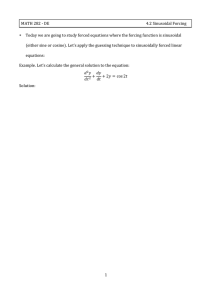

Mid-Term Review

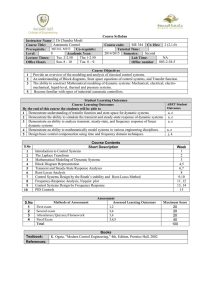

advertisement

Mid-Term Review Classical Thermodynamics The science of the conversion of energy from one form to another. The science of energy and entropy. Topics of Study • • • • • • • • Control volumes Properties of pure substances Work and heat 1st Law 2nd Law Entropy Power and refrigeration cycles Thermodynamic relations Experimental observations have evolved into a set of laws that form the basis of the science of Thermodynamics: • • • • 0th law (temperature) 1st law (energy) 2nd law (entropy) 3rd law (absolute entropy) Applications of these laws requires the use of mathematical models which, in turn, contain variables that describe the “state” of the system. We call these “state variables” the properties of the thermodynamic system: • • • • • temperature pressure mass density, or specific volume enthalpy entropy Temperature • A sense of hotness or coldness at the touch. • Not very satisfying! • Equality of temperature. • Zeroth law of thermodynamics Temperature Scales • Celcius • triple point of water • steam point • Kelvin (absolute scale) • Fahrenheit • Rankine Chapter 3 PROPERTIES OF A PURE SUBSTANCE Independent Properties of Pure Substances • The state of a simple, compressible pure substance can be defined by two independent properties • Not any two properties; e.g., pressure and temperature are not always independent Low and Moderate Density Gases (high specific volume) • Implies very low intermolecular potential energy; i.e., ideal gas behavior • PV = nR*T , PV = (m/M)R*T , PV = mRT , Pv = RT • Where is P α 1/v on the P-v-T surface? Chapter 4 WORK AND HEAT 04-05 Polytropic Processes n PV = constant Modes of Heat Transfer • Conduction • Convection • Radiation dT Q kA dx Q AhT Q ATS4 Heat and Work Comparisons • Both are transient; systems possess neither; both can cross system boundary when the system undergoes a change of state • Both are boundary phenomena representing energy crossing a boundary • Both are path functions; inexact differentials Chapter 5 THE FIRST LAW OF THERMODYNAMICS E = U + KE + PE dE = dU + d(KE) + d(PE) = δQ – δW and integrating between states 1 and 2, U2 – U1 + ½m(V22 – V21 ) + mg(Z2 – Z1 ) = Q1-2 – W1-2 Internal Energy as a Thermodynamic Property U = Uliq + Uvap mu = mliq uf + mvap ug u = (1-x)uf + xug u = uf + xufg Specific Heats δQ = dU + δW = dU + PdV 1 Q 1 U u Cv m T v m T v T v 1 Q 1 H h Cp m T p m T p T p Internal Energy, Enthalpy, and Specific Heat of Ideal Gases Internal Energy for Superheated Steam P , kPa T, °C 10 100 500 1000 200 2661.3 2658.1 2642.9 2621.9 700 3479.6 3479.2 3477.5 3475.4 1200 4467.9 4467.7 4466.8 4465.6 The First Law as a Rate Equation • We’ve already seen the first law in differential form in equation 5.7: dE = dU +d(KE) + d(PE) = δQ – δW • Dividing by δt and taking the limit, we can also write the first law as a rate equation: U KE PE Q W 05-13 Chapter 6 FIRST-LAW ANALYSIS FOR A CONTROL VOLUME 06-01 06-02 06-03 06-04 The Steady-State Process • The control volume is stationary • The state of the mass at each point in the control volume does not vary with time • For mass flowing across the boundary, the mass flux and the state of mass at each area of flow on the control surface do not vary with time. • The rates at which heat and work cross the control surface are constant. Steady-State Devices: Heat Exchangers • Heat transferred to/from fluids flowing through pipes • Usually constant pressure • No work gets done • ΔKE and ΔPE usually small • Little heat transfer with surroundings if C.V. includes both fluids Steady-State Device: A Heat Exchanger 06-06 Steady-State Devices: Nozzles • A device for creating high-velocity fluid streams • Smooth transition to higher velocity produces lower pressures (Bernoulli’s equation, which is just another statement of the 1st Law) • No work done • Little or no change in potential energy • Little or no heat transfer • Inlet KE usually negligible Steady-State Device: A Nozzle 06-07 Steady-State Devices: Diffusers • Anti-nozzle: A device for decelerating fluid flow to produce an increase in pressure • As with nozzles, only inlet and exit enthalpies and inlet KE contribute to the 1st Law 06-16 Steady-State Devices: Throttles • Sudden restrictions in flow passage that produces a drop in pressure • Not smooth like a nozzle; not much change in KE • No change in PE • No work done • No heat transfer • Net result: pressure drop at constant enthalpy • Can involve a change in phase; e.g., an expansion valve in a refrigerator Steady-State Device: A Throttle 06-08 Steady-State Devices: Turbines • Rotary machines that produce shaft work at the expense of working fluid pressure • Steam or gas • Inlet pressure controlled by previous pumping or compression process • Exit pressure determined by environment • Two internal processes: – Nozzles to increase velocity and reduce pressure – High velocity fluid directed at rotating blades that turn the shaft and generate work; low-pressure, low-velocity fluid exits the turbine • • • • Negligible change in PE Negligible inlet KE Normally taken to be an adiabatic process Normally, work output is change in enthalpy from inlet to outlet Steady-State Device: A Turbine 06-09 Steady-State Devices: Compressors and Pumps • Devices that use shaft work to increase pressure in the working fluid • Two types: – Rotary; an anti-turbine – Piston/cylinder • • • • Usually taken to be adiabatic Negligible change in PE Negligible inlet KE Heat transfer negligible for rotary compressors; can be significant for piston/cylinder type Steady-State Device: A Pump 06-11 Steady-State System: A Power Plant 06-12 Steady-State System: A Refrigerator 06-13