Linac Coherent Light Source Status Overview John N. Galayda Director of LCLS Construction

Linac Coherent Light Source

Status Overview

John N. Galayda

Director of LCLS Construction

7 June 2006

LCLS Science Advisory Committee

1

John N. Galayda galayda@slac.stanford.edu

CD-3b Approved 28 March 2006

7 June 2006

LCLS Science Advisory Committee

2

John N. Galayda galayda@slac.stanford.edu

LCLS Cost/Schedule Status Report - Work Breakdown Structure

Cumulative to Date ($K)

1.1 Project Management

1.2 Injector

1.3 Linac

1.4 Undulator

1.5 X-ray Transport

1.6 X-ray Endstations

1.9 Conventional Facilities

1 LCLS Total Base Cost

WBS

Budgeted Cost

Work

Scheduled

14,521

15,331

8,094

15,706

8,063

1,321

17,247

80,284

Work

Performed

14,207

12,876

6,136

14,409

7,677

1,067

16,787

73,159

Actual Cost

Work

Performed

15,992

12,902

5,147

14,568

7,433

995

16,855

73,890

Variance

Schedule

Construction 26% complete

Contingency 29% of Estimate to Complete

-314

-2,455

-1,958

-1,298

-386

-254

-461

-7,125

Cost

-1,784

-26

989

-159

244

73

-68

-731

LCLS Total Estimated Cost

Avail. Contingency

Performance Indices

SPI

% Contingency / ETC

0.98

0.84

0.76

0.92

0.95

0.81

0.97

0.91

CPI

0.89

1.00

1.19

0.99

1.03

1.07

1.00

0.99

2.1 LCLS Project Mgmt, Planning & Admn (OPC)

2.2 Injector (OPC)

2.3 Linac (OPC)

2.4 Undulator (OPC)

2.5 X-ray Transport (OPC)

2.6 X-ray Endstations (OPC)

2.9 Conventional Facilities (OPC)

2 LCLS Total Other Project Cost

5,327

779

1

798

489

494

0

7,889

5,392

709

1

747

489

498

0

7,836

5,397

731

31

794

427

175

0

7,556

65

-70

0

-51

0

4

0

-53

% Complete LCLS Base Cost

-5

-22

-30

-47

62

322

0

280

1.01

0.99

1.01

0.91

1.00

0.94

1.00

1.00

0.97

0.04

0.94

1.14

2.84

1.04

LCLS Other Project Cost

LCLS Total Obligations = $97,316.4K

Avail. Management Reserve

% Management Reserve / ETC

LCLS Total Project Cost 88,173 80,995 81,446 -7,177

% Comp LCLS Other Project Cost

-451 0.92

% Complete LCLS TPC

*Management Estimate at Complete includes the Budget at Complete, a weighted CPI and SPI, proposed Baseline Change Requests and known risk contingencies.

0.99

7 June 2006

LCLS Science Advisory Committee

3

John N. Galayda galayda@slac.stanford.edu

30-Apr-06

Budgeted

At Completion ($K)

Management

Estimate at

Complete*

Variance

315,000

54,831

29.3%

28.1%

33,425

5,754

2,545

4,623

4,930

5,246

621

57,145

64,000

27,741

21,028

24,248

41,095

24,149

14,220

107,689

260,169

6,855

13.9%

13.7%

379,000

25.5%

315,000

34,417

16.6%

26.1%

33,540

5,807

2,575

1,672

4,878

4,932

621

54,026

64,000

32,189

22,156

23,517

42,516

26,960

16,021

117,224

280,583

9,974

21.6%

14.5%

379,000

24.2%

4,448

1,128

-731

1,421

2,811

1,801

9,535

20,414

-115

-52

-30

2,951

52

314

0

3,119

1%

0%

10%

Awarded Contracts

Total Estimated LCLS Contract Awards ~$175M (unesc)

• ~38% of LCLS contracts awarded.

9%

CF Subcontracts

37%

5%

PMCS, A/E, CM/GC,

S20/MMF, Undulator mat'ls & assembly, most of Injector/Linac

38%

Awards Under Contract

Conventional Facilities

Injector

Linac

Undulator

X-ray Transport

X-ray Endstations

• By end of FY06, 80% of contracts will be awarded.

•At that point, much more information & less risk

• Remaining contracts have some specialty components but most are commodities.

(vacuum, cabling, etc.)

• Cost Risks

•CF subcontracts

•Schedule performance

•System Integration

7 June 2006

LCLS Science Advisory Committee

4

John N. Galayda galayda@slac.stanford.edu

PROJECT INJURY EXPERIENCE TO DATE

SubContractors

29 K Hours worked

(03/31/2006)

Zero Injuries

2.5

Lost Time Injury Rate

2.1

2

Contractors

LCLS

Total Project

1.5

LCLS Collaboration

>460 K Hours worked

One shoulder strain

>250 Days Worked

Without Injuries

1

DOE

Construction

0.5

0.43 0.41

0

0

Project To Date

Note: Injury rates based on 200 K hours (100 manyears) of effort.

