenyls Other Waste Antifreeze Storm Sewer Cleanouts Sanitary Sewer Cleanouts X-Ray/Photo Solutions Water Based Cleaning Solutions Grease Trap Wastes 007L 014L 017L 019L 021L 026L 029L 030L 031L 032L 033L 034L 036L Universal Waste There are certain hazardous wastes that a business can choose to manage in an alternative manner in place of the more complex hazardous waste regulations. Advantages of Universal Waste Regulations - Waste can be accumulated up to one year - A Hazardous waste manifest is not required - Volume is not included in determining generator status - Less labeling is required Types of Universal Waste - Batteries - Electric Lamps - Electronic components - Mercury-Containing Devices - Pesticides - Pharmaceuticals Electronic Equipment – Computer Monitors & TVs CRT’s (cathode ray tubes) in monitors and TV’s have been tested and show lead levels exceeding the regulatory limit of 5.0 mg/L. Some models also contain barium, chromium, or mercury. Meeting the definition of hazardous waste allows these electronics to be managed as universal waste. Regulated Medical Waste Intended to help employees avoid injuries and disease. Regulated medical waste, n.o.s., 6.2, UN3291, PG II Waste code possibilities: 029L or N/A Blood borne Pathogens Use OSHA’s universal precaution method. Treat all blood as dangerous. -Blood-soaked bandages -Discarded surgical gloves and instruments -Cultures -Hepatitis -Tetanus -HIV Sharps Can inflict injuries and disease. -Broken glass -Lancets -Needles -Razor blades The point of packaging is to make sure that the stuff stays inside the packaging during normal transportation. Includes temperature changes, handling, vibration caused by rough roads or curves. The type of packaging you can use The standards or specifications the packaging has to meet The rules for filling and closing the package When different hazardous materials may be placed in the same package Requirements in column 8 of HM table 172.101 Combination packaging Single packaging 49 CFR 178.503 Marking of packages Empty containers DOT vs. EPA Standards If empty, package is not subject to hazardous material regulations. DOT empty containers Cleaned of residue and purged of vapor All hazardous markings and labels have been removed or covered Remaining residue is not a hazardous waste or marine pollutant EPA empty containers Must contain less than 1 inch of residue or less than 3% by weight of material Gas cylinder must equal atmospheric pressure If contained acutely hazardous waste, container must be triple rinsed or inner liner removed Must accompany the shipment Printed legibly in English, no abbreviations Keep copy for 3 years Must get copy from TSDF within 45 days. If not, call EPA. The person signing a hazardous waste manifest is also signing the DOT-required shipper’s certification, certifying that the entire shipment is in full compliance with all applicable DOT regulations. Anyone who prepares, completes or signs a hazardous waste manifest must have training as required by the DOT’s hazmat employee training standard under 49 CFR 172 subpart H. Markings identify: What the material is Correct emergency response actions Shipper’s name and address Special handling precautions Markings include: Proper shipping name, UN number, shipper’s name and address EPA ID number, manifest tracking number Technical names of hazardous materials and waste codes “Hazardous Waste” Statement. Labels identify: What hazard the material has Special handling precautions Labels include: Diamond shaped hazard class labels Square precaution labels Label Examples: 1- Hazardous Warning Statement 2- Generator Name and Address 3- Generator EPA ID Number 4- Accumulation Start Date 5- EPA Waste Codes 6- Manifest Document Number 7- Proper Shipping Name, Technical Name, Special Hazard Warning (if applicable) and DOT Exemptions (If applicable) 1 2 U of M – Flint Riverfront 602 Mill Street (810) 766-6762 Flint Act 451, Part 121 Regulated Materials (used oil) 7 MI 3 MID 085 043 891 4 U of M – Flint Riverfront 602 Mill Street Flint 2 MI 48503 48503 6 D001,D002,F003 Waste Flammable Liquid, Corrosive, n.o.s., 3(8), UN2924, PGII (Methanol, Acetic Acid) 7 5 The shipper or generator must ensure that placards are provided Displayed on all four sides Visible without interference on each side and horizontal placement Table 1 -----------------------------------------------------------------------Placard Category of material (Hazard design class or division number and Placard name section additional description, as reference appropriate) (§ ) -----------------------------------------------------------------------1.1.............................. EXPLOSIVES 1.1.......... 172.522 1.2.............................. EXPLOSIVES 1.2.......... 172.522 1.3.............................. EXPLOSIVES 1.3.......... 172.522 2.3.............................. POISON GAS.............. 172.540 4.3.............................. DANGEROUS WHEN WET...... 172.548 5.2 (Organic peroxide, Type B, ORGANIC PEROXIDE........ 