Food Safety in South Carolina Schools 1 Prepared:

Food Safety

in South Carolina Schools

Prepared: May 21, 2012

Modified: August 15, 2014

1

Prepared by:

Angela Fraser, Ph.D., Food Safety Specialist

Amanda Henderson, Nutrition and Dietetics Student

Clemson University, SC

Gregg Ferguson, MBA, Education Associate

SC Department of Education

Pam Vaughan, Child Nutrition Director

Darlington County Schools, SC

© 2010 Clemson University. These materials are protected by United States copyright law and may not be reproduced, distributed, transmitted, displayed or published without the express prior written permission of Clemson University.

The Clemson University Cooperative Extension Service offers its programs to people of all ages, regardless of race, color, sex, religion, national origin, disability, political beliefs, sexual orientation, marital or family status and is an equal opportunity employer.

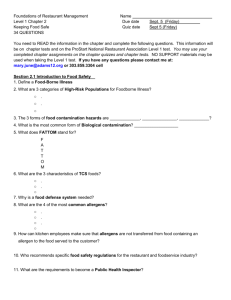

Introduction 2

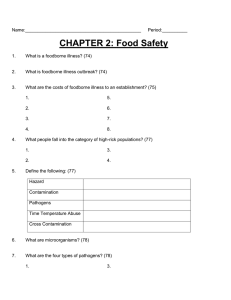

Foodborne illness

Foodborne illness

– Defined as diseases caused by agents that enter the body through eating contaminated food or drink.

Foodborne Outbreak

Two or more unrelated persons with onset of similar symptoms after eating a common food/drink or after eating at a common source, such as a foodservice operation.

Each year there are:

– 48 million Americans (1 in 6) who get sick,

– 128,000 who are hospitalized, and

– 3,000 who die from foodborne illness.

Introduction 3

Who is at Risk?

• Infants

• Toddlers

• Pregnant women

• Elderly – 65 years and older

• Immunocompromised

• Individuals who take specific medications

Introduction 4

What foods cause foodborne illness?

• Any food that is prepared and served in schools can cause foodborne illness if not handled safely.

• Safely handle food from the time it is received until the time it is served.

Introduction 5

Unsafe Food Handling Practices

• Using food from unsafe

(unapproved) sources.

• Not cooking foods to temperatures noted on the standardized recipes.

• Holding foods at unsafe temperatures for more than four hours.

• Improperly cleaning and sanitizing equipment after it has become contaminated.

• Not properly washing hands when handling food.

• Handling food while sick.

Introduction 6

Contaminated Food

• Contaminated food can cause foodborne illness. Any food can become contaminated.

• Some foods support the growth of bacteria. These are called potentially hazardous foods (PHF) or timetemperature control for safety (TCS) foods.

• A PHF/TCS food:

– is typically low acid, moist, and contains protein.

– requires temperature control to prevent the growth of bacteria.

Introduction 7

Who’s Responsible for Food Safety?

• The foodservice manager is responsible.

• The manager must:

– keep food safe and wholesome throughout the establishment at all times.

– demonstrate his/her knowledge by:

• complying with the U.S.

Food Code,

• becoming a certified food protection manager, or

• correctly answering an inspector's questions.

– monitor the food handling practices in the operation.

Introduction 8

Food Safety in South

Carolina

Food Safety in SC Schools 9

School HACCP

• All schools must have in place an effective food safety plan based on process HACCP principles.

• In SC you have two binders:

– Binder 1 -- Menu and Recipe Summary

– Binder 2 -- HACCP Plan.

• Each site manager responsible for making sure

HACCP Plan is properly implemented.

• Materials posted at:

– www.foodsafetysite.com/foodservice/conducting/SCSchools/SCSchoolsHome

Food Safety in SC Schools 10

BINDER 1: Menu and Recipe Summary

• Components of a HACCP Plan

• 1-1: Menu and Recipe Summary

• 1-2: No Cook Recipes

• 1-3: Same Day Recipes

• 1-4: Complex Cooking Recipes

• 1-5: Non-potentially hazardous Recipes

• Standardized Recipe Template

• Standardized Procedures

Food Safety in SC Schools 11

BINDER 2: HACCP Plan

• 2-1: Food Safety Team

• 2-2: School Description

• 2-3: Operation Assessment

• 2-4: Prerequisite Programs

• 2-4: New Workers Training Form

• 2-5: Safe Food Handling

• 2-6: Monitoring Summary

• 2-6: Monitoring -- Production Plan

• 2-7: Corrective Actions

• 2-8: Verification

• 2-9: Employee Training

Food Safety in SC Schools 12

Microbial Hazards

Microbial Hazards 13

Microbial Hazards

Microorganisms are everywhere -- they can be:

– Pathogens – cause disease

–

Spoilers

– make food go bad

– Beneficial –used for food production and present in and on the body

Microbial Hazards 14

Three Microbial Hazards

Three types of microorganisms cause foodborne illness:

– bacteria

– viruses

– parasites

Microorganisms are:

– naturally present or

– get into food through poor food handling practices, dirty water, or contaminated surfaces.

Microbial Hazards 15

Common Symptoms of Foodborne Illness

• Diarrhea

• Vomiting

• Fever

• Sore throat with fever

• Jaundice

Microbial Hazards 16

Bacteria Basics

• Pathogenic bacteria only grow in potentially hazardous food.

• Some produce spores.

• Some produce toxins.

• Not necessarily destroyed by freezing or cooking.

• Can cause infection, intoxication, or toxinmediated infection.

Microbial Hazards 17

Vegetative Cells vs. Spores

• Only vegetative cells grow in food.

• Spores cannot grow in food.

• Spores in cooked food that is temperature-abused can become vegetative cells.

• The vegetative cells can grow and cause foodborne illness.

• Keep hot foods hot and cold foods cold.

