HEALTH STATE MONITORING SYSTEM DESIGN A Project

advertisement

HEALTH STATE MONITORING SYSTEM DESIGN

A Project

Presented to the faculty of the Department of Electrical and Electronic Engineering

California State University, Sacramento

Submitted in partial satisfaction of

the requirements for the degree of

MASTER OF SCIENCE

in

Electrical and Electronic Engineering

by

Viorel Rotar

FALL

2012

HEALTH STATE MONITORING SYSTEM DESIGN

A Project

by

Viorel Rotar

Approved by:

__________________________________, Committee Chair

Dr. Warren D. Smith

__________________________________, Second Reader

Koullis Pitsillides

____________________________

Date

ii

Student: Viorel Rotar

I certify that this student has met the requirements for format contained in the University

format manual, and that this Project is suitable for shelving in the Library and credit is to

be awarded for the Project.

__________________________, Graduate Coordinator, __________________

Preetham B. Kumar

Date

Department of Electrical and Electronic Engineering

iii

Abstract

of

HEALTH STATE MONITORING SYSTEM DESIGN

by

Viorel Rotar

The health of hospitalized patients often deteriorates, because the available

medical staff is unaware of the deterioration. The condition of normally healthy people

under stressful situations can deteriorate, because they are not aware that they have

reached their physical limits. Infants can die in their “Sleep” because of Sudden Infant

Death Syndrome (SIDS). Death could be prevented by waking the child, but the parents

are unaware that the infant experiences lack of oxygen. People with epilepsy can die

because a seizure was not detected in a timely manner. In severe epileptic episodes, death

from airway constriction can occur in less than 3-5 minutes unless help is immediately

provided.

Therefore, a Health State Monitoring System (HSMS), able to detect and alarm

when a health abnormality develops, is desirable. The HSMS should be broadly useful

from being used by professional health-care providers to personal in home use. It should

be easy to use by first responders, military personnel, firefighters, athletes, and parents

monitoring infants.

iv

The HSMS consists of a wearable device with sensor and communication

circuitry, a personal computer (PC) based graphical user interface (GUI), and a basestation interface between the wireless sensor and the PC. The wearable device

incorporates sensors that can provide a quick general assessment of a person’s cardiorespiratory status, temperature, and level of physical activity. The cardio-respiratory

status is assessed by a pulse oximeter, which gives the percent oxygen saturation in the

blood. Heart rate is derived from the pulsatile waveform of the pulse oximeter which

corresponds to the cardiac cycle. Skin temperature is measured with a digital temperature

sensor. A micro Secure Digital (microSD) card is used to store raw data for extended

periods of time. The sensors for vital data acquisition are non-invasive and do not require

a professional health care provider for attachment to the body. The system is configurable

to accommodate different applications. For continuous patient monitoring, the system can

be configured to wirelessly transmit collected data to a computer. These data then can be

sent to a physician, who then reviews the data and intervenes when necessary. For

applications where a computer is out of wireless communications range, like when

monitoring the effect of stressful situation on health of first responders, the data are saved

on the microSD card for later review. For applications where just an alarm is necessary to

indicate a breathing or heart rate abnormality, such as monitoring of infants for the

detection of SIDS, for example, the system can be configured to activate the light and/or

sound alarm.

v

In this project, a small wearable wireless sensor was designed and built that

incorporates multiple sensors, and all the sensors operated properly in a laboratory

setting. The sensors that are less susceptible to motion artifacts, such as temperature,

were easier to implement. The pulse oximeter performed well under different light

conditions, but data were disrupted or incorrect as a result of motion artifacts.

Development of software algorithms to reduce the effects of motion artifacts is desirable.

The pulse oximeter signal was obtained easily when a finger was placed over the sensor,

but the sensor was not tested at other locations on the body. The wireless communication

was stable, with a range suitable for hospital and home use. The necessity for different

component values for the transceiver, if there is a need to change the frequency band to

comply with local radio-communication rules, is a drawback.

Approved by:

__________________________________, Committee Chair

Dr. Warren D. Smith

____________________________

Date

vi

ACKNOWLEDGEMENTS

It is a pleasure to acknowledge the assistance received during the development of

the Health State Monitoring System from Dr. Warren D. Smith, who is committee chair

for the project, and Koullis Pitsillides, a biomedical engineer from Endosomatic Systems.

vii

TABLE OF CONTENTS

Page

Acknowledgements ........................................................................................................... vii

List of Figures .................................................................................................................... xi

Chapter

1.

INTRODUCTION ........................................................................................................1

2.

BACKGROUND ..........................................................................................................5

2.1.

2.2.

2.3.

Temperature Monitoring ....................................................................................5

2.1.1.

Temperature Monitoring Importance ................................................. 5

2.1.2.

Temperature Measurement Principle ................................................. 6

Activity Monitoring ...........................................................................................8

2.2.1.

Activity Measurement Importance ..................................................... 8

2.2.2.

Activity Measurement Principle ......................................................... 9

Cardio-Respiratory Assessment .......................................................................10

2.3.1.

Pulse Oximeter Importance .............................................................. 10

2.3.2.

Principle of Pulse Oximeter Measurements ..................................... 11

2.3.3.

Optical Properties of the Tissue ....................................................... 12

2.3.4.

Transmission and Reflectance Modes of Pulse Oximeter

Measurements .................................................................................. 18

2.3.5.

3.

Interference to the Pulse Oximeter Signal ........................................ 19

HEALTH STATE MONITOR CIRCUITRY ............................................................21

viii

3.1.

Health State Monitor Circuitry Overview........................................................21

3.2.

Sensor Circuitry ...............................................................................................23

3.3.

3.4.

4.

3.2.1.

Temperature Monitoring Circuitry ................................................... 24

3.2.2.

Activity Monitoring Circuitry .......................................................... 25

3.2.3.

Pulse Oximeter Circuitry .................................................................. 26

Supporting Circuitry ........................................................................................31

3.3.1.

Power Supply Circuitry .................................................................... 31

3.3.2.

Microcontroller (MCU) Circuitry..................................................... 32

3.3.3.

Radio Communication Circuitry ...................................................... 35

3.3.4.

MicroSD Card Circuitry ................................................................... 36

3.3.5.

Alarm Circuitry ................................................................................ 37

Base-Station Circuitry......................................................................................38

WIRELESS SENSOR SOFTWARE ..........................................................................39

4.1.

Microcontroller Main Routine .........................................................................39

4.2.

Temperature Acquisition .................................................................................42

4.3.

Accelerometer Acquisition ..............................................................................43

4.4.

Pulse Oximeter Acquisition .............................................................................44

4.4.1.

Pulse Oximeter Software Overview ................................................. 44

4.4.2.

Controlling the LEDs and Taking Data Samples ............................. 46

4.4.3.

Red and Infrared (IR) Signal Processing .......................................... 49

4.4.4.

Calculating the Heartbeats ................................................................ 52

ix

4.4.5.

5.

Calculating the Percent Oxygen Saturation in Blood ....................... 55

4.1.

MicroSD Card Software ..................................................................................58

4.2.

Wireless Communication .................................................................................61

GRAPHICAL USER INTERFACE (GUI) ................................................................63

5.1.

Initializing a Wireless Sensor ..........................................................................63

5.2.

Controlling a Wireless Sensor .........................................................................63

5.3.

Displaying Sensor Data....................................................................................66

5.4.

Saving Sensor Data ..........................................................................................66

6.

BASE STATION INTERFACE SOFTWARE ..........................................................69

7.

TESTING RESULTS .................................................................................................70

8.

SUMMARY, CONCLUSIONS, AND RECOMMENDATIONS .............................73

References ..........................................................................................................................77

x

LIST OF FIGURES

Figures

Page

1.

Figure 2.1. Circadian temperature rhythm. ......................................................... 5

2.

Figure 2.2. Temperature measurement variation with location. ......................... 7

3.

Figure 2.3. Data from a daily routine activity monitor. ...................................... 9

4.

