Project Status Commissioning Preparation for First Experiments

advertisement

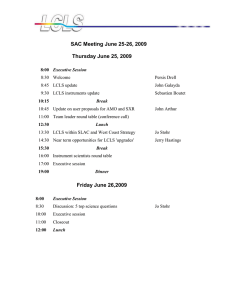

LCLS Project Overview and Assessment 16 June 2008 Project Status Commissioning Preparation for First Experiments Charge to FAC June 16, 2008 FAC Project Overview 1 John N. Galayda galayda@slac.stanford.edu 2005 Project Baseline Revised Baseline TEC $315M, TPC $379M CD-4 3/2009 Start of Operations TEC $352M, TPC $420M Early Finish 7/2009 Start Near Hall Ops Characterize x-ray flux @ 1.5 Angstroms, in front end enclosure (FEE) Detect X-rays in the Far Experimental Hall Characterize x-ray flux at 1.5 Angstroms, in front-end enclosure Detect X-rays in the Near Experimental Hall CD-4 7/2010 Project Complete Detect X-rays in the Far Experiment Hall June 16, 2008 FAC Project Overview 2 John N. Galayda galayda@slac.stanford.edu Construction >82% complete Table 2; Linac Coherent Light Source Re-Baselined Funding Profile ($M) FY02 FY03 FY04 FY051 FY06 FY072 FY08 FY09 0 5.93 7.46 49.67 84.69 101.16 51.35 36.50 TEC 0 2.00 4.00 3.50 13.00 15.50 17.00 OPC 1.50 TPC 1.50 5.93 9.46 53.67 88.19 114.16 66.85 53.50 1 2 June 16, 2008 FAC Project Overview FY10 Total 15.24 352.00 11.50 68.00 26.74 420.00 FY2005 TEC funding includes $29,760,000 for long lead procurements. FY07 TPC funding reflects the ~$8M reduction as a result of the FY2007 CR and directed change. 3 John N. Galayda galayda@slac.stanford.edu LCLS Cost/Schedule Status Report 30-Apr-08 Cumulative to Date ($K) WBS Budgeted Cost Work Scheduled Work Performed Actual Cost Work Performed Variance Schedule Budget At Complete ($K) Performance Indices Cost SPI CPI % Complete 1.1 Project Management 19,171 19,171 19,140 0 31 1.00 1.00 22,822 84% 1.2 Injector 20,239 20,239 20,237 0 2 1.00 1.00 20,239 100% 1.3 Linac 24,882 24,166 23,618 -717 548 0.97 1.02 28,257 86% 1.4 Undulator 41,140 40,455 41,429 -685 -974 0.98 0.98 45,355 89% 1.5 X-ray Transport 21,319 20,827 21,511 -491 -684 0.98 0.97 27,494 76% 2,785 2,734 2,793 -50 -58 0.98 0.98 9,115 30% 114,437 113,902 113,565 -535 337 1.00 1.00 136,040 84% 29,236 28,926 28,749 -310 177 0.99 1.01 41,369 70% 273,210 270,421 271,042 -2,788 -621 0.99 1.00 330,691 82% 1.6 X-ray Endstations 1.9 Conventional Facilities 1.X LCLS Controls 1 LCLS Total Base Cost LCLS Total Estimated Cost 2.1 LCLS Project Mgmt, Planning & Admn (OPC) 352,000 Contingency 21,309 % Contingency on ETC 35.4% 15,181 15,181 15,074 0 108 1.00 1.01 24,246 63% 2.2 Injector (OPC) 5,252 5,281 5,399 28 -118 1.01 0.98 5,789 91% 2.3 Linac (OPC) 1,226 1,226 1,189 0 37 1.00 1.03 2,027 60% 2.4 Undulator (OPC) 4,430 4,424 3,841 -7 582 1.00 1.15 9,772 45% 2.5 X-ray Transport (OPC) 2,098 2,064 1,874 -34 190 0.98 1.10 3,861 53% 2.6 X-ray Endstations (OPC) 1,798 1,798 1,852 0 -54 1.00 0.97 8,089 22% 2.9 Conventional Facilities (OPC) 411 388 319 -24 68 0.94 1.21 1,865 21% 2.X LCLS Controls (OPC) 940 898 769 -41 129 0.96 1.17 2,815 32% 31,337 31,260 30,317 -77 942 1.00 1.03 58,463 53% 2 LCLS Total Other Project Cost LCLS Other Project Cost 68,000 Management Reserve 9,537 % Management Reserve on ETC LCLS Total Project Cost June 16, 2008 FAC Project Overview 304,547 301,681 301,359 4 -2,866 321 0.99 35.1% 1.00 420,000 78% John N. Galayda galayda@slac.stanford.edu WBS 1.2 LCLS Injector 100% Complete WBS 1.3 LCLS Linac 86% Complete Commissioning Complete 3/2008 Commissioning Complete 9/2007 June 16, 2008 FAC Project Overview 5 John N. Galayda galayda@slac.stanford.edu LCLS UNDULATOR SYSTEM 5/33 rf Beam Position Monitors @ SLAC 8/33 Beam Finder Wires Wire Position Monitor RFI @ SLAC Hydrostatic level system RFI @ SLAC WBS 1.4 