Microbial Hazards 18

Bacterial Growth

Growth in Temperature-Abused Foods

Minutes

0

• Bacteria increase in numbers not size.

• Bacteria can double every 30 minutes under ideal conditions.

30

60

90

120

150

180

210

240

270

300

Number of Bacteria

10

20

40

80

160

320

640

1,280

2,560

5,120

10,240

Microbial Hazards 19

Controlling Bacteria

Good personal hygiene

– Only allow healthy workers to handle food.

– Have all workers wash their hands properly and frequently.

Prevent cross-contamination

– Store foods properly.

– Only use cleaned and sanitized utensils and surfaces for food preparation.

Time-temperature control

– Cook potentially hazardous foods to proper temperatures.

– Hold potentially hazardous foods at proper temperatures.

Microbial Hazards 20

Common Foodborne Bacteria

• Bacillus cereus

•

Campylobacter

• Clostridium botulinum

•

Clostridium perfringens

• E. coli

•

Listeria monocytogenes

• Salmonella

•

Shigella

• Staphylococcus aureus

•

Vibrio

•

Yersinia

Microbial Hazards 21

Virus Basics

• Do not grow in food.

• Use food as a vehicle to get from one person to another.

• Can contaminate any food.

• Cause most foodborne illnesses in the U.S.

• Cause foodborne infection not foodborne intoxication.

Microbial Hazards 22

Controlling Viruses

• Prevent getting viruses into food because they might not be destroyed by cooking.

• Prevent introduction by:

–

Promoting good personal hygiene . Only workers who are not sick can handle food. Workers must frequently and properly wash their hands.

–

Buying all food from an approved and safe source .

Food sources regulated by the government are safe.

–

Using safe water for food preparation and cleaning.

Safe water is drinking quality.

Microbial Hazards 23

Common Foodborne Viruses

Norovirus

Hepatitis A

Rotavirus

Microbial Hazards 24

Parasite Basics

• Do not grow in food.

• Sources of parasites:

– improperly treated water;

– foods handled by infected person; or

– vegetables and fruits grown in soils fertilized with feces

• Found naturally in many animals, such as:

– pigs,

– cats,

– rodents, and

– fish.

• Cause foodborne infection and not foodborne intoxication.

Microbial Hazards 25

Controlling Parasites in Food

• Get food from an approved and safe source.

• Cook foods to proper temperatures.

• Wash hands frequently and properly.

• Use safe water sources for food preparation and cleaning.

Microbial Hazards 26

Common Foodborne Parasites

• Anisakis simplex

•

Cryptosporidium parvum

•

Cyclospora cayetanensis

•

Giardia duodenalis

•

Toxoplasma gondii

•

Trichinella spiralis

Microbial Hazards 27

Mold Basics

• Common cause of food spoilage.

• Some form toxins that can cause illness.

• Grow in a wide range of foods – high acid, low moisture.

• Freezing does not destroy.

• Requires air to grow.

Microbial Hazards 28

Other Hazards

Other Hazards 29

Chemical Hazards

• Toxic Metals -Lead, copper, brass, zinc, pewter

•

Cleaning and Sanitizing Chemicals --

Detergents, sanitizers, polishers, abrasive cleaners, lubricants

•

Pesticides and insecticides

Other Hazards 30

Physical Hazards

• Stones and metal fragments

• Insulation

• Bone

• Plastic

• Personal effects

Other Hazards 31

Allergens

• 6-7 million Americans have food allergies.

• Most common food allergens:

– Milk

– Eggs

– Fish

– Shellfish

– Wheat

– Soy

– Peanuts and tree nuts

Other Hazards 32

The Safe Operator

The Safe Operator 33

Workers and Contamination

• Workers can contaminate food by:

– working while sick.

– touching pimples or sores.

– touching hair.

– not wearing a band-aid and single-use gloves over sores and wounds.

– not washing hands properly.

The Safe Operator 34

Proper Handwashing

1. Wet your hands with warm water.

2. Put enough liquid, powder, or bar soap on your hands to create a lather; it does not have to be antibacterial.

3. Scrub for 10-15 seconds—rub palms, between fingers, and around nails.

4. Rinse thoroughly under warm water.

5. Dry your hands with disposable towels (preferred) or a hand dryer.

6. Instant hand antiseptic is not required

The Safe Operator 35

Demonstration

Glo-Germ

The Safe Operator 36

Always wash your hands:

• When switching from raw to ready-to-eat food.

• After handling garbage.

• After touching your cell

• After using the bathroom.

• After coughing, sneezing, smoking, eating, or drinking.

• After touching face or hair.

phone or handling other personal belongings.

• After handling dirty equipment or utensils.

When else should you wash your hands?

The Safe Operator 37

Fingernails

• Fingernails (real or artificial) and nail polish can be physical hazards.

• Keep nails trimmed and filed.

• Workers cannot wear fingernail polish or false fingernails.

The Safe Operator 38

Cover cuts, wounds, and sores

• Do not handle food if you have a sore that has pus or is infected unless it is bandaged and covered.

• Cover affected area with a bandage, a finger cot, and then cover with a nonlatex, single-use glove.

The Safe Operator 39

Bare-hand Contact

•

No bare-hand contact of exposed ready-to-eat food.

• Ready-to-eat food (RTE) includes:

– Cooked food

– Raw fruits and vegetables

– Baked goods

– Canned food

– Snack foods

– Beverages

• Alternatives to no bare-hand contact

– Single-use gloves

– Utensils

– Deli wraps

The Safe Operator 40

When Can You Use Bare Hands?

There are times when you can touch food with your bare hands, such as when:

– Handling raw foods before they are cooked.

– Capping containers of food.

– Pinching rolls.

– Restocking and stocking packaged foods.

When else can you touch foods with bare hands?

The Safe Operator 41

Single-use Gloves

• Single-use gloves are an alternative to bare hand contact.

• Wear non-latex gloves because latex gloves might cause an allergic reaction in some workers.