Figure 2.4. Laser light penetration. .................................................................... 13

5.

Figure 2.5. Tissue light absorption. .................................................................. 14

6.

Figure 2.6. Absorption of oxygenated and deoxygenated haemoglobin versus

wavelength...................................................................................... 15

7.

Figure 2.7. Ratio of red to infrared amplitudes versus blood oxygenation....... 16

8.

Figure 2.8. Dependence of light absorption on tissue. ...................................... 17

9.

Figure 2.9. Dependence of blood cell alignment on flow. ................................ 17

10.

Figure 2.10. Systole and diastole correlation to signal. .................................... 18

11.

Figure 2.11. Transmission mode (left) and reflectance mode (right) ............... 19

12.

Figure 2.12. Normal and undesirable pulse oximeter signals. .......................... 20

13.

Figure 3.1. Wireless sensor schematic. ............................................................. 22

14.

Figure 3.2. Base-station schematic ................................................................... 23

15.

Figure 3.3. Temperature sensor circuitry .......................................................... 24

16.

Figure 3.4. Accelerometer circuitry .................................................................. 25

17.

Figure 3.5. Wireless sensor electronic assembly .............................................. 26

xi

18.

Figure 3.6. Red and IR light source. ................................................................. 27

19.

Figure 3.7. Photodetector and amplification circuitry ...................................... 28

20.

Figure 3.8. Relative intensity versus wavelength. ............................................ 29

21.

Figure 3.9. Photodiode relative spectral sensitivity versus wavelength ........... 30

22.

Figure 3.10. Power supply circuit ..................................................................... 32

23.

Figure 3.11. Microcontroller circuit.................................................................. 35

24.

Figure 3.12 RF circuit ....................................................................................... 36

25.

Figure 3.13. MicroSD card circuit .................................................................... 37

26.

Figure 3.14. Sound and light alarm circuit ....................................................... 38

27.

Figure 4.1. Wireless sensor initialization .......................................................... 39

28.

Figure 4.2. Wireless sensor microcontroller ..................................................... 40

29.

Figure 4.3. IR (bottom) and red (top) LEDs on/off sequence ........................... 47

30.

Figure 4.4 First stage amplifier settling time .................................................... 47

31.

Figure 4.5. First (top) and second (bottom) stage amplifier outputs ................ 48

32.

Figure 4.6. Displaying unfiltered red and filtered IR signals ........................... 51

33.

Figure 4.7. Pulse detecting signal (on T channel) ............................................. 52

34.

Figure 4.8. IR heart pulse (top) and pulse detect (bottom) ............................... 54

35.

Figure 4.9. The ac and dc components of the IR signal. ................................... 56

36.

Figure 4.10. Percent oxygen saturation versus R/IR ratio. ............................... 57

37.

Figure 4.11. Pulse oximeter function ................................................................ 59

38.

Figure 4.12. MicroSD card function ................................................................. 60

xii

39.

Figure 5.1. GUI timed acquisition control panel .............................................. 64

40.

Figure 5.2. Wireless sensors grouped for timed acquisition ............................. 65

41.

Figure 5.3. Wireless sensors grouped for timed acquisition for different

On/Sleep times ............................................................................... 65

42.

Figure 5.4. Display monitor. ............................................................................. 67

43.

Figure 5.5. Plotting saved data in Excel. .......................................................... 68

44.

Figure 7.1. Accelerometer data (three axis) ...................................................... 72

xiii

1

CHAPTER 1

1. INTRODUCTION

Development of continuous remote health monitoring is necessary, because

people live longer and “baby boomers” are aging, threatening to overwhelm health-care

providers [1]. Implementation of continuous health monitoring contributes to an increase

in health-care quality and a decrease in health-care cost. Prevention of the onset of

chronic disease can dramatically reduce hospitalization time and increase the quality of

life, with the associated reduction of health care costs.

A person’s health can drastically worsen between scheduled physician visits. But,

with continuous health state monitoring, office visits can be reduced, because a physician

reviews collected data more frequently. Continuous remote health monitoring will enable

aging people and people with chronic illnesses to live in their homes and be independent.

A continuous health monitoring system will aid people with epilepsy. The

standardized mortality rate (SMR) is 1.6-9.3 times higher for people with epilepsy than in

the healthy population [2]. In severe epileptic episodes, death from airway constriction

can occur in less than 3-5 minutes unless help is immediately provided. Detecting

changes in heart rate and oxygen concentration in the blood would indicate that the

person is in crisis or that a crisis is imminent and help is needed.

Continuous monitoring aids in detecting changes in health condition in postoperative hospitalized patients. A post-operational patient monitoring system for

detecting deterioration in post-operative hospitalized patients, where medical staff is

2

available but is unaware of the deterioration, has proven very useful [3]. The monitoring

system consisted of pulse oximeters worn by the patients that notified a nurse via wireless

pager when abnormalities were detected. The system helped doctors to intervene before a

critical situations developed. According to the results of the study, rescue events

decreased from 3.4 to 1.2 per 1,000 patient discharges and intensive care unit transfers

from 5.6 to 2.9 per 1,000 patient days. Pulse-oximeter implementation saved the 36-bed

intensive care unit 135 days per year.

In the United States, about 2,500 infants die each year because of SIDS [4].

Apparently, the brain triggers the babies to wake from sleep and cry when a lack of

oxygen is detected. This response changes their heartbeat and breathing patterns to make

up for the lowered oxygen and excess carbon dioxide. If this mechanism is not

developed, the infants die in their sleep. A continuous monitoring system, capable of

measuring heart rate and oxygen concentration in blood, could prevent many infant

deaths.

Continuous health monitoring could be used for healthy people who are in

stressful situations, such as firefighters, combat personnel, and athletes. The development

and initial bench testing of a continuous monitoring system using a pulse oximeter and an

accelerometer has been done for such applications [5]. The system was used for

monitoring first responders and critically injured persons. The oxygen concentration and

heart rate gives the health state of a soldier, and the accelerometer shows the soldier’s

activity and body orientation.

3

An internet-based health monitoring system has been developed and tested for

monitoring brain-injured children [6]. The test results showed that even though the

system needs improvements, 78% of patients and families were interested in further use

of the system.

Continuous health monitoring will play a big role in the health-care industry and,

according to Kalorama, the market will increase from $ 5.7 billion in 2009, with an

annual growth of around 26 % through 2014 [7]. General Electric and Intel joined to

create a health-care company to develop telehealth systems [8].

The goal of this project is to develop a remote continuous noninvasive Health

State Monitoring System (HSMS), capable of indirect measurement of the percent

oxygen saturation in the blood, heart rate, physical activity, and temperature. The system

would consist of a wearable device with a unique identification number (ID), containing

sensors and communicating circuitry, called further the “wireless sensor,” a personal

computer (PC) based graphical user interface (GUI), and a base-station interface between

the wireless sensor and the PC. The wireless sensor, with a unique ID, consists of a pulse

oximeter, activity and temperature sensors, wireless circuitry for communication with the

base-station, a programmable microcontroller, local data storage, and local sound/light

alarms.

The GUI allows the user to remotely access an individual ID addressable wireless

sensor for controlling the wireless sensor and for retrieving the sensor data in real time.

The control involves setting the sensor’s data acquisition rate, enabling/disabling the

sensors, enabling/disabling data saving on the wireless sensor microSD card, and setting

4

the source and levels for triggering sound and/or light alarms. The base-station is an

interface between the PC and the wireless sensor that allows the wireless sensor to send

data to the PC and the PC to control the wireless sensor.

This report is structured as follows: Chapter 2 provides a background description

of the sensors for collecting vital data used in the project. The description includes the

importance of the sensor measurement, application areas, and the potential for expanding

the application areas. Chapter 3 describes the circuit that was built for this project. The

circuit description is divided into two main sections, the sensor circuitry and supporting

circuitry. The sensor circuitry section describes the circuits and hardware of the

temperature, activity, and pulse oximeter sensors. The core components of each sensor

are described. The supporting circuitry section describes the circuit and the hardware of

the power supply, wireless communication, microcontroller features, microSD storage,

the sound and light alarm, and the microcontroller that controls the hardware. Chapters 4,

5, and 6 describe the software and provide software flowcharts and code snippets for the

HSMS. There are three independent units: the wireless sensor software is described in

Chapter 4, the GUI software is described in Chapter 5, and the base-station software is

described in Chapter 6. Test results for the HSMS are provided in Chapter 7. Chapter 8

gives a summary, conclusions, and recommendations for improving the system.