Undulator >89% complete ANL: 95% complete 33/33 Undulators +6 spares @ SLAC 33/33 Quadrupoles +4 @ SLAC 19 quad. vac. spools @ SLAC 10 RFBPMs @ SLAC 33/33 Supports with movers @ SLAC 15/33 Beam Finder Wires @ SLAC Aluminum extrusions all @ SLAC Components at varying stages of prep./readiness June 16, 2008 FAC Project Overview 6 John N. Galayda galayda@slac.stanford.edu Beam Finder Wire Quadrupole (RFBPM HIDDEN) Vacuum Chamber (aligned, under a protective cover Undulator Rollaway Rails Pedestal June 16, 2008 FAC Project Overview Cam Mover 7 Support John N. Galayda galayda@slac.stanford.edu Girder Successful chamber alignment & integration with undulator Shim interference with undulator motion- now resolved 8 Girders assembled, one fully aligned June 16, 2008 FAC Project Overview 8 John N. Galayda galayda@slac.stanford.edu Undulator Ctl/Diag racks awaiting shipment from ANL June 16, 2008 FAC Project Overview 9 John N. Galayda galayda@slac.stanford.edu X-Ray Transport/Optics/Diagnostics WBS 1.5 is >76% complete Front end X-ray optics being assembled All mirrors ordered; soft X-ray mirror figure meets spec Most diagnostics under assembly at LLNL Gas Detector Hard x-ray Monochromator (K Spectrometer) Solid Attenuator Slit Gas Attenuator e- Gas Detector FAC Project Overview Soft X-Ray Offset mirror system Direct Imager Pulse Energy Thermal Detector Muon Shield June 16, 2008 5 mm collimator Hard X-Ray Offset mirror system LLNL 10 Start of Experimental Hutches John N. Galayda galayda@slac.stanford.edu Integration and Testing at LLNL: Fixed Mask, Slit, Pump Cart, Control Racks Fixed Mask Slit Control Racks Beam Direction Pump Cart June 16, 2008 FAC Project Overview 11 John N. Galayda galayda@slac.stanford.edu WBS 1.6 XR End Stations >30% complete LCLS LUSI LUSI LUSI 1.5, 1.6 procurements delayed to start of FY2009 in response to FY2007 BA cut Prompt budget authorization for 1Q2009 requested to minimize schedule risk June 16, 2008 FAC Project Overview 12 John N. Galayda galayda@slac.stanford.edu 1.9 Conventional Facilities >84% complete Turner Construction Co. >89% complete Undulator Hall (175m) Linac-to-Undulator (227m) Beam Dump (40M) Front End (29m) Near Expt’l. Hall Far Expt’l. Hall X-ray Transport (200m) 14 m Near Experimental Hall June 16, 2008 FAC Project Overview 64.6 m 13 John N. Galayda galayda@slac.stanford.edu LUSI Status Instrument scientists on board Successful DOE Conceptual Design Review CD1 approved Continuing Resolution: FY2008 budget reduced from $10M to $6M 2009 budget requested $15M, will surely be delayed by CR Extraordinary situation with 2010 budget – restoration of $4M FY2008 cut in FY2011? Schedule impact being assessed LUSI CD2 review late 18 August 2008 – baseline for XPP, CXI, XCS LUSI-LCLS Interface Working Group recent business: Conventional facilities – hutch design Controls/Data acquisition – Details of data flow, storage, interface to detectors Precisely defining LUSI/LCLS interfaces June 16, 2008 FAC Project Overview 14 John N. Galayda galayda@slac.stanford.edu LTU system installation 6/10/08 June 16, 2008 FAC Project Overview 15 John N. Galayda galayda@slac.stanford.edu UNDULATOR HALL June 16, 2008 FAC Project Overview 16 John N. Galayda galayda@slac.stanford.edu Undulator stands installed Getting filled with sand June 16, 2008 FAC Project Overview 17 John N. Galayda galayda@slac.stanford.edu June 16, 2008 FAC Project Overview John N. Galayda NEAR EXPERIMENTAL HALL SUBBASEMENT 18 galayda@slac.stanford.edu Far Hall rebar lattice Tunnel construction complete 25 April 2008 June 16, 2008 FAC Project Overview 19 John N. Galayda galayda@slac.stanford.edu