Master Workplace Inspection Checklist

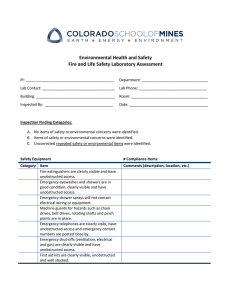

advertisement

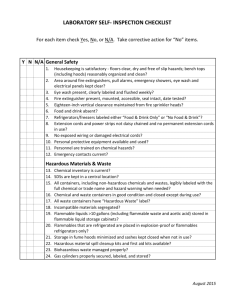

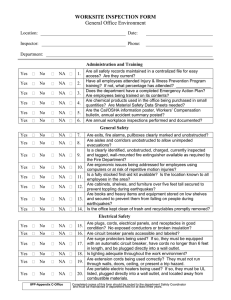

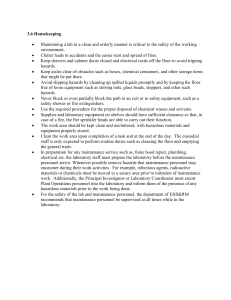

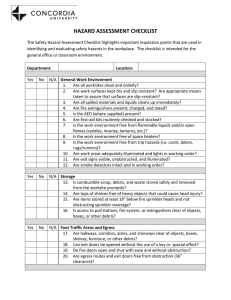

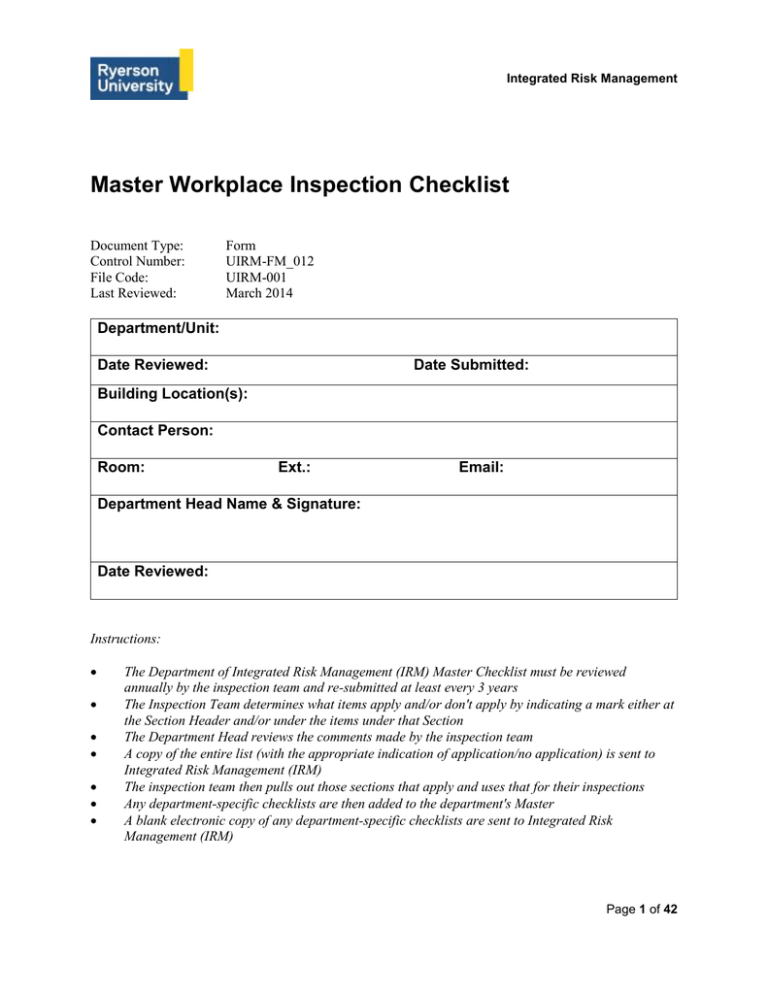

Integrated Risk Management Master Workplace Inspection Checklist Document Type: Control Number: File Code: Last Reviewed: Form UIRM-FM_012 UIRM-001 March 2014 Department/Unit: Date Reviewed: Date Submitted: Building Location(s): Contact Person: Room: Ext.: Email: Department Head Name & Signature: Date Reviewed: Instructions: The Department of Integrated Risk Management (IRM) Master Checklist must be reviewed annually by the inspection team and re-submitted at least every 3 years The Inspection Team determines what items apply and/or don't apply by indicating a mark either at the Section Header and/or under the items under that Section The Department Head reviews the comments made by the inspection team A copy of the entire list (with the appropriate indication of application/no application) is sent to Integrated Risk Management (IRM) The inspection team then pulls out those sections that apply and uses that for their inspections Any department-specific checklists are then added to the department's Master A blank electronic copy of any department-specific checklists are sent to Integrated Risk Management (IRM) Page 1 of 42 A DNA SA = = = Applies to Department/Unit Does Not Apply to Department/Unit Some of the Section Applies -- Section attached with items marked Item A DNA SA Description 1.0 AISLEWAYS, CORRIDORS AND STAIRWAYS (Interior & Exterior) 2.0 COMMUNICATIONS 3.0 COMPRESSED GASES 4.0 CONFINED SPACES 5.0 CONVEYORS 6.0 ELECTRICAL POWER SYSTEMS 7.0 EMERGENCY INSTRUCTIONS 8.0 EMERGENCY RESCUE EQUIPMENT 9.0 EMPLOYEES 10.0 ERGONOMIC FACTORS 11.0 EXITS/EGRESS 12.0 EYE BATHS AND SHOWERS 13.0 FIRE PROTECTION 14.0 FIRST AID 15.0 FLOORS 16.0 FUMES/DUST/VAPOURS 17.0 GENERAL 18.0 POWERED, NON-POWERED AND FIXED TOOLS 19.0 HAZARDOUS MATERIALS/MSDS’S/LABELING 20.0 HYDRAULIC POWER SYSTEMS 21.0 LADDERS 22.0 LIGHTING Page 2 of 42 23.0 LOCK-OUT SYSTEMS 24.0 MACHINE TOOLS AND GUARDING 25.0 MATERIALS HANDLING EQUIPMENT 26.0 MECHANICAL POWER SYSTEMS 27.0 MOBILE EQUIPMENT (Fork Trucks, Pump Trucks, etc) 28.0 NOISE EXPOSURE 29.0 PERSONAL PROTECTIVE EQUIPMENT (PPE) 30.0 PLATFORMS/SCAFFOLDING 31.0 PRESSURE VESSELS 32.0 RESPIRATORY PROTECTION DEVICES 33.0 SIGNS AND TAGS 34.0 STACKING AND STORAGE 35.0 STAIRS 36.0 TEMPERATURES 37.0 TRANSPORT OF HAZARDOUS MATERIALS 38.0 VALVES AND MECHANICAL CONTROLS 39.0 VENTILATION 40.0 VIBRATION 41.0 WARNING SYSTEMS 42.0 WASTE DISPOSAL 43.0 WELDING, CUTTING, AND BRAZING 44.0 GENERAL OFFICE INSPECTION 45.0 GENERAL LABORATORY 46.0 EMPLOYEE KITCHEN FACILITIES 47.0 GENERAL LOUNGE AREA 48.0 CLASSROOM / MEETING ROOM / BOARDROOM Page 3 of 42 49.0 WASHROOMS 50.0 WOOD WORKING WORKHOP MASTER WORKPLACE INSPECTION CHECKLIST Date Inspector(s) Reviewed: Department Head: Date Department Head Reviewed: 1.0 AISLEWAYS, CORRIDORS AND STAIRWAYS (Interior & Exterior) 1.1 Are aisles, corridors and stairways clear, unobstructed, and free of litter? 1.2 Are aisles, corridors and stairways sufficient width for all normal movements? 1.3 Are aisles ways, corridors and stairways adequately maintained? 1.4 Are these areas free of slip, trip, or fall hazards? 1.5 Are pathways clear from snow, ice and accumulating water? 1.6 Are there adequate railings, cautions, and warning signs to indicate and guard against personal hazards? N (Failed Inspection) Inspector(s): N/A Building Location(s): Y (Passed Inspection) Department: Y N/A N Page 4 of 42 2.0 COMMUNICATIONS 2.1 Are precautions in place so that a worker is not alone while performing a job? 2.2 Are workers working alone provided with an effective means of communication, i.e. walkie talkie, radio, telephone, to security or other persons able to assist the employee in case of emergency? 2.3 Is there a "buddy" system in place for hazardous operations? 3.0 COMPRESSED GASES 3.1 Are cylinders stored upright and secured against falling over? 3.2 Are cylinders segregated by contents and legibly marked? 3.3 Do cylinders not in use have tightly placed safety caps? 3.4 Are cylinders protected against rust/corrosion? 3.5 Are cylinders stored away from heat sources? 3.6 Are cylinders stored away from stairs, elevators and egress routes? 3.7 Are cylinders inspected for dents, corrosion, and test records? 3.8 Is there adequate ventilation in cylinder storage areas? 3.9 Is there a stamp indicating that cylinders have been hydrostatically tested in the last 5 years? (Acetylene cylinders are EXEMPT.) 3.10 Do cylinders have safety-relief devices, such as pressure-relief valves, rupture discs, and fuse plugs? (Higher toxic gases may be EXEMPT.) 3.11 Are areas where compressed gas cylinders stored and used adequately ventilated? Y N/A N Y N/A N Page 5 of 42 4.0 CONFINED SPACES 4.1 Are all confined spaces (e.g. pits, tanks, vaults, etc.) properly labelled? 4.2 Is there a confined space entry procedure including pre-testing, ventilation, PPE, etc.? 4.3 Are the hazards, access, and exit procedures posted? 4.4 Are the testing requirements for personnel entry included in the area or process/procedures? 4.5 Are emergency and rescue procedures in place? 5.0 CONVEYORS 5.1 Are gears, shafts, pulleys, and nip points guarded? 5.2 Are drop guards installed to catch falling material? 5.3 Are emergency stop controls adequately located and operational? 5.4 Is there adequate access? 6.0 ELECTRICAL POWER SYSTEMS 6.1 Are high voltage and control panels closed and secured? 6.2 Are Control panels identified and accessible? 6.3 Is wiring, insulation, and fixtures (e.g. switches, fuses) in good general condition? 6.4 Has grounding been tested? 6.5 Are flexible cords free of splices, tape, and fraying? 6.6 Are Lockout provisions as prescribed? Y N/A N Y N/A N Y N/A N Page 6 of 42 6.7 Is electrical equipment protected from fluids? 6.8 Are operating switches identified as to their use? 6.9 Are electrical installations in hazardous dust or vapour areas specifically guarded against fire and explosion? 6.10 Are fuses and circuit breakers the right type and size for the load on each circuit? 6.11 Do switches show evidence of over-heating? 6.12 Is adequate emergency lighting provided? 6.13 Are all electrical equipment, devices, and controls properly maintained? 6.14 Are proper electrical warning signs provided and clearly visible? 6.15 Is there a record of inspection/maintenance of the electrical system to ensure code compliance? 6.16 Are all breakers, emergency disconnects, switches, and other electrical fittings labeled? 6.17 Are all electrical and control components securely mounted and/or installed? 6.18 Are the emergency disconnects accessible and unobstructed? 