NUMBER: EHS- SAFE - 006 TITLE: Respiratory Protection Program DATE OF ADOPTION

advertisement

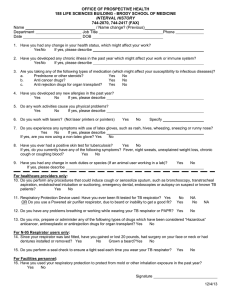

NUMBER: EHS- SAFE - 006 TITLE: Respiratory Protection Program DATE OF ADOPTION: 3/7/2006 DATE OF REVISION: APPROVED BY: AT: 1.0 Purpose......................................................................................................................... 2 2.0 Scope and Applicability .............................................................................................. 2 3.0 Reference ..................................................................................................................... 2 4.0 Program Mission ......................................................................................................... 2 5.0 Definitions .................................................................................................................... 2 6.0 General Provisions ...................................................................................................... 5 6.1 Training ..................................................................................................................... 5 6.2 Hazard Assessment ................................................................................................... 5 6.3 Respirator Selection .................................................................................................. 6 6.4 Purchasing ................................................................................................................. 6 6.5 Medical Monitoring .................................................................................................. 6 6.6 Fit Testing ................................................................................................................. 7 6.7 Recordkeeping .......................................................................................................... 8 6.8 Respirator Care ......................................................................................................... 8 7.0 Specific Responsibilities.............................................................................................. 9 7.1 Department Heads ..................................................................................................... 9 7.2 Supervisors .............................................................................................................. 10 7.3 Competent Person ................................................................................................... 10 7.4 Employees ............................................................................................................... 10 7.5 Safety Office ........................................................................................................... 10 8.0 Audit and Review ...................................................................................................... 10 8.1 Items Subject to and Frequency of Audit and Review ........................................... 10 8.2 Record Keeping; Format; Destruction .................................................................... 10 Appendix A: Training Course Attendance Sheet ........................................................ 11 Appendix B: Medical Questionnaire and Physicians Evaluation ............................... 12 Appendix C: Respirator Fit Test Form ........................................................................ 16 Appendix D: Respirator Maintenance Record............................................................. 17 Page 1 of 17 1.0 Purpose The purpose of this Respiratory Protection Program is to establish safety guidelines for Clarkson University employees who may be exposed to airborne respiratory hazards on the job. The use of a respirator is required only when engineering and administrative controls fail to maintain airborne contaminants at or below human exposure limits. 2.0 Scope and Applicability The respiratory system provides the most direct route of human exposure to toxic, airborne materials. This Respiratory Protection Program applies to employees who, as a result of his/her job duties, may be exposed to hazardous environments where contaminants exceed the human exposure limits or that regulatory authorities have determined to be immediately dangerous to life and health. This program presents guidelines for the use of respiratory protection and includes provisions for training, hazard assessments, respirator selection, medical monitoring, fit testing, record keeping, and equipment care and storage. This program also details the responsibility for Managers, Supervisors, competent persons and employees. 3.0 Reference The Occupational Safety and Health Standards for General Industry (29 CFR 1910.251 - 1910.257). 