5

CHAPTER 2

2. BACKGROUND

2.1. Temperature Monitoring

2.1.1. Temperature Monitoring Importance

Temperature measurement commonly is used to determine if a person has a fever

and, if so, the severity of the fever. However, body temperature also is affected by

stressful situations, a person’s age and activity, time of the day and season, pregnancy,

hormonal contraceptives, etc. The temperature of the human body has a twenty-four hour

pattern (see Figure 2.1), called a circadian rhythm, and a season pattern, called a

circannual rhythm [9].

Figure 2.1. Circadian temperature rhythm.

The figure show 24-hour temperature variation for various location [9].

6

Continuous temperature measurement can provide additional information about a

person’s state of health. For example, the disruption in timing of acrophase (the time at

which the peak of a rhythm occurs) is associated with insomnia and several chronic

diseases, including cancer and HIV. Continuous temperature measurement not only can

be used for detecting medical abnormalities but also for evaluating the effectiveness of

medications.

2.1.2. Temperature Measurement Principle

The importance of clinical temperature measurement is traced back to the times of

Hippocrates [10]. At that time, hands were used to estimate the heat or cold of a human

body. The first physician to use a thermometer at his patients' bedside is considered to be

Hermann Boerhaave in the 16th century. Sir Thomas Allbutt invented in 1867 the first

practical medical thermometer used for taking the temperature. It was portable, 6 inches

in length, and able to record a patient's temperature in 5 min. Many devices were

developed for temperature measurement. One of the most common devices for measuring

temperature is the glass thermometer which uses the thermal expansion properties of a

liquid (spirits, mercury). Modern thermometers are based on semiconductor temperature

sensors and are capable of taking a measurement in 5 to 10 s. Temperature sensors are

available from different manufacturers. A sensor needs to be selected based on size,

accuracy, type of output (analog or digital), power consumption, sensor price, and, for

digital sensors, the choice of I2C or SPI communication protocol.

7

For this project, a low-cost temperature sensor, the TMP121 from Texas

Instruments (TI), Dallas, Texas, with ± 1.5 °C accuracy and with the 0.0625 °C resolution

was selected. For continuous monitoring, body tracking temperature variation is more

important than accuracy. Body temperature varies based on gender and on different

locations on the body (Figure 2.2) and depends on the season, time of the day, and the

person’s fitness [9]. The body temperature measurement is done every 30 s (default

setting), because body temperature changes relatively slowly.

Figure 2.2. Temperature measurement variation with location.

The figure shows the temperature measurement variation in dependence of gender and

measurement location [9].

8

2.2. Activity Monitoring

2.2.1. Activity Measurement Importance

Health is in direct relationship with a person’s lifestyle. Many health problems

could be prevented by sufficient physical activity and by sufficient rest. Staying “in

shape” requires exercise [11]. But, over-exercising harms health. For example, “intense

exercise can cause scarring and fibrosis in the heart” [12]; vigorous activity can “increase

the risk of sudden cardiac death and acute myocardial infarction” [13]. Insufficient as

well as excessive [14] sleep can cause cardiovascular diseases [15], diabetes, mental

problems [16], [17], and accidents [18]. Therefore, by monitoring activity, in correlation

with other physiological measurements, a safe exercise intensity and rest time program

can be set. For example, cardiac infarction can occur during jogging. By correlating the

occurrence of heart abnormalities with activity intensity, a safe level of activity intensity

can be determined. Exceeding the set activity level would trigger an alarm, warning the

jogger to decrease the activity. By analyzing the rest time (sleep, watching TV etc.) of a

person, a correction to the lifestyle can be suggested. Figure 2.3 shows an example of

data from a daily routine activity monitoring [19].

A decrease in activity during the day or increase in activity during the night, in

comparison with the previously collected data for a specific person, can indicate that the

person experiences some discomfort. For example, a person suffering from pain may

reduce daily activities. At the same time, because of the pain, the person might not sleep

well, resulting in an increase in activity during the rest period.

9

Figure 2.3. Data from a daily routine activity monitor.

The figure shows three-axes accelerometer data in dependence of the persons activity.

The standing, sitting, walking, lying and running activities are detected.

Activity monitoring can be used for fall detection [20], balance control

evaluation, and determining walking [21]. Falling is one of the major causes of injuries

for elderly, and even if diligent efforts are made to prevent elderly, falls are often

inevitable [20]. Fall detection can alert that a person has fallen and needs help.

2.2.2. Activity Measurement Principle

For the project, a three-axis accelerometer is used for continuous activity

monitoring. The accelerometer is capable of detecting six directions of movement and

10

can accurately detect gravity. Therefore, activities such as running, standing, and lying

can be determined. The accelerometer can be set to generate an interrupt if the activity

decreases below a set threshold or when activity exceeds a set threshold for a user set

time duration. The variability in daily activity of a person can be used to estimate a

person’s health.

2.3. Cardio-Respiratory Assessment

2.3.1. Pulse Oximeter Importance

A pulse oximeter measures the percent oxygen saturation in the blood. Because

the pulse oximeter quickly gives a general assessment of a patient's cardio-respiratory

status, and the measurement is non-invasive, the pulse oximeter has become a standard

monitoring device before, during, and after operations [22]. The device also is used in

intensive care, recovery rooms, and in emergencies [23].

Existing pulse oximeters, due to their high power consumption, are not intended

for long term monitoring and are usually attached to a finger, an earlobe, or the forehead.

Using a pulse oximeter for long term monitoring allows determining the heart rate

variability (HRV). The importance of HRV is that it can be used to predict potential

complications in pregnancies, fetal distress, and in neonatal critical care [24]. The HRV

can be used for assessing the severity of congestive heart failure [25], stroke, Parkinson’s

disease and depression for people with chronic disorders [26].

11

2.3.2. Principle of Pulse Oximeter Measurements

Blood oxygen concentration, pulse, and pressure show the function of the heart

and lungs. Pulse oximeter devices use (at least) two sources of light of different

wavelengths and use the fact that oxygen saturated blood and unsaturated blood absorb

the light differently.

The oxygen in the body is carried by the protein hemoglobin (Hb) in the red blood

cells. The oxygen is bound to hemoglobin in the lungs and then transported through the

entire organism for respiratory processes. Oxygen saturation (SO2) is defined as the ratio

of the concentration of oxygenated hemoglobin (HbO2) to the total concentration of

hemoglobin. This is,

SO2

CHbO2

CHbO2 CHb

,

(0.1)

where C is concentration and Hb is deoxygenated hemoglobin.

Using two light sources with such wavelengths that one is absorbed more by the

oxygenated hemoglobin and another more by the unoxygenated hemoglobin allows

determining the blood oxygen saturation. The relevant parameter for estimating the blood

oxygen concentration is the light intensity, which is affected by absorption, and is

measured by a photosensor. The signal detected by the photodetector consists of ac and

dc parts. The ac part corresponds to the light absorption by the blood cells, and the dc

part corresponds to the light absorption by the tissue. The dc part corresponds to the light

12

absorption by the tissue because the consistency of the tissue (water, melanin) changes

very slowly. Because the light absorption by blood cells varies as a result of blood

pulsation, it results in the ac part of the detected signal. The ratio of ratios formula that is

needed for calculating the blood oxygen saturation is

I max Red

)

I min Red

R

,

I

ln( max IRed )

I min IRed

ln(

(0.2)

where I min Red and Imin IRed are the minimum values of the ac components of the red and

infrared light sources, respectively, and Imax Red and I max IRed are the maximum values of

the ac components of the red and infrared light sources, respectively. The ratio of

logarithmic normalized intensities is used to calculate the oxygen concentration using an

empirical calculated calibration curve.