Oscillator Diode Pump Laser Laser Performance Reliability has been excellent >99% availability Hot spare pump laser in place for JEDI CW Pump for multi-pass amp. is planned June 16, 2008 FAC Project Overview 20 Cathode spot size control tFWHM John 6.5 ps N. Galayda galayda@slac.stanford.edu Gun probes upgrade completed 120 Hz capability June 16, 2008 FAC Project Overview 21 John N. Galayda galayda@slac.stanford.edu Projected Emittance in the Injector (0.25 nC) gex = 0.89 μm sx,y 60 mm OTR Screen at 135 MeV routine result gey = 0.92 μm June 16, 2008 FAC Project Overview 22 John N. Galayda galayda@slac.stanford.edu Coherent Effects in Optical Transition Radiation Diagnostic Total light energy disproportionate with chargeStill hampers use of OTR screens A. Fisher, J. Frisch looking at the properties of COTR Can be controlled with “laser heater”, due ~ 1/2009 June 16, 2008 FAC Project Overview 23 John N. Galayda galayda@slac.stanford.edu LCLS-Quality Beam Demonstrated Electron beam emittance measurements 9.2 GeV point in linac 0.25 nC, 75 fs 14 GeV e-beam can deliver ~1012 photons @ 8 keV June 16, 2008 FAC Project Overview 24 John N. Galayda galayda@slac.stanford.edu Commissioning Readiness Process LCLS, SSO planning readiness process through e-beam dump and x-ray front-end enclosure to support January 2009 start of ebeam/FEL commissioning Near Hall Hutch Readiness Review to support start of experiments in July 2009 June 16, 2008 FAC Project Overview 25 John N. Galayda galayda@slac.stanford.edu First Light in FEH CD-4 (7/31/2010) FEH Install First Light in FEE X-Rays in NEH FEH Hutch BO PPS Cert. LTU/Dump FEE/NEH Install LTU/Und/Dump Install now PEP-II run ends LCLS Installation and Commissioning Time-Line PPS J F M AM J J A S ON D J F MAM AM J J A S ON D J F M A M J J Down 2008 2009 2010 Linac/BC2 Commissioning Re-commission Inj/BC2 to SL2 June 16, 2008 FAC Project Overview LTU/Und Comm. FEE Comm. 26 AMO Experiment program begins XPP Experiment program begins April 18, 2008 John N. Galayda galayda@slac.stanford.edu Safety Good safety record for LCLS collaboration & contract work managed directly by LCLS LCLS has been pro-active in interfacing to SLAC safety management policy/procedures LCLS/SLAC set appropriate standards for civil construction Safety record for TCCo-managed construction has been poor LCLS/TCCo have struggled with this issue 4th PE, 2nd PM, 2nd Super, 3rd ESH Exerted major effort to communicate LCLS expectations to TCCo upper management Generally good response since 11/2007 TCCo engagement was encouraging Active involvement of TCCo VP in safety management TCCo response was encouraging BUT Two serious incidents (1/2008, 4/2008) Quality of Pre-task Planning by subcontractors – enforcement of LCLS standards was inadequate Enforce good pre-task planning Finish the job with NO ADDITIONAL INJURIES SSO has been a resource June 16, 2008 FAC Project Overview 27 John N. Galayda galayda@slac.stanford.edu PROJECT SAFETY EXPERIENCE Through May 2008 DART Rate 4 Total Project Hours 3.5 1.82 M Hours worked 3 SubContractors Construction Industry 3.7 LCLS Contractors 3.2 2.5 490 K Hours worked DART Rate 3.7 (9 Incidents) TRC Rate 4.5 (2 Incidents) LCLS Collaboration 2 Total Project 1.5 LCLS Collaboration 1 1,329 K Hours worked DART Rate 0.3 (2 Incidents) 1 0.5 0 0.3 . Injury rates based on 200 K hours (100 man years) of effort DOE/SC Goal is a Reportable Case (TRC) rate of < 0.25 and a Days Away, Restricted, or Transferred (DART) rate < 0.65 per 100 FTEs. June 16, 2008 FAC Project Overview 28 John N. Galayda galayda@slac.stanford.edu CONVENTIONAL FACILITIES SAFE