4.0 Program Mission To provide a place of employment free from recognized hazards that may cause or are likely to cause death or serious physical harm to employees or the public. When respiratory hazards exist in the work place that cannot be eliminated by administrative and engineering controls, the Respiratory Protection Program will be implemented. Only NIOSH approved respiratory protection equipment, provided by the University, will be used. 5.0 Definitions Administrative Control: Work rules or guidelines intended to reduce employee exposure to airborne contaminants that may include; job rotation, limiting the length of time an employee is permitted to work in the affected area. (Also see Engineering Controls.) Air-Purifying Respirator: A respirator with a filter, cartridge, or canister that removes specific air contaminants by passing ambient air through a disposable air-purifying element. Page 2 of 17 Approved: Evaluated and listed as permissible for intended use by a recognized authority. Aerosol: Particulate solids or liquids suspended in air. Atmosphere-Supplying Respirator: A respirator that supplies the user with breathing air from a source independent of the surrounding atmosphere, and includes supplied-air respirators (SARs) and self-contained breathing apparatus (SCBA). Canister or Cartridge: A filter, or catalyst, or combination, which removes specific contaminants from the air that is passed through them. Competent Person: An individual trained to identify existing and predictable conditions in the work environment which may be unsafe or pose a health risk to employees, and who has the authority to take immediate corrective actions to eliminate those conditions. Contaminant: A harmful or irritating airborne material that represents a respiratory hazard. Dust: Particles of solid material that float in the air or settle onto surfaces. Dusts are produced by operations such as grinding, crushing, drilling, blasting, and milling. Dust Mask: A paper or cloth face covering providing partial air filtration, absent of a negative pressure seal with the face. Exposure: Being in the presence of a contaminant(s) in concentrations that may adversely affect human health and safety as determined by regulating authorities. Engineering Control: A mechanical system designed to maintain safe work place conditions by removing or containing a hazard(s.) Exposure Limit: The maximum allowable concentration of a contaminant to which a human may be exposed. These may be labeled as time-weighted averages, exclusion limits, ceiling limits or short-term limits. Such limits are established and published by recognized authorities and regulatory agencies. Fit Test: An established protocol to assess the quality of respirator fit to the wearer. Fume: The result of a solid material vaporizing at high temperature. Fumes can come from operations such as welding, smelting, and pouring of molten metal. Gases: Substances similar to air in their ability to diffuse or spread freely throughout a container or area. Examples include oxygen, carbon monoxide and carbon dioxide, nitrogen, and helium. Page 3 of 17 Hazard Assessment: The evaluation of a job task for identifiable hazards including monitoring for contaminants, physical hazards or unplanned events/conditions as performed by a Competent Person High Efficiency Particulate Air (HEPA) Filter: A filter that is at least 99.97% efficient in removing particles of 0.3 micrometers in diameter. Immediately Dangerous to Life or Health (IDLH): An atmosphere that poses an immediate threat to life, would cause irreversible adverse health effects, and/or would impair an individual's ability to escape. Licensed Health Care Professional: An individual who is legally permitted to practice or provide health care advice. Mists: Airborne liquid particles formed by atomization and/or condensation. Negative Pressure Respirator: A respirator which, due to a tight fitting seal, has an internal air pressure that is less than the ambient air pressure surrounding it. Oxygen Deficient Atmosphere: An atmosphere in which the oxygen content is below 19.5% by volume. Permissible Exposure Limit (PEL): OSHA’s established limits for contaminants: Eight hour time weighted average (TWA) Short Term Exposure Limit (STEL) Ceiling (C) Excursion Limits (EL) Qualitative Fit Test (QLFT): A pass/fail test to assess the adequacy of respirator fit that relies on the individual's response to test agents. Quantitative Fit Test (QNFT): An assessment of the adequacy of respirator fit by numerically measuring the amount of leakage into the respirator. Seal Check: An action conducted by the respirator user to determine if the respirator is properly sealed to the face. Service Life: The period of time that a respirator, filter or other respiratory equipment provides adequate protection to the user. Threshold Limit Value: The safe limit for exposure, as established by the Industrial Hygiene Association, to a specific contaminant, expressed in a time-weighted average over a normal 8-hour workday. Page 4 of 17 Vapors: The gaseous substances produced by evaporating liquids or solids under specific atmospheric pressures and temperatures. Examples would be the vapors from gasoline, paint thinners and degreaser solvents. 