The Safe Operator 42

Changing Gloves

• Change gloves:

– when they tear;

– when you handle a different food

– when you touch a dirty surface;

– when going from a nonfood preparation task to a food preparation task,

– after cleaning tables, scraping, or washing dirty dishes and utensils,

– after four hours of constant use with the same type of food item.

• Once you take them off, throw them out – never reuse single-use gloves.

The Safe Operator 43

Examples of Single-Use Gloves

• Do you wash your hands before putting on gloves?

•

How do you remove your gloves?

• Where do you store your gloves?

The Safe Operator 44

Demonstration

Taking Off Single-use Gloves

The Safe Operator 45

Clothes

• Your clothes can contaminate food so wear:

– clean clothes – if wearing long sleeves pull up to threequarter length

– District-approved hair restraint

• It is best to change into your uniform shirt when you get to work.

The Safe Operator 46

Jewelry

While preparing food, never wear jewelry on your forearms and hands.

– This includes medical information jewelry and watches.

– The only exception is a plain wedding band.

Follow your District’s policy for wearing other jewelry.

The Safe Operator 47

Other Policies

• When handling food, never smoke, chew gum, or eat food

• You can drink from a covered container with a straw.

• Store all drinks away from food preparation/service areas.

The Safe Operator 48

Activity

The Safe Operator -- Right or Wrong?

The Safe Operator 49

Right or Wrong?

The Safe Operator s

50

Right or Wrong?

The Safe Operator 51

Right or Wrong?

The Safe Operator 52

Restricting a Worker

• Workers who have a sore throat with fever can be restricted.

•

A restricted food worker can handle packaged food, wrapped single-service or single-use articles, or soiled food equipment or utensils.

The Safe Operator 53

When to Exclude a Worker

• Workers who have one or more of the following symptoms:

• vomiting,

• diarrhea, or

• jaundice.

– has been diagnose d with Salmonella Typhi,

Shigella, E. coli, Hepatitis A virus, or

Norovirus.

The Safe Operator 54

Thermometers

Thermometers 55

How do you use these thermometers?

Thermometers 56

Which is the best way to store your food thermometers?

Where do you store food thermometers at your school?

Thermometers 57

Checking the Accuracy of Food

Thermometers

• Check the accuracy of all metal-stem food thermometers:

‾ first thing in the morning and

‾ every time the thermometer is dropped.

•

Use the ice-point method to check accuracy.

•

If not correct, calibrate.

Thermometers 58

Ice Water Method

• Fill large container with crushed ice. If only cube ice is available, crush it.

• Add clean tap water until the container is full.

• Place thermometer into water so sensing area is completely covered.

• Wait thirty seconds until you have a stable reading.

• If you need to calibrate, hold calibration nut securely with a wrench or other tool.

• Thermometer mus t read 32 o F.

Thermometers 59

Ice Water Method

Thermometers 60

Demonstration

Calibrating a Food Thermometer

Thermometers 61

Digital Thermometers

• Most digital and thermocouples cannot be calibrated in-house.

– If your digital thermometer is off more than 2 o F, throw it out.

– Return thermocouples to manufacturer for recalibration.

Thermometers 62

Temperature Calibration Log

Thermometers 63

Thermometers

• Decrease the length of time that potentially hazardous food is in the temperature danger zone by:

– checking the temperature of the food during cooking and while in the hot-holding cabinet; and

– checking the temperature of refrigerators and hotholding cabinets each morning before food preparation begins.

Thermometers 64

Receiving

Receiving 65

Safe and Approved Food Source

• Buy food from sources that comply with pertinent laws and regulations.

• Home-prepared food cannot be used or served in a food establishment.

• Fresh, uncut produce must be GAPs certified.

Receiving 66

Criteria for Accepting Food

• All food must:

– be in packaging that is in clean and good condition.

– not show signs of tampering or damage

• Never accept food that is past the date stamped on the package.

• Check that frozen foods are rock solid and no water marks appear on the packaging.

• All potentially hazardous food must be at 41 o F or colder.

Receiving 67

Inspect before You Accept

• Spot check delivery vehicles to be sure they are clean.

• Use an infrared thermometer to check the surface temperature of potentially hazardous foods.

Receiving 68

Inspecting Dry Foods

• When inspecting dry foods:

– turn over packages and look at the bottom for pin holes or insect debris.

– never just look at the top packages in a stack.

– examine the second and third packages down from the top.

Receiving 69

Accepting Cans

• No swollen ends, leaks, rusts or dents

• Label can be read and is attached to product

• No signs of tampering or counterfeiting

• Not past the date stamped on the label

Receiving 70

Are these acceptable?

Receiving 71

How about this can?

Receiving 72

Monitoring during Receiving

Receiving 73

Storage

Storage 74

General Storage Guidelines

• It is best to not remove labels from packaging. If label is removed, mark the side of the container with the name of the contents using a permanent black marker.

• Store products so that the oldest is used first.

• Throw out food that is past the date stamped on the label.

• Keep all storage areas clean and dry.

• Store food on clean shelves that are at least six inches off the floor.

Storage 75

Dry Storage

• Store dry food on clean shelves that are six inches away from the walls.

• Store food in durable, food-grade containers that are not in direct sunlight.

• Store food in containers that cannot be damaged by water or pests.

Storage 76

Refrigerated Storage

• Store raw foods below ready-to-eat foods.

• Check refrigeration temperatures daily.

• Store food to allow for good air circulation.

• Never line shelves with foil or other materials.

• Keep the refrigerator door closed as much as possible.

• Do not put large amounts of hot food into the refrigerator to cool.

• Cover food with a food grade lid, plastic wrap, or aluminum foil .

Storage 77

Frozen Storage

• Do not overload freezers.

• Check freezer temperatures daily.

• Place frozen deliveries in the freezer as soon as they have been inspected.

• Do not put hot food directly inside the freezer.