2.3.3. Optical Properties of the Tissue

The tissue is made up of cells of different functions and sizes; therefore, the tissue

is an inhomogeneous medium with different and randomly distributed absorbers and

scatterers. When the tissue is irradiated by light, photo-thermal and photochemical

reactions occur, including fluorescence, optical reflectance, and transmission processes.

The absorption of light through the tissue is wavelength dependent; therefore, the

penetration depth of light in tissue is different for different wavelengths (see Figure 2.4)

13

[4]. The peak depth penetration of 1.4 mm is at 1064 nm. Light penetration depth is

defined as the depth where the incident irradiance of the light is decreased to 37 % of the

original intensity.

KrF XeCl Dye Argon Diode Nd:YAG Tm:YAG Ho:YAG Er:YAG CO2

248 308 465 514.5 830

1064

2010

2100

2940

10600 λ (nm)

1 µm

5µm

20 µm

40 µm

150 µm

250 µm

330 µm

300-400 µm

1300 µm

1400 µm

Figure 2.4. Laser light penetration.

The figure shows light penetration depth in tissue the dependence of laser light

wavelength (adapted from [27]).

Figure 2.5 shows plots of absorption coefficients versus wavelength for protein,

melanin, collagen, water, deoxygenated hemoglobin, and oxygenated hemoglobin - the

main components of the tissue. At wavelengths lower than the 805 nm isosbestic point,

14

Figure 2.5. Tissue light absorption.

The figure shows the light absorption coefficients for protein, melanin, collagen, water,

deoxygenated hemoglobin, and oxygenated hemoglobin versus wavelength [28].

Hb is the strongest absorbent, and at wavelengths higher than 805 nm, HbO2 is the

strongest absorbent. In the range from 600 nm to 1000 nm, the deoxygenated and

oxygenated hemoglobin are the main light absorbents, and this range is called the tissue

window. The range of the tissue window and the absorption coefficients of Hb and HbO2

in this window dictate the wavelengths used for a pulse oximeter. In this tissue window,

660 nm, created by a red light emitting diode (LED), and 940 nm, created by an infrared

LED, wavelengths are chosen. The absorptions of the red and infrared signals are not

equal, as seen in Figure 2.6. Therefore, different signal amplitudes are expected for red

and infrared LEDs having equal light intensities, and the changes in signal amplitude

15

Figure 2.6. Absorption of oxygenated and deoxygenated haemoglobin versus

wavelength.

The figure shows the relative light absorbtion levels of oxygenated and deoxygenated

blood versus wavelength [29]. The light absorption levels for the red and infrared are

marked. The isobestic point (light absorbtion coefficients of oxygenated and

deoxygenated blood are equal) is at 805 nm and cannot be used for pulse oximetry.

received from red and infrared LEDs are different for different levels of oxygen

concentration in blood. For saturations below 85 %, the signal from the red LED has the

largest ac part and for oxygen saturations higher than 85 %, the infrared (IR) signal has

the largest ac part. At 85 % oxygen saturation, the ratios of the red to the IR ac

components of the signals equals one, and at 100 %, the signals’ ac ratio is 0.43 [6].

16

Figure 2.7 [30] shows the ratio of the red to infrared signal amplitudes for different

percentage oxygen saturation in blood.

Figure 2.7. Ratio of red to infrared amplitudes versus blood oxygenation.

The figure shows that the amplitude of the red signal decreases (absorption increases) and

the amplitude of the infrared signal increases (absorption decreases) with the increase of

oxygenation [30].

Equation (0.1) shows the oxygen saturation determined by a pulse oximeter. The

measurement is actually called the functional oxygen concentration, because there are

other types of hemoglobin in blood, such as carboxyhemoglobin (COHb) and

methemoglobin (MetHb). The dependence of light absorption on tissue is shown in

Figure 2.8 [28]. The light absorption by the tissue, venous blood, and nonpulsating

arterial blood in the path of the light constitutes the constant portion of the signal.

17

Figure 2.8. Dependence of light absorption on tissue.

The figure shows that the ac component of light absorption is created by the pulsating

arterial blood and the dc component is created by nonpulsating tissue [28].

Figure 2.9 [29] shows that the ac portion is affected by the changes in the orientation of

the blood versus blood flow rate. During systole (maximum), the blood cells, which have

the form of a biconcave disk, are aligned perpendicular to the blood flow, increasing light

absorption, and during diastole (minimum), the blood cells are aligned parallel to the

flow (see Figure 2.10 [31]).

Figure 2.9. Dependence of blood cell alignment on flow.

The figure shows changes in blood cell alignment during and in between heartbeats [29].

18

Figure 2.10. Systole and diastole correlation to signal.

The figure shows blood cell alignment at systole and diastole and correlation to the

detected signal [27].

2.3.4. Transmission and Reflectance Modes of Pulse Oximeter Measurements

Transmission and reflectance type of pulse oximeters use the same technology.

The difference is in the photodetector and light sources relative placement.

In transmission mode, the light source and the photodetector are placed on

opposite sides of the investigated object. This method is more common and is used in

hospitals where a sensor-clip is attached to the person’s finger or ear lobe.

19

In reflective mode, the light sources and the photodetector are placed on the same

surface. This configuration allows making smaller patch type sensors, which also have

less restriction on body placement. Figure 2.11 shows the transmission mode and

reflectance mode principle.

Figure 2.11. Transmission mode (left) and reflectance mode (right).

The figure shows the position of the photodetector relative to the light sources for

transmission and reflective types of pulse oximeters [32].

2.3.5. Interference to the Pulse Oximeter Signal

The pulse oximeter signal is degraded by the low perfusion, noise artifacts, and

motion artifacts. Figure 2.12 [30] shows the shape of a normal pulse oximeter signal (top)

and degraded pulse oximeter signals. Noise artifacts are created by electrical sources.

High frequency noise can be reduced by low pass filtering. To reduce low frequency

noise, the signal can be averaged over multiple pulses.

20

Figure 2.12. Normal and undesirable pulse oximeter signals.

The figure shows the waveforms obtained from a pulse oximeter. The shape of a normal

signal is the desired signal. Low perfusion is caused by health conditions (cardiac

arrhythmias, heart failure, peripheral vascular disease, hypotension) [33]. Noise artifacts

are caused by electrical equipment. Motion artifacts are caused by the movments of the

person using the pulse oximeter.

21

CHAPTER 3

3. HEALTH STATE MONITOR CIRCUITRY

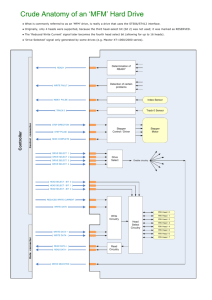

3.1. Health State Monitor Circuitry Overview

The HSMS circuitry consists of the wireless sensor circuitry and base-station

circuitry. An overview of the wireless sensor circuitry is shown in Figure 3.1 and consists

of

1.

Sensor circuitry

2.

Temperature sensor circuitry (TEMP)

3.

Accelerometer circuitry (ACCEL)

4.

Pulse oximeter circuitry that consist of photodetector (AMP) and light

generation and control (IR_RED) circuitries

5.

Supporting circuitry

6.

Power supply circuitry (PS) for controlling the power supply voltage

7.

Microcontroller (MCU) circuitry that controls all the circuits

8.

Wireless communication circuitry (RF)

9.

Local data storage circuitry (microSD)

10.

Light and sound (ALARM) alarm circuitry.

22

Figure 3.1. Wireless sensor schematic

An overview of the base-station circuitry is shown in Figure 3.2 and consists of

1.

Power supply circuitry (PS) for controlling the power supply voltage

23

2.

Microcontroller circuitry (MCU) that controls all the circuits

3.

Wireless communication circuitry (RF)

4.

Serial communication.