6.19 Is emergency power provided? 6.20 Are junction boxes, outlets, switches, and fittings adequately covered? 6.21 Is all fixed metal electrical equipment grounded? 6.22 Are polarity tests regularly carried out? 6.23 Are electrical appliances grounded? Page 7 of 42 7.0 EMERGENCY INSTRUCTIONS 7.1 Are operational placards/decals on emergency controls? (e.g. on-off, openclose) 7.2 Are emergency instructions located at primary telephone in each work area? 7.3 Are fire hazard symbols on facilities containing hazardous substances? 7.4 Are back up communication systems available? 8.0 EMERGENCY RESCUE EQUIPMENT 8.1 Is adequate equipment available and properly located? 8.2 Is equipment in proper and functioning condition? 9.0 EMPLOYEES 9.1 Are the rules enforced in regard to loose clothing, long hair, dangling jewellery, and rings? 10.0 ERGONOMIC FACTORS 10.1 Does design allow normal body positions when seated or standing? 10.2 Do controls follow normal response patterns? (e.g. down for off, up for on, etc.) 10.3 Are standard colour codings used for warnings and information displays? (e.g. red for warning, stop) 10.4 Do hand tools used permit normal body positions? 10.5 Is the weight, size and nature of materials moved by people safe? 10.6 Are there situations in which unusual body movements or positions are required to do the job? Y N/A N Y N/A N Y N/A N Y N/A N Page 8 of 42 10.7 Are personnel physically suited to the demands of the job? 10.8 Do personnel use proper lifting techniques? 11.0 EXITS/EGRESS 11.1 Are exits sufficient for prompt escape in case of emergency? 11.2 Are there NO locks or fastenings restricting escape? 11.3 Are routes and exits clearly marked? 11.4 Are exits and exit signs adequately illuminated? 11.5 Is there more than one exit from the work area? 11.6 Are approaches to exits unobstructed? 11.7 Are flammable materials kept out of exits? 11.8 Do exits open in the direction of expected travel in the event of an emergency and onto a level surface? 11.9 Are exits paths outside of the facility maintained free of ice, snow and other clutter? 11.1 Are extraordinary means of egress (e.g. ladders, ramps) maintained in usable condition? 11.11 Are controls in place for areas requiring limited occupancy? 11.12 Are alternate exits provided to protect employees during construction and repair operations? 12.0 EYE BATHS AND SHOWERS 12.1 Are eyewash stations readily available and accessible in areas where caustic/corrosive chemicals are used? 12.2 Does the water supply provide a minimum of 15 minute flush time at a comfortable temperature? Y N/A N Y N/A N Page 9 of 42 12.3 Are there proper signs and instructions marking the eyewash station area? 12.4 Are eyewash basins flushed frequently to keep free of contaminants and blockages? 12.5 Are eyewash stations kept clean and clear? 12.6 Are drains clear and located appropriately so as to prevent pooling? 13.0 FIRE PROTECTION Y 13.1 Are portable extinguishers appropriate for type of materials and readily accessible in their designated area? 13.2 Are extinguishers inspected monthly and documented as acceptable on the inspection tag? 13.3 Are fire hoses properly mounted, accessible, maintained, and inspected? 13.4 Is fire equipment visibly marked? 13.5 Are fire exits in good repair, marked, and unobstructed? 13.6 Do sprinkler heads have proper clearance from materials and furnishings? 13.7 Are sprinkler master control valves accessible and locked open? 13.8 Do extinguishers appear to be in good repair and operable? 13.9 Are personnel familiar with proper use of fire extinguishers? 13.10 Is the Fire Emergency Response Plan posted and reviewed by all occupants? 13.11 Are fire doors kept closed and in good operating condition? 13.12 Are flammable & combustible liquids stored in an approved storage cabinet, kept closed at all times, and are vents unobstructed? 13.13 Are flammable/combustible liquids used daily stored in approved safety containers? 13.14 Are solvent use areas away from any ignition sources? N/A Page 10 of 42 N 13.15 Are no smoking signs posted and enforced? 13.16 Are flammable/combustible liquids and empty containers properly disposed of? 13.17 Are solvent rag safety bins in use and emptied daily? 13.18 Do the flammable storage cabinets contain only as much material as they are designed for? 13.19 Are the flammable storage cabinets properly grounded? 13.20 Are there any incompatible materials stored together? 13.21 Are there sufficient fire extinguishers for the area? 13.22 Is there an installed automatic fire sprinkler or deluge system? 13.23 Has the fire sprinkler or deluge system been tested in the past year? 13.24 Is there documentation of training and/or drills in the exercise of the evacuation plan? 13.25 Are fire extinguishers and sprinklers/deluges properly located for the hazards that are present? 13.26 Is there an area warning system that informs all personnel in exposure area of an emergency? 13.27 Do the fire suppression systems match the fire hazard type? 13.28 Are interior stand pipes and valves inspected regularly? 13.29 Are doors unobstructed and protected against obstruction? 13.30 Are fusible links in place? 13.31 Are sprinkler heads protected by metal guards where exposed to mechanical damage or paint spray etc.? 13.32 Are high hazard areas identified (e.g. signs, labels, controls)? 13.33 Are fume hoods inspected regularly? Page 11 of 42 13.34 Is there NO storage of items on fume hoods? 14.0 FIRST AID 14.1 Are first aid materials located in the area? 14.2 Are first aid kits fully stocked? 14.3 Are the names of qualified first aid attendants posted? 14.4 Are instructions on accident reporting posted? 14.5 Are there adequate numbers of people trained in first aid to cover all locations? 14.6 Is the location of first aid facilities clearly marked/known? 14.7 Are emergency phone numbers posted? 15.0 FLOORS 15.1 Are the floors in a clean, orderly, and sanitary condition? 15.2 Is drainage maintained? 15.3 Are floors free of slip, trip, or fall hazards? 15.4 Are floors free of protrusions, nails, etc? 15.5 Are openings covered or barricaded? 15.6 Are load limits posted on upper floors? 15.7 Are floors adequately illuminated? 15.8 Are stand mats, platforms, or similar protection provided to protect employees from wet floors where appropriate? Y N/A N Y N/A N Page 12 of 42 15.9 Are floor openings provided with toe boards and railings or a floor hole cover? 16.0 FUMES/DUST/VAPOURS 16.1 Are fumes, dusts, or vapours present in the area? 16.2 Do procedures specify engineering controls or PPE that must be used to abate the hazards? 16.3 Are these controls in use in the operation? 17.0 GENERAL 17.1 Are housekeeping habits satisfactory? 17.2 Are equipment, fixtures, and furnishings free from damage? 17.3 Photocopiers NOT emitting strong fumes? 