LCLS Undulator System Update FAC Review April 16 & 17

advertisement

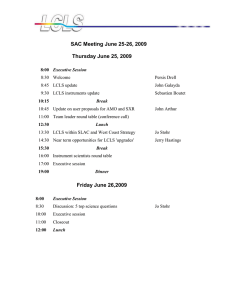

LCLS Undulator System Update FAC Review April 16th & 17th 2007 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov LCLS Management at ANL Change in ANL Project Director since last FAC Milton becomes director for Fermi project at Elettra Feb 1st 07 Pile takes over Jan 8th 07 ANL/LCLS project retains direct link in org chart to ANL ALD Efim Gluskin becomes ANL/LCLS Scientific Advisor ANL/LCLS gets more support from ASD and ESD 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov ANL Organization Chart 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Approximately 50 matrixed workers = ~ 20 FTEs 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov ANL LCLS Major Effort Issues 1.4.1 Management: Need to Hire Integration Engineer (replacement for Pile) Will need to replace QA Engineer ~June 07 Will need to replace Engineer for Progress, Task Coordination & Documentation ~June 07 Need secretarial assistance now 1.4.2 Controls: Needed to ramp up effort - CPI and SPI need improvement. Utilizing additional 2.5 Engineers + 1 technician from ESD 1.4.3 Undulator Magnet and Support: Need to replace Vendor manager/contract specialist (GL’s contract could not be renewed) Hired 66% of STA for checking drawings and SOWs. (Will use for Controls, Vac & Diag) Sufficient Effort from ME groups - continued support required 1.4.4 Undulator Vacuum System: Sufficient Effort from NE and ME groups - continued support required 1.4.5 Diagnostics: BPM - Hired additional 25% of NE mechanical engineer for BPM production BLM - Utilizing almost 1 combined extra FTE from Diagnostics group 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Effort required from ASD Diagnostics BERG, WILLIAM LILL, ROBERT M. YANG, BINGXIN ZABEL, RANDALL B. DOMBROWSKI, PATRICK ERWIN, LESTER L. ASD- Diag ASD- Diag ASD- Diag ASD- Diag ASD-Diag ASD-Diag Magnetic Devices DEJUS, ROGER J. JASKI, MARK KASA, MATTHEW MERRITT, MICHAEL MOOG, ELIZABETH SASAKI, SHIGEMI TERHAAR, JOHN VASSERMAN, ISAAC ASD-MD ASD-MD ASD-MD ASD-MD ASD-MD ASD-MD ASD-MD ASD-MD Operations PASKY, STAN ASD-Ops 588 0.5 Physics WHITE, MARION ASD-Phy 1092 0.93 RF Systems WALDSCHMIDT, GEOFF LANHAM, RENEE ASD-RF ASD-RF 1050 980 280 490 350 1176 3.68 385 280 280 70 280 280 1.34 40 0.03 LCLS STA LAWRENCE, GLEN 16th &17th April 2007 LCLS Und. System Update ASD-STA 1008 0.86 Geoff Pile pileg@aps.anl.gov Effort required from ESD 16th &17th April 2007 LCLS Und. System Update Controls STEIN, S. JOSHUA NORUM, WILLIAM ERIC SHOAF, STEVEN XU, JOSEPH Z. LAIRD,BOB BENES, SCOTT FARRELL, SHARON AES -Con AES -Con AES -Con AES -Con AES -Con AES -Con AES -Con 1092 1092 1176 280 480 720 588 4.62 Design Drafting BUFFINGTON, TOM GIVENS, MICHELLE KEITHLEY, ROBERT L. JR. CAPATINA, DANIELA AES-DD AES-DD AES-DD AES-DD 140 240 672 280 1.13 Mechanical Engineering & Design LEE, SOON HONG MORRISON, LEONARD COKELEY, LORETTA COLLINS, JEFFREY T. DIDENKO, ALEXANDER TRAKHTENBERG, EMIL AES-MED AES-MED AES-MED AES-MED AES-MED AES-MED 840 700 70 385 280 840 2.65 Survey and Alignment JANSMA, WILLIAM G. AES-SA 100 0.09 Geoff Pile pileg@aps.anl.gov Effort required from Others: Note 2 additional AES staff QA BARSZ, THOMAS AES-ADM 560 0.5 *Temps being replaced * LEWELLEN, JOHN W. * SCHNEIDER, JOHN F. * SKUBAL, LAURA R. AST-ONR AST-ONR AST-ONR 255 1176 1176 2.22 ECT VOOGD, RICH FMS-Electronics LCLS COOSE, FRANCES LCLS PILE, GEOFFERY WALTERS, DEAN LCLS-ADM LCLS-PM LCLS-PM 840 0.71 1176 1 1176 1176 2 Vacuum HARRIS, GUY AES-Vac 840 0.71 Nuclear Engineering CLARK, FRANCES NE 301 0.26 Nuclear Engineering Bailey, James MORGAN, JAMES NE- Me NE- Me 1176 875 1.74 Nuclear Engineering DORAN, DARRELL SCOTT GHILARDI, DONALD SALAZAR, ESIQUIO KMAK, RONALD T. NE-DD NE-DD NE-DD NE-DD 1176 210 140 700 1.89 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Effort Summary to ANL The LCLS Undulator System will require ~15 APS FTEs (+ 5 “others”) of effort to complete FY07 APS Group Leaders must own their Staff’s part of the schedule for the LCLS project Roughly 50 different people are named This is spread over 16 groups This is an estimate - we will still need to meet our commitment if our estimate isn’t perfect 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Major Deliverables 1.4.1 Management: Safety Quality Assurance Budget and Schedule Integration and Installation Admin. – Procurement, vendor management and documentation. 