6.0 General Provisions 6.1 Training Mangers and Supervisors will assure that training is provided to each employee prior to a task/assignment that may require the use of a respirator. Training shall include: Review of the Clarkson University Respiratory Protection Program Identification of respiratory hazards that may be encountered on the job Purpose/application of respirators Proper selection and use of respirators Limitations of respirators Maintenance and care of respiratory protective equipment Fit testing Inspection Medical conditions potentially limiting the effective use of respirators Medical monitoring program Employees should be trained annually and are required to demonstrate their understanding through a written test and/or hands on exercises. Employee training shall be documented on a Training Attendance Form. A written copy of this program will be available for employee review upon request. 6.2 Hazard Assessment The purpose of a Hazard Assessment is to determine if hazards exist which would endanger employees assigned to a job or work area, and what methods or best practices may be available to neutralize or eliminate those hazards. A competent person(s) shall perform a hazard assessment and make recommendations for administrative or engineering controls. Where administrative and/or engineering controls will not reduce employee risk to an acceptable level, the hazard assessment shall include recommendations for PPE and/or special procedures that may further assure safety. Employee exposure assessments shall consider air monitoring, process information, the physical work environment, historical data, and best practices relative to the type of hazard. With regard to specific airborne contaminants, the proper respirator and cartridges shall be selected to control exposures above the Threshold Limit Value (TLV). Page 5 of 17 The TLV of an air contaminant does not have to be exceeded for an employee to use a respirator. The employee may request the use of a respirator because of a nuisance exposure or for personal reasons. However, if exposure limits are exceeded, mandatory use of respiratory PPE is not negotiable. Clarkson University’s Respiratory Protection Program is limited to the use of half face air purifying cartridge type respirators. Any use of air supplied or full face respirators designed for use in atmospheres of less than 21% oxygen is beyond the scope of this program and is therefore prohibited. Likewise, use of respirators for entry into an atmosphere where airborne concentration may exceed 25 percent of the lower explosive limit is prohibited. 6.3 Respirator Selection The common types of cartridges used on air purifying respirators at Clarkson are: P100, Organic Vapor Combination P100/OV/Acid Gas- welding with fluxes containing acids Only the National Institute of Occupational Safety and Health (NIOSH) approved type respirators and cartridges shall be used by Clarkson employees to protect themselves from airborne contaminants. The respirators and cartridges shall be selected to provide the adequate protection from specific airborne contaminants in concentrations above the established TLV for substances known to be present. 6.4 Purchasing 6.2.8 Purchasing Only NIOSH approved type respirators shall be purchased and kept in stock along with an adequate supply of cartridges, replacement parts, and cleaning supplies. Unapproved respirators shall be removed from inventory. To maintain consistency throughout the University, the Environmental Health and Safety Committee recommends North brand respirators be used. 6.5 Medical Monitoring 6.2.9 Medical Employees who may be required to wear a respirator must first be medically certified to do so. A Medical Evaluation will be scheduled by the University for each employee so a Physician or Other Licensed Health Care Professional may determine if they are fit to wear a respirator as part of their job. Any employee refusing the medical evaluation will not be allowed to work in an area or on a job where a respirator is required and may be subject to discipline. Follow-up or additional medical evaluations may be required as determined by the Physician. The University will provide additional evaluations if: Page 6 of 17 1. An employee reports new medical conditions, signs or symptoms that could impact his/her ability to use a respirator; 2. A Physician, informs the University that an employee needs to be reevaluated; 3. Observations made during fit testing or program evaluation, indicate a need for employee reevaluation; 4. A change occurs in workplace conditions that may result in a substantial increase in the physiological burden placed on an employee; and/or 5. An incident resulting in over-exposure to a chemical/contaminant or an employee showing signs of over-exposure to a chemical/contaminant. 6.6 Fit Testing Fit testing is required for employees required to wear respirators. The employee must be fit tested with the exact make, model and size of respirator that will be used on the job. Fit testing of cartridge filter respirators shall be accomplished by performing quantitative or qualitative fit testing under positive and negative pressure. Fit testing may not be done until employees are cleared to wear a respirator by a Physician. Employees are prohibited from wearing a respirator under conditions that might prevent them from achieving a good face seal such as: certain styles of facial hair, interference by corrective eye wear, or the absence of one or both dentures. Clean-shaven skin under the respirator sealing surfaces is a must, even a mild growth of whiskers might interfere with this seal. Fit testing will be done annually as well as any time