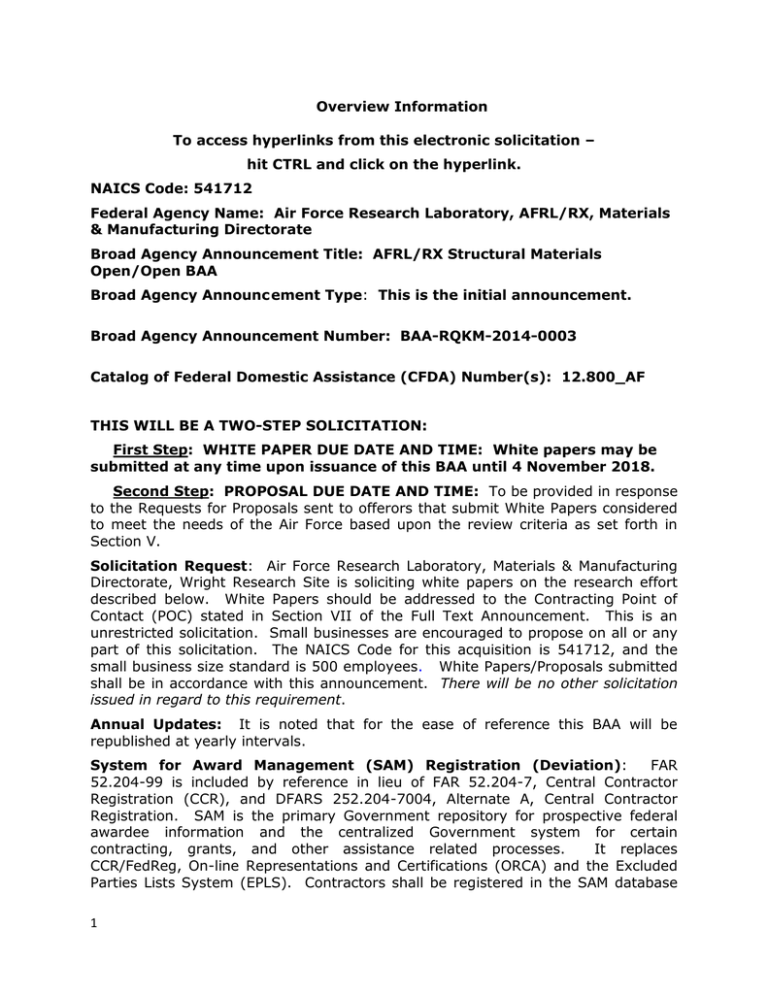

Overview Information To access hyperlinks from this electronic solicitation –

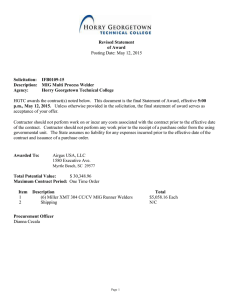

advertisement