1.4.2 Controls: Cables (tunnel and inter-undulator): cable trays, and racks. Motion controls: sub micron leveling, control algorithms and software. Ancillaries: Thermal monitoring, undulator limit switches etc. Vacuum controls: Interface integration only – some limit protection. Diagnostic controls: Beam Finder Wire, Beam Position Monitor, Beam Loss monitor etc. Integration of Wire Position Monitor (SLAC component) Communications: Integrated Tunnel Electronics Rack with on board IOC etc. EPICs programming. 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Major Deliverables 1.4.3 Undulator Magnet and Support: Undulator Magnet Assemblies Quad magnets and translation stages Fixed Supports and Motion Systems 1.4.4 Undulator Vacuum System: Stainless steel Chambers+ Support and leveling System Pumping – acquisitions move to SLAC Bellows 1.4.5 Diagnostics: Beam Position Monitors Beam Loss Monitors Beam Finder Wire 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov CurrentCo-occupancy ANL delivery schedules Beneficial Occupancy Undulator Support Stands Cables/Cable Trays Support Mover System Girders, Control Electronics Systems 16th &17th April 2007 LCLS Und. System Update First Light: Geoff Pile18, 2008 July pileg@aps.anl.gov LCLS Installation and Commissioning Time-Line Drive-Laser Commissioning Drive-Laser Installed LTU/und. Install Controls Checkout LTU/und. hall “ready” First Spont. Light A SOND J FMAM J J A SOND J FMAM J J 2006 2007 2008 Gun/Inj./BC1 Install (8/21 – 2/20) 16th &17th April 2007 LCLS Und. System Update Gun/Inj./BC1 Commissioning Inj./Linac/BC2 Commissioning linac/BC2 Install LTU/und. Commissioning Geoff Pile pileg@aps.anl.gov Cost and Performance Report: 02-28-07 Rpt Period 02-28-2007 WBS Level 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 04 04 04 04 04 04 04 04 04 04 04 04 04 Description 3 4 5 6 01 02 03 04 05 06 01 02 03 04 05 06 UNDULATOR SYSTEM Undulator System Management & Integration Controls Undulator Magnet & Support Vacuum System Diagnostics Undulator System Installation and Alignment Undulator System Management & Integration Controls Undulator Magnet & Support Vacuum System Undulator System Diagnostics [OPC] Undulator System Commissioning 16th &17th April 2007 LCLS Und. System Update Cumulative to Date Budgeted Cost Variance Actual Cost Work Work Work Cost Scheduled Performed Performed Schedule 26,601,394 24,293,209 27,034,248 -2,308,185 -2,741,039 6,293,913 6,293,913 6,418,288 0 -124,375 1,779,283 581,698 387,213 -1,197,585 194,485 15,003,747 15,152,054 16,810,262 148,307 -1,658,208 1,103,937 775,479 1,357,650 -328,458 -582,171 2,399,599 1,467,505 2,031,856 -932,094 -564,351 20,916 22,561 28,979 1,645 -6,419 393,786 393,786 367,440 0 26,346 129,614 36,739 41,028 -92,875 -4,289 896,872 1,071,965 69,025 175,093 1,002,940 217,205 212,736 222,171 -4,469 -9,435 237,938 263,565 125,791 25,627 137,774 0 0 0 0 0 Geoff Pile pileg@aps.anl.gov Perf. Indices SPI 0.91 1.00 0.33 1.01 0.70 0.61 1.08 1.00 0.28 1.20 0.98 1.11 CPI 0.90 0.98 1.50 0.90 0.57 0.72 0.78 1.07 0.90 15.53 0.96 2.10 FY 07 Financial Situation and the effects of the Continuing Resolution The FY07 Technical Addendum to ANL MOU states that ANL will receive ~ $15M. Early September 06 - Advanced payment of $2M for FY07 undulator assemblies Oct 07 – ANL uses carry over funds -CR is an issue but Vacuum and Support Mover Systems could do with more R&D and Production Engineering Stainless Vs Aluminum Vac chamber effort created – (was good strategy to confirm processes before production) January 07 - CR Now becomes a major issue Mid-January Enough funding left for 6 weeks of effort only Put all procurements on hold Planned core team disaster scenario 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov FY07 and the CR Received additional $2M 2/6/07 February 07 prioritized procurements – zero funded >$50K procurements for vendor responses. planned to release only low value long lead items but had “commitments” issue Received additional $2M 3/16/07 March 07 released low value long lead items Received $6m end of March 07 April 07 – routing funded requisitions for re-approvals Remaining $3M will be required as soon as Support Mover contract and Vacuum requisitions have been placed. (SM vendor evaluations are in progress at