• Store food to allow for good air circulation.

• Keep freezer closed as much as possible.

• Cover food with a food-grade lid, plastic wrap, or aluminum foil.

Storage 78

First In, First Out (FIFO)

• Past-dated foods will lose their quality and sometimes become unsafe.

• FIFO ensures proper rotation of foods in storage.

• When foods are received, put the oldest in the front and the newest in the back.

• Identify package date, preparation date, or date of purchase.

Storage 79

How to Label

• Dry storage:

– Write the month, day, and year on the package with a permanent black marker.

– Example: 8/1/9, which means August 1, 2009.

Storage 80

How To Label

• Refrigerator and

Freezer storage :

– Write the month, day and year on the package with a permanent black marker.

– Example:8/31/9, which means August 31,

2009.

Storage 81

Storage Containers

• Food that is removed from its original package must be stored in a durable storage container.

• All containers must be foodgrade.

• The container must be identified with the common name of the food.

Storage 82

Cross-contamination in Storage

• Bacteria can be transferred from one food to another if food is not properly stored.

• Properly cover foods except while hot food is being cooled.

• Store raw food below cooked or ready-to-eat food.

Storage 83

Preventing Cross Contamination

• To prevent cross- contamination when storing food:

– Store food in designated storage areas.

– Store food in proper containers.

– Store raw meat and poultry separately from prepared and ready-to-eat food.

– Wrap food properly before storing it.

Storage 84

Activity

Storage – Right or Wrong?

Storage 85

Storage – Right or Wrong?

Storage 86

Storage – Right or Wrong?

Storage 87

Storage – Right or Wrong?

Storage 88

Storage – Right or Wrong?

Storage 89

Storage – Right or Wrong?

Storage 90

Chemical Storage

• Keep chemicals, such as cleaning supplies and sanitizers, separate from all food, dishes, utensils, linens, and single-use items.

• It is best to keep chemicals in their original containers.

• If chemicals are not in their original containers, clearly label the side of the container with the name of the contents. Never label the lid because lids are interchangeable.

Storage 91

Preparation

Preparation 92

General Preparation Guidelines

• Use standardized recipes or standardized procedures to prepare all menu items.

• Clean and sanitize work areas, cutting boards, knives, and utensils that are used to prepare food.

• Wipe all lids of cans and jars with a clan wet cloth that has been immersed in a properly prepared sanitizing solution.

• Do no use soapy water to wipe cans and jars.

Preparation 93

Thawing

• Improperly thawed food can support the growth of bacteria.

• Safe methods of thawing are:

– in the refrigerator (best way)

– during cooking (good way)

– Under cold running water

Preparation 94

Washing Produce

• Put all uncut produce in a clean colander before washing in the sink.

• Wash under lukewarm water before:

– cutting

– combining with other ingredients

– cooking

– offering for immediate consumption

•

After washing, store at 41 o F or colder for best quality.

Preparation 95

Cooling Room Temperature Foods

• Some potentially hazardous foods are made from ingredients that are stored at room temperature.

These foods are not cooked but require cooling after preparation.

• Examples of menu items include:

– Tuna salad

– Chicken salad

– Melons

• Refrigerate all ingredients the day before you assemble them.

Preparation 96

Cooking Temperatures

• Harmful bacteria grow and increase at temperatures between

41 o F and 135 o F, known as the temperature danger zone.

• Food cannot be in the temperature danger zone for more than four hours.

• Always use a thermometer to confirm final cooking temperatures.

• Be sure cooking is completed no more than 20 minutes before service.

• Batch cook as needed to reduce holding times for food to no more than 20 minutes.

Preparation 97

Preventing Temperature-Abuse

To keep food out of the temperature danger zone:

•

Remove only enough food from the refrigerator to be prepared in a short time.

•

Prepared food in small batches.

•

Refrigerate or cook food as soon as preparation is done.

Preparation 98

Cooking Temperatures

Food

Poultry

Stuffing and stuffed meat

Dishes that include potentially hazardous ingredients

Ground meats (including beef, pork, and other meat or fish)

Injected meats (including brined ham and flavor-injected roasts)

Pork and beef

Eggs (shell, liquid, or powdered)

Fruits or vegetables that will be hot-held

Commercially processed, ready-to-eat food

Thermometers

Minimum temperature

165 o F

165 o F

165 o F

155 o F

155 o F

145 o F for steaks/chops

155 o F surface temperature for roasts

145 o F

135 o F

135 o F

99

Cooking Temperatures

• Cook all potentially hazardous foods to the temperature noted on the standardized recipe or procedure.

• Cooking is a critical control point (CCP) for all menu items labeled “Same Day” or “Complex.”

• Commercially processed foods that are labeled

“fully cooked” only need to be cooked to 135 o F or hotter. k

Preparation 100

Standardized Recipe

Preparation 101

Activity

What’s My Cooking Temperature?

Preparation 102

What’s My Cooking Temperature?

Char-broiled beef patty

Chicken fajita strips

Preparation 103

What’s My Cooking Temperature?

Scrambled eggs

Steamed rice

Preparation 104

What’s My Cooking Temperature?

Commercially processed fish sticks

Cheese pizza

Preparation 105

Sensing Areas of Thermometers

Metal-stem Thermometer Digital Thermometer

Preparation 106

Measuring Cooked Food Temperatures

• Remove thermometer from its case and sanitize before taking the first temperature.

• Sanitize by:

– Using an alcohol swab or

– Immersing in a sanitizing solution

• Insert sensing portion of thermometer into product at two different places in the middle of the pan.

• Always clean the probe after taking both temperatures by wiping off with a clean paper towel.

• Sanitize before putting thermometer back into its case.

