LCLS Installation & Planning – IMT Integration process 2007 Installation Planning

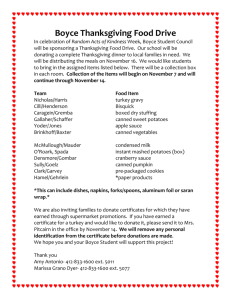

advertisement

LCLS Installation & Planning Integration process – IMT 2007 Installation Planning BTH -> NEH 2008 Installation Planning April 16, 2007 FAC Review 1 Richard M. Boyce boyce@slac.stanford.edu Integration Management Team Overview IMT Organization Integration Area managers are points of contact for changes and schedules Changes are documented in a Design Change Request (DCR) form Signatures from Integration Area Managers and System Managers assures acknowledgement and communication across systems Project Office final approval – assures funding path is known and approved DCR to CF provides clear direction that action on change is approved and can begin CCB to be submitted by group performing work April 16, 2007 FAC Review APD Conventional Facilities (Jess Albino) APD Engineering (Tom Fornek) 2 Richard M. Boyce boyce@slac.stanford.edu System Design/Construction Integration Integration Management process Integration Management Team Established core team to ensure systems wide communication Review and approve change requests to CF from technical groups Review IFC drawings for technical requirements and compatibility Review installation plans and provide input on integration activities Document change requests that are cross divisional (affecting more than one system) Processes A Design Change Request, once approved, gets turned into a BCR by group doing work Technical requirement documents (ESD, PRD, RDS, ICD) are tracked by the QA Manager April 16, 2007 FAC Review 3 Richard M. Boyce boyce@slac.stanford.edu Integration Management Team IMT Design Topics and Issues DCRs complete Service Building Power: IMT-DCR-1006-01 (Controls-CF) Offset Mirror support pad relocation: IMT-DCR-1006-02 (XTOD/XES-CF) Electron Beam dump: IMT-DCR-1106-01 (Linac-CF) NEH Concrete Wall Penetrations: IMT-DCR-0207-01 (XTOD/XES-CF) BTH West Room Data Sheets (RDS) (CF-all) DCRs in process FEE Electrical Alcove: IMT-DCR-0307-01 (XTOD/XES-CF) NEH Floor Plan Re-design (XTOD/XES-CF) LCW for LTU (PM/Linac-CF) Issues being worked PPS requirements for CF (lighting controls, AC power, HVAC/ventilation controls, etc) Concrete floor stability wrt support structure anchor installations April 16, 2007 FAC Review 4 Richard M. Boyce boyce@slac.stanford.edu Integration Management Team Systems Integration IMT will assist in overall integration of activities Involved in installation scheduling Knowledgeable of CF schedule and Technical components Important to understand relationships between systems to avoid “items” falling through the cracks Important to have communication between systems to ensure “items” have responsible owners and get scheduled Key individuals as points of contact; heavily involved in their areas of responsibility April 16, 2007 FAC Review 5 Richard M. Boyce boyce@slac.stanford.edu Installation Planning 2006 Installation is complete, last meeting held on 4/3/07 ~550 line schedule covering all activities 2007 SLAC Shutdown SLAC downtime – September, October, November 2007 Assuming 2 weeks for PPS in Nov 2007 Installation Planning Installation through BC2 & all cable plant; including cables through the BSY into the BTH West Will develop Integrated schedule using P3 Will use SLAC Schedule process for resource loading Installation risk is tracked in Risk Registry; handling plan being worked 2008 Installation Planning LCLS installations begin at Early Occupancy dates defined by TCCo Draft 2008 Installation schedule used to begin detailed planning & integration process Staggered Early Occupancy dates Will use P3 for detailed install schedule Installation Organization Chart in development Key individuals being identified Meetings to be held weekly April 16, 2007 FAC Review 6 Richard M. Boyce boyce@slac.stanford.edu April 16, 2007 FAC Review 7 Richard M. Boyce boyce@slac.stanford.edu SLAC/LCLS 2007 Downtime Schedule – sample SLAC Downtime Schedule Controlled by Area Managers Tasks show SLAC resources LCLS is one part of the downtime schedule Weekly meetings to review schedule and site outages LCLS Downtime meetings Weekly meetings held by various groups plus weekly integration meeting Interfacing with SLAC groups on a routine basis SLAC Downtime Schedule format will be used for LCLS 2007 Linac area Installations Needed to coordinate resources and accelerator turn on dates April 16, 2007 FAC Review 8 Richard M. Boyce boyce@slac.stanford.edu 2007 Installation Planning 