WORK Project (Turner) Safety Performance History LCLS Prepares for Field Work to begin Safety Record as part of selection process Site Safety and Health Plan Driving home the message Result: Procedural Violations Actions Stand Down of Construction Activities Review of Approval Process for field work Review of Project safety statistics – Analyze Hazards / Define Controls inadequate Check/correction of existing documentation Turner Construction “in full swing” Data points indicate rising trends (near misses) Paperwork trivialized by CM/GC and trade contractors Result: Injury to Concrete Pump Operator Actions: Stand Down of Construction Activities CM/GC and trade Personnel changes / fines levied Letter to Turner Corporate Joint Safety Stewardship Committee established June 16, 2008 FAC Project Overview 29 John N. Galayda galayda@slac.stanford.edu CONVENTIONAL FACILITIES SAFE WORK Safety Performance (continued) Turner Construction “over the hump” Injury rate increases (DART rate above national average) Turner personnel and trade personnel changes / fines levied Tunnel contractor begins to de-mobilize Result: Serious injuries (shoulder and hand) Actions: Work Activity stopped. Trade personnel changes made Safety statistics reviewed – Perform the Work inadequate Letter to Turner Corporate Plan for joint observation and monitoring of the work planning and execution prepared. Review of JSA / Pre-task meeting notes Attendance at each Pre-task meeting (Turner augmented by CF UTRs) Monitoring Specific trade contractors or activities for safe work practices We own Safety. It is our obligation to complete the project injury free! June 16, 2008 FAC Project Overview 30 John N. Galayda galayda@slac.stanford.edu Key Issues Safety Extraordinary collaboration with TCCo for the next four months Early Science Installation activities preceding BO Assembly/alignment/installation of undulators Complete X-Ray Front End and AMO Instrument FY2009 CR – Early BA June 16, 2008 FAC Project Overview 31 John N. Galayda galayda@slac.stanford.edu Target Running Schedule – Operation Hours 2009: AMO, SXR 2010: AMO, SXR, XPP 2011: AMO, SXR, XPP, CXI 2012: AMO, SXR, XPP, CXI, XCS HED? June 16, 2008 FAC Project Overview 32 John N. Galayda galayda@slac.stanford.edu Guidance for First Round of Proposals Early ops Mature Electron energy 4.3 GeV 4.3 GeV Repetition rate 30 Hz 120 Hz Bunch length 200 fs FWHM 200 fs FWHM FEL peak power 500 MW 5 GW FEL bandwidth 0.25% 0.2% Energy per pulse 0.1 mJ 2 mJ Photons/0.1%BW 3 1011 1 1013 Peak brightness 3 1030 3 1031 Average brightness 2 1019 2 1021 June 16, 2008 FAC Project Overview 33 John N. Galayda galayda@slac.stanford.edu Access to LCLS Information LCLS Web Page http://lcls.slac.stanford.edu/ Proposal Submission Through LCLS web page Will go live at end of June 2008 AMO Workshop 2-3 June 2008 http://www-conf.slac.stanford.edu/amo/2008/ 60 registrants – very useful outcomes XPP Workshop 20-21 June 2008 http://www-conf.slac.stanford.edu/xpp June 16, 2008 FAC Project Overview 34 John N. Galayda galayda@slac.stanford.edu Operations Organization June 16, 2008 FAC Project Overview 35 John N. Galayda galayda@slac.stanford.edu Charge to FAC Committee Assess Installation Planning Identify technical risks remaining in Photon Beam Systems LUSI Assess Controls Applications Strategy Comments on risks Manpower, priorities Assess Commissioning Plans Advise on how best to integrate LUSI into FAC mission June 16, 2008 FAC Project Overview 36 John N. Galayda galayda@slac.stanford.edu End of Presentation June 16, 2008 FAC Project Overview 37 John N. Galayda galayda@slac.stanford.edu