Preparation s

107

Demonstration

Cleaning and Sanitizing

Thermometer Probe before Use

Preparation 108

Measuring Cooking Temperatures

•

Batch cooking

– cooking an amount of food in the same equipment at one time:

– Steamer

– Ovens, including combination ovens and pizza ovens

– Kettles and braising pans

– Fryers

– Ranges/stovetop

•

Batch cooking – chicken nuggets

– Measure temperature of each batch at two points.

– Record the lowest temperature of the first batch on the

Daily

Production Record.

Preparation s

109

Measuring Cooking Temperatures

• Cook all at once – lasagna

•

Measure temperature in the middle of each pan.

•

Record lowest temperature on the Daily Production

Record.

•

Liquids -- chili

•

Stir food thoroughly.

•

Measure temperature at two points in the middle of the pan.

•

Record lowest temperature on the Daily Production

Record.

Preparation s

110

How to Take Food Temperatures

Preparation 111

Recording Cooked Food

Temperatures

1. Record the lowest safe temperature of the first batch on the

Daily Production

Record.

2. Temp all batches as they are removed from temperature control but do not record.

Preparation 112

Thermometer Sleeves

• Never put a dirty thermometer back in to its sleeve.

• The inside of the sleeve can become contaminated and they are very difficult to clean and sanitize.

• If they become contaminated, you must clean by immersing in the three-compartment sink and then immersing in sanitizing solution.

Preparation 113

Cooling Potentially Hazardous Foods

Properly cool potentially hazardous food by:

– reducing quantity to smaller container;

– using an ice water bath; or

– stirring

Cool cooked food within four hours from 135 o F to

41 o F or colder.

Label properly cooled foods with the date and time it was prepared.

Preparation 114

Cooling Solid Foods

• Break down larger portions into smaller portions.

• Place portions into shallow pans at a level no deeper than 2 inches.

• Place pans into refrigerator uncovered to cool.

• Once cooled to 41 0 F, cover pan.

Preparation 115

Cooling Liquid Foods

• Reduce the amount of hot liquid into smaller portions and place into shallow pans at a level no deeper than two inches.

• Place the pans in larger pan of ice or in an ice bath in a food preparation sink.

• Stir the food as it is cooling.

• Label properly cooled foods with the date and time it was prepared.

Preparation 116

Pre-prepared Foods

• Pre-prepared foods are those that are made with the intent to serve on a later date.

• All pre-prepared foods should be covered and labeled with the amount and date the food was prepared.

• Pre-prepared foods must be frozen and used within one menu cycle.

• All foods that are pre-prepared must be listed and filed in Binder 1: Menu Summary and Recipes.

Preparation 117

Leftovers

• Temperature must be 135 o F or hotter, or 41 0 F or colder to be a safe leftover.

• Leftovers on a self-service bar and not packaged must be thrown out.

• Leftovers on the serving line are refrigerated and thrown out in 3 days.

• Leftovers that have been prepared but not placed on a serving line can be frozen for up to one menu cycle or 30 days, whichever comes first.

Preparation 118

Where Record on Production

Record

Preparation 119

Cooling Leftovers

Preparation 120

Storage of Leftovers

• The temperature of leftovers cannot be monitored properly so limit the amount of leftovers.

• Cover leftovers and label with the food name and date of preparation.

• Check temperature before leaving and write the temperature and time on the label.

Preparation 121

Reheating Foods

• Reheat all food that has been cooked in house and then cooled to at least 165 o F for 15 seconds.

• The total time to reheat a food must not be more than two hours.

• After second reheat, the remaining food must be thrown out.

• If you throw out foods, record this on the

Daily

Production Record under comments.

Preparation 122

Cooling Complex Foods

• Examples of “Complex Foods” include:

– Pork roast

– Turkey roast

• The temperature of foods labeled “Complex

Foods” must be checked every hour during cooling.

• The temperature must be recorded on the

Complex Cooling Log.

Preparation 123

Complex Cooling Log

Preparation 124

Foods of Concern for

Temperature Abuse

• All potentially hazardous foods must be:

– Cooked to proper temperatures;

– Held at proper temperatures – 41 o F or colder OR 135 o F or hotter;

– Cooled to 41 o F or colder if stored as a leftover; and

– Reheated to 165 o F if served hot.

• Some foods are of increased concern because they are thick so take longer to cool and/or reheat.

Check the temperatures of these foods frequently to prevent temperature abuse.

Preparation 125

Chili Chicken Alfredo BBQ Riblet Sub

Oven-Roasted

Chicken

Salisbury Steak

Broccoli, Cheese & Rice

Casserole

Refried Beans

Preparation

Lasagna

Ground Beef and

Spanish Rice

126

Service

Service 127

Serving Line

• Do not touch food-contact areas of plates, bowls, glasses, or cups.

• Store flatware and utensils so that only handles will be touched.

• Practice good personal hygiene by wearing clean clothes and hair restraints.

• Wash hands often and properly.

• Never mix a product that is on the serving line with a new product.

Service 128

Self-service Areas

• Protect food in display with a sneeze guard or food shield.

• Label containers on food bar.

• Label handles with name of salad dressings.

• Replenish food on a timely basis.

• All exposed foods on a self-service bar must be discarded at the end of service.

• Keep hot food at 135 0 F or hotter and cold food at 41 0 or colder.

• Never mix a product that is on the serving line with a new product.

Service 129

Holding Temperatures

• Keep food at safe temperatures:

– Cold-holding – 41 o F or colder

– Hot-holding – 135 o F or hotter

• Always check the temperature before putting any new food on the serving line.

• Check the temperatures of potentially hazardous foods that are on the serving line every 30 minutes.

– You do not need to record these temperatures.

– If not at safe temperature, remove from the serving line.

Service 130

Re-serving Food

• Once food touches a student's tray it has been served.

• Only packaged foods can be re-served, such as:

– packaged cookies

– cartons of milk

– ice cream bars

– juice boxes.

Service 131

Re-serving Food

• If a student places a packaged food on his or her tray but cannot pay for it, the food can be recovered by the cashier and re-served.