there are changes in the employees physical condition that could affect the fit (i.e. significant weight gain or loss, facial scarring). Seal checks of the respirator: The individual who uses a tight-fitting respirator is to perform a user seal check to ensure that an adequate seal is achieved each time the respirator is put on. Both the positive and negative pressure checks listed below shall be used. A. Positive pressure seal check Close off the exhalation valve and exhale gently into the face piece. The face fit is considered satisfactory if a slight positive pressure can be built up inside the face piece without any evidence of outward leakage of air at the seal. B. Negative pressure seal check Close off the inlet opening of the canister or cartridge(s) by covering with the palm of the hands. Inhale gently so that the face piece collapses slightly, and hold the breath for ten seconds. If the face piece remains in its slightly collapsed condition and no inward leakage of air is detected, the tightness of the respirator is considered satisfactory. Page 7 of 17 6.7 Recordkeeping 6.2.7 Records shall be maintained by the Safety Office on each employee who participates in the respiratory protection program. A sample medical questionnaire and sample physician’s evaluation form are included in the Appendix. The completed medical questionnaire is confidential and when completed should be given to the physician at the time of medical evaluation. A physician’s evaluation concerning the employee’s ability to wear a respirator will be issued by the physician to the Clarkson University Safety Office. The physician’s evaluation and fit testing records will be kept by the Safety Office. 6.8 Respirator Care Clarkson University employees are responsible for maintaining their respirator, which includes cleaning the respirator, changing filters or cartridges, and inspection. Employees will take care of their respirator as follows: Inspection: The wearer of a respirator will inspect it prior to each use and check for proper fit, usage, and condition. The use of a defective respirator is prohibited. If a defective respirator is found during inspection, it must be repaired with manufacturer parts or returned to the stockroom for replacement. Worn or deteriorated parts will be replaced prior to use. Respirators are to be properly maintained at all times in order to ensure they function properly and adequately protect the employee. Before each use, the respirator will be inspected by the wearer for the following: Inspection Procedure: 1. Check for worn or frayed straps. 2. Look for wear or damage on the seal of the face piece. 3. Be sure all parts are tight. 4. Check rubber and plastic parts for flexibility. 5. Valves should be clean and seated perfectly. 6. Be sure filters and cartridges are the right kind for the atmosphere in which work is to be done. 7. Review entire respirator for cleanliness and missing parts. Change Schedule: Employees wearing air-purifying respirators shall change the cartridges on their respirator if they begin to experience difficulty breathing or note the odor of a potential contaminant. Cleaning Procedure: Respirators will be cleaned after each use. Each employee shall clean their own respirator. When cleaning a respirator, remove filters, cartridges, valve assemblies, and any other detachable parts. Clean and dry each part of the respirator and inspect it carefully to be sure it is in good condition before reassembling. Follow the Page 8 of 17 manufacturer's instructions for cleaning and disinfecting the respirator. Generally, a mild detergent and soft brush are used for cleaning. Rinse the respirator thoroughly in clean, warm water. Rinsing is extremely important because a residue of the cleaning agent can damage the respirator and cause skin irritation the next time the respirator is worn. Use a soft, lint-free cloth to absorb most of the water. Be sure all parts are thoroughly dried before reassembling the respirator. Repair: Respirators that do not pass inspection will be removed from service and will be discarded or repaired. Repair of the respirator must be done with parts designed for the respirator in accordance with the manufacturer’s instructions. No attempt will be made to replace components or make adjustments, modifications or repairs beyond the manufacturer’s recommendation. Storage Procedure: The respirator should be placed in the storage area in such a way that no part of it will be stretched, bent, or compressed. Do not put anything on top of it that will affect its shape. Respirators stored incorrectly can easily become distorted and develop leaks. The respirator and cartridges must be stored in separate air-tight containers to prevent contamination. When storing a respirator, even overnight, first flex the rubber parts to make sure they are not twisted or bent. Store the respirator where it will be protected from the following elements: Physical Damage Sunlight Extreme Heat Dust Extreme Cold Moisture Damaging Chemicals Failure to properly care for and maintain an assigned respirator can jeopardize the respirator’s effectiveness to protect against the containment or hazard. 