17.4 Carpet is NOT worn or torn causing an unsafe condition? 17.5 No open drawers or swinging doors? 17.6 Ceiling tiles in place and in good condition? 17.7 Extension cords NOT laid across walkways? 18.0 POWERED, NON-POWERED AND FIXED TOOLS 18.1 Are tools, electrical cords, and air hoses in proper general condition? 18.2 Are tools stored properly when in use? 18.3 Are tools properly stored when not in use (controlled area)? Y N/A N Y N/A N Y N/A N Page 13 of 42 18.4 Are guards and safety devices present? 18.5 Are tools electrical grounding or double insulation protected? 18.6 Are power tools equipped with constant pressure switches where required?. 18.7 Are employees using tools and equipment instructed on their proper use? 18.8 Are hand tools used in the process appropriate for the work to be done with them? 18.9 Is there control over the use of tools that are damaged or have missing handles? 18.10 Are portable abrasive wheels appropriately guarded? 18.11 Is the abrasive wheel the correct type for the operation? 18.12 Is the abrasive wheel properly mounted? 18.13 Are goggles or face shields always worn when grinding, chipping, or cutting? 18.14 Are spray guns only used by trained personnel? 19.0 HAZARDOUS MATERIALS/MATERIAL SAFETY DATA SHEETS/LABELING 19.1 Are chemical storage and use areas properly designated? 19.2 Do hazardous material storage areas have adequate means of exit/egress? 19.3 Is there no eating or drinking in any chemical storage areas? 19.4 Are "No Smoking" rules enforced in areas involving storage and use of hazardous materials? 19.5 Is a hazardous materials inventory maintained and documented? 19.6 Are hazardous materials and decanting containers properly labeled in accordance with WHMIS, and are the labels legible and intact? 19.7 Are MSDS's complete, current (within last 3 years) and readily available? Y N/A Page 14 of 42 N 19.8 Is there an MSDS readily available for all hazardous materials in the area? 19.9 Are MSDS's available in the primary language of the workplace? 19.10 Are tanks/drums made of steel or other appropriate material? 19.11 Are tanks/drums adequately supported and free from tipping hazards? 19.12 Are tanks adequately vented? 19.13 Are pressure relief valves provided on tanks? 19.14 Are adequate spill containment and spill procedures in place? 19.15 Are proper spill absorbent materials and/or drainage provided? 19.16 Are spill control procedures reviewed and understood by all personnel? 19.17 Is adequate storage cabinets provided, fire resistant and vented? 19.18 Is storage shelving secure and not exceeding maximum support weight? 19.19 Do storage volumes remain within maximum limit? 19.20 Is storage heated by means not constituting a source of ignition? 19.21 Are drums stored out of direct sunlight? 19.22 Is bulk or drum storage in accordance with fire codes, with respect to separation distance, shielding, and lighting protection? 19.23 Are non-arching type fans in hazardous flammable substance storage areas? 19.24 Are materials separated appropriately to avoid incompatibility reactions? 19.25 Are containers protected against corrosion? 19.26 Are there appropriate chemical waste disposal procedures in place? Page 15 of 42 19.27 Does chemical dispensing occur in designated, controlled areas? 19.28 Are appropriate quantities of flammables kept in the operating area? (no more than are necessary for the job). 19.29 Are all connections tight on drums and combustible liquid piping? 19.30 Are piping systems identified as to content and direction of flow? 19.31 Are flammable liquids kept in closed containers when not in use? 19.32 Are spills of flammable or combustible liquids cleaned up properly? 19.33 Are bulk drums of flammable liquids grounded and bonded to containers during dispensing? 19.34 Are gasoline and other flammable liquids stored in approved containers? 19.35 Does storage of toxic and explosive substances meet legislative requirements? 19.36 19.37 Do storage rooms for flammable and combustible liquids meet legislative requirements? Are storage cabinets for flammable and combustible liquids appropriately labelled? 19.38 Are storage cabinet vents unobstructed? 19.39 Are legislative standards met for all spray painting or dip tank operations involving flammable/combustible liquids? 19.40 Are processes which produce gas, dust, or fumes with explosion potential adequately safeguarded? 19.41 Are dust collectors that exceed cfm capacity, located either externally or in a separate room? 19.42 Is there a fire control system in place to prevent fire propagation from tank to tank? 19.43 Is there adequate ventilation where dispensed and/or used? 19.44 Are procedures in place for the safe handling of corrosive and toxic materials? 19.45 Are safe work permit systems in effect? Page 16 of 42 20.0 HYDRAULIC POWER SYSTEMS 20.1 Is pressure regulated within power limits? 20.2 Are systems in good general condition - no leaks, dents, nicks, severe scratches? 20.3 Are fluid pressure lines clearly identified? 20.4 Is remote shut-off available? 20.5 Are regular maintenance checks conducted? 21.0 LADDERS 21.1 Are safety feet in good condition and do they provide adequate slip resistance? 21.2 Are ladders unpainted and free of grease and oil? 21.3 Are ladders used by only one person at a time? 21.4 Are ladders properly positioned (base 1 foot out for every 4 feet vertical height), and tied in at top? 21.5 Are doors blocked open, locked, or guarded if in front of ladder? 21.6 Are ladders supported in place against window openings? 21.7 If used for access to a roof, does the ladder extend 3 feet above roof? 21.8 Do defective ladders have danger tags affixed and are they restricted from use? 21.9 Are both rails of the ladder fully supported when in use? Y N/A N Y N/A N Page 17 of 42 22.0 LIGHTING 22.1 Are walking and working areas adequately illuminated during periods of occupancy? 22.2 Are lighting fixtures clean? 22.3 Is illumination level sufficient for detail or work performed? 22.4 Are there emergency lights installed? 22.5 Are emergency lights routinely tested? (At least once every 3 months) 23.0 LOCK-OUT SYSTEMS 23.1 Are positive lock-outs provided for all power systems and individual powered equipment? 23.2 Do lock-outs permit multiple lock-out? 23.3 Do tags or colour codes indicate the user of the lock-out? 23.4 Does the lock-out system provide means to reduce system/ equipment to zero energy state (steam, air, electrical, hydraulic, etc.)? 23.5 Are lock-out procedures enforced and personnel properly instructed? 24.0 MACHINE TOOLS AND GUARDING 24.1 Are machine tools and guards in proper condition and well maintained? 24.2 Are mechanical power transmissions guarded? 24.3 Are pinch points, in-running nip points, and points of operation guarded? 24.4 Are fixed guards secured in position? 