• If a student pays for the item, leaves the serving line, and then wants to return the item, it can not be re-served. It must be thrown out.

Service 132

Salad Bars

• All unpackaged foods on a self-service salad bar must be thrown out at the end of service.

• Packaged foods can be reserved if they are at proper temperatures.

• To minimize waste, put smaller amounts on the salad bar.

Service 133

Activity

Service – Right or Wrong?

Service 134

Service – Right or Wrong?

Service 135

Equipment and

Facilities

Equipment and Facilities 136

Facilities Requirements

Surfaces

– Smooth, nonabsorbent, and in good repair.

Utility lines and pipes

– Not unnecessarily exposed

– Should not prevent the cleaning of floors, walls, and ceilings

Floors

– Wear-resistant, slip-resistant, nonporous and graded to drain

Equipment and Facilities 137

Equipment Standards

Constructed from materials that are:

– Safe

– Durable, corrosion-resistant, and nonabsorbent

– Sufficient in weight and thickness to withstand repeated washing

– Smooth and easily cleanable

– Resistant to pitting, chipping, crazing, and scratching

All equipment must meet

ANSI- accredited set of standards.

Equipment and Facilities 138

Equipment Standards

Equipment that does not need to meet these standards includes:

• toasters,

• mixers,

• microwave ovens,

• water heaters,

• washers,

• dryers, and

• hoods.

Equipment and Facilities 139

Non-Food-Contact Surfaces

• Some surfaces are called non-food-contact surfaces.

• These equipment surfaces must be:

– smooth;

– nonabsorbent;

– corrosion-resistant;

– free of unnecessary ledges, projections, and crevices; and

– constructed to be easy to clean and maintain .

Equipment and Facilities 140

Requirements for Utensils

Utensils include:

– Kitchenware, tableware, single-service or singleuse gloves and thermometers

Utensils must be:

– durable;

– smooth; and

– easily cleanable.

Equipment and Facilities 141

Other Things to Consider

• Portable equipment is often easier to clean than permanently installed equipment.

• Stationary equipment must be mounted on legs that are at least six inches off of the floor or sealed to a masonry base.

• Stationary equipment that is mounted on legs that are on a table top must be at least four inches between the base of the equipment and the tabletop.

• All cracks or seams over 1/32 inches must be filled with a non-toxic, food-grade sealant.

Equipment and Facilities 142

Lighting Requirements

• Position lights above workstations so workers do not cast shadows on their work surface.

• Light bulbs must be shielded, coated, or shatter-proof in food preparation areas.

•

Walk-ins and dry storage

– 10 foot-candles of light

•

Self-service bars or where fresh produce or packaged food is displayed – 20 foot-candles of light

•

Food preparation areas

– 50 foot-candles of light.

Equipment and Facilities 143

Lighting – Right or Wrong?

Equipment and Facilities 144

Ventilation Requirements

• Fresh air, at correct temperatures and humidity, is essential to worker comfort.

• Ventilation systems must meet local regulations and be:

– properly constructed

– properly maintained

– properly cleaned

Equipment and Facilities 145

Requirements for Linens

• Linens are fabric items, such as cloth hampers, cloth napkins, wiping cloths, work clothes.

• They must be:

– Stored in a clean area.

– Washed in a washing machine. Wiping cloths can be washed in a sink.

– Dry them in a dryer. Linens cannot be air-dried in the kitchen.

Equipment and Facilities 146

Water

Water for drinking, food preparation, and washing must be from an approved source.

– Public water systems must meet national drinking water regulations.

– Nonpublic water systems must meet state drinking water quality standards.

A non-drinking water supply can only be used if its use is approved. If approved it can be used for:

– Air conditioning, nonfood equipment cooling, fire protection, and irrigation.

Equipment and Facilities 147

Water

• The water source, including hot water, must be able to meet the peak water demands of the establishment.

• Water under pressure must be provided to all fixtures, equipment, and nonfood equipment that are required to use water.

• Alternative water supplies include:

– bottled drinking water;

– closed portable water containers;

– enclosed vehicle water tank; or

– on-premises water storage tank.

Equipment and Facilities 148

Plumbing

• Improperly maintained plumbing has been documented as the cause of many foodborne illness outbreaks.

• Plumbing must meet local regulations and be properly constructed and maintained.

Equipment and Facilities 149

Cross-connections

• A cross connection is a physical link through which contaminants from drains, sewers, or other wastewater sources can enter a safe water supply.

– For example, a faucet located below the flood rim of a sink.

• Properly installed plumbing will prevent this from happening.

Equipment and Facilities 150

Backflow Prevention

Air gap

• An air gap between the water supply inlet and the flood level rim must be at least twice the diameter of the water supply inlet but not less than 1 inch.

Backflow or backsiphonage

• Must meet American Society of

Sanitary Engineering (ASSE) standards.

Equipment and Facilities 151

Grease Condensation and Leaky Pipes

• Grease traps must be:

– easy to access;

– installed by a licensed plumber; and

– cleaned on a routine basis.

• Overhead wastewater pipes or fire safety sprinkler systems can leak and become a source of contamination.

Equipment and Facilities 152

Other Plumbing Considerations

• One handwashing sink.

• One toilet and urinal.

• At least one service sink or one curbed cleaning facility equipped with a floor drain for cleaning of mops and disposing of wastewater.

Equipment and Facilities 153

Location of Handwashing Sinks

• Handwashing sinks must provide hot and cold running water at a temperature of at least 110 o F.

• Handwashing sinks must also be conveniently located in food preparation areas, service areas, warewashing areas, and restrooms.

• They must also be equipped with a sign indicating that workers are required to wash hands before returning to work.

Equipment and Facilities 154

Handwashing Sinks

Handwashing sinks must:

• provide water at a temperature of at least 110 o F.

• provide a flow of water for 10-15 seconds without the need to reactivate the faucet.