7.0 Specific Responsibilities 7.1 Department Head Department Heads are responsible for ensuring that adequate funds are available and budgeted for the purchase of respiratory protection equipment and related supplies. They will also be responsible for identifying the employees affected by this respiratory protection program and that those employees have received medical clearance before being assigned to operations where a respirator is required. Page 9 of 17 7.2 Supervisors Supervisors will not allow any employee who has not received the required training or medical evaluation to perform any of the tasks or activities requiring respiratory protection. They will also ensure that respirators are properly worn and maintained. Supervisors will be responsible for communicating appropriate needs to the Department Head. They will also be responsible for ensuring that an adequate supply of respirators, cartridges, and replacement parts are available. 7.3 Competent Person A competent person shall be designated by the Department Head to be responsible for conducting, or arranging for, air monitoring where there is known or suspected air contamination. The competent person shall have the necessary training and knowledge to perform hazard assessments, workplace evaluations, recommend exposure controls and have the authority to take prompt corrective action. 7.4 Employees Employees shall comply with all applicable guidelines contained in this program. They will maintain and clean the respirator assigned to them, and properly store the respirator when not in use. Employees will also ensure their respirator has a proper fit and seal. 7.5 Safety Office The Safety Office will provide assistance to Department Heads, supervisors, competent persons, and employees in any matter concerning this respirator program. The Safety Office will review compliance with this program by performing both recordkeeping and field evaluations. 8.0 Audit and Review 8.1 Items Subject to and Frequency of Audit and Review Department Heads shall review employee compliance with this program at least annually and at any time a work task changes or pattern develops that may affect the respiratory protection to be worn by their employees. The Safety Office will review the program annually, or as regulations change to ensure that it remains in compliance with applicable rules and standards. 8.2 Record Keeping; Format; Destruction A training record must be completed and documented for each training session attended by an employee. A copy of this record should be kept by the Safety Office. Page 10 of 17 Appendix A: Training Course Attendance Sheet Clarkson University Safety/Environmental Training Topic ________________________ Instructor ______________ Date: ________________________ Time: __________________ Attendees: (Print) (Sign) ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ Page 11 of 17 Appendix B: Medical Questionnaire For Work Related Respirator Use Clarkson University Safety Office To the employee: In order to maintain the confidentiality of this Medical Questionnaire, once completed, this form should be deliver to and maintained by the health care professional who will review it. Do not return this portion of the form to Clarkson University --------------------------------------------------------------------------------------------------------------------------------Part A. Section 1. The following information must be provided by every employee who has been selected to use any type of respirator (please print). Today's date: _________________________________ Your name: _________________________________________________________________ Your age (to nearest year): ____________ Sex (circle one): Male Your height: _____ ft. _____ in. Female Your weight: __________ lbs. Your job title: _______________________________________________________________ A phone number where you can be reached by the health care professional who reviews this questionnaire (include the Area Code): _(_____)_____________________ The best time to phone you at this number: _____________________________ This evaluation will only apply to the use of a half-face air purifying cartridge respirator. Have you ever worn a respirator before (circle one): Yes If "yes", what type (s)? No Part A. Section 2 Questions 1 through 9 below must be answered by every employee who has been selected to use any type of respirator (please circle "yes" or "no"). 1. Do you currently smoke tobacco, or have you smoked tobacco in the last month: 2. Have you ever had any of the following conditions? a. Seizures (fits): b. Diabetes (sugar disease): c. Allergic reaction that interfere with your breathing: d. Claustrophobia (fear of closed-in-places): e. Trouble smelling odors: Have you ever had any of the following pulmonary or lung problems? a. Asbestos: b. Asthma: Page 12 of 17 Yes Yes Yes Yes Yes Yes No No No No No Yes Yes No No No c. Chronic bronchitis d. Emphysema: e. Pneumonia: f. Tuberculosis: g. Silicosis: h. Pneumothorax: i. Lung cancer: j. Broken ribs: k. Any chest injuries or surgeries: l. Any other lung problem that you've been told about: 4. Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes No No No No No No No No No No Do you currently have any of the following symptoms of pulmonary or lung disease: a. Shortness of Breath: Yes b. Shortness of breath when walking fast on level ground or walking up a slight hill or incline: Yes c. Shortness of breath when walking with other people at an ordinary pace on level ground: Yes d. Have to stop for breath when walking at your own pace on level ground: Yes e. Shortness of breath when washing or dressing yourself: Yes f. Shortness of breath that interferes with your job: Yes g. Coughing that produces phlegm (thick sputum): Yes h. Coughing that wakes you early in the morning: Yes i. Coughing that occurs mostly when you are lying down: Yes j. Coughing up blood in the last month: Yes k. Wheezing: Yes l. Wheezing that interferes with your job: Yes m. Chest pain when you breathe deeply: Yes n. Any other symptoms that you think may be related to lung problems: Yes No No No No No No No No No No No No No No 5. Have you ever had any of the following cardiovascular or heart problems? a. b. c. d. e. f. g. h. Heart attack: Stroke: Angina: Heart failure: Swelling in your legs or feet (not caused by walking): Heart arrhythmia (heart beating irregularly): High blood pressure: Any other heart problem that you've been told about: Yes Yes Yes Yes Yes Yes Yes Yes No No No No No No No No Yes Yes Yes No No No Yes Yes No No Yes No 6. Have you ever had any of the following cardiovascular or heart symptoms? a. b. c. d. Frequent pain or tightness in your chest: Pain or tightness in your chest during physical activity: Pain or tightness in your chest that interferes with you job: In the past two years, have you noticed your heart skipping or missing a beat: e. Heartburn or indigestion that is not related to eating: f. Any other symptoms that you think may be related to heart or circulation problems: 7. Do you currently take medication for any of the following problems? Page 13 of 17 a. b. c. d. Breathing or lung problems: Heart trouble: Blood pressure: Seizures (fits): Yes Yes Yes Yes No No No No 8. If you've used a respirator, have you ever had any of the following problems: (If you've never used a respirator, check the following space and go to question 9:) a. b. c. d. e. Eye irritation: Skin allergies or rashes: Anxiety: General weakness or fatigue: Any other problem that interferes with your use of a respirator: Yes Yes Yes Yes Yes No No No No No 9. Would you like to talk to the health care professional who will review this questionnaire about your answers to this questionnaire: Yes No Page 14 of 17 Physician’s Evaluation For Work Related Respirator Use (To be Returned to Clarkson Univeristy Safety Office) ____________________________________________________________________ Employee/ Patient Name: ___________________________________________ I. No restrictions on respirator use II. Some specific use restrictions (see comments) III. No respirator use permitted Comments: _________________________________________ _______________________________________________________________ _______________________________________________________________ _______________________________________________________________ _______________________________________________________________ _______________________________________________________________ __________________________________ Physician Name (Please Type or Print) __________________________________ Date________________________ Physician’s Signature Page 15 of 17 Appendix C: Respirator Fit Test Form Employee:_________________________________________Date:___________ Employee #: ______________ Bureau/District:__________Expiration Date: ________ Manufacturer ____________ Model____________Size: Sm._ Med._ Lrg.___ Conditions Which Could Affect Respirator Fit: Clean Shaven 1-2 Day Beard Growth Over 2 Day Growth Mustache None Facial Scar Dentures Absent Glasses Other: ____________________ Comments:__________________________________________________________ ____________________________________________________________________ ________________________________________________________________________ _________________________________________________________ FIT CHECK (Quantitative): Negative Pressure .......... Positive Pressure ........... Pass Pass Fail Fail FIT TEST (Qualitative) - (Only One Test Is Required): Isoamyl Acetate Irritant Smoke Sweetener Pass Pass Pass Fail Fail Fail Comments: __________________________________________________________________ _____________________________________________________________ Test Conducted By: ________________________________Date: ___________ Employee Acknowledgment Of Test Results: Employee Signature: ______________________________ Date: ___________ Page 16 of 17 Appendix D: Respirator Maintenance Record Employee Name: __________________________________________ Date: ___________________________________________________ Respirator Type: __________________________________________ Defects Found A. B. C. D. E. F. G. H. I. J. K. L. Facepiece Inhalation Valve Exhalation Valve Assembly Headbands/Straps Filter Cartridge Cartridge/Canister Harness Assembly Hose Assembly Speaking Diaphragm Gaskets Connections Other Defects Page 17 of 17 Corrective Action

![_______________________________________________________________________ [employee name – printed]](http://s2.studylib.net/store/data/014960296_1-23d73d86035811d14b35a5fb01f5bbff-300x300.png)