24.5 Are interlocked guards operative and in good condition? Y N/A N Y N/A N Y N/A N Page 18 of 42 24.6 Are automatic and operator guards properly adjusted? 24.7 Are operating controls guarded against inadvertent activation? 24.8 Are operating controls locked and the key removed when not in use? 24.9 Are emergency stop buttons operational, correctly positioned, labelled, and colour coded? 24.10 Is isolation and lock-out provided for servicing, set-up, lubrication, etc? 24.11 Are guards provided for rotating parts, chips or particles, sparks, kickbacks, etc? 24.12 Are operator and service manuals available? 24.13 Are safety interlocks appropriate for the operation? 24.14 Are safety interlocks maintained intact - not bridged or by-passed? 24.15 Are sprockets and V-Belt drives within reach of platforms and passageways or less than seven feet from the floor, completely enclosed? 24.16 Are required signs/notices posted? 24.17 Are operating and maintenance records kept? 24.18 Are standard operating procedures in place? 25.0 MATERIALS HANDLING EQUIPMENT 25.1 Are ramps provided where necessary, kept in serviceable condition, and secured to prevent slipping. 25.2 Are containers in good repair? 25.3 Are pallets and skids of correct type and in good repair? 25.4 Are chains, slings, and ropes adequate for loads, in good repair, and marked accordingly? 25.5 Are wheel chocks provided and used? Y N/A Page 19 of 42 N 25.6 Are forklifts and other mobile material handling units posted with their rated capacities? 25.7 Is there a periodic inspection, maintenance, and testing procedure for material handling items? 25.8 Are controls labeled on material handling equipment? 25.9 Are controls readily accessible to the operator? 25.10 Is the emergency disconnect or "kill" switch readily accessible to the operator? 25.11 Is there a daily or periodic operator's checklist completed prior to the operation of the material handling equipment? 25.12 Are only trained operators allowed to operate powered lift trucks? Other vehicles? 25.13 Is changing of electric batteries performed only in designated areas? 25.14 Are "No Smoking" rules enforced near electric battery charging units? 25.15 Are elevators, hoists, etc. properly used with appropriate signals and directional warning signs? 25.16 Is there safe clearance for all equipment through aisles and doors? 26.0 MECHANICAL POWER SYSTEMS 26.1 Are mechanical power systems in good general condition and fully functional? 26.2 Are rotating collars, couplings, clutches, fly-wheels, bolt ends, nip points, etc. guarded? 26.3 Are emergency stops operational, easily accessible and clearly identified? 27.0 MOBILE EQUIPMENT (Fork Trucks, Pump Trucks, etc) 27.1 Are overhead guards provided where overhead clearance is a factor? 27.2 Are there designated areas for battery recharging? Y N/A N Y N/A N Page 20 of 42 27.3 Is mobile equipment operated by qualified personnel only? 27.4 Is mobile equipment in good general condition and fully functional? 27.5 Are daily pre-shift inspections completed by the operator? 27.6 27.7 Does the operator use a signaler when a full view of the intended path of travel is not possible? Is mobile equipment immobilized and secured against use and accidental movement when left unattended? 27.8 Are loads carried as close to the floor as possible and within the load capacity of the vehicle? 27.9 Is mobile equipment operated in a safe manner at all times? 27.10 Are forks, buckets, blades and similar parts in the lowered position or solidly supported when powered equipment is left unattended? 27.11 Are manufacturer operating manuals available, easily accessible to the operator, and legible? 28.0 NOISE EXPOSURE 28.1 Are engineering controls (e.g. enclosure, maintenance) in place as required to manage noise exposure? 28.2 Is hearing protection provided when sound levels exceed standard (85dBA)? 28.3 Are hazardous noise areas identified and marked? 29.0 PERSONAL PROTECTIVE EQUIPMENT (PPE) 29.1 Are areas requiring PPE appropriately identified? 29.2 IS PPE being used in areas where it is required? Y N/A N Y N/A N Page 21 of 42 29.3 Is PPE available/provided, including respirators where required? 29.4 Is PPE in good condition and adequately maintained? 29.5 Is PPE correctly selected for the hazard exposure being controlled? 29.6 Are PPE storage facilities appropriate? 29.7 Are there PPE cleaning facilities? 29.8 Do the operating procedures identify when and under what circumstances PPE must be used? 29.9 Are there observations on the floor of violations to the documented requirements? 30.0 PLATFORMS/SCAFFOLDING 30.1 Are working platforms at least 46 centimetres wide? 30.2 Is a toeboard provided along all sides? 30.3 Are platforms and scaffolding used only on proper flooring (non-slip, even)? 30.4 Is there a mesh screen below the floor in areas of open construction? 30.5 Are access gates self-closing and locking? 30.6 Are platforms and scaffolds equipped with standard guard rail? 30.7 Are scaffolds used only on sound, rigid footing? 30.8 Is there no accumulation of tools or materials? 30.9 Is there no altering of scaffolds in use? 30.10 Is each caster or wheel in proper working condition with a suitable breaking device on each caster or wheel? 30.11 Are jacks and leveling screws in good condition? Y N/A Page 22 of 42 N 31.0 PRESSURE VESSELS 31.1 Are meters and controls located on operating floor? 31.2 Are safety valves operational? 31.2 Are drains clear and freeze protected? 31.3 Is the inspection certificate/label appropriate for the type of pressure vessel? 31.4 Are pipes, connections, and vessels, free from dents, notches, and severe scratches? 31.5 Are shields, platforms, and landings available as required? 31.6 Is remote shut-off to pumps available? 31.7 Is respiratory/rescue and confined space equipment available? 31.8 Are there fail-safe features such as relief valves, alarms, trip circuits, etc? 31.9 Do relief and vent streams discharge to a safe place? 32.0 RESPIRATORY PROTECTION DEVICES 32.1 Are respirators provided where necessary? 32.2 Are written standard operating procedures for the selection and use of respirators available to the employee? 32.3 Is the employee-user instructed and trained in the proper use of respirators? 32.4 Are respirators cleaned and disinfected after use? 32.5 Are respirators stored in a convenient, clean, and sanitary location? 32.6 Are respirators inspected at regular intervals by qualified people? Y N/A N Y N/A N Page 23 of 42 33.0 SIGNS AND TAGS 33.1 Are hazard warnings, directional and informational signs and tags used where there are immediate dangers, potential hazards, or where there is a need for general instructions? 33.2 Are signs and tags consistent in use throughout the facility? 33.3 Are tags affixed to all defective equipment that are not secured against use? 34.0 STACKING AND STORAGE 34.1 Are aisles and access paths clear and unobstructed? 