Automatic handwashing equipment must:

• be installed according to manufacturer's instructions.

Equipment and Facilities 155

Garbage and Refuse Disposal

• Refuse is solid waste that cannot go through a sewage disposal system.

• Garbage is all food waste that cannot be recycled.

• Disposal rules:

– Provide trash cans that are large enough.

– Clean cans each week.

– Dispose of trash regularly.

Equipment and Facilities 156

Sewage

• Adequate drainage must be installed to handle sewage and wastewater.

• Areas with a lot of water exposure must have floor drains.

• A backup of raw sewage is a cause for immediate closure.

– The problem will have to be corrected and the establishment thoroughly cleaned before it can be reopened.

Equipment and Facilities 157

Cleaning and Sanitizing

Cleaning and Sanitizing 158

Cleaning and Sanitizing

•

Cleaning -- removing food and dirt from a surface.

•

Sanitizing

– decreasing the number of microorganisms that are on a properly cleaned surface to a level that will not make one sick.

Cleaning and Sanitizing 159

Sanitizing

• Sanitizing is the process of reducing the number of microorganisms that are on a properly cleaned surface to a safe level.

• Sanitizing agents only work on properly cleaned and rinsed surfaces.

Cleaning and Sanitizing 160

Methods for Sanitizing

Heat

– Hot water – 171 o F

Chemicals

– Chlorine – 50 ppm

– Quaternary Ammonia – per manufacturer instructions

– Iodine – 12.5-25.0 ppm

Cleaning and Sanitizing 161

Three-compartment Sink

1. Wash -- Water temperature at least 110 o F

2. Rinse -- Water temperature at least 110 o F

3. Sanitize -- Hot water temperature of 171 o F chemical solution of 50 ppm

4. Air-dry -- Do not hand dry.

Dry on shelves 6 inches off of the floor.

Never mix chemical sanitizers with washing water detergents

Cleaning and Sanitizing 162

High-temperature Dish Machines

• Final sanitizing rinse must be 180 o F or hotter

• Measure water temperature at the manifold.

• Record your observation on

Daily Operation

Inspection form.

Cleaning and Sanitizing 163

Daily Operation Inspection

Cleaning and Sanitizing 164

Measuring Sanitizer Strength

• A test kit that accurately measures the concentration of sanitizing solutions must be available.

• The strength of sanitizing solutions must be measured frequently during the day.

• Record reading on the

Daily Operation

Inspection form.

Cleaning and Sanitizing 165

Food-Contact Surface

• All food-contact surface must cleaned and sanitized after becoming contaminated.

• Examples include:

– utensils,

– cutting

– boards,

– slicers,

– countertops,

– refrigerator shelves

Cleaning and Sanitizing 166

Food-Contact Surface

A food-contact surface is:

– a surface that food normally touches or

– a surface where food might drain, drip, or splash into a food or onto a surface that normally touches food.

Examples:

– Utensils, cutting boards, slicers, countertops, storage bins, baking sheets, and refrigerator shelves

Cleaning and Sanitizing 167

Cleaning Food-Contact Surfaces

Immersion

– Wash with detergent

– Rinse under warm running water.

– Immerse in a properly prepared sanitizing solution.

Cleaning and Sanitizing 168

In-Place Sanitizing

• Unplug equipment before cleaning.

• Remove food and soil from under and around equipment.

• Detachable parts are removed and manually washed, rinsed, and sanitized. Can also be run through a dish machine.

Cleaning and Sanitizing 169

In-place Sanitizing

• All food contact surfaces that can not be removed are washed and rinsed.

• Spray or wipe properly with a prepared sanitizing solution.

• All parts are air-dried then reassembled.

• Food contact surfaces touched with bare-hands during reassembly are sanitized again.

Cleaning and Sanitizing 170

Cleaning Non-Food Contact Surfaces

• Non-food contact surfaces:

– exterior of refrigerator, stovetops, and refrigerator gaskets.

• Wash with detergent and rinse but do not need to sanitize.

• Keep free of dirt, dust, and debris.

Cleaning and Sanitizing 171

Cleaning and Sanitizing

Refrigerators

• Throw out any spoiled foods.

• Remove shelves.

• Wash, rinse, and sanitize shelves.

• Wash the interior of the refrigerator and freezer with hot water.

• Rinse with sanitizing solution.

• Leave door open for 15 minutes to allow air to circulate.

Cleaning and Sanitizing 172

Storing Cleaned and Sanitized Items

• Store in clean, dry location.

• Not exposed to splash, dust, or other contamination.

• At least 6 inches above the floor.

• In a self-draining position.

• Covered or inverted.

Cleaning and Sanitizing 173

Activity

Food-contact Surface or Not?

Cleaning and Sanitizing 174

Food-contact Surface or Not?

Cleaning and Sanitizing 175

Food-contact Surface or Not?

Cleaning and Sanitizing 176

Food-contact Surface or Not?

Cleaning and Sanitizing 177

Food-contact Surface or Not?

Cleaning and Sanitizing 178

Storing Cleaned and Sanitized Items

• Store in a clean, dry location

• Not exposed to splash, dust, or other contamination

• At least 6 inches above the floor

• In a self-draining position

• Covered or inverted

Cleaning and Sanitizing 179

Chemicals

• Store separate from food, equipment, utensils, linen, and single-service and single-use items.

• If removed from their original package, label the container in which they are stored. Do not label lids.

• Mark chemicals with an

“X” to help those who cannot read.

Cleaning and Sanitizing 180

Material Safety Data Sheets

• OSHA requires a Material Safety Data Sheet (MSDS) for all chemicals.

• On every MSDS, be familiar with the following sections:

– 4.0 Fire and explosion data

– 5.0 Reactivity data

– 6.0 Spill or leak procedures

– 7.0 Health hazard data

– 8.0 First aid

– 9.0 Protective measures

– 10.0 Additional information/precautions

• Highlight important information on the MSDS.