172.552 liquid or solid, temperature controlled). 6.1 (inhalation hazard, Zone A or POISON INHALATION HAZARD 172.555 B). 7 (Radioactive Yellow III label RADIOACTIVE \1\......... 172.556 only). -----------------------------------------------------------------------\1\ RADIOACTIVE placard also required for exclusive use shipments of low specific activity material and surface contaminated objects transported in accordance with § 173.427(a) of this subchapter. Table 2 -----------------------------------------------------------------------Placard Category of material (Hazard design class or division number and Placard name section additional description, as reference appropriate) (§ ) -----------------------------------------------------------------------1.4.............................. EXPLOSIVES 1.4.......... 172.523 1.5.............................. EXPLOSIVES 1.5.......... 172.524 1.6.............................. EXPLOSIVES 1.6.......... 172.525 2.1.............................. FLAMMABLE GAS........... 172.532 2.2.............................. NON-FLAMMABLE GAS....... 172.528 3................................ FLAMMABLE............... 172.542 Combustible liquid............... COMBUSTIBLE............. 172.544 4.1.............................. FLAMMABLE SOLID......... 172.546 4.2.............................. SPONTANEOUSLY COMBUSTIBLE 172.547. 5.1.............................. OXIDIZER................ 172.550 5.2 (Other than organic peroxide, ORGANIC PEROXIDE........ 172.552 Type B, liquid or solid, temperature controlled). 6.1 (other than inhalation POISON.................. 172.554 hazard, Zone A or B). 6.2.............................. (None).................. ........... 8................................ CORROSIVE............... 172.558 9................................ Class 9 (see § 172.560 172.504(f)(9)). ORM-D............................ (None).................. ........... ------------------------------------------------------------------------ Materials handled to prevent damage during loading and unloading. -This end up -No smoking by classes 1,2,3,4,5. Segregated and separated to prevent incompatible material from mingling during transportation. -Incompatibles 4 feet from each other -Use segregation table Secured and braced to prevent movement and damage during transportation -strapped in truck every 10 feet -watch for load shifting In transportation: Protect the general public Control and clean up releases Prevent or extinguish fires Any person or place that creates hazardous waste LQG – Large Quantity Generator Generates 2,200 pounds or more waste per month Can accumulate on site for 90 days No limit on amount stored Must be at least one employee available to respond to emergency Written plans for handling emergencies SQG – Small Quantity Generator Generates 220 to 2,200 pounds of waste per month May accumulate on site for up to 180 days Accumulation limit is 13,200 pounds Must be at least one employee available to respond to emergency No written emergency plan needed CESQG – Conditionally Exempt Small Quantity Generator Can generate 220 pounds or less waste per month Accumulation limit is 2,200 pounds No plans or reporting required Accumulation Mark the accumulation start date on each container Mark each container with words “hazardous waste” Have written emergency plan Keep containers closed and in good condition Inspect containment area and document Security Plans Personnel security Unauthorized access En route security Plan in writing and kept EPA Security Awareness DOT Required for all hazmat employees An awareness of security risks Recognize possible security threats Know how to respond Security Awareness OSHA Regulates workplace storage of flammable and combustible liquids Size, amount and place of containers Personal protective equipment supplied if needed Safety plans and exit routes National Fire Protection Association Based on possible fire situations Standard system for the identification of hazardous materials Assists in effective fire and emergency planning Division rating scale 0, 1 - unlikely to become dangerous 2 - depends on the circumstances 3, 4 - it is dangerous now Enforcement and penalties EPA has authority to inspect facilities Can require corrective actions to take place Criminal penalties or fines FINES & PENALTIES Summary Act Sanction Intent RCRA Civil None (Hazardous Criminal Knowingly Waste) Maximum Fines Maximum Imprisonment $32,500/day $25,000/day (doubled for second offense) 1 year (doubled for second offense) $250,000 $1,000,000(organizations) 2 years Knowing $250,000 extreme $1,000,000(organizations) indifference to human life 5 years Knowing imminent endangerment to human life Hazardous Materials & Hazardous Waste Training September 10, 2008 Drug & Laboratory Disposal, Inc. 331 Broad Street Plainwell, MI 49080