7 June 2006

LCLS Science Advisory Committee

5

John N. Galayda galayda@slac.stanford.edu

LCLS Project Organization (Mar06)

• Feb06 Lehman committee recommended strengthening

Project Office

•APD – Engr

•APD – Civil

•Procurement

• Continued strengthening of

Conv Facilities

• LCLS PMOG functioning

7 June 2006

LCLS Science Advisory Committee

6

John N. Galayda galayda@slac.stanford.edu

Injector and Linac

Injector 61% complete

Gun fabrication at SLAC- Hot test at ASTA August

Laser delivery in July 2006

Linac BC-1

Articulated vacuum chamber received installation in Fall shutdown

Injector installation schedule runs into 2006/2007 shutdown

Shutdown schedule – 21 August 2006 to 5 January 2007

In-tunnel work (BC-1) must have priority

Pursue all prudent means to speed schedule and preemptively mitigate schedule problems

Add design staff

Off-site fabrication, sources for rigging etc.

Commissioning start – January 2007

Commissioning applications software will be rudimentary at start

7 June 2006

LCLS Science Advisory Committee

7

John N. Galayda galayda@slac.stanford.edu

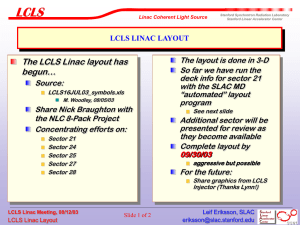

Installation Schedule

6 MeV 135 MeV 250 MeV 4.30 GeV 13.6 GeV

Linac-0

L =6 m

Linac-X

L =0.6 m rf gun

Linac-1

L 9 m

Linac-2

L 330 m

Linac-3

L 550 m

...existing

linac

21-1 b,c,d

X

‘Wall region’

Injector, 2006 down

BC1

L 6 m

21-3b

24-6d

25-1a

30-8c

BC2

L 22 m

Linac, 2007 down

SLAC linac tunnel undulator

L =130 m

DL2

L =275 m research yard

7 June 2006

LCLS Science Advisory Committee

8

John N. Galayda galayda@slac.stanford.edu

Status of Gun Fabrication and Testing

Gun machining and brazing in progress

Gun will be furnace baked after final tuning

Final braze of power splitter this week

Gun solenoid received, magnetic measurement plan completed

Test plan reviewed

Mechanical design of gun & solenoid supports approved

Gun Solenoids

7 June 2006

LCLS Science Advisory Committee

Dual Feed Full-Cell

9

John N. Galayda galayda@slac.stanford.edu

Gun Fabrication in Progress

Cathode Plate (rear)

Dual-Feed Waveguide

Dual-Feed Full Cell

7 June 2006

LCLS Science Advisory Committee

Cathode Cell

10

Cathode Cell

John N. Galayda galayda@slac.stanford.edu

Readying Components for 2006 Down

Gun Solenoid

Injector Quadrupoles

7 June 2006

LCLS Science Advisory Committee

Shortened

Accelerator

Sections

11

John N. Galayda galayda@slac.stanford.edu

Commissioning

Begins after all components have previously been installed, aligned, connected, and verified by installers

Commissioning :

Pre-Beam Checkout

Final component verification, made mostly in tunnel by system physicist ( e.g.

, polarities, motion-control, etc.)

Systems validation ( e.g.

, power supplies, software applications, etc.)

Beam Commissioning

Component and system verification/calibration with beam

(hardware and software; e.g.

, BPM tests)

Optimization of beam transport and tuning ( e.g.

, steering)

Characterization of beam quality ( e.g.

, emittance meas.)

7 June 2006

LCLS Science Advisory Committee

12

John N. Galayda galayda@slac.stanford.edu

Commissioning Plans - Preparation

Plan development assigned to each system team:

Drive Laser (White, Gilevich)

Gun & Injector (Dowell, Limborg, Schmerge)

Linac (Emma, Wu)

Undulator (Nuhn, Welch)

FEL (Welch, Nuhn)

XTOD/XES (Arthur, M öller, Stefan, Tompkins)

Each developed an MS-Project file detailing both schedule and strategy

Goal was to force early development of tuning strategy

(what to measure, what to tune, in what order – simulations encouraged now)

Files now merged into master file and time-frame locked to project schedule (thanks to Jim Welch)

7 June 2006

LCLS Science Advisory Committee

13

John N. Galayda galayda@slac.stanford.edu

Machine Commissioning Plans

Schedule developed in MS-Project

One file/manager per system

Link to milestones and events in Master file

V:\LCLS\Group\Commissioning\Commissioning Schedule\Commissioning_Master.mpp

install Injector-BC1

Dec.

‘05

Aug.

‘06

7 June 2006

LCLS Science Advisory Committee

Dec.