Figure 3.2. Base-station schematic

3.2. Sensor Circuitry

This section describes the circuitry of the sensors that are used for determining

health status data. It includes temperature, activity, and pulse oximeter circuitry. For

measuring temperature and activity, dedicated integrated sensors are used.

24

3.2.1. Temperature Monitoring Circuitry

For temperature measurement, a dedicated integrated sensor, the TMP121 is used.

It has 12 bits of resolution plus one bit for indicating negative temperatures. The sensor

has 0.0625 °C resolution and ± 1.5 °C accuracy in the −25 °C to +85 °C temperature

range. In the anticipated temperature range, based on circadian rhythm (see Figure 3.3),

the accuracy is -0.5, +0.9 °C. The temperature sensor is accessed via a serial peripheral

interface (SPI), acquires a new temperature measurement every 0.5 s and needs 0.25 s to

perform the conversion. The sensor has the following features:

1.

Power supply range: 2.7 V to 5.5 V

2.

Current Consumption

a. Temperature acquisition - 50 µA

b. Idle state - 20 µA

c. SPI access - unspecified

Figure 3.3. Temperature sensor circuitry

25

3.2.2. Activity Monitoring Circuitry

For activity measurement, an integrated three-axis 12-bit resolution

accelerometer, the LIS331DLH from STMicroelectronics (Geneva, Switzerland) is used.

Accelerometer circuitry is shown in Figure 3.4. The sensor has dynamically selectable

full-scale ranges of ±2 g, ±4 g, and ±8 g, six direction detection, and a data rate of up to 1

kHz. From the available accelerometer options, of interest are low (lower than set

threshold value) and high (higher than set threshold value) interrupts and, depending on

the application, six direction detection.

Figure 3.4. Accelerometer circuitry

Low activity interrupts combined with the time period of low activity are useful

for detecting lower than usual activity for a certain individual or for detecting no activity

26

at all, as when the individual is unconscious. High level activity interrupts are useful for

detecting falls or discomfort. For example, higher than usual activity for a specific

individual during the rest period can indicate that the person feels some discomfort and

needs assistance.

3.2.3. Pulse Oximeter Circuitry

The pulse oximeter circuitry was designed specifically for this project with low

power consumption and small size (see Figure 3.5) as the primary criteria. The pulse

Figure 3.5. Wireless sensor electronic assembly

27

oximeter circuitry consists of red and IR light-emitters (Figure 3.6), and photodetector

and amplifier circuitry (see Figure 3.7). The microcontroller controls the light-emitting

circuitry. It powers sequentially each LED with such a voltage that the LED generates

strong enough light for the photodetector to detect the light reflected by blood cells, but

not too strong to exceed the amplifier U7 (see Figure 3.7) output range and the

microcontroller’s analog-to-digital converter (ADC) input range.

Figure 3.6. Red and IR light source.

The red and IR LEDs’ anodes are connected to individual pins of the

microcontroller, with which the microcontroller controls each LED. The cathodes of the

LEDs are connected to the digital-to-analog converter (DAC) microcontroller pin, via

which the microcontroller adjusts the intensity of the LEDs. The red and the IR LEDs

require different voltage levels to generate equal light intensities. In addition, the

photodetector sensitivity is different for red and infrared lights. Plots of light intensity

Figure 3.7. Photodetector and amplification circuitry

28

29

versus wavelength for the LEDs are shown in Figure 3.8 [34], and the plot of

photodetector sensitivity versus wavelength is shown in Figure 3.9 [35]. The necessary

voltages for the LEDs are calculated and are provided by the DAC. A specialized part,

the SML12R3KIR941T LED from Ledtronics (Torrance, CA), that contains red and

infrared LEDs in one package is used as the light emitting source.

Figure 3.8. Relative intensity versus wavelength.

The figure shows the relative light intensity of the red LED (top), and infrared LED

(bottom) of the light source (LIS331DLH) used in this project [34]

30

Figure 3.9. Photodiode relative spectral sensitivity versus wavelength.

The figure shows the VBPW34S (Vishay Semiconductors, Malvern, PA) photodetector

relative sensitivity versus wavelength [35].

If the wireless sensor is on, then every 10 ms, the microcontroller performs the

following sequence:

1.

turns infrared LED on

2.

waits 500 µs

3.

ADC samples amplifier U7 (see Figure 3.6) output

4.

turns infrared LED off

5.

turns red LED on

6.

waits 500 µs

7.

ADC samples amplifier U7 (see Figure 3.6) output

8.

Turns red LED off.

31

The photodetector circuit consists of a photodiode and a two-stage amplifier. The

first stage is an OPA381 transimpedance amplifier from TI. The second stage is an

OPA333 op-amp, also from TI. The output from the first stage is sampled and is used for

calculating the intensity of the LEDs. Another microcontroller DAC provides an

adjustable voltage to the non-inverting input of the second stage amplifier for removing

the dc component. The microcontroller samples the second stage amplifier output, which

is the signal for calculating the heartbeats and the percent oxygen saturation in blood.

3.3. Supporting Circuitry

This section describes wireless sensor supporting circuitry. It includes power

supply, microcontroller, wireless communication, microSD card, and sound and light

alarm circuitry.

3.3.1. Power Supply Circuitry

The power supply circuit consists of an LM3670 dc-to-dc adjustable converter

from TI. The circuit is shown in Figure 3.10. It provides 3.3 V or 1.8 V. In the active

mode, the power supply voltage is set to 3.3 V. In “Sleep” mode, the output is 1.8 V and

is set by connecting PS_REG to ground. In active mode, the microcontroller switches the

pin to high input impedance.

32

Figure 3.10. Power supply circuit

3.3.2. Microcontroller (MCU) Circuitry

An ATXMEGA32A4 microcontroller from Atmel (San Jose, CA) is used in this

project. The microcontroller circuit is shown in Figure 3.11. It was chosen because of the

following features:

1.

Five “Sleep” modes.

2.

16-bit Real Time Counter (RTC) with a separate oscillator, which runs at 38 kHz.

From the microcontroller’s “Sleep” mode options, the power-save option is

chosen. In this mode, the microcontroller has the lowest power consumption that

has the RTC running. When the wireless device in active mode, the RTC wakes

up the microcontroller from the power-save mode to start data acquisition every

10 ms. When the wireless device is in “Sleep” mode, the RTC wakes the

microcontroller every 2 s.

33

3.

One twelve-channel, 12-bit, 2 Msps ADC. It is possible to configure the ADC to

have up to four differential inputs with or without gain. The gain is software

selectable from 1 x, 2 x, 4 x, 8 x, 16 x, 32 x or 64 x. For this project, the ADC is

configured to have one differential input with gain and one single-ended input.

The differential input is used for acquiring the signal from the photodetector’s

second stage amplifier. The single-ended input is used to acquire the signal from

the photodetector’s first stage, which is used for calculating the LEDs’ light

intensities.

4.

Two-channel, 12-bit, 1 Msps DAC. One channel is used to adjust the LEDs

intensities, and another for adjusting the second stage amplifier dc offset.

5.

Multiple options for ADC and DAC reference. According to the datasheet, the

ADC can use the internal 1 V, internal Vcc/1.6, or external voltage reference on

the AREFF pin as a reference voltage. The DAC has an internal 1 V, external

AVcc, or AREFF reference voltage. In this project, for the DAC, AVcc is the

reference, and for the ADC, Vcc/1.6, which is 2 V for a 3.3 V supply, is the

reference.

6.

Five 16-bit Timer/Counters. Only one timer is used to handle all needed delays.

For example, it handles the 500-µs delay needed for each LED. The wireless

transceiver uses various delays for tune-up and data transmission. During the

delays, the microcontroller is in the idle power saving mode. The timer interrupt

wakes the microcontroller after each delay.

34

7.

Two SPIs. Only one SPI is used to handle the wireless transceiver, accelerometer,

temperature sensor, and the microSD card communications.

8.

Multiple interrupt options for I/O pins. Only one interrupt is used to handle all the

transceiver requests.

9.