34.2 Are all stacks stable and secure against sliding/collapsing? 34.3 Is there proper drainage in storage area? 34.4 Are storage areas clean and cleared of foreign objects/materials? 34.5 Are rack and platform load limits posted and observed? 34.6 Is there appropriate clearance between sprinkler heads and stored material? 34.7 Are shelving and racks stable? 34.8 Is empty pallet storage proper? 34.9 Are pallets in satisfactory condition? (not broken or damaged) 34.10 Is there a designated place for everything used in the operation such as tools, supplies, solvents, etc. 34.11 Is there proper storage of articles not in use? 34.12 Are overhead materials and objects secured against falling? 34.13 Are storage areas free from tripping hazards? Y N/A N Y N/A N Page 24 of 42 34.14 Does internal and external storage of metal drums meet legislative requirements? 34.15 Does bulk storage, above and below ground meet legislative standards? 34.16 Are bulk storage areas inspected and tested regularly? 34.17 Are drop and false ceilings free of stored materials? 34.18 Are catwalks free of stored materials? 34.19 Is sprinkler equipment unobstructed (e.g. free of hanging objects)? 34.20 Are wall and ceiling fixtures securely fastened? 35.0 STAIRS 35.1 Are stairs at least 24 centimetres in tread width? 35.2 Are steps uniform in height and tread depth? 35.3 Do outdoor stairs have grating type treads? 35.4 Are treads and nosings slip resistant? 35.5 Are long flights broken by rest platforms as prescribed? .35.6 Are hand rails provided on open sides? 35.7 Are hand rails on at least one side if closed? 35.8 Do stairs have a vertical clearance of 7 feet? 35.9 Are stairways adequately lighted? 35.10 Are stairways are adequately clear and unobstructed? 35.11 Are combustible materials or other materials stored in the stairwell? Y N/A Page 25 of 42 N 35.12 Is a non-slip material used for steps? 36.0 TEMPERATURES 36.1 Is exposure to extreme heat and cold controlled with engineering and/or administrative controls? 36.2 Is PPE available for these extreme conditions? 36.3 Does extreme heat and cold exposures remain within the ASHRAE guidelines? 37.0 TRANSPORT OF HAZARDOUS MATERIALS 37.1 Have local police been called before on-site transport of hazardous materials? 37.2 Have danger placards been posted? 37.3 Does the transported load not exceed 1100 lbs for on-site operations? 37.4 Does on-site transportation of hazardous materials not exceed 1 kilometre? 38.0 VALVES AND MECHANICAL CONTROLS 38.1 Are valves and mechanical controls labelled and colour coded? 38.2 Are valves and controls operational and free from defect? 38.3 Are valves and controls readily accessible? Y N/A N Y N/A N Y N/A N Page 26 of 42 39.0 VENTILATION 39.1 Is there adequate ventilation for removal of contaminants especially in areas of toxic, noxious, or asphyxiant materials? 39.2 Are appropriate engineering controls in place for contaminant of concern and generation process? 39.3 Does ventilation maintain proper air balancing? 39.4 Is ventilation equipment designed to draw contaminants away from breathing zone? 39.5 Has the ventilation system been checked for optimal operational capacity in the past year? 39.6 Is there any evidence of deterioration in the system? 39.7 Are hoods used for reasons other than their intended use? (e.g. storage of materials). 39.8 Are spray paint booths, dip tanks, etc. cleaned regularly? 39.9 Is excessive force required to open doors entering into fan rooms? 40.0 VIBRATION 40.1 Is vibration/oscillation disconcerting at any of the work stations? 41.0 WARNING SYSTEMS 41.1 Are fire/emergency alarm systems operational, tested, and documented as required? 41.2 Do hazard warning systems exist on appropriate vehicles and equipment? 41.3 Do overpressure warning systems exist on pressure vessels? 41.4 Do over-temperature warning systems exist on fired pressure vessels, critical hazardous material storage, and powered equipment? Y N/A N Y N/A N Y N/A N Page 27 of 42 42.0 WASTE DISPOSAL 42.1 Are there an adequate number of appropriate refuse containers? 42.3 Are separate containers provided for oily rags, dusts, flammable scrap, chemical wastes, broken glass, etc? 42.4 Are chemical spill absorbents/neutralizers available in work areas with appropriately labeled waste containers? 42.3 Are there procedures for the handling and disposal of process waste? 42.4 Are the handling and disposal procedures for process waste followed in the work area? 42.5 Is there proper disposal of waste materials, scrap, broken glass, sharp objects, etc.? 43.0 WELDING, CUTTING, AND BRAZING 43.1 Are only trained competent employees allowed to use welding equipment? 43.2 Do operators have a copy of operating instructions? 43.3 Is proper eye protection worn by welders? 43.4 Are adjacent workers adequately protected? 43.5 Is eye protection (goggles, helmets) provided and worn as a protection against sparks and other debris? 43.6 Is suitable fire extinguishing equipment available? 43.7 Are all compressed gas cylinders legibly marked for identifying the content? 43.8 Are the cylinder valves shut off when the cylinder is not in use? 43.9 Is welding always conducted at a safe distance from flammable liquids, wet or dry dusty areas and other flammable materials? Y N/A N Y N/A N Page 28 of 42 43.10 Are cylinders secured and stored where they cannot be knocked over? 43.11 Are cylinder protective caps in place except when the cylinder is in use? 43.12 Are compressed gas cylinders kept away from sources of heat, elevators, stairs, etc.? 43.13 Are electrical welding equipment and cables properly maintained? 44.0 GENERAL OFFICE INSPECTION 44.1 Lighting is adequate? 44.2 Ventilation is adequate? 44.3 Temperature is adequate? 44.4 Noise levels appear comfortable? 44.5 Dust levels are kept to a minimum? 44.6 Working space is adequate? 44.7 Office arrangement allows easy egress under emergency conditions? 44.8 Walls, Floor, Ceiling and/or Floor Covering in good condition? 44.9 Carpeting is in good condition and not badly worn or torn? 44.10 44.11 44.12 44.13 Y N/A Office furniture, equipment and electrical appliances are arranged to obtain maximum safety and use of installed facilities, such as overhead lighting, wall outlets, telephones, and other services? Desks, file cabinets, etc., are arranged so that drawers do not open into aisles or walkways? Wall mounted Cabinets, Stand-alone bookcases, and wall mounted shelves are secured to building surfaces to prevent their falling over? Weight is distributed in file cabinets so that upper drawer contents do not create a top-heavy condition? Page 29 of 42 N 44.14 44.15 44.16 Wall Mounted Shelves not overloaded? (Eg. Not more than 75% full -- heavy items on the bottom or stored somewhere else) Wall Mounted Shelves are not coming away from the wall/missing straps/missing screws? Floors are clear of pencils, bottles, electrical/phone cords, loose tiles, wastebaskets, briefcases, projections or other objects/protrusions on the floor that create a tripping hazard? 