‘06

14 install BC2 LTU-und.

Aug.

‘07

Nov.

‘07

Mar.

‘08

John N. Galayda galayda@slac.stanford.edu

SLAC-Wide Effort on LCLS Safety Assessment

Document

7 June 2006

LCLS Science Advisory Committee

15

John N. Galayda galayda@slac.stanford.edu

Preparations for Accelerator Readiness Review

Integrated with design review process

Component and System PDRs and FDRs are being conducted following LCLS guidelines.

Safety aspects are a normal part of the technical requirements.

Working to report safety analyses in a uniform way to facilitate future assessments.

SLAC Citizen’s Committees participate in the review process, following normal SLAC practice.

Citizen’s Committees involvement specified through the SLAC

Safety Oversight Committee.

Need to ensure that all aspects of the project are reviewed, and that the completeness is presentable in a coherent way.

7 June 2006

LCLS Science Advisory Committee

16

John N. Galayda galayda@slac.stanford.edu

Accelerator Readiness Review

LCLS ARR for Injector Commissioning will take place Sept.- Nov. 2006, once Citizen Committees’ reviews are complete and the SOC is satisfied.

Working with the DOE SSO to ensure that the review process outlined here will be appropriate.

7 June 2006

LCLS Science Advisory Committee

17

John N. Galayda galayda@slac.stanford.edu

Undulator Systems

Undulator production underway

Prototype at SLAC for measurement

Chamber finish tests underway

Single Undulator Tests ongoing

RFBPM fabrication test encouraging

Undulator Measurements at SLAC

MMF startup in August

7 June 2006

LCLS Science Advisory Committee

18

John N. Galayda galayda@slac.stanford.edu

Photon Beam Systems

John Arthur is staffing up

Deputy – Hal Tompkins

X-ray Transport/Optics/Diagnostics

XTOD Liaison physicist- Peter Stefan

Prototype gas attenuator assembled, vac. tested

Design reviews for XRT vacuum, collimators

End Station Systems

Staffing up- Layout of experiments is settled down

AMO Liaison physicist – John Bozek

Detector Liaison physicist - Niels van Bakel

7 June 2006

LCLS Science Advisory Committee

19

John N. Galayda galayda@slac.stanford.edu

X-Ray Transport/Optics/Diagnostics

Prototype gas attenuator cell tested at LLNL

7 June 2006

LCLS Science Advisory Committee

20

John N. Galayda galayda@slac.stanford.edu

NEH

AMO SXR hard x-ray line

X-ray pumpprobe

Flipper Mirrors

7 June 2006

LCLS Science Advisory Committee

21

John N. Galayda galayda@slac.stanford.edu

FEH

XPCS

Coherent x-ray imaging

High energy density science

7 June 2006

LCLS Science Advisory Committee

22

John N. Galayda galayda@slac.stanford.edu

Sector 20

Beneficial Occupancy 21 April

Installation underway in vault tray supports floor

7 June 2006

LCLS Science Advisory Committee

23

John N. Galayda galayda@slac.stanford.edu

Magnet Measurement Facility Beneficial

Occupancy 14 April 2006

7 June 2006

LCLS Science Advisory Committee

24

John N. Galayda galayda@slac.stanford.edu

Final Focus Test Beam Cleanout

Phase 1 completed 28 April preservation of technical components

Phase 2 began 1 May completed 2 June removal of shielding blocks

Phase 3 started floor/soil excavation

7 June 2006

LCLS Science Advisory Committee

25

John N. Galayda galayda@slac.stanford.edu

Project Highlights and Key Considerations

Conventional Facilities

Architectural design @ 100%

Construction manager on board

Bids for first major packages in hand

Second group of bids due 14 June third group of bids (for CLOC) due in September

Beneficial occupancy of entire e-beam path and NEH by August 2007

7 June 2006

LCLS Science Advisory Committee

26

John N. Galayda galayda@slac.stanford.edu

First Bid Package – Entire Beam Path

Bids higher than estimates

Considerable draw on contingency required

Various alternatives under consideration

Changes to beam path, halls and FEL commissioning schedule are NOT under consideration

Economies required to deliver 2-floor CLOC

7 June 2006

LCLS Science Advisory Committee

27

John N. Galayda galayda@slac.stanford.edu

Summary

Injector and Bunch Compressor 1 will be ready for commissioning in January

Preparations for commissioning the injector

Address engineering, physics, operations, safety

Undulator Systems Coming Together

X-Ray Front End design maturing

End Station Systems layout maturing

Civil Construction organized, prepared to start

Civil Construction cost control an issue

LCLS is well on its way to groundbreaking science

7 June 2006

LCLS Science Advisory Committee

28

John N. Galayda galayda@slac.stanford.edu

End of Presentation

7 June 2006

LCLS Science Advisory Committee

29

John N. Galayda galayda@slac.stanford.edu