Thirty four programmable input/output (I/O) pins. From 34 pins, 30 are

connected. The rest have important functions but were difficult to access. This

microcontroller has a 49-ball VFBGA package. Accessing these pins requires

micro-vias that would increase the cost of the printed circuit board (PCB). Two

connected I/Os also are not used. There are two pins for controlling the power

supply voltage, but in this design, only one is used for switching between 1.8 and

3.3 V. The pin connected to the microSD card detect also is not used.

10.

Multiple dynamically selected clock options. To minimize the wireless sensor

size, only the internal microcontroller clock sources are of the interest. The

internal clock options are: 32-MHz run-time calibrated RC oscillator, 2-MHz runtime calibrated RC oscillator, 32.768-kHz calibrated RC oscillator, 32-kHz Ultra

Low Power (ULP) oscillator with 1-kHz output, and a phase lock loop (PLL) with

1 to 31 x multiplication. The microcontroller always starts at 2 MHz after reset.

For all microcontroller processes, an 8-MHz (2 MHz clock · 4PLL) clock is

selected.

11.

Low power supply voltage. The microcontroller works in the 1.6-3.6 V range.

12.

Small 5 x 5 mm package size.

35

Figure 3.11. Microcontroller circuit

3.3.3. Radio Communication Circuitry

For the wireless communications, the SI4432, a highly integrated single chip

transceiver from Silicon Labs (Austin, Texas) is used. The schematic is shown Figure

3.12. This transceiver covers frequencies from 240–960 MHz in 156-Hz or 312-Hz steps,

has high (–121 dBm) sensitivity, and has seven power transmission options with +20

36

dBm maximum power output for extended range. The wide frequency range can

accommodate RF regulations in different countries. However, it requires different

component value for different frequencies.

Figure 3.12 RF circuit

3.3.4. MicroSD Card Circuitry

The microSD circuit just needs a microSD cardholder. The connections to the

cardholder are shown in Figure 3.13. The microSD card supports SPI communication.

Only R14 and R31 are placed in the microSD card circuitry. In a future version, the

microcontroller universal synchronous asynchronous receiver transmitter (USART) in

37

SPI mode will be used for communication with the microSD card. The microcontroller

supports DMA access to the USART. Using the microcontroller direct memory access

(DMA) capability for writing to the microSD card will decrease power consumption.

Figure 3.13. MicroSD card circuit

3.3.5. Alarm Circuitry

The alarm schematic is shown in Figure 3.14 and consists of an LED (D9) and a

buzzer (SG2) with separate activating lines. Each is activated by the microcontroller

when a monitored parameter is out of the range set by the user.

38

Figure 3.14. Sound and light alarm circuit

3.4. Base-Station Circuitry

Base-station circuitry consists of the following:

1.

Power supply circuitry (PS) for controlling the power supply voltage

2.

Microcontroller circuitry (MCU), that controls all the circuits

3.

Wireless communication circuitry (RF)

4.

Serial communication.

The wireless sensor contains all the base-station sub-circuits, including the serial

communication, which it does not use. Therefore, a wireless sensor is used as a basestation. It requires different software and a serial-to-universal serial bus (USB) converter.

In the project, a serial-to-USB converter is used that also provides 3.3 V to power the

circuit, eliminating the need for a separate power supply. The base-station communicates

with the PC at 115200 bps.

39

CHAPTER 4

4. WIRELESS SENSOR SOFTWARE

This chapter describes the software of the wireless sensor microcontroller. The

software is written in C language, and the CVAVR compiler from HP InfoTech

(Bucharest, Romania) is used.

4.1. Microcontroller Main Routine

After powering up, the wireless sensor configures the ports and the real time clock

(RTC) for 2 s, and then goes into power save mode. The flow chart for wireless sensor

initialization is shown in Figure 4.1. All processes start after the RTC interrupt, which

occur every 2 s if the wireless sensor is in the “Sleep” mode and every 10 ms if it is in

active mode.

Start

Initialization

Sleep

Figure 4.1. Wireless sensor initialization

The processes that the microcontroller performs after each RTC interrupt are

shown in the flow chart Figure 4.2. In the “Sleep” mode, after each RTC interrupt, the

40

REAL TIME CLOCK INTERRUPT

YES

NO

IS T

INTERVAL

>1S?

IS ON

MODE?

NO

YES

GET TEMPERATURE

CHECK IF RX DATA

YES

IS RF DATA?

IS

ACCELEROMETER

ON?

UPDATE SETTINGS

YES

GET ACCELEROMETER

NO

NO

YES

IS

OXIMETER

ON?

GET OXIMETER

NO

IS ALARM

STATUS

CHANGED?

NO

YES

SET ALARM ON\OFF MODE

IS RX

RECEIVED?

YES

IS SD ON?

NO

YES

SD FUNCTION

UPDATE SETTINGS

NO

YES

IS TX

BUFFER

FULL?

NO

NO

IS RX TIME?

NO RX FOR

>18S?

NO

SET SLEEP 10US

YES

SER SLEEP 2S

YES

TRANSMIT\RECEIVE DATA

SLEEP

Figure 4.2. Wireless sensor microcontroller

41

microcontroller checks for an incoming RF signal. If no signal is received from the basestation, the wireless sensor goes to “Sleep” for 2 s to repeat the procedure again. If a

base-station transmission was received, the wireless sensor updates its settings based on

the received information and then checks again the sleep/on setting and proceeds

accordingly.

If the wireless sensor is in the “On” mode, then it acquires the temperature data if

more than 30 s elapsed since the last temperature acquisition. Then, the microcontroller

checks the accelerometer. If the accelerometer is set for continuous data acquisition, then

the accelerometer data are acquired based on the sampling rate set for the accelerometer.

If the accelerometer is set to generate an out-of-range interrupt, then the microcontroller

checks the interrupt, and if an interrupt is registered, then accelerometer data are

acquired.

Then the microcontroller acquires the pulse oximeter data if the oximeter is

activated. The flow chart for pulse oximeter data acquisition is described in section 4.4.4.

After that, the microcontroller checks the light and sound alarms. If any of the

parameters set to be monitored is out of range, the alarm set to be activated is activated. If

either of the alarms was previously activated, and a command to deactivate is received

from the base-station, then the microcontroller disables the alarm.

Next, the microcontroller checks if the acquired data are to be saved on the

microSD card. The microSD card routine and flow chart are described in section 4.5.

After data acquisition, the microcontroller checks if more than 1 s passed since

the last command from the base-station was received, and if so, then regardless of the

42

amount of data in the buffer, the data are sent to the base-station, along with the code

querying the base-station for a command. If the last RF transmission was less than 1 s

ago, then the microcontroller checks if the 64-byte buffer is full, and if it is full, then the

data are transmitted to the base-station.

If a code querying the base-station for a command was sent, then the wireless

sensor enables the wireless receiver and waits for 2 ms for a command from the basestation. If a command was received from the base-station, then the wireless sensor

updates its settings and goes into power-save mode for the remaining time to complete 10

ms. If no command was received from the base-station for more than 20 s, then the

wireless sensor assumes that the base-station is not in the range and goes into “Sleep”

mode.

4.2. Temperature Acquisition

The temperature sensor is accessed via a three-wire interface and does not accept

any incoming data. It is the only sensor that requires more than 12 bits to represent the

data and does not fit the 12 bits data plus four bits for sensor identification scheme used

for the wireless protocol, which is described in section 4.6. The temperature data are

provided in two’s compliment format and consist of twelve bits plus one sign bit. To fit

the 12+4 format, the sensor data could be trimmed to represent only positive temperatures

or to reduce the resolution.