ANL – Vac system component orders are being processed now) 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.1 Management Organization and Responsibilities ANL is now mainly in the procurement and delivery stages of the project Developed the ASK procurement and delivery system software and are currently loading information – will deploy May1st 07 SLAC also granted remote access to ANL ICMS document system Equipment has started to arrive at SLAC. Minor Integration and design issues are being seen in MMF and CMM during assembly We are working with SLAC to develop standard processes to handle changes. Early resolution of these issues now will avoid delays during the assembly bottleneck in FY08 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.1 Management ANL is committed to delivering a well documented, well engineered, high quality Undulator System We have improved & standardized our documentation We have increased the level of QA effort We have added an engineering design checker We have renegotiated appropriate level of effort to complete the project (from ANL divisions) 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.3 Magnets and Supports Undulator #33 was accepted on 15 February 2007. Thirty- five undulators are now complete Enough Undulators have been manufactured to complete the full installation in the LCLS tunnel - this is a milestone of sorts. 20 undulators at SLAC, 1 at ANL and fourteen ready to ship from vendors All forty undulator assemblies will be completed in June Final Design Pre-production support stands and a girder have been delivered to ANL The support installation and girder assembly process is a “work in progress” –see LTT slides 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.3 Magnets and Supports Support Mover System. Designs, drawings, documentation and Statement of Work completed. Zero funded req allowed for vendor bids - Currently evaluating responses, Funds are available & should place contract in next week or two. Schedule may be an issue with some potential vendors Quadrupoles Working with Everson -TESLA to advance the schedule of first articles. Details for the production units are being decided upon as and when we get info from the vendor- delivery schedule is very tight. No additional info on corrector effects – no power planned for correctors Quad production support/translation stage requisition processed in April 07delivery schedule looks promising 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Long Term Test The re-designed support mover stands and their mounts were tested in the Long Term Test area. The installation technique proved successful. The supports deflected less than 1.5 microns during an 80mm roll out of 1000lb weight (simulating the undulator). 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Long Term Test Quad centre is affected by undulator weight during roll out Keyence Testing of micron level movements to pedestal caused by 1000lbs of 80mm roll out Final design of support mounting improves stand deflection by at least three times 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Long Term Test 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.4 Vacuum System FY07 – Risk reduction required due to uncertainties in design, production and schedule of Stainless Chambers Started parallel effort and construction of Aluminum Vs Stainless prototype Chambers Progress review and decision tree applied to both systems in February – neither system mitigates all risks Reviewers choose Stainless Chamber and Aluminum effort is dropped 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.4 Vacuum System Two full sized prototypes have been built. All planned fabrication steps have been performed. Seam Welds were performed by Laser Welding. Even though leaks were found, they have been repaired. The vendor is organizing further work to address them. Construction of the 12 foot fixture and initial development of the AC Diode Sputtering process has lead to Aluminum coatings applied to both prototypes. The chambers have been baked and their measured outgassing rate is lower than the specification See string tests in Dean Walters Talk Many preparations for production are in-process or in place. 