44.17 Wall outlet and junction box covers are in place? 44.18 Light Lense Covers/Ceiling Tiles are not missing? 44.19 Are Light Lense Covers/Ceiling Tiles properly installed/not broken/secure/not out of place? 44.20 Ceiling tiles free from water/rust stains and/or excessive dirt? 44.21 44.22 Extension cords are NOT being used as a permanent remedy due to a lack of electrical outlets? (If more outlets are required, contact CPF Help and place a work order request). Extension cords are arranged so that they are not placed over radiators and/or steam pipes? 44.23 Extension cords are the three-wire grounded type and in good condition – no splices or broken insulation? 44.24 Cords and plugs are in good condition? 44.25 Electrical cords are not run through openings in doors, walls, ceilings or under carpets? 44.26 Multi-outlet strips are not plugged into other multi-outlet strips? Extension cords are not plugged into other extension cords? 44.27 44.28 44.29 Electrical devices show no signs of overheating? (Cords or equipment should not be hot to the touch) Electric fans are protected with guards of not over ½ inch mesh, which prevents fingers getting inside the guard? Reviewed the Policy on Use of Personal Electrical Appliances within the University? Approval Required? Website: www.ryerson.ca/policyprocedure/policies.html Space heater is UL listed? It has an automatic "shut-off" feature that will actuate if the heater tips over? It is plugged directly into a wall receptacle? It is located at least three feet from combustible material? It has been approved for use by Campus Facilities & Sustainability? Reviewed the Policy on Use of Personal Electrical Appliances within the University? Website: www.ryerson.ca/policyprocedure/policies.html Page 30 of 42 44.30 Computer workstation is arranged in an ergonomic way? Website eTool: www.osha.gov/SLTC/etools/computerworkstations/index.html 44.31 Adjustable seating is available when appropriate? 44.32 Footrests are available for those who need them? 44.33 Adjustable keyboard tray is available when appropriate? 44.34 Step stools are provided for reaching materials on shelves? 44.35 No excessive storage of combustible materials? (paper, wood, etc) 44.36 Recycling, cartons and trash are removed on a regular basis? 44.37 Emergency numbers are prominently posted? (In case of emergency Dial 80 Sticker on phone base) 44.38 Other 45.0 GENERAL LABORATORY INSPECTION 45.1 Are laboratory chemicals used in the smallest quantities practical, stored correctly, and decanted on a day-to-day basis? 45.2 Are fume and flow hoods used as designated and in good condition? 45.3 Are sharps containers available for proper disposal? 45.4 Do lab workers and students wear required personal protective equipment, and is hair and jewellery contained? 45.5 Is housekeeping adequate to prevent leaks, spills and contamination? 45.6 Are sources of open flame and extreme heat turned off when not in use and located away from chemicals and flammable materials? 45.7 Are all chemicals and laboratory-sized samples labeled and capped properly? 45.8 Is laboratory ventilation adequate and in good working order? 45.9 Are chemical spill kits, first aid kits, eyewash stations and fire extinguishing equipment available and in good working order? Y N/A Page 31 of 42 N 45.10 Are emergency numbers posted in a conspicuous location? 45.11 Is the lab area free of debris, obstruction and spills? 45.12 Are GFCI outlets available near sinks and routinely wet areas? 45.13 Lighting is adequate? 45.14 Ventilation is adequate? 45.15 Temperature is adequate? 45.16 Noise levels appear comfortable? 45.17 Dust levels are kept to a minimum? 45.18 Working space is adequate? 45.19 Office arrangement allows easy egress under emergency conditions? 45.20 Walls, Floor, Ceiling and/or Floor Covering in good condition? 45.21 Carpeting is in good condition and not badly worn or torn? 45.22 45.23 Office furniture, equipment and electrical appliances are arranged to obtain maximum safety and use of installed facilities, such as overhead lighting, wall outlets, telephones, and other services? Desks, file cabinets, etc., are arranged so that drawers do not open into aisles or walkways? 45.24 Wall mounted Cabinets, Stand-alone bookcases, and wall mounted shelves are secured to building surfaces to prevent their falling over? 45.25 Weight is distributed in file cabinets so that upper drawer contents do not create a top-heavy condition? 45.26 Wall Mounted Shelves not overloaded? (Eg. Not more than 75% full -- heavy items on the bottom or stored somewhere else) 45.27 45.28 Wall Mounted Shelves are not coming away from the wall/missing straps/missing screws? Floors are clear of pencils, bottles, electrical/phone cords, loose tiles, wastebaskets, briefcases, projections or other objects/protrusions on the floor that create a tripping hazard? Page 32 of 42 45.29 Wall outlet and junction box covers are in place? 45.30 Lense Covers/Ceiling Tiles are not missing? 45.31 Are Light Lense Covers/Ceiling Tiles properly installed/not broken/secure/not out of place? 45.32 Ceiling tiles free from water/rust stains and/or excessive dirt? 45.33 45.34 Extension cords are NOT being used as a permanent remedy due to a lack of electrical outlets? (If more outlets are required, contact CPF Help and place a work order request). Extension cords are arranged so that they are not placed over radiators and/or steam pipes? 45.35 Extension cords are the three-wire grounded type and in good condition – no splices or broken insulation? 45.36 Cords and plugs are in good condition? 45.37 45.38 45.39 45.40 45.41 45.42 Electrical cords are not run through openings in doors, walls, ceilings or under carpets? Multi-outlet strips are not plugged into other multi-outlet strips? Extension cords are not plugged into other extension cords? Electrical devices show no signs of overheating? (Cords or equipment should not be hot to the touch) Electric fans are protected with guards of not over ½ inch mesh, which prevents fingers getting inside the guard? Reviewed the Policy on Use of Personal Electrical Appliances within the University? Approval Required? Website: www.ryerson.ca/policyprocedure/policies.html Space heater is UL listed? It has an automatic "shut-off" feature that will actuate if the heater tips over? It is plugged directly into a wall receptacle? It is located at least three feet from combustible material? It has been approved for use by Campus Facilities & Sustainability? Reviewed the Policy on Use of Personal Electrical Appliances within the University? Website: www.ryerson.ca/policyprocedure/policies.html Computer workstation is arranged in an ergonomic way? Website eTool: www.osha.gov/SLTC/etools/computerworkstations/index.html 45.43 Adjustable seating is available when appropriate? 