43

The wireless sensor is intended to be placed on human skin, and negative

temperatures are not expected. Therefore, only positive temperatures are measured for

this project. The code snippet for temperature acquisition is

void get_TMP(void)

{

S16 temp_tmp;

TMP_cnt_SR+=RTC_PERf;

if (TMP_cnt_SR<SR_TMP)return;//is not acquisition time

TMP_ON;

((unsigned char *) &temp_tmp)[1]=spic_master_tx_rx(0);

((unsigned char *) &temp_tmp)[0]=spic_master_tx_rx(0);

if(((unsigned char *) &temp_tmp)[1] & 0x80!=0)return;

//negative temp detected

temp_tmp>>=3;

sensor_data[data_amount++]=((unsigned char *)

&temp_tmp)[1]|ID_TMP;

sensor_data[data_amount++]=((unsigned char *) &temp_tmp)[0];

TMP_OFF;

TMP_cnt_SR=0 .

}

4.3. Accelerometer Acquisition

The 12-bit three-axis accelerometer is accessed via SPI communication. It is

programmed for the ±2 g range. The accelerometer can be set to generate an interrupt

when a value lower and/or higher than preset threshold value is measured. The following

options are available from the GUI:

1.

enabling/disabling the accelerometer

2.

continuous operation or interrupt-based monitoring

44

3.

in continuous operation, setting the data acquisition sampling rate

(maximum 100 Hz)

4.

in interrupt-based monitoring, setting the free fall detection, minimum,

and maximum activity out-of-range detection.

The data acquisition sampling rate refers to the frequency the accelerometer is accessed;

the accelerometer itself is set to a 100-Hz sampling rate.

4.4. Pulse Oximeter Acquisition

4.4.1. Pulse Oximeter Software Overview

If the pulse oximeter is enabled, then regardless of the pulse oximeter sample rate

setting, the data are sampled at 100 Hz. The oximeter sample rate that is set by the user

refers to the rate the sampled data are sent to the PC. The display of detected red and IR

signals is useful for positioning the wireless sensor on a patient. For continuous

monitoring of the percent oxygen saturation in blood and heart rate, the sampling rate is

set to a lower rate. Physiologically relevant changes in the percent oxygen saturation in

blood and heart rate do not change abruptly; therefore, a lower sampling rate is desired to

increase data storage and lower power consumption.

The software for the pulse oximeter routine has the following hardware access

and control:

1.

Turning on and off and adjusting the intensity of the red and IR LEDs.

45

2.

Differential DAC with gain to sample the output of the second stage

photodetector amplification circuitry.

3.

DAC voltage output to the second stage non-inverting amplifier input for

controlling the second stage amplifier output offset.

4.

DAC to the output of the first stage amplifier. These data are used for adjusting

the intensity of the IR and red LEDs.

Briefly, the pulse oximeter software turns on the IR LED and applies a voltage

offset to the second stage amplifier, waits for the processes to settle, takes measurements

of the first and second amplifier outputs, turns the IR LED off and removes the offset.

After that, the microcontroller checks if the output from the second amplifier is in the

DAC measurable range. If data are not in range, the microcontroller uses the data from

the first amplifier stage to calculate the new LED intensity for the next measurement.

Then it does the same procedure with the red LED. If the red, IR, or both red and IR data

are out of range, then new LED intensities are calculated. This procedure eliminates

creating a software loop for adjusting the light intensity. It takes up to 10 to 20 s to get

the signal in range when the wireless sensor is placed on a patient or when the

surrounding conditions change for a prolonged time. But, in this way, attempts to adjust

the LED intensities to accommodate out of range signals caused by short duration motion

artifacts are minimized. The signal from the second stage amplifier is filtered and is used

to calculate the heart rate and percent oxygen saturation in the blood. After that, based on

the user setting, the filtered wave data or calculated heartbeats and percent oxygen

46

saturation are sent to the transceiver to be transmitted to the PC or saved on the wireless

sensor microSD card.

4.4.2. Controlling the LEDs and Taking Data Samples

Every 10 ms, if the oximeter is active, the pulse oximeter routine starts with

connecting the IR LED’s anode to a high voltage, by reconfiguring the corresponding

microcontroller control pin from input to a pulled up output. The output voltage from the

DAC is connected to the common LED anode. The decrease in the DAC voltage causes

an increase in LED intensity. The voltage from the second DAC channel is applied to the

second stage non-inverting amplifier input for adjusting the output offset. After that, the

microcontroller is put in “Sleep” mode for 500 µs. The on/off red and IR LED sequences

are shown in Figure 4.3. The voltage rise on the output of the first stage in response to the

LED light is shown in Figure 4.4.

A timer-interrupt wakes up the microcontroller after 500 µs. After this time, all

the processes settle. The LED light and the amplifier output voltages are settled. The

microcontroller samples the outputs of both amplifier stages. The second stage amplifier

is sampled by the ADC configured as a differential input with gain. For the differential

input configuration, the microcontroller has 1x, 2x, 4x, 8x, 16x, 32x, or 64x options for

software selectable gain. In the project, the gain is adjusted based on the maximum wave

swing, with a maximum gain limit of the 8x.

47

Figure 4.3. IR (bottom) and red (top) LEDs on/off sequence

Figure 4.4 First stage amplifier settling time

48

The code snippet for controlling the red LED and sampling both amplifiers is

dacb_write(1,Roffset); //apply v offset to the non-inverting input, second

stage

dacb_write (0,Rintensity);//apply v to LED’s cathode

R_LED_ON;

//apply high voltage to red LED anode

SET_t_out_us (500);

//set time out

idle ();

//set microcontroller in idle

ad_R_data= adca_read1 (0);//sample second stage amplifier

in_level_R= adca_read (3); //sample first stage amplifier

R_LED_OFF;

//turn red LED off

The ac component of the useful signal from the first stage has a swing of 3-10

ADC units. This swing does not affect the measurement for detecting the dc component,

which could be up to 300 times bigger. For example if the measured signal is 3000 ADC

units, with a useful signal swing of 3-10 ADC units, 2990 ADC units can be safely

removed without affecting the useful signal.

Figure 4.5. First (top) and second (bottom) stage amplifier outputs

49

The code snippet for calculating the light intensity for the red LED is

if (in_level_R>top)

{

if (Rintensity<min_light)Rintensity++;

}

else if (in_level_R<btm)

{

if (Rintensity>0)Rintensity--;

}.

The first and second amplifier stage wave outputs are shown in Figure 4.5.

4.4.3. Red and Infrared (IR) Signal Processing

To suppress noise in the signal, including 60-Hz and 120-Hz noise caused by

fluorescent lights and other electrical equipment, the signal is lowpass filtered. The

heartbeat frequencies of interest are considered to be from 30 to 270 beats/min. That is,

from

30 beats

1 min.

1 min.

= 0.5 Hz

60 s

(0.3)

270 beats

1 min.

1 min.

= 4.5 Hz .

60 s

(0.4)

f=

to

f=

Therefore, a 5-Hz second-order Butterworth Infinite Impulse Response (IIR)

digital lowpass filter is used. Filter coefficients were determined by “WinFilter” software,

50

from http://www.winfilter.20m.com/, that generates 16-bit quantized filter coefficients

and also generates the filter code. The signal obtained while the IR LED is on (IR signal)

and the signal obtained while the red LED was on (Red signal) have independent filter

functions. The code snippet for filtering the Red signal (see Figure 4.6) is

int R_lpf2_5hz (int NewSample)

{

static signed long int y[]={2024,2024,2024};

static signed int x[]={2024,2024,2024};

const int ACoef[] = { 10543, 21086, 10543};

const long int BCoef[] = {16384, -25575, 10507 };

const char NCoef=2;

const char DCgain=32;

long int A,B;

U8 n;

//shift the old samples

for(n=NCoef; n>0; n--) {

x[n] = x[n-1];

y[n] = y[n-1];

}

//Calculate the new output

x[0] = NewSample;

y[0] = ACoef[0];

y[0] *= x[0];

for(n=1; n<=NCoef; n++)

{

A=ACoef[n];

A*=x[n];

B= BCoef[n];

B *= y[n];

y[0]+= A - B;

}

y[0] /= BCoef[0];

return (y[0] / DCgain);}.

51

Figure 4.6. Displaying unfiltered red and filtered IR signals.

The figure shows the effect of the highpass filer. The red signal (on RED channel) is

unfiltered. The IR signal (on IRED channel) is filtered by a highpass filter.