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.4 Vacuum System ANL will be the “General Contractor” for manufacture of the vacuum Chambers Materials acquisition (in House) Aluminum Coating (in House) QA and engineering oversight (in House) Machining (outside vendors) Laser Welding (outside vendor) 2-3 month (up front) Schedule slip caused by lack funds for long lead materials - CR has had it’s effects. 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Vacuum System Schedule 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.5 Diagnostics RF BPM Single RF BPM at brazing vendor Vendor problems during development of brazing fixtures – first brazed bpm delivery is delayed possibly another month Three bpms waiting for brazing immediately first bpm braze is perfected Production schedule for BPMs is of serious concern – Prototype brazing is taking much longer than planned Current production estimates push us out many months late – We know we have to do everything we can to pull dates back 3 BPM Test Modifications decided on Test with beam similar to LCLS injector beam See R. Lill’s talk for details 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Prototype BPMs for 3-BPM test 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov LEUTL 3 BPM Test Readiness Mid-May Testing Scheduled PC gun beam 325 MeV to dump 33 Hor. and 23 Vert. micron normalized emittance Compressed beam less than 1 ps 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.5 Diagnostics Beam Finder Wire Weldment, Machined Parts, Chamber, Catalog Items and all Hardware Design and Procurement Documents are complete and are in the procurement process Wire Card is currently under final design. Fixture designs are 90% complete. Alignment and Assembly Procedures are 50% complete Schedule for production looks tight and will require good vendor management to keep on target See Dean Walters talk for schedule 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov 1.4.5 Diagnostics BFW Assembly (Body Sectioned) Wire Card Down in Inactive Mode Electrical Connectors (Down Position) Potentiometer (Out Position) Internal Return Spring (Expanded Position) Internal Kinematic Stop Plates (Open Position) Bellows Seal (Compressed Position) BEAM From J. Bailey et al. 16th &17th April 2007 LCLS Und. System Update Pneumatic Solenoid Valve (Cylinder Vent Position) Lower Limit Switch (Actuated Position) Wire card (Down Position) Geoff Pile pileg@aps.anl.gov 1.4.5 Diagnostics Beam Loss Monitor Conceptual designs are in good shape Multi-tiered to cover a very large dynamic range Simulations In Process Determination of distribution and dose Engineering Begun but design is in flux PRD is not complete – is BLM a diagnostic or a binary MPS input? Cost is a major issue 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov Summary Good progress is being made in many areas Hot spots Vacuum Chamber Production quality, welding, coating and permeability require careful management/oversight Quadrupoles Schedule –close attention req. Hysteresis 16th &17th April 2007 LCLS Und. System Update Beam Loss Monitor Completion of design Final Large Procurements Support Mover Schedule concerns RF BPM Vacuum Chambers materials Beam Finder Wire Card Beam Loss Monitor Geoff Pile pileg@aps.anl.gov Re-cap: FY07 and the CR Effects October 06 thru early January 07 No new long lead production procurements started Vacuum chamber competition used to enhance production –delays large value procurements Support Motion drawings & documentation developed to more acceptable levels – SM system Statement Of Work allows for construction of complete system by General Contractor (s) Effort : planned worst case scenarios Mid January 07 thru March 07 Effort commitments from ANL: not easy to negotiate. Procurements put on hold - very difficult to plan Utilized every aspect of ANL’s procurement systems to generate approved zero funded reqs April 07 Funds available - routing funded requisitions for re-approvals Re-planning of Cost and Schedule +BCRs Effects: are schedule slips ~3 to 4 months – core team needs to be around until end of FY08 Costs: 1 month burn rate of ANL effort and service centers ~$600K x 4mnths = $2.4M Management effort needs to be increased and extended Controls effort needs to be increased and extended Vacuum system hardware costs increase LTT costs added Need: funds to cover CR schedule and cost effects – should be CR rebate not contingency 16th &17th April 2007 LCLS Und. System Update Geoff Pile pileg@aps.anl.gov