45.44 Footrests are available for those who need them? 45.45 Adjustable keyboard tray is available when appropriate? Page 33 of 42 45.46 Step stools are provided for reaching materials on shelves? 45.47 No excessive storage of combustible materials? (paper, wood, etc) 45.48 Recycling, cartons and trash are removed on a regular basis? 45.49 Emergency numbers are prominently posted? (In case of emergency Dial 80 Sticker on phone base) 45.50 Phone in good working order (dial tone)? 45.51 Other 46.0 EMPLOYEE KITCHEN FACILITIES 46.1 Are all appliances in good condition and CSA/UL-approved? 46.2 Are GFCI outlets available near sinks and routinely wet areas? 46.3 Are floors and counters clean and dry? 46.4 Are circuits loaded properly (not overloaded)? 46.5 Are refuse containers provided and emptied regularly? 46.6 Is lighting adequate and in working order? 46.7 Light Lense Covers/Ceiling Tiles are not missing? 46.8 Are Light Lense Covers/Ceiling Tiles properly installed/not broken/secure/not out of place? 46.9 Ceiling tiles free from water/rust stains and/or excessive dirt? 46.10 Walls, Floor, Ceiling and/or Floor Covering in good condition? 46.11 Carpeting is in good condition and not badly worn or torn? Y N/A Page 34 of 42 N 46.12 46.13 46.14 46.15 46.16 46.17 Wall mounted Cabinets, Stand-alone bookcases, and wall mounted shelves are secured to building surfaces to prevent their falling over? Extension cords are NOT being used as a permanent remedy due to a lack of electrical outlets? (If more outlets are required, contact CPF Help and place a work order request). Cords and plugs are in good condition? Electrical cords are not run through openings in doors, walls, ceilings or under carpets? Multi-outlet strips are not plugged into other multi-outlet strips? Extension cords are not plugged into other extension cords? Electrical devices show no signs of overheating? (Cords or equipment should not be hot to the touch) 46.18 No excessive storage of combustible materials? (paper, wood, etc) 47.0 GENERAL LOUNGE AREA 47.1 Are floors and walking surfaces clean, dry and in good condition? 47.2 Are lounge areas free from dirt and debris? 47.3 Is furniture and equipment free of sharp edges and in good condition? 47.4 Is access and egress unobstructed? 47.5 Is lighting adequate and in working order? (Exception: Some lights may be out intentionally for comfort.) 47.6 Light Lense Covers/Ceiling Tiles are NOT missing? 47.7 Are Light Lense Covers/Ceiling Tiles properly installed/NOT broken/secure/not out of place? 47.8 Ceiling tiles free from water/rust stains and/or excessive dirt? 47.9 Walls, Floor, Ceiling and/or Floor Covering in good condition? 47.10 Carpeting is in good condition and not badly worn or torn? Y N/A Page 35 of 42 N 47.11 47.12 47.13 47.14 47.15 Wall mounted Cabinets, Stand-alone bookcases, and wall mounted shelves are secured to building surfaces to prevent their falling over? Extension cords are NOT being used as a permanent remedy due to a lack of electrical outlets? (If more outlets are required, contact CPF Help and place a work order request). Cords and plugs are in good condition? Electrical cords are not run through openings in doors, walls, ceilings or under carpets? Multi-outlet strips are not plugged into other multi-outlet strips? Extension cords are not plugged into other extension cords? 47.16 Electrical devices show no signs of overheating? (Cords or equipment should not be hot to the touch) 47.17 No excessive storage of combustible materials? (paper, wood, etc) 47.18 Other 48.0 CLASSROOM / MEETING ROOM / BOARDROOM 48.1 Is furniture and equipment in good condition? 48.2 Are blinds/curtains fully functional and in good condition? 48.3 Is access and egress unobstructed? 48.4 Are refuse containers provided and emptied regularly? 48.5 Is material stored and stacked safely? 48.6 Are room occupancy limits and safe seating arrangements posted? 48.7 In rooms with fixed seating, are there NO additional seating measures taken? (No extra desks and chairs) 48.8 In rooms with non-fixed seating, does the chair count stay within the room's occupancy limit? 48.9 Light Lense Covers/Ceiling Tiles are not missing? 48.10 Improperly installed/Broken/Loose/Out of Place Light Lense Covers/Ceiling Tiles? Y N/A Page 36 of 42 N 48.11 Ceiling tiles free from water/rust stains and/or excessive dirt? 48.12 Walls, Floor, Ceiling and/or Floor Covering in good condition? 48.13 Carpeting is in good condition and not badly worn or torn? 48.14 48.15 Wall mounted Cabinets, Stand-alone bookcases, and wall mounted shelves are secured to building surfaces to prevent their falling over? Extension cords are NOT being used as a permanent remedy due to a lack of electrical outlets? (If more outlets are required, contact CPF Help and place a work order request). 48.16 Cords and plugs are in good condition? 48.17 Electrical cords are not run through openings in doors, walls, ceilings or under carpets? 48.18 48.19 Multi-outlet strips are not plugged into other multi-outlet strips? Extension cords are not plugged into other extension cords? Electrical devices show no signs of overheating? (Cords or equipment should not be hot to the touch) 48.20 No excessive storage of combustible materials? (paper, wood, etc) 49.0 WASHROOMS 49.1 Are mirrors in good condition and firmly secured? 49.2 Are floors, ceilings, and walls in good condition? 49.3 Are locks on stalls in good condition and fully operational? 49.4 Are hinges on doors in good condition and correctly fixed? 49.5 Are water taps and sinks in good condition? (Not leaking) 49.6 Are soap containers present? 49.7 Are toilets flushable and in good working order? Y N/A Page 37 of 42 N 49.8 Are refuse containers present and in good condition? 49.9 Are washrooms clean, tidy and free from spills and debris? 49.10 Are sink and floor drains clear, allowing liquids to drain freely? 50.0 WOOD WORKING WORKSHOP Y N/A Housekeeping 50.1 Are aisles (means of egress) properly marked and kept clear of materials and equipment? 50.2 Are wet surfaces covered with non-slip materials? 50.3 Are combustible scrap, debris and waste materials (i.e. oily rags) placed in covered metal receptacles and removed from the worksite by the end of the day? 50.4 Are work areas clean and orderly? Lighting/Ventilation 50.5 Is adequate lighting provided in all work areas and walkways? 50.6 Is the work area’s ventilation system appropriate for work being performed (e.g. dusts, fumes, vapors, grinding, buffing, painting)? 50.7 Is there a dust collection system for wood shavings? 