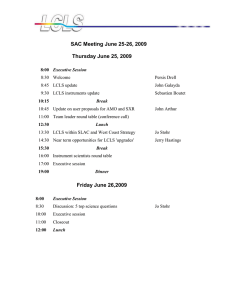

Electron Beam Systems ETC and Methodology Schedule Overview Start-Up Test Plan

advertisement

Electron Beam Systems ETC and Methodology David Schultz E-Beams Systems Manager Electron Beam Systems Definition of terms Schedule Overview Start-Up Test Plan E-Beams Costs Risk Analysis LCLS EIR, 10/9/07 D. Schultz 1 E-Beams Systems layout Sector 21 Sector 20 Laser lab BC1 L1 Injector LCLS EIR, 10/9/07 D. Schultz LX Injector Commissioning complete 2 Laser beam transport LCLS EIR, 10/9/07 D. Schultz The electron gun in the Injector Electron gun 3 E-Beams Systems layout 6 MeV Linac-1 L 9 m ...existing linac Linac-2 L 330 m 13.6 GeV Linac-3 L 550 m X BC2 L 22 m BC1 L 6 m Injector/BC1 L2/BC2/L3 SLAC linac tunnel LCLS EIR, 10/9/07 D. Schultz 4.30 GeV Linac-X L =0.6 m Linac-0 L =6 m rf gun 250 MeV 135 MeV 4 undulator L =130 m LTU L =275 m research yard E-Beams Systems layout Beam Transport Hall Transport the electron beam to the Undulator Undulator Hall Underground tunnel housing the undulator. Controls Beamline and diagnostics control for e-beams systems. SLAC Linac LCLS uses the last 1/3 of the existing Linac. Electron Beam Dump Underground facility for the beam dump. Near and Far Halls – Areas for xray experiments LCLS EIR, 10/9/07 D. Schultz 5 E-Beams Systems WBS structure Injector WBS 1.02, 2.02 Jose Chan, Control Account Manager Laser/Gun/L0/Spectrometer – Installed and commissioned Create electrons, accelerate, analyze beam quality Laser Heater Accelerator R&D activity LCLS EIR, 10/9/07 D. Schultz 6 E-Beams Systems WBS structure Linac WBS 1.03, 2.03 Jose Chan, CAM L1/Lx/BC1 – Installed and commissioned Accelerate the beam, initial beam bunch compression L2/BC2/L3 Full beam acceleration, second compression of bunch LTU Transport electron beam from Linac to Undulator Electron dump Safely dispose of the electron beam LCLS EIR, 10/9/07 D. Schultz 7 E-Beams Systems WBS structure Undulator WBS 1.04, 2.04 Generate x-rays as the high power electron beam passes through. Undulator Systems at ANL, Geoff Pile, CAM Fabricate components and supports for the Undulator system Undulator Integration at SLAC, Rodd Pope, CAM Tune, fiducialize, assemble, and install the Undulator system LCLS EIR, 10/9/07 D. Schultz 8 E-Beams Systems WBS structure Accelerator Controls WBS 1.02.02, 2.02.02, 1.03.02, 2.03.02, 1.04.02, 2.04.02 Hamid Shoaee, CAM Controlling hardware, cable plant and software for Injector, Linac and Undulator Systems Commissioning WBS 2.01.01, 2.02.17, 2.03.07, 2.04.06 David Schultz, CAM LOE manpower for LCLS personnel and maintenance groups during the electron beam commissioning process. LCLS EIR, 10/9/07 D. Schultz 9 System Design Management System engineering resource loaded schedule is controlled through P3. Design process: Interface Control Documents specify which group has responsibility for each system. Physics Requirements Documents are written by the LCLS Physics group specifying subsystem needs. Engineering group holds Design Reviews, and writes Engineering Specification Documents to detail how the PRD is to be satisfied. Physicists and Engineers sign-off on component assembly and testing prior to installation. LCLS EIR, 10/9/07 D. Schultz 10 E-Beams Systems Level 3 Milestones L3 milestones sufficient and properly distributed to monitor performance. LCLS EIR, 10/9/07 D. Schultz 11 E-Beams Systems Level 3 Milestones LCLS EIR, 10/9/07 D. Schultz 12 LCLS Installation and Commissioning Time-Line X-ray tunnel/FEH Install LTU/Und/Dump Install Flux milestone CF Early Occupancy FEH X-rays milestone CD-4 FEE/NEH Install (7/30/10) PPS PPS S OND J FMAM J J A S OND J FMAM J J A SOND J FMAM 2007 2008 2009 2010 Linac/BC2 Install LCLS EIR, 10/9/07 D. Schultz Linac/BC2 Commissioning LTU/Und Commissioning Tunnel/FEH Commissioning FEE/NEH Commissioning 13 Start Up Test Planning LCLS Safety Assessment Document is due 7/2008 LCLS Accelerator Readiness Review is needed 10/2008 Systems installed, checked out, signed off by responsible parties. Safety officers’ signoffs on approvals and installations. Safety specific systems (Personnel Protection) certified. Maintenance groups have procedures and training in place. Procedures in place for Operations, and Operators trained. Beam Authorization Sheet prepared. Detailed commissioning schedule and performance goals are produced by the LCLS Physics group. Approval to begin commissioning given by the Director’s office LCLS EIR, 10/9/07 D. Schultz 14 E-Beams Systems Cost Estimation As installation is approaching, systems are well defined. Installation costs Based on experience in 2006 Injector installation. Hardware install estimate done top-down and bottom-up. Based on experience on undulator prototype at ANL. Cable plant install estimated using R.S. Means. Fabrication/procurement Costs based on quotes and experience with prototypes at SLAC and ANL. Engineering and Commissioning Timetable for completion well understood. LCLS EIR, 10/9/07 D. Schultz 15 Risk Assessment Design maturity and cost/schedule exposure are used in the contingency analysis for all DCE activities. Major risks are identified as Risk Registry entries, and assessed and maintained by the System Manager. The Senior Management team reviews the Registry monthly. Summary of E-Beams Systems entries: Linac (2) Risk: Linac diagnostics may need to be enhanced to have sufficient sensitivity for FEL commissioning. Mitigation: The upcoming BC2 commissioning will determine if an upgrade is warranted. LCLS EIR, 10/9/07 D. Schultz 16 Risk registry Summary of entries (cont.): Undulator (3) The assembly of the Undulator Girders is a pacing item for Undulator commissioning. Several components from ANL are close to being the limiting factor Risk: Any rework or modification of parts at SLAC will delay girder assembly. Mitigation: We have multiple weekly video meetings with ANL and quarterly Undulator collaboration meetings to ensure coordination. Integration engineers at ANL and at SLAC have been established to coordinate the receipt and assembly. LCLS EIR, 10/9/07 D. Schultz 17 Summary Electron Beams Systems are approaching final installation. Systems are well defined, Based on Project documentation. Resource loaded schedule in P3. Costs have a solid basis. The start up test plan is based on the successful turn-on of the LCLS Injector. Identified risks are being controlled. LCLS EIR, 10/9/07 D. Schultz 18