Cleaning and Sanitizing 181

Material Safety Data Sheet

Product Name

Emergency Contact

Information

Chemical

Ingredient

List

First Aid Procedures

PPE

Cleaning and Sanitizing 182

Integrated Pest

Management

Prepared by:

Michael Waldvogel, Ph.D.

NC Cooperative Extension Service

North Carolina State University

IPM 183

Problems Caused By Pests

• Customer perception

• Damage to food, supplies, and facilities

• They can contaminate food and preparation surfaces

• They can spread diseases such as Salmonella

IPM 184

A Pest Management Program should:

• rely less on pesticides.

• emphasize sanitation and exclusion of the pests.

• train employees.

• use a licensed pest control operator (PCO).

IPM 185

Cockroaches

Can be introduced into the establishment through boxes, bags, and workers’ personal items.

German cockroach female with egg case

IPM

University of Nebraska

186

Cockroach Feces and Egg Cases

Noticeable oily odors

IPM

Egg cases and feces

187

Critical Areas for Cockroaches

IPM 188

Use Glue Traps to Monitor Cockroach

Activity

IPM

Check traps once per day.

189

Chemical Control of Cockroaches

Crack and crevice treatment and spot treatment

• Target use of insecticides to reduce amount used.

• Do not contaminate food prep surfaces and equipment.

• Apply insecticides after business hours.

IPM 190

Cockroach Baits

Bait Station

Gel bait

IPM 191

Rodent Problems

• Rats and mice (usually mice are the more common problem).

• Damage/contaminate food and property.

• Can spread diseases through their feces and urine or by contact with surfaces.

IPM 192

Rodents nest outdoors in areas hidden by tall grass, landscaping, “clutter” or down in sewers.

IPM 193

Mouse Nesting Sites

IPM 194

Burrows and Runs

IPM 195

Rodent Gnawing

IPM 196

Rub Marks and Droppings

IPM 197

Excluding Rodents

• Foam sealants alone will not stop rodents.

• Use metal hardware cloth to seal large openings.

IPM 198

Traps and Baits

• Use for insects and rodents

• Check rodent traps daily

• Leave rodent baiting to the professionals.

IPM 199

Rodent Baiting

Bell Laboratories, Inc.

Madison, WI 53704

IPM 200

Proper Use of Rodent Baits

No

IPM

Yes

201

Common Fly Pests

•“Filth” flies -- house flies and blow flies

•Others -- fruit flies, drain flies, fungus gnats

U-Nebraska-Entomology

IPM

Univ. of Florida

202

Fly Control

IPM 203

Flour beetle

Stored Product Pests

Common Foods Attacked

• Flour

• Baked items

• Spices

• Pastas

• Dried fruit

• Powdered milk

• Shelled nuts

• Bird seed

• Grass seed

• Rodent baits

• Cereals

Cigarette beetle

Sawtooth Grain beetle

Indianmeal moth

IPM 204

Stored Product Pest Control

• Keep food storage, prep and serving areas clean and easy to inspect.

• Discard or return infested items.

• Store susceptible items in sealable, food-grade containers.

IPM 205

Use a Pest Logbook

A means of two-way communication

IPM 206

Pesticides Can be Hazardous

IPM

• Liability issue

• Do not let untrained employees apply pesticides.

• Preferably - use licensed pest management professionals.

• Keep copies of the MSDS for all pesticides used in your facility.

207

Insecticide Application

• Leave the job to the professionals.

• Do not contaminate food and equipment.

IPM 208

Outside Trash Cans:

Dumpsters, Trash, and Recycle Bins

• Keep pads/area clean.

• Keep lids closed.

• Use trashcan liners.

• Empty and clean trash once per week.

IPM 209

What’s Wrong This Picture?

IPM 210

What’s Wrong This Picture?

IPM 211

What’s Wrong This Picture?

IPM 212

Food Safety

Regulations

Food Safety Regulations 213

Government Regulations

• Government regulations of food in the U.S. are at three levels:

– U.S. Department of Agriculture is responsible for the inspection and quality grading of meat, meat products, poultry, dairy products, eggs, and egg products, and fruit and vegetables shipped across state lines.

–

Food and Drug Administration inspects all other food processing plants.

–

Local Foodservice Regulations . City, county, or state health inspectors conduct foodservice inspections in most states.

Food Safety Regulations 214

Inspections

• Cafeterias are inspected to protect the public’s health and to help food service operators identify potential food safety problems.

• When an inspector comes into your establishment he or she will:

– Evaluate whether you are meeting minimum sanitation and food safety standards;

– Require you to provide food that is safe, uncontaminated, and presented properly; and

– Provide you with a written report, noting flaws, so that you can bring your establishment into compliance with minimum sanitation and food safety standards .

Food Safety Regulations 215

Foodservice Inspection Process

• The health department will perform regular inspections four times a year.

• The inspector will use the local health code as a guide.

Food Safety Regulations 216

Successful Inspections

• Ask the inspector for identification.

• Cooperate with the inspector and instruct your workers to do so.

• Take notes about any problems noted by the inspector.

• Keep the relationship professional.

• Be prepared to provide records requested by the inspector.

• Discuss violations and time frames for correcting problems with the inspector.

• Follow up to correct problems and critical violations.

Food Safety Regulations 217

The Food Code

• Written by the FDA and is a model document for foodservice regulations.

• It is intended to help state health departments develop regulations for their foodservice inspection program.

Food Safety Regulations 218

Closure

• If the inspector determines that the cafeteria posses an immediate health hazard a suspension of the permit to operate may be issued.

• Examples of health hazards include:

– inadequate refrigeration;

– backup of sewage into the establishment itself or its water supply;

– emergency, such as building fire or flood;

– serous infestation of insects or rodents; and

– long interruption of electrical or water service .

Food Safety Regulations 219