50.8 Are spray booths, dip tanks, and the like, cleaned regularly and maintained in accordance with the manufacturer’s instructions? Personal Protective Equipment 50.9 Is required protective equipment posted? 50.10 Has the shop coordinator attended PPE coordinator training? 50.10 Is training provided to each employee who is required to use personal protective equipment with training records kept in a training log? Page 38 of 42 N 50.10 50.11 50.11 50.12 50.13 50.14 If protective equipment is required, is it appropriate for the job, in good condition, kept clean and sanitary, and stored appropriately when not in use? Are operators dressed safely for the job (no loose fitting clothing, jewelry, long hair, or open-toed shoes)? Are approved safety glasses required to be worn at all times in areas where there is risk of eye injury, such as impact, flying debris, chemical splash, or light radiation? Are protective gloves, aprons, shields, or other means provided against cuts, abrasions, punctures, corrosive liquids and chemicals? Is appropriate foot protection required where there is risk of foot injuries from hot, corrosive, poisonous substances, falling objects, and crushing or penetrating actions? Are first-aid kits easily accessible to each work area, with necessary supplies available, periodically inspected and replenished as needed? Fire safety 50.15 Are emergency telephone/pager numbers posted where they can be readily found in case of emergency? 50.16 Are fire extinguisher(s) in your area free from obstructions or blockage and have employees been trained to use it/them? 50.17 Is there a posted emergency evacuation plan for the shop? 50.18 Are gas connections that need to be turned off in case of fire clearly marked? 50.19 Are flammable materials stored properly? Hazard Communication (Chemical Storage) 50.20 Are Material Safety Data Sheets (MSDSs) available for hazardous substances used in shop? 50.21 Are employee exposures to chemicals kept below permissible exposure limits? Does EHSS need to monitor? 50.22 Are eye wash stations and safety showers provided in areas where corrosive chemicals are handled? 50.23 50.24 Are employees required to use personal protective clothing and equipment when handling chemicals? Is each hazardous substance container (i.e. vats, bottles, storage tanks) labeled with product identity and a hazard warning (communication of specific health and physical hazards)? Page 39 of 42 50.25 When lunches are eaten on the premises, are they eaten in areas where there is no exposure to toxic materials or other health hazards? 50.26 Are chemical piping systems clearly marked as to their contents? Is lead solder used? 50.27 Is vacuuming used, rather than blowing or sweeping dusts, whenever possible for cleanup? Electrical Safety 50.28 Do extension cords in use have a grounding conductor? 50.29 Are multiple plug adapters prohibited? 50.30 Is exposed wiring and cords with frayed or deteriorated insulation repaired by a qualified electrician or replaced promptly? 50.31 Are flexible cords, cable, and raceway connections free of splices or taps and otherwise intact and secure? 50.32 50.33 50.34 Are portable electrical tools and equipment grounded or of the double insulated type? In wet or damp locations, are electrical tools and equipment appropriate for the use or location, or otherwise protected (e.g. use of ground fault circuit interrupters)? Are all disconnecting switches and circuit breakers labeled to indicate use or equipment served? 50.35 Are electrical enclosures such as switches, receptacles, junction boxes provided with tight-fitting covers or plates? 50.36 Is the breaker panel accessible and each circuit properly labeled? 50.37 Can power to each machine be locked out for maintenance, repair, or security? 50.38 Are the non-current-carrying metal parts of electrically operated machines bonded and grounded? Training 50.39 Is there a training program in place to instruct shop users on the safe methods of machine operations? 50.40 Do operators and maintenance workers have the necessary training in how to use the safeguards and why? 50.41 Have operators and maintenance workers been trained in how and under what circumstances guards can be removed? Page 40 of 42 50.42 Have workers been trained in the procedures to follow if they notice guards that are damaged, missing, or inadequate? Machinery 50.43 50.44 50.45 50.46 Is the owner’s manual for each machine stored at the shop? Are all machines that are designed for a fixed location securely anchored to prevent walking, tipping, or moving? Is sufficient clearance (3 foot minimum) provided around and between machines to allow for safe operations, set-up and servicing, materials handling, and waste removal? Are machines properly grounded? Maintenance and Repair 50.47 Is there a regular safety inspection of each piece of machinery or equipment? 50.48 Have workers received up-to-date instruction on the machines they service? 50.49 50.50 Are workers trained in the requirements of lockout/tagout hazards, and are the procedures for lockout/tagout evaluated or developed before they attempt their tasks? Do workers lockout the machine from its power sources before beginning repairs? 50.51 Do workers have electrical plug locks or disconnect switches? 50.52 Where several persons work on the same machine, are multiple lockout devices used? 50.53 Do workers use appropriate and safe equipment in their repair work? 50.54 Is the maintenance equipment itself properly guarded? Machine Guarding 50.55 50.56 Are guards in place to protect against point of operation, nip points, rotating parts, flying chips, and sparks (e.g. gears, sprockets, pulleys, belts, and flywheels)? Are guards securely positioned and functioning correctly and arranged such that they do not present a hazard themselves? Guards must be affixed to the machine where possible, or anchored securely elsewhere otherwise. Page 41 of 42 50.57 Are coolant splashguards in place to prevent employee exposure? 50.58 Are revolving drums, barrels, and containers guarded by an enclosure interlocked with the drive mechanism so that revolution cannot occur unless the guard enclosure is in place? Machine Operations 50.59 Are start, stop (must be red), and other operating controls within the operator’s easy reach? 50.60 Is a standard operating procedure (SOP) available for the machine and located at the machine? 50.61 Is there adequate supervision to ensure that shop users are following safe machine operating procedures? 50.62 Are foot-operated switches guarded or arranged to prevent accidental actuation by personnel or falling objects? 50.63 Are manually operated valves and switches guarded or arranged to prevent accidental actuation by personnel or falling objects? Questions? Contact Integrated Risk Management at 416-979-5000, ext. 7096 or irm@ryerson.ca. Page 42 of 42