The calculation of the percent oxygen saturation in the blood needs the maximum

and minimum values of both signals. The code for determining these values for the red

signal is

if (ad_IR_data > s_max_ir) s_max_ir = ad_IR_data;

if (ad_IR_data < s_min_ir) s_min_ir = ad_IR_data;.

For determining the number of heartbeats per min., the IR signal is passed

through a highpass first-order IIR digital filter and then rectified. The code for the

highpass filter and rectifier is

hpf_data = (hpf9 (ad_IR_data));

if (hpf_data < 0) hpf_data = 0; //rectifier

int hpf9 (int NewSample)

{

static signed long int y[]={2024,2024};;

static signed int x[]={2024,2024};;

const int ACoef[] = { 25391,-25391 };

const long int BCoef[] = { 32768, -18014 };

long int A,B;

x[1] = x[0];

52

y[1] = y[0];

//Calculate the new output

x[0] = NewSample;

y[0] = ACoef[0];

y[0] *= x[0];

A=ACoef[1];

A*=x[1];

B= BCoef[1];

B *= y[1];

y[0]+= A - B;

y[0] /= BCoef[0];

return (y[0]);

}.

For visualizing the shape of the highpass filter, the signal was temporarily redirected to

the temperature channel, and the waveform is shown in Figure 4.7.

Figure 4.7. Pulse detecting signal (on T channel)

4.4.4. Calculating the Heartbeats

The resulting signal, obtained after highpass filtering and shown in Figure 4.7, is

very clean, and it is easy to calculate the heartbeats. The code snippet is

53

time++;//10ms period

if (hpf_data>threshold && detect_beat==0)

{

detect_beat=1;

beats++;

}

else if(hpf_data==0 && detect_beat==1)

{

detect_beat=0;

beat_min.=6000/time; // (1/ (t*10ms)*1000ms/s*60sec/min

time=0;

}.

For the signal depicted in Figure 4.7, the heartbeat calculation is correct for a threshold

level of zero. For the signal depicted in Figure 4.6, the threshold should be higher to

eliminate the signal “bumps” that appears in between heartbeats.

To suppress signal artifacts created by motion, a more complicated algorithm for

detecting noise and calculating the heartbeats has been implemented. The algorithm

analyzes the signal to detect heartbeats, noise, and out-of-range signal. An out-of-range

signal is a signal that exceeds the minimum or maximum allowable signal duration.

The maximum allowable period of a signal is calculated from the heartbeat

frequency in (0.3) and is

TMAX =

1000 ms

= 2000 ms .

0.5 Hz

(0.5)

If no pulse is detected and TMAX is exceeded, then it is possible that the wireless sensor is

removed from the patient or the patient is in a crisis. Therefore, exceeding TMAX is

always a good reason for setting off the alarm.

54

The minimum signal period is calculated from the heartbeat frequency in (0.4)

and is

TMIN =

1000 ms

= 222 ms .

4.5 Hz

(0.6)

When looking for a pulse, the time up to TMIN can be used for determining the threshold

of the noise in the signal. In this project, the threshold for heartbeat detection is the

maximum value of the pulse detect signal during the 200 ms after a heartbeat is detected.

Figure 4.8, depicts a heartbeat corresponding to an 80 beat/min. heart rate. The pulse

detect signal maximum occurs 100 ms after a pulse is detected. If a maximum occurs

after 200 ms, then the pulse is considered to be contaminated with noise and is discarded.

Each valid detected pulse is passed through a second-order averaging filter, and after

detecting 10 heartbeats, the heartbeat rate is averaged.

350

300

IR heart pulse and pulse detect

250

200

150

100

50

0

40

80

120

160

200

240

280

320

360

400

440

480

520

560

600

640

680

720

760

800

840

880

920

960

1000

1040

0

Figure 4.8. IR heart pulse (top) and pulse detect (bottom)

ms

55

4.4.5. Calculating the Percent Oxygen Saturation in Blood

All the calculations are done by the microcontroller. Calculating the ratio of

logarithmic normalized intensities as in (2.1) could be a difficult task for a

microcontroller. The software for oxygen saturation calculation is based on the

relationship of oxygen saturation to the ratio of red to IR [29].

Thus, instead of calculating the ratio of logarithmic normalized intensities, the

ratio of normalized red and IR values obtained by the pulse oximeter are used. That is,

R

VRED

,

VIR

(0.7)

VR

AC RED

DCRED

(0.8)

VIR

ACIR

.

DCIR

(0.9)

where VR and VIR are, respectively,

and

Figure 4.9, [29] shows the ac and dc components of the signal. Then the ratio formula is

R

ACRED / DCRED

.

ACIR / DCIR

(0.10)

56

Figure 4.9. The ac and dc components of the IR signal.

The figure shows that the dc component for the red and IR signals are not equal [29].

This difference in the dc component of the signal is caused mainly by the different light

intensities of the LEDs and by the change in photodiode sensitivity with wavelength.

From Figure 4.9, the dc value is the minimum value of the ac component. As the

minimum and maximum values of each signal are collected, the minimum and maximum

values can be substituted in the ratio formula,

R

ACRED / DCRED

( R max R min) / R min

ACIR / DCIR

( IR max IR min) / IR min

(0.11)

( R max R min) IR min

.

( IR max IR min) R min

(0.12)

R

The signal of the second stage amplifier output, shown in Figure 4.5, decreases with the

increase of the light intensity and is inverted in comparison with the signal shown in

Figure 4.9. The ac portion of the signal remains the same, while the dc portion is

57

calculated as the difference between the high level voltages corresponding to no-light

level and collected maximum values. Therefore, for calculating the dc portion of the

signal, the voltage of the second stage amplifier is measured when the LEDs are off.

Then the formula becomes

R

( R max R min) (Vdark IR max)

.

( IR max IR min) (Vdark R max)

(0.13)

The oxygen saturation is converted from R using the curve shown in Figure 4.10 [29].

Figure 4.10. Percent oxygen saturation versus R/IR ratio.

The figure shows the empirical calibration curve [29]. The 70% to 100% oxygen

saturation range, which is of the interest in this project, can be approximated by a linear

equation.

58

In practice, the

S PO2 a b R

(0.14)

clinical empirical formula for the oxygen saturation is used. The a and b are coefficients

are determined when the pulse oximeter is calibrated and could be determined by

performing the linear fit of the R values of multiple samples using the least squares

method. Because oxygen saturation below 70 % is not of interest, then the a and b

coefficients are 110 and 25 respectively [36]. The software snippet for calculating the

oxygen saturation is

arr = ((long)lpf_dataIR+offset)/(lpf_dataR+offset);// IR/R

R = (((long) (s_max_r-s_min_r))*arr)/ (s_max_ir-s_min_ir);

arr = 110 -25*R;

Sp_O2_mf[rr_array_counter] = OxiMovingAverage(arr);

Sp_O2 = median_filter (Sp_O2_mf); .

The software flow diagram for pulse oximeter acquisition is shown in Figure 4.11.

4.1. MicroSD Card Software

The option to save on the wireless sensor microSD card can be activated by the

GUI and is used for continuous monitoring when the base-station and the PC are out of

RF range. The flow chart of the microSD card function is shown in Figure 4.12.

59

START

SUPPLY OFFSET VOLTAGE TO THE 2ND STAGE AMPLIFIER

TURN INFRARED LED ON

WAIT 500 ms

ADC 1ST AND 2ND STAGES ACQUISITION FOR IR WAVE

TURN INFRARED LED OFF

SUPPLY OFFSET VOLTAGE

TURN RED LED ON

WAIT 500ΜS

ADC 1ST AND 2ND STAGES ACQUISITION FOR R WAVE

TURN RED LED ON

YES

NO

IS THE R AND IR

WAVE IN RANGE?

ADJUST R AND IR LEDS INTENSITY

LPF(IR AND R DATA)

HPF(LPF IR DATA) PEAK DETECTING

NO

IS NOISE