2007 Installation Planning A 2007 Installation Schedule Readiness Review was held on March 16 - report determined that: Integrated schedule is needed; amount of work shown by independent schedules does not match downtime duration and conflict with each other Controls schedule does not match component installation schedule Detailed plans are needed to track component fabrication and processing to ensure RFI dates are held Clear scope definition needed for downtime work to avoid unplanned activities being added late in the down Majority of system will be ready for the down; just need to fit into the timeline Consideration is being given to defining early March 2008 as the start of BC2 commissioning Allows time for Controls integration and testing over a longer duration, but will require ROD periods which are an impact on PEPII Allows 6 months BC2 commissioning time Detailed schedule being developed in P3 Integration of individual system schedules April 16, 2007 FAC Review 9 Richard M. Boyce boyce@slac.stanford.edu 2008 Installation Planning 2008 Installation Planning LCLS installations begin at Early Occupancy dates defined by TCCo Draft RMB 2008 Installation schedule used to begin detailed planning & integration process Staggered Early Occupancy dates Planned sequence of work Metrology Core drilling Stand installation Cable installation Component installation Cable termination Testing & Checkouts Will use P3 for detailed install schedule 2008 Installation Schedule Readiness Review in early May April 16, 2007 FAC Review 10 Richard M. Boyce boyce@slac.stanford.edu 2008 LCLS Installation Schedule 1 - DRAFT 2008 High Level Planning Schedule Staggered Early Occupancy dates BTH West through Far Hall areas Major subcontracts used for installations Supports Electrical Concrete drilling Etc April 16, 2007 FAC Review 11 Richard M. Boyce boyce@slac.stanford.edu 2008 LCLS Installation Schedule 2 - DRAFT 2008 High Level Planning Schedule Detailed integrated schedule required below each major heading Planning will be done to pull in schedule 10 hr days double shifts Etc April 16, 2007 FAC Review 12 Richard M. Boyce boyce@slac.stanford.edu 2008 LCLS Installation Schedule 3 - DRAFT 2008 High Level Planning Schedule No delays in Early Occupancy dates yield a ready to commission into NEH by early October 2008 Note: X-ray & FEH dates do not yet reflect CR impact and will slide accordingly April 16, 2007 FAC Review 13 Richard M. Boyce boyce@slac.stanford.edu Summary 2007 Installation Planning 2007 SLAC downtime to install Linac hardware Use P3 integrated schedule to cover all activities Need to continue to use SLAC format for resources 2008 Installation Planning Installation schedule will use detailed P3 schedule with hourly task durations Early occupancy of Conventional Facilities will begin installation process for technical systems Does not require Linac/PEPII down for LCLS installations Need to coordinate several subcontracts (~6-10?) to install mechanical systems and cable plant simultaneously Starting process now – Integration of overall plan is a must to be successful and meet schedule 2008 Install Schedule Readiness Review to be held in early May Installation/Commissioning Timeline to CD-4a - DRAFT Draft version based on RMB 2008 install schedule Still needs to be reviewed and approved by management Will be scrubbed after 2008 IRR April 16, 2007 FAC Review 14 Richard M. Boyce boyce@slac.stanford.edu LCLS Installation Time-Line April 11, 2007 rmb DRAFT BTH/LTU Install CF Early Occupancy Und/Dump Install First Spont. Light Linac PPS re-certification & Linac/LCLS/NEH global certification Facility work requiring downtime??? CD-4a PPS A S O N D J F M AM J J A S O N D J F M AM J J A S O N D J F M 2006 2007 2008 2009 BTH-NEH B.O. linac/BC2 Install X-Ray/FEH B.O. LCLS PPS Certification FEE/NEH Install Electrons through Undulator April 16, 2007 FAC Review 15 Richard M. Boyce boyce@slac.stanford.edu LCLS Installation and Commissioning Time-Line Drive-Laser Commissioning DriveControls Laser Checkout Installed April 11, 2007 rmb DRAFT LTU/Und/Dump FEE/NEH Install First Spont. Light LTU/und. hall “ready” CD-4a PPS A S O N D J F M AM J J A S O N D J F M AM J J A S O N D J F M 2006 2007 2008 2009 Gun/Inj./BC1 Gun/Inj/BC1 Install Commissioning Controls checkout linac/BC2 Install April 16, 2007 FAC Review 16 Checkouts LTU/und. Linac/BC2 Commissioning Commissioning Richard M. Boyce boyce@slac.stanford.edu End of Presentation April 16, 2007 FAC Review 17